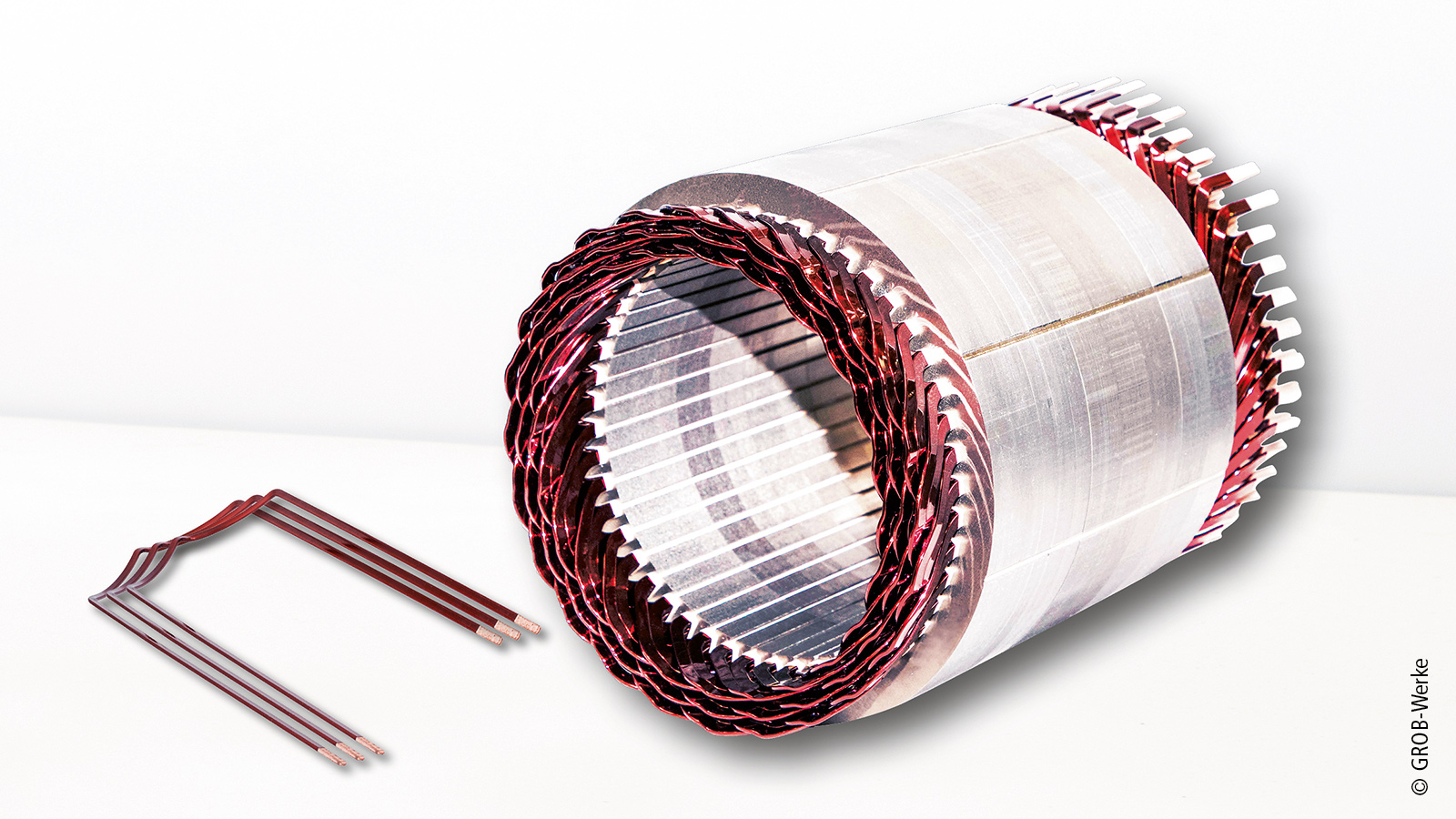

Hair Pin Stator . Fastest prototyping in the world. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Rectangular copper rods replace the coiled copper wires. Additive drives offers the world’s fastest hairpin prototypes. Hairpins are the trend technology in the field of electric motors. From the idea to the finished stator in 4 weeks! Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Comau’s hairpin stator manufacturing process. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density.

from www.beckhoff.com

Rectangular copper rods replace the coiled copper wires. Fastest prototyping in the world. Additive drives offers the world’s fastest hairpin prototypes. Comau’s hairpin stator manufacturing process. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Explore the main features of hairpin stator processes, from prototyping to fully automatic. From the idea to the finished stator in 4 weeks! Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. Hairpins are the trend technology in the field of electric motors. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles.

