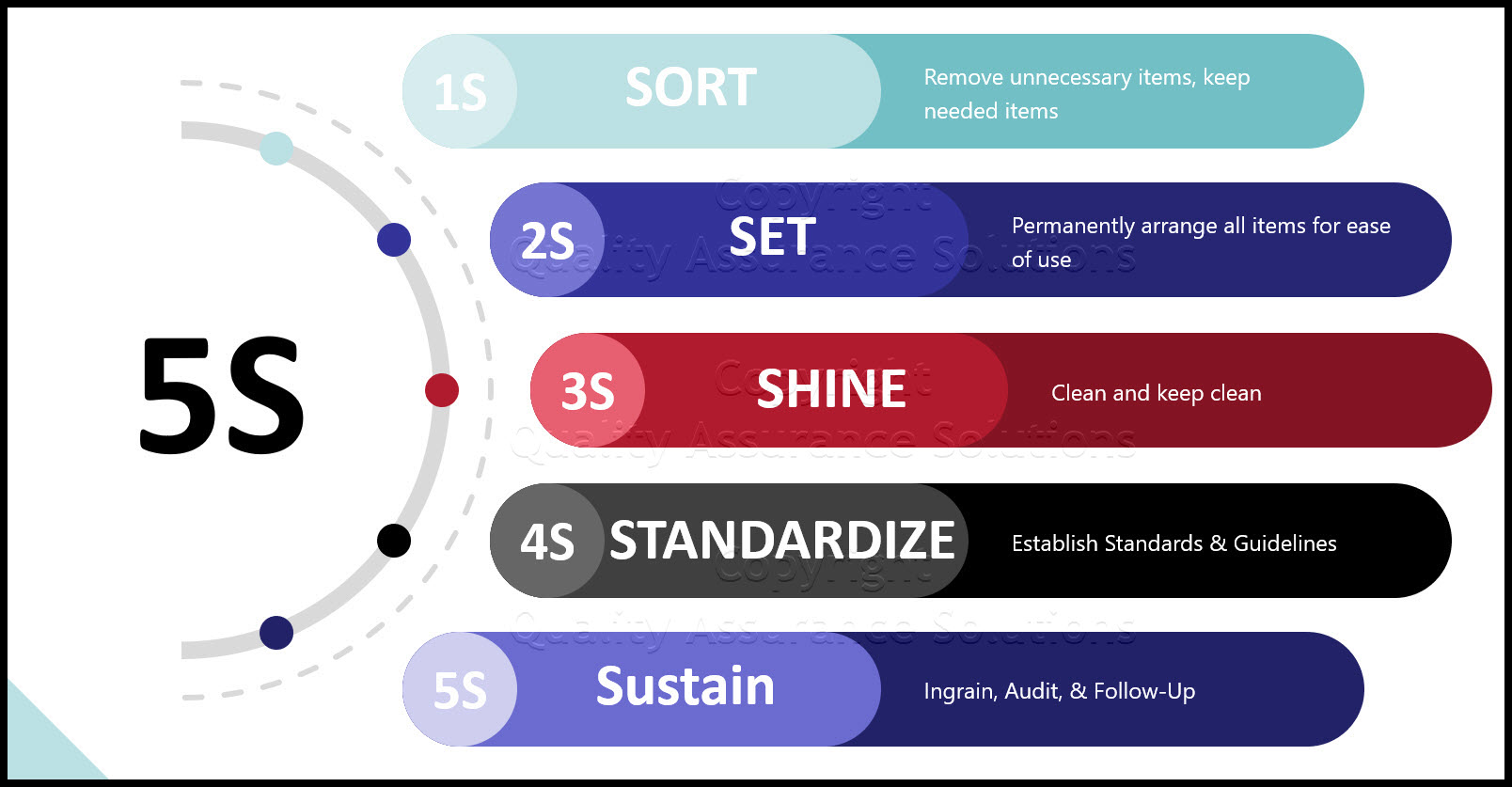

What Is The 5S System In Manufacturing . 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. In english, the 5s’s are: What is 5s in manufacturing? 5s principles guide manufacturers through simplification on the plant floor. It's designed to help build a quality work environment,. 5s is a system for organizing spaces so work can be. 5s lean manufacturing is a systematic methodology focused on creating. Sort, straighten, shine, standardize, and. 5s had its early beginnings with. While the focus of 5s is simplification, its foundation and industry influence are remarkably.

