Condensing Steam Power . Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. Condensation can be done by removing heat from exhaust steam using circulating cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022.

from www.linquip.com

During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. Condensation can be done by removing heat from exhaust steam using circulating cooling water. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam.

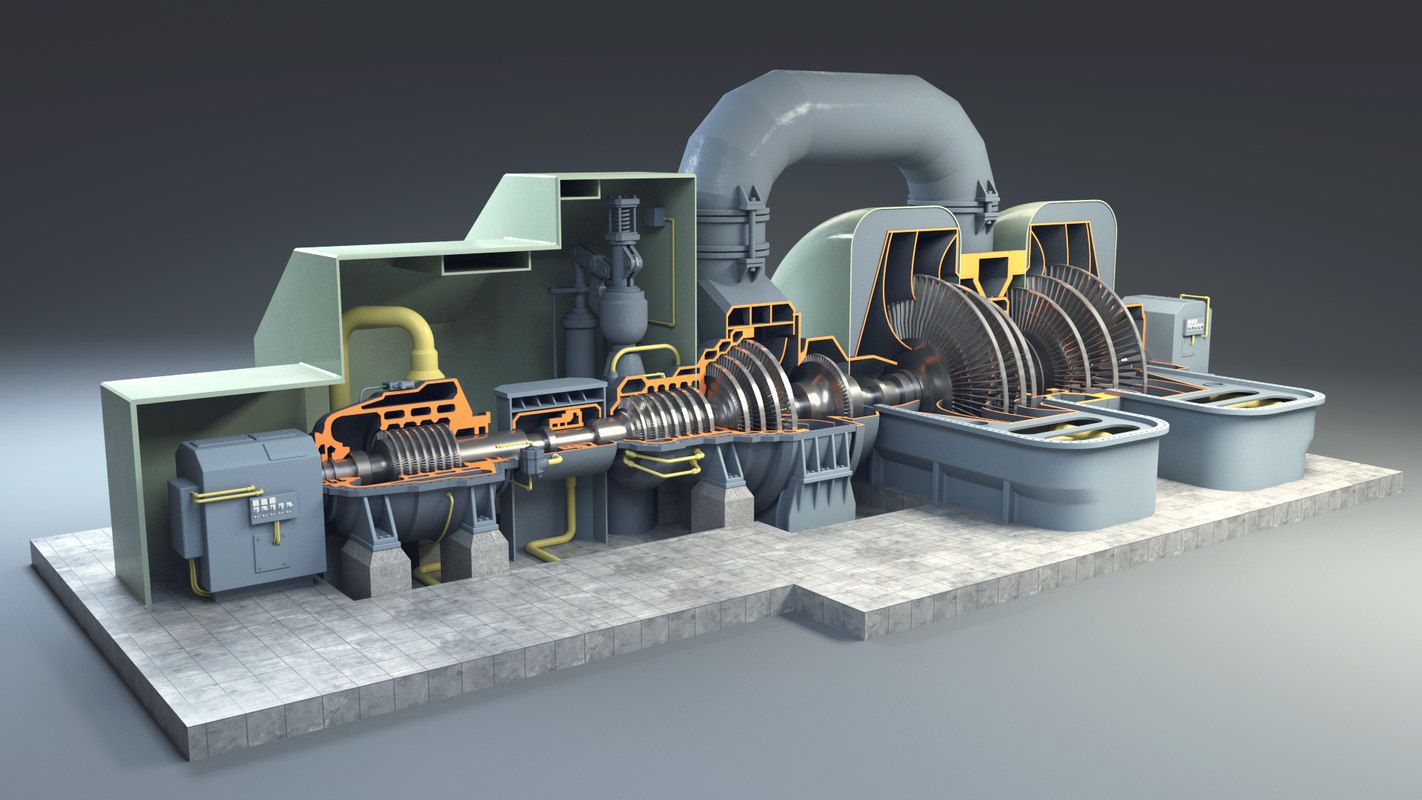

Types of Steam Turbine Impulse & Reaction Turbine Linquip

Condensing Steam Power This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. Condensation can be done by removing heat from exhaust steam using circulating cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam.

From www.pbs.cz

Steam condensing turbines PBS Condensing Steam Power Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent. Condensing Steam Power.

From grindingballsupplier.en.made-in-china.com

CE and ISO Approved Multi Stage Condensing Steam Turbine Thermal Condensing Steam Power During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Condensation can be done by removing heat from exhaust steam using circulating cooling water. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling. Condensing Steam Power.

From dizz.com

Steam Condensing Plant Definition, Components, FAQ's [PDF] Design Condensing Steam Power During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. Steam condensers are devices in which the exhaust steam from the steam turbine. Condensing Steam Power.

From www.slideserve.com

PPT Design &Types of Steam Turbines PowerPoint Presentation ID5327050 Condensing Steam Power In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. This allows. Condensing Steam Power.

From www.researchgate.net

3 Schematic diagram of a geothermal condensing steam power plant Condensing Steam Power In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling. Condensing Steam Power.

From www.nuclear-power.com

Condensing Steam Turbine Characteristics Condensing Steam Power This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. In. Condensing Steam Power.

From www.ctgpowersystems.com

NEW 30MW CONDENSING STEAM TURBINE GENERATOR SET CTG Power Systems Condensing Steam Power Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. Condensation can be done by removing heat from exhaust steam using circulating cooling water. This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. In. Condensing Steam Power.

From www.indiamart.com

Electric Power 5 Bar To 87 Bar Condensing Steam Turbine, For Power Condensing Steam Power Condensation can be done by removing heat from exhaust steam using circulating cooling water. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating. Condensing Steam Power.

From mepacademy.com

Steam Heating System Basics MEP Academy Condensing Steam Power During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust. Condensing Steam Power.