Flexible control technology with fast cycle times increases efficiency

Hair Pin Stator From the idea to the finished stator in 4 weeks! Explore the main features of hairpin stator processes, from prototyping to fully automatic. Fastest prototyping in the world. From the idea to the finished stator in 4 weeks! Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Comau’s hairpin stator manufacturing process. Rectangular copper rods replace the coiled copper wires. Hairpins are the trend technology in the field of electric motors. Additive drives offers the world’s fastest hairpin prototypes. Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density.

From www.powertransmissionworld.com

Hairpin technology at the service of drive motors for electric cars Hair Pin Stator Comau’s hairpin stator manufacturing process. Fastest prototyping in the world. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. From the idea to the finished stator in 4 weeks! Hairpin stator motors share a similar shape as traditional induction windings, but with higher. Hair Pin Stator.

From www.youtube.com

REVO 2 multi sensor system Hairpin stator inspection YouTube Hair Pin Stator From the idea to the finished stator in 4 weeks! Hairpins are the trend technology in the field of electric motors. Comau’s hairpin stator manufacturing process. Additive drives offers the world’s fastest hairpin prototypes. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles.. Hair Pin Stator.

From www.jescoprojects.com

Hair Pin Stator Line Hair Pin Stator Explore the main features of hairpin stator processes, from prototyping to fully automatic. Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. Hairpins are the trend technology in the field of electric motors. Additive drives offers the world’s fastest hairpin prototypes. Fastest prototyping in the world. Aumann develops and realises automated manufacturing solutions. Hair Pin Stator.

From www.eurekamagazine.co.uk

Eureka Comau unveils hairpin stator solutions for emotor manufacturing Hair Pin Stator Additive drives offers the world’s fastest hairpin prototypes. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Rectangular copper rods replace the coiled copper wires. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density.. Hair Pin Stator.

From www.lonco-asia.com

Lonco Hairpin Hair Pin Stator Fastest prototyping in the world. Comau’s hairpin stator manufacturing process. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Explore the main features of hairpin stator processes, from. Hair Pin Stator.

From www.metalworkingworldmagazine.com

Automated assembling of electric motors with hairpin technology Metal Hair Pin Stator Explore the main features of hairpin stator processes, from prototyping to fully automatic. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. From the idea to the finished. Hair Pin Stator.

From www.specialmachinetool.it

Rotors hairpin technology SMT Special Machine Tool Brescia Srl Hair Pin Stator Hairpins are the trend technology in the field of electric motors. Additive drives offers the world’s fastest hairpin prototypes. Rectangular copper rods replace the coiled copper wires. From the idea to the finished stator in 4 weeks! Fastest prototyping in the world. Comau’s hairpin stator manufacturing process. Explore the main features of hairpin stator processes, from prototyping to fully automatic.. Hair Pin Stator.

From www.electrichybridvehicletechnology.com

Zeiss and VW’s innovative solution for EV hairpin stator technology Hair Pin Stator Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Comau’s hairpin stator manufacturing process. Hairpins are the trend technology in the field of electric motors. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Explore the main. Hair Pin Stator.

From yongkangtinen.en.made-in-china.com

Tnhp128hat Haripin Stator 12V 240A 128od 110ID with Wire Insolated Hair Pin Stator Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Fastest prototyping in the world. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Hairpins are the trend technology in the field of electric motors. Rectangular copper rods. Hair Pin Stator.

From www.electrichybridvehicletechnology.com

Zeiss and VW’s innovative solution for EV hairpin stator technology Hair Pin Stator Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. Explore the main features of hairpin stator processes, from prototyping to fully automatic. From the idea to the finished stator in 4 weeks! Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Stators with hairpin technology are used. Hair Pin Stator.