from viquepedia.com

5s lean manufacturing is a systematic methodology focused on creating. 5s principles guide manufacturers through simplification on the plant floor. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. While the focus of 5s is simplification, its foundation and industry influence are remarkably. Sort, straighten, shine, standardize, and. 5s is a system for organizing spaces so work can be. It's designed to help build a quality work environment,. 5s had its early beginnings with. What is 5s in manufacturing? In english, the 5s’s are:

5S's Techniques of Lean Manufacturing Viquepedia

What Is The 5S System In Manufacturing 5s lean manufacturing is a systematic methodology focused on creating. What is 5s in manufacturing? 5s lean manufacturing is a systematic methodology focused on creating. While the focus of 5s is simplification, its foundation and industry influence are remarkably. Sort, straighten, shine, standardize, and. 5s had its early beginnings with. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. In english, the 5s’s are: 5s principles guide manufacturers through simplification on the plant floor. 5s is a system for organizing spaces so work can be. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment,.

From leanabc.blogspot.com

Lean Manufacturing Concepts 5S System A place for everything & safe What Is The 5S System In Manufacturing 5s is a system for organizing spaces so work can be. Sort, straighten, shine, standardize, and. It's designed to help build a quality work environment,. In english, the 5s’s are: 5s principles guide manufacturers through simplification on the plant floor. What is 5s in manufacturing? 5s was adopted to such a widespread extent that it helped to shape the entire. What Is The 5S System In Manufacturing.

From www.milliken.com

Incorporating 5S Within Your Daily Management System to Drive What Is The 5S System In Manufacturing 5s is a system for organizing spaces so work can be. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. While the focus of 5s is simplification, its foundation and industry influence are remarkably. In english, the 5s’s are: It's designed to help build a quality work environment,. Sort, straighten,. What Is The 5S System In Manufacturing.

From mavink.com

Lean 5s Examples What Is The 5S System In Manufacturing It's designed to help build a quality work environment,. 5s lean manufacturing is a systematic methodology focused on creating. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. While the focus of 5s is simplification, its foundation and industry influence are remarkably. Sort,. What Is The 5S System In Manufacturing.

From viquepedia.com

5S's Techniques of Lean Manufacturing Viquepedia What Is The 5S System In Manufacturing While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s principles guide manufacturers through simplification on the plant floor. 5s is a system for organizing spaces so work can be. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. What is 5s in manufacturing? 5s. What Is The 5S System In Manufacturing.

From mungfali.com

5S Lean Manufacturing What Is The 5S System In Manufacturing 5s is a system for organizing spaces so work can be. What is 5s in manufacturing? While the focus of 5s is simplification, its foundation and industry influence are remarkably. In english, the 5s’s are: It's designed to help build a quality work environment,. 5s lean manufacturing is a systematic methodology focused on creating. 5s had its early beginnings with.. What Is The 5S System In Manufacturing.

From smathanshse.blogspot.com

HSE Insider The 5S System What Is The 5S System In Manufacturing While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s lean manufacturing is a systematic methodology focused on creating. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. In english, the 5s’s are: 5s principles guide manufacturers through simplification on the plant floor. Sort, straighten,. What Is The 5S System In Manufacturing.

From www.creativesafetysupply.com

5S Lean Methodology & Principles [Lean Manufacturing] What Is The 5S System In Manufacturing In english, the 5s’s are: 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. 5s had its early beginnings with. 5s lean manufacturing is a systematic methodology focused on creating. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to. What Is The 5S System In Manufacturing.

From blog.unex.com

The Importance of 5S Lean Manufacturing What Is The 5S System In Manufacturing It's designed to help build a quality work environment,. 5s lean manufacturing is a systematic methodology focused on creating. What is 5s in manufacturing? While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s had its early beginnings with. 5s is a system for organizing spaces so work can be. In english, the 5s’s are:. What Is The 5S System In Manufacturing.

From www.nixonhire.co.uk

Implementing 5S Methodology Across Our Depot Network What Is The 5S System In Manufacturing It's designed to help build a quality work environment,. In english, the 5s’s are: What is 5s in manufacturing? 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. 5s is a system for organizing spaces so work can be. While the focus of. What Is The 5S System In Manufacturing.

From blog.proactioninternational.com

Lean 5S How to implement and perpetuate Lean Manufacturing What Is The 5S System In Manufacturing While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. 5s had its early beginnings with. 5s is a system for organizing spaces so work can be. 5s lean manufacturing is a systematic methodology focused on creating.. What Is The 5S System In Manufacturing.

