Rocker Arms Engine Roller Rockers . When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. There are two primary types of rocker arms commonly used in automotive engines: Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. Roller rockers and standard rockers. The rocker can handle engine speeds in excess of. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. Some rocker arm designs include roller bearings or a roller tip. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. These components help to decrease friction between the rocker.

from tdmotion.com

There are two primary types of rocker arms commonly used in automotive engines: Some rocker arm designs include roller bearings or a roller tip. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. The rocker can handle engine speeds in excess of. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. Roller rockers and standard rockers. These components help to decrease friction between the rocker.

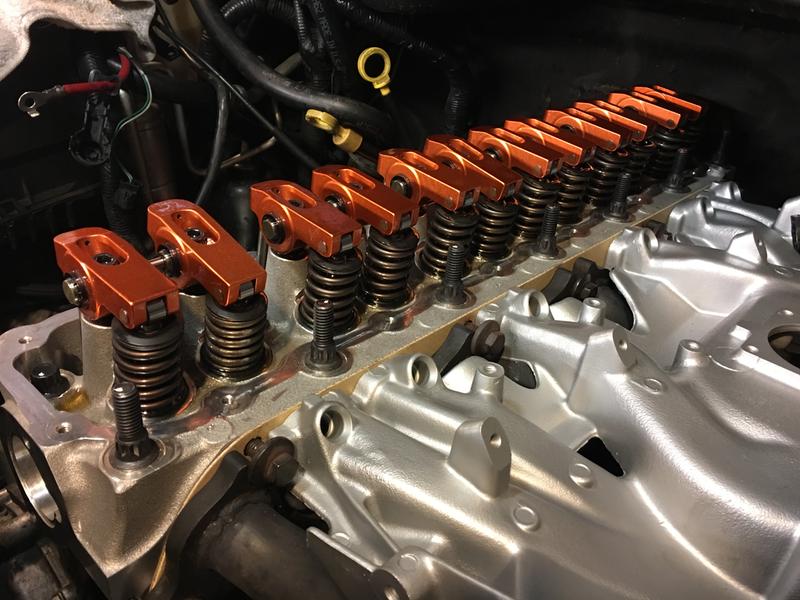

Harland Sharp 4.0 Jeep Roller Rocker Arms Bolt Down Rockers

Rocker Arms Engine Roller Rockers These components help to decrease friction between the rocker. The rocker can handle engine speeds in excess of. These components help to decrease friction between the rocker. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Some rocker arm designs include roller bearings or a roller tip. There are two primary types of rocker arms commonly used in automotive engines: Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. Roller rockers and standard rockers.

From www.performanceparts.com

PRW Engine Rocker Arm Kit 3231812; PlatinumSeries 1.6 Stainless Steel Rocker Arms Engine Roller Rockers There are two primary types of rocker arms commonly used in automotive engines: These components help to decrease friction between the rocker. Some rocker arm designs include roller bearings or a roller tip. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Rocker arms are. Rocker Arms Engine Roller Rockers.

From www.autozone.com

Proform 1.7in Ratio Pedestal Roller Rocker Arm Set For 302HO and 351W Rocker Arms Engine Roller Rockers But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits. Rocker Arms Engine Roller Rockers.

From rolliesspeedshop.com

Roller Rocker Arm Kit. Fits MilwaukeeEight 2017up. Rollies Rocker Arms Engine Roller Rockers Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. The rocker can handle engine speeds in excess of. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. There are two primary types of rocker arms commonly. Rocker Arms Engine Roller Rockers.

From rpmspeed.com

Mast Motorsports L92/LS3/L76/L99 1.8 Shaft Roller Rocker Arms Rocker Rocker Arms Engine Roller Rockers Roller rockers and standard rockers. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. These components help to decrease friction between the rocker. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. The rocker can handle engine speeds in. Rocker Arms Engine Roller Rockers.

From www.ebay.com

CXRacing Aluminum Roller Rocker Arms For 6BT 5.9L 12V Cummins Diesel Rocker Arms Engine Roller Rockers Roller rockers and standard rockers. There are two primary types of rocker arms commonly used in automotive engines: But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. The rocker can handle engine speeds in excess of. These components help to decrease friction between the rocker.. Rocker Arms Engine Roller Rockers.

From powerdrivendiesel.com

24v Cummins Tool Steel Roller Rocker Arm Assembly Power Driven Diesel Rocker Arms Engine Roller Rockers Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. These components help to decrease friction between the rocker. Roller rockers and standard rockers. Some rocker arm designs. Rocker Arms Engine Roller Rockers.