From www.autoevolution.com

Tesla's New Hairpin Stator Revealed in Drive Unit Teardown, Sandy Munro Hair Pin Stator Comau’s hairpin stator manufacturing process. From the idea to the finished stator in 4 weeks! Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Rectangular copper rods replace the coiled copper wires. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Additive drives offers the world’s fastest hairpin prototypes. Fastest. Hair Pin Stator.

From www.powertransmissionworld.com

Hairpin technology at the service of drive motors for electric cars Hair Pin Stator Fastest prototyping in the world. Rectangular copper rods replace the coiled copper wires. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Explore the main features of hairpin. Hair Pin Stator.

From djausa.com

Hairpin Motors DJA USA Hair Pin Stator Hairpins are the trend technology in the field of electric motors. Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. Additive drives offers the world’s fastest hairpin prototypes. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Fastest prototyping in the world. Comau’s hairpin stator manufacturing process. Rectangular copper. Hair Pin Stator.

From presse.porsche.de

Stator with hairpin technology in the Taycan Hair Pin Stator Explore the main features of hairpin stator processes, from prototyping to fully automatic. Comau’s hairpin stator manufacturing process. Fastest prototyping in the world. Rectangular copper rods replace the coiled copper wires. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Additive drives offers. Hair Pin Stator.

From www.powertransmissionworld.com

Hairpin technology at the service of drive motors for electric cars Hair Pin Stator From the idea to the finished stator in 4 weeks! Rectangular copper rods replace the coiled copper wires. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Fastest prototyping in. Hair Pin Stator.

From www.autoevolution.com

Tesla's New Hairpin Stator Revealed in Drive Unit Teardown, Sandy Munro Hair Pin Stator Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Hairpins are the trend technology in the field of electric motors. From the idea to the finished stator in. Hair Pin Stator.

From www.autoevolution.com

Tesla's New Hairpin Stator Revealed in Drive Unit Teardown, Sandy Munro Hair Pin Stator Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Comau’s hairpin stator manufacturing process. Rectangular copper rods replace the coiled copper wires. From the idea to the finished stator in 4 weeks! Hairpins are the trend technology in the field of electric motors. Explore the main features of hairpin stator processes, from prototyping to. Hair Pin Stator.

From aboutinsider.com

Hairpin Motor is the Outlet For The Development of the New Hair Pin Stator Explore the main features of hairpin stator processes, from prototyping to fully automatic. Hairpins are the trend technology in the field of electric motors. Rectangular copper rods replace the coiled copper wires. Comau’s hairpin stator manufacturing process. From the idea to the finished stator in 4 weeks! Additive drives offers the world’s fastest hairpin prototypes. Stators with hairpin technology are. Hair Pin Stator.

From imautomation.com

Hairpin Technology IMA Automation Hair Pin Stator Fastest prototyping in the world. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Rectangular copper rods replace the coiled copper wires. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. From the idea to the finished. Hair Pin Stator.

From www.electricmotorengineering.com

Zeiss and Volkswagen new measuring solution for hairpin stators Hair Pin Stator Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Hairpins are the trend technology in the field of electric motors. Additive drives offers the world’s fastest hairpin prototypes. Stators with hairpin technology are used in connection with the manufacture of. Hair Pin Stator.

From www.beckhoff.com

Flexible control technology with fast cycle times increases efficiency Hair Pin Stator Comau’s hairpin stator manufacturing process. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. From the idea to the finished stator in 4 weeks! Additive drives offers the world’s fastest hairpin prototypes. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger. Hair Pin Stator.

From www.autoevolution.com

Tesla's New Hairpin Stator Revealed in Drive Unit Teardown, Sandy Munro Hair Pin Stator Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. Explore the main features of hairpin stator processes, from prototyping to fully automatic. From the idea to the finished stator in 4 weeks! Fastest prototyping in the world. Hairpins are the trend technology in the field of electric motors. Rectangular copper rods replace the. Hair Pin Stator.

From www.electrichybridvehicletechnology.com

Zeiss and VW’s innovative solution for EV hairpin stator technology Hair Pin Stator Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Hairpins are the trend technology in the field of electric motors. Additive drives offers the world’s fastest hairpin prototypes.. Hair Pin Stator.