From www.5stoday.com

What is 5S? 5S System is explained including tips on getting a 5S What Is The 5S System In Manufacturing While the focus of 5s is simplification, its foundation and industry influence are remarkably. What is 5s in manufacturing? 5s had its early beginnings with. In english, the 5s’s are: 5s principles guide manufacturers through simplification on the plant floor. Sort, straighten, shine, standardize, and. 5s was adopted to such a widespread extent that it helped to shape the entire. What Is The 5S System In Manufacturing.

From www.safetyscience.be

Lean 5S Six Sigma Safety Science What Is The 5S System In Manufacturing While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s lean manufacturing is a systematic methodology focused on creating. What is 5s in manufacturing? Sort, straighten, shine, standardize, and. 5s is a system for organizing spaces so work can be. 5s was adopted to such a widespread extent that it helped to shape the entire. What Is The 5S System In Manufacturing.

From leanabc.blogspot.com

Lean Manufacturing Concepts 5S System A place for everything & safe What Is The 5S System In Manufacturing 5s is a system for organizing spaces so work can be. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. Sort, straighten, shine, standardize, and. What is 5s in manufacturing? 5s had its early beginnings with. 5s lean manufacturing is a systematic methodology. What Is The 5S System In Manufacturing.

From mungfali.com

5S Lean Manufacturing What Is The 5S System In Manufacturing 5s is a system for organizing spaces so work can be. Sort, straighten, shine, standardize, and. While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s principles guide manufacturers through simplification on the plant floor. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. It's. What Is The 5S System In Manufacturing.

From eleymet.com

Applying 5S Methodology in the Manufacturing Industry Eley Metrology What Is The 5S System In Manufacturing In english, the 5s’s are: What is 5s in manufacturing? 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. 5s lean manufacturing is a. What Is The 5S System In Manufacturing.

From www.starbank-uk.com

5S Workplace Lean Manufacturing Starbank Panel Products Ltd What Is The 5S System In Manufacturing While the focus of 5s is simplification, its foundation and industry influence are remarkably. Sort, straighten, shine, standardize, and. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. 5s principles guide manufacturers through simplification on the plant floor. 5s was adopted to such. What Is The 5S System In Manufacturing.

From mygreendot.co.in

5S Methodology Explain 5s Methodology What Is The 5S System In Manufacturing In english, the 5s’s are: Sort, straighten, shine, standardize, and. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. 5s principles guide manufacturers through simplification on the plant floor. 5s had its early beginnings with. 5s is a system for organizing spaces so. What Is The 5S System In Manufacturing.

From www.fudy.com.tw

Fudy Group has fully implemented the 5S/6S lean management throughout What Is The 5S System In Manufacturing 5s principles guide manufacturers through simplification on the plant floor. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. In english, the 5s’s are: What is 5s in manufacturing? 5s is a system for organizing spaces so work can be. Sort, straighten, shine, standardize, and. While the focus of 5s. What Is The 5S System In Manufacturing.

From www.cisco-eagle.com

The 5S Process 7 Visualizations That Explain It Best What Is The 5S System In Manufacturing What is 5s in manufacturing? 5s principles guide manufacturers through simplification on the plant floor. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. Sort, straighten, shine, standardize, and. 5s had its early beginnings with. In english, the 5s’s are: It's designed to. What Is The 5S System In Manufacturing.

From leansmarts.com

What is Lean 5S Methodology Training & Overview Lean Smarts What Is The 5S System In Manufacturing In english, the 5s’s are: It's designed to help build a quality work environment,. What is 5s in manufacturing? 5s principles guide manufacturers through simplification on the plant floor. 5s is a system for organizing spaces so work can be. Sort, straighten, shine, standardize, and. While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s. What Is The 5S System In Manufacturing.

From www.aiophotoz.com

What Is 5s Methodology 5s Quality System 5s Workplace Methodology What Is The 5S System In Manufacturing 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. What is 5s in manufacturing? 5s is a system for organizing spaces so work can be. It's designed to help build a quality work environment,. In english, the 5s’s are: 5s lean manufacturing is a systematic methodology focused on creating. 5s. What Is The 5S System In Manufacturing.

From h-s-p.co.uk

HSP invest in 5S lean manufacturing system Hydraulic System Products What Is The 5S System In Manufacturing 5s lean manufacturing is a systematic methodology focused on creating. In english, the 5s’s are: 5s principles guide manufacturers through simplification on the plant floor. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. What is 5s in manufacturing? Sort, straighten, shine, standardize, and. While the focus of 5s is. What Is The 5S System In Manufacturing.