From www.cholaturbo.com

Condensing Steam Turbine, Vapour turbines, Single stage steam turbine Condensing Steam Power In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure. Condensing Steam Power.

From www.nuclear-power.com

Extraction Turbine Turbine with Steam Extraction Condensing Steam Power Condensation can be done by removing heat from exhaust steam using circulating cooling water. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Condensing turbines (used in large power plants to generate electricity) turn the steam. Condensing Steam Power.

From farad.gr

Steam Condensers Farad S.A. Condensing Steam Power In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. This allows. Condensing Steam Power.

From jetflowtechnologies.com

Steam Condensing System Manufacturer Steam Condenser manufacturer Condensing Steam Power In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and. Condensing Steam Power.

From www.jetflowtechnologies.com

Steam Condensing System Manufacturer Steam Condenser manufacturer Condensing Steam Power Condensation can be done by removing heat from exhaust steam using circulating cooling water. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. In. Condensing Steam Power.

From citiczt.en.made-in-china.com

Electric 3000 Kw Condensing Steam Turbine Generator for Power Plant Condensing Steam Power Condensation can be done by removing heat from exhaust steam using circulating cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. This allows the steam to expand more and helps the turbine extract the. Condensing Steam Power.

From americas.fujielectric.com

Large Reheat Condensing Steam Turbine 1000 MW High Efficiency Steam Condensing Steam Power During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more. Condensing Steam Power.

From www.watco-group.co

Surface Condenser in Thermal Power Plant Watco Group Condensing Steam Power In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. Condensation can be done by removing heat from exhaust steam using circulating cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust. Condensing Steam Power.

From www.millpiniongears.com

Electric 300 Kw Condensing Steam Turbine Generator of electric power plant Condensing Steam Power This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. Condensation can be done by removing heat from exhaust steam using circulating cooling water. Condensing. Condensing Steam Power.

From www.linquip.com

Types of Steam Turbine Impulse & Reaction Turbine Linquip Condensing Steam Power The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. Condensation can be done. Condensing Steam Power.

From www.youtube.com

Steam Condenser YouTube Condensing Steam Power During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water. Condensing Steam Power.

From www.researchgate.net

Power cycle or flow diagram of binary geothermal system Download Condensing Steam Power In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Condensation can be done by removing heat from exhaust steam using circulating cooling water. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. During condensation, the working substance (steam) changes. Condensing Steam Power.

From www.dreamstime.com

Steam Condenser in Power Plant. Stock Photo Image of piping, pipe Condensing Steam Power Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. Condensation can be done by removing heat from exhaust steam using circulating cooling water. In a power generation plant the main. Condensing Steam Power.

From electricala2z.com

Combined Heat and Power Plants Steam, Gas, Micro Turbine, Fuel Cell Condensing Steam Power The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Condensation can be done by removing heat. Condensing Steam Power.

From www.youtube.com

Operation Animation SR Steam Condensing Heat Exchanger YouTube Condensing Steam Power Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of. Condensing Steam Power.

From www.researchgate.net

Steam cycle of a small condensing power plant, Case CPP. BFBbubbling Condensing Steam Power Condensation can be done by removing heat from exhaust steam using circulating cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. In a. Condensing Steam Power.

From mungfali.com

Steam Turbine Cycle Condensing Steam Power Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent. Condensing Steam Power.

From quizlet.com

Consider a 210MW steam power plant that operates on a simpl Quizlet Condensing Steam Power Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure. Condensing Steam Power.

From www.indiamart.com

20 W 4 Psw Condensing Steam Turbine, Power Capacity 12 W at Rs 4000000 Condensing Steam Power This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent. Condensing Steam Power.

From genenovag.web.fc2.com

Extraction Condensing Steam Turbine Pdf Condensing Steam Power Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. Condensation can be done by removing heat from exhaust steam using circulating cooling water. During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. In a power generation. Condensing Steam Power.

From grindingballsupplier.en.made-in-china.com

Multi Stage Condensing Steam Turbine 1000kw, 1500kw, 2000kw, 3000kw Condensing Steam Power Condensation can be done by removing heat from exhaust steam using circulating cooling water. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. During condensation, the working substance (steam) changes. Condensing Steam Power.

From www.mechanicalbooster.com

Steam Condenser Definition, Working, Types and Advantages Condensing Steam Power Condensation can be done by removing heat from exhaust steam using circulating cooling water. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. This allows the steam to expand more and helps the turbine extract the maximum energy from it, making the electricity generating process much more efficient. Steam condensers are devices in which the. Condensing Steam Power.

From runhpower.en.made-in-china.com

Industrial Condensing Steam Turbine for Power Generation Biomass Condensing Steam Power During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling. Condensing Steam Power.

From ac-dc-motor-furnace.en.made-in-china.com

Industrial Back Pressure and Condensing Steam Turbine Generator Steam Condensing Steam Power During condensation, the working substance (steam) changes its phase from vapour to liquid and rejects latent heat as shown in figure 1. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. This allows the steam to expand more and helps the turbine extract the maximum energy from it, making. Condensing Steam Power.

From www.steamturbine.be

Fully Condensing Steam Turbine Condensing Steam Power Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. Steam condensers are devices in which the exhaust steam from the steam turbine is condensed by means of cooling water. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. This. Condensing Steam Power.

From www.watco-group.co

Surface Condenser in Thermal Power Plant Watco Group Condensing Steam Power Condensing turbines (used in large power plants to generate electricity) turn the steam at least partly to water using condensers and giant concrete cooling towers. The heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022. In a power generation plant the main turbine condenser establishes the turbine exhaust conditions of pressure and exhaust steam. In a. Condensing Steam Power.