From www.jescoprojects.com

Hair Pin Stator Line Hair Pin Stator Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. Hairpins are the trend technology in the field of electric motors. From the idea to the finished stator in 4 weeks! Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Explore the main features of hairpin stator processes,. Hair Pin Stator.

From www.aumann.com

Hairpin stators Aumann AG Hair Pin Stator Hairpins are the trend technology in the field of electric motors. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Comau’s hairpin stator manufacturing process. From the idea to the finished stator in 4 weeks! Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. Fastest prototyping in the world.. Hair Pin Stator.

From www.electricmotorengineering.com

Electric Motor Engineering Hair Pin Stator Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. From the idea to the finished stator in 4 weeks! Additive drives offers the world’s fastest hairpin prototypes. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Stators with hairpin technology are used in connection with the manufacture of electric. Hair Pin Stator.

From www.schaeffler.com

Innovative Electric Motors and Power Electronics Schaeffler Group Hair Pin Stator Additive drives offers the world’s fastest hairpin prototypes. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Comau’s hairpin stator manufacturing process. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Hairpins are the trend technology in the field of electric motors. Stators with hairpin technology are used in connection. Hair Pin Stator.

From www.specialmachinetool.it

Hairpin Technology SMT Special Machine Tool Brescia Srl Hair Pin Stator Hairpins are the trend technology in the field of electric motors. Fastest prototyping in the world. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. From the idea to the finished stator in 4 weeks! Explore the main features of hairpin stator processes, from prototyping to fully automatic. Rectangular copper rods replace the coiled. Hair Pin Stator.

From www.autoevolution.com

Tesla's New Hairpin Stator Revealed in Drive Unit Teardown, Sandy Munro Hair Pin Stator Comau’s hairpin stator manufacturing process. Fastest prototyping in the world. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. Hairpin stator motors share a similar shape as traditional induction windings, but with higher power density. From the idea to the finished stator in. Hair Pin Stator.

From www.youtube.com

Automobile hairpin stator Coil insertion machine YouTube Hair Pin Stator From the idea to the finished stator in 4 weeks! Additive drives offers the world’s fastest hairpin prototypes. Fastest prototyping in the world. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Comau’s hairpin stator manufacturing process. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric. Hair Pin Stator.

From www.metalworkingworldmagazine.com

Automated assembling of electric motors with hairpin technology Metal Hair Pin Stator Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Fastest prototyping in the world. Hairpins are the trend technology in the field of electric motors. From the idea to the finished stator in 4 weeks! Explore the main features of hairpin stator processes, from prototyping to fully automatic. Comau’s hairpin stator manufacturing process. Rectangular. Hair Pin Stator.

From www.jescoprojects.com

Hair Pin Stator Line Hair Pin Stator Additive drives offers the world’s fastest hairpin prototypes. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Comau’s hairpin stator manufacturing process. From the idea to the finished stator in 4 weeks! Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and. Hair Pin Stator.

From www.electrive.com

RWTH announces progress researching construction of hairpin stators Hair Pin Stator Hairpins are the trend technology in the field of electric motors. Rectangular copper rods replace the coiled copper wires. Fastest prototyping in the world. Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Hairpin stator motors share a similar shape as. Hair Pin Stator.

From www.emobility-engineering.com

'Hairpin' ambition for motors EMobility Engineering Hair Pin Stator Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. From the idea to the finished stator in 4 weeks! Explore the main features of hairpin stator processes, from prototyping to fully automatic. Rectangular copper rods replace the coiled copper wires. Comau’s hairpin stator manufacturing process. Fastest prototyping in the world. Hairpin stator motors share. Hair Pin Stator.

From www.electrichybridvehicletechnology.com

Zeiss and VW’s innovative solution for EV hairpin stator technology Hair Pin Stator Aumann develops and realises automated manufacturing solutions for hairpin stators tailored to the respective requirements. Rectangular copper rods replace the coiled copper wires. Fastest prototyping in the world. Explore the main features of hairpin stator processes, from prototyping to fully automatic. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric. Hair Pin Stator.