From toolsformanufacturing.com

5S for manufacturing What is 5s System? and how to Implement in What Is The 5S System In Manufacturing 5s had its early beginnings with. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. While the focus of 5s is simplification, its foundation and industry influence are remarkably. In english, the 5s’s are: It's designed to help build a quality work environment,. 5s lean manufacturing is a systematic methodology. What Is The 5S System In Manufacturing.

From lablean.blogspot.com

Lean Laboratory 5S for the Laboratory What Is The 5S System In Manufacturing 5s principles guide manufacturers through simplification on the plant floor. While the focus of 5s is simplification, its foundation and industry influence are remarkably. It's designed to help build a quality work environment,. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. 5s. What Is The 5S System In Manufacturing.

From clientsfirst-tx.com

What is 5S? Lean Manufacturing Simplified Clients First Acumatica What Is The 5S System In Manufacturing 5s principles guide manufacturers through simplification on the plant floor. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. In english, the 5s’s are: 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity.. What Is The 5S System In Manufacturing.

From www.kymc.com

5S implementation in the printing & packaging industry What Is The 5S System In Manufacturing 5s principles guide manufacturers through simplification on the plant floor. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. It's designed to help build a quality work environment,. Sort, straighten, shine, standardize, and. 5s is a system for organizing spaces so work can be. In english, the 5s’s are: 5s. What Is The 5S System In Manufacturing.

From www.leanstrategiesinternational.com

5S System Lean Strategies International What Is The 5S System In Manufacturing 5s lean manufacturing is a systematic methodology focused on creating. 5s is a system for organizing spaces so work can be. 5s principles guide manufacturers through simplification on the plant floor. While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s had its early beginnings with. In english, the 5s’s are: 5s was adopted to. What Is The 5S System In Manufacturing.

From trdsf.com

5s Lean Tools & Techniques TRADESAFE What Is The 5S System In Manufacturing In english, the 5s’s are: 5s principles guide manufacturers through simplification on the plant floor. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. 5s is a system for organizing spaces so work can be. 5s is defined as a methodology that results in a workplace that is clean, uncluttered,. What Is The 5S System In Manufacturing.

From leanabc.blogspot.com

Lean Manufacturing Concepts 5S System A place for everything & safe What Is The 5S System In Manufacturing 5s had its early beginnings with. 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment,. Sort, straighten, shine, standardize, and. In english, the 5s’s are: 5s was adopted to such a widespread extent that. What Is The 5S System In Manufacturing.

From mungfali.com

5S Lean Manufacturing What Is The 5S System In Manufacturing Sort, straighten, shine, standardize, and. While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s is a system for organizing spaces so work can be. It's designed to help build a quality work environment,. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. 5s principles. What Is The 5S System In Manufacturing.

From www.leanproduction.com

5S Methodology, Steps, & Benefits Lean Production What Is The 5S System In Manufacturing 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. What is 5s in manufacturing? 5s had its early beginnings with. 5s lean manufacturing is a systematic methodology focused on creating. 5s was adopted to such a widespread extent that it helped to shape. What Is The 5S System In Manufacturing.

From www.brightlysoftware.com

Operational Best Practices You May Not Know About 5S Brightly What Is The 5S System In Manufacturing Sort, straighten, shine, standardize, and. 5s had its early beginnings with. It's designed to help build a quality work environment,. 5s is a system for organizing spaces so work can be. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. 5s is defined as a methodology that results in a. What Is The 5S System In Manufacturing.

From omm1969.blogspot.com

The Lean Manufacturing Site 5S What Is The 5S System In Manufacturing 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. 5s was adopted to such a widespread extent that it helped to shape the entire concept of lean manufacturing. 5s lean manufacturing is a systematic methodology focused on creating. 5s is a system for. What Is The 5S System In Manufacturing.

From www.linkedin.com

10 Easy Steps To Implement 5S In Your Factory What Is The 5S System In Manufacturing 5s had its early beginnings with. 5s is a system for organizing spaces so work can be. It's designed to help build a quality work environment,. In english, the 5s’s are: While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s lean manufacturing is a systematic methodology focused on creating. 5s is defined as a. What Is The 5S System In Manufacturing.

From www.visualmitra.com

Create a Visual Factory with 5s system Visualmitra What Is The 5S System In Manufacturing It's designed to help build a quality work environment,. Sort, straighten, shine, standardize, and. 5s lean manufacturing is a systematic methodology focused on creating. 5s had its early beginnings with. In english, the 5s’s are: While the focus of 5s is simplification, its foundation and industry influence are remarkably. 5s is a system for organizing spaces so work can be.. What Is The 5S System In Manufacturing.