From www.speedmaster79.com

Speedmaster® Rocker Arm PCE261.1107 Buy Direct with Fast Shipping Rocker Arms Engine Roller Rockers There are two primary types of rocker arms commonly used in automotive engines: But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Some rocker arm designs include roller bearings or a roller tip. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the. Rocker Arms Engine Roller Rockers.

From findinges.com

Top 10 Best Roller Rockers For Sbc Based On Scores Findinges Rocker Arms Engine Roller Rockers These components help to decrease friction between the rocker. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. Some rocker arm designs include roller bearings or a roller tip. Rocker. Rocker Arms Engine Roller Rockers.

From www.carid.com

Harland Sharp® S4006NBK HeavyDuty™ Roller Rocker Arms Rocker Arms Engine Roller Rockers Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. There are two primary types of rocker arms commonly used in automotive engines: These components help to. Rocker Arms Engine Roller Rockers.

From www.iwflsports.com

7 Best Roller Rockers for SBC 2023 Review and Buying Guide Rocker Arms Engine Roller Rockers Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. These components help to decrease friction between the rocker. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. Roller rockers and standard rockers. Some rocker arm designs. Rocker Arms Engine Roller Rockers.

From www.dragzine.com

Rocking The Valves A Look At T&D's Shaft Mount Rocker Arms Rocker Arms Engine Roller Rockers Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. Some rocker arm designs include roller bearings or a roller tip. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. The rocker can handle engine speeds in excess. Rocker Arms Engine Roller Rockers.

From www.univbrg.com

What Are Roller Rocker Arms? Universal Bearings Rocker Arms Engine Roller Rockers Some rocker arm designs include roller bearings or a roller tip. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. The rocker can handle engine speeds in excess of. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will. Rocker Arms Engine Roller Rockers.

From www.jrpwracing.com

Gage Ultralite Roller Rocker Arms 1.3 Ratio JRPW Racing Rocker Arms Engine Roller Rockers When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. Roller rockers and standard rockers. These components help to decrease friction between the rocker. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. But engine masters ’ david freiburger and. Rocker Arms Engine Roller Rockers.

From www.wwww.performancetrends.com

Rocker Arms Rocker Arms Engine Roller Rockers But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up. Rocker Arms Engine Roller Rockers.

From www.getlowered.com

S&S Roller Rocker Arms for 20172020 Harley M8 9001084 Get Rocker Arms Engine Roller Rockers These components help to decrease friction between the rocker. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. There are two primary types of rocker arms commonly used in automotive. Rocker Arms Engine Roller Rockers.

From forhemisonly.com

Valvetrain For Hemis Only Rocker Arms Engine Roller Rockers The rocker can handle engine speeds in excess of. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. There are two primary types of rocker arms commonly used in automotive engines: Some rocker arm designs include roller bearings or a roller tip. Rocker arms are commonly designed to increase lift. Rocker Arms Engine Roller Rockers.

From www.atracingworld.com

Mopar Chrysler BB 383 440 1.6 Stainless Steel Roller Rocker Arms W Rocker Arms Engine Roller Rockers Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. The rocker can handle engine speeds in excess of. Roller rockers and standard rockers. But engine masters ’ david. Rocker Arms Engine Roller Rockers.

From www.streetmachine.com.au

Roller rockers explained Rocker Arms Engine Roller Rockers There are two primary types of rocker arms commonly used in automotive engines: But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. The. Rocker Arms Engine Roller Rockers.

From www.performanceparts.com

Elgin Engine Rocker Arm Kit SSR840RS; ProSeries 1.5 3/8" Stainless Rocker Arms Engine Roller Rockers The rocker can handle engine speeds in excess of. Roller rockers and standard rockers. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. Some rocker arm. Rocker Arms Engine Roller Rockers.

From www.enginelabs.com

Rock Out With T&D's ShaftMounted F710S Cylinder Head Rocker Arms Rocker Arms Engine Roller Rockers When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. Some rocker arm designs include roller bearings or a roller tip. The rocker can handle engine speeds in excess of. These components help to decrease friction between the rocker. Rocker arms are commonly designed to increase lift at the valve. Rocker Arms Engine Roller Rockers.

From www.kmjperformance.com

351C 400M 429 460 Ford Stainless Steel Full Roller Rocker Arms 1.7 Rocker Arms Engine Roller Rockers When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. The rocker can handle engine speeds in excess of. These components help to decrease friction between the rocker. There are two primary types of rocker arms commonly used in automotive engines: But engine masters ’ david freiburger and steve dulcich. Rocker Arms Engine Roller Rockers.

From jamsionline.com

Chevy SBC Roller Rocker Arm 1.5 Ratio ChromeMoly Steel 7/16" Stud 07 Rocker Arms Engine Roller Rockers Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. There are two primary types of rocker arms commonly used in automotive engines: Some rocker arm designs include roller bearings or a roller tip. These components help to decrease friction between the rocker. The rocker can handle engine. Rocker Arms Engine Roller Rockers.

From tdmotion.com

Harland Sharp 4.0 Jeep Roller Rocker Arms Bolt Down Rockers Rocker Arms Engine Roller Rockers These components help to decrease friction between the rocker. Some rocker arm designs include roller bearings or a roller tip. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. There are two primary types of rocker arms commonly used in automotive engines: When installing adjustable roller rockers on this engine,. Rocker Arms Engine Roller Rockers.

From www.jesel.com

HighPerformance Jesel Premium Stud Rockers for Ultimate Engine Rocker Arms Engine Roller Rockers Roller rockers and standard rockers. Some rocker arm designs include roller bearings or a roller tip. The rocker can handle engine speeds in excess of. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to. Rocker Arms Engine Roller Rockers.

From www.warrendiesel.com

Jessel 6.0 Powerstroke Steel Adjustable Rocker Arm System Rocker Arms Engine Roller Rockers Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. There are two primary types of rocker arms commonly used in automotive engines: When installing adjustable roller rockers on. Rocker Arms Engine Roller Rockers.

From www.autozone.com

Proform 1.6in Ratio Pedestal Roller Rocker Arm Set For Ford 302HO and Rocker Arms Engine Roller Rockers The rocker can handle engine speeds in excess of. Roller rockers and standard rockers. These components help to decrease friction between the rocker. Some rocker arm designs include roller bearings or a roller tip. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Rocker arms. Rocker Arms Engine Roller Rockers.

From www.ebay.com

Ford 302C 351C 400M 1.7 Bolton Adjustable Stainless Steel Roller Rocker Arms Engine Roller Rockers There are two primary types of rocker arms commonly used in automotive engines: Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. Roller rockers and standard rockers. Some. Rocker Arms Engine Roller Rockers.

From www.raceplumbing.net

Scorpion Rockers 1037 SBC Roller Rocker Arms 1.5 Ratio 3/8 Rocker Arms Engine Roller Rockers The rocker can handle engine speeds in excess of. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. Some rocker arm designs include roller bearings or a roller tip. There are two primary types of rocker arms commonly used in automotive engines: But engine masters ’ david freiburger and. Rocker Arms Engine Roller Rockers.

From www.kmjperformance.com

Small Block Chevy SBC 350 Aluminum Roller Rockers Arms Kit 1.60 Ratio 7 Rocker Arms Engine Roller Rockers The rocker can handle engine speeds in excess of. Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. These components help to decrease friction between the rocker. Roller rockers and standard rockers. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the. Rocker Arms Engine Roller Rockers.

From www.totalperformance.net.au

162116 Ultra Pro Magnum 1.5 Ratio Shaft Mount Roller Rockers Arm Kit Rocker Arms Engine Roller Rockers Roller rockers and standard rockers. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. There are two primary types of rocker arms commonly. Rocker Arms Engine Roller Rockers.

From www.kmjperformance.com

396 427 454 BBC Big Block Chevy Aluminum Roller Rocker Arms 1.7 Ratio 7 Rocker Arms Engine Roller Rockers Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. These components help to decrease friction between the rocker. When installing adjustable roller rockers on this engine, you will need to restrict the oiling passage in the cylinder head. The rocker can handle engine speeds in excess of. There are two. Rocker Arms Engine Roller Rockers.

From www.whichcar.com.au

What are Roller Rockers? Rocker Arms Engine Roller Rockers Conventional wisdom says roller rockers increase horsepower by reducing valvetrain friction—with the biggest benefits showing up at high rpm. The rocker can handle engine speeds in excess of. There are two primary types of rocker arms commonly used in automotive engines: These components help to decrease friction between the rocker. But engine masters ’ david freiburger and steve dulcich are. Rocker Arms Engine Roller Rockers.

From www.whichcar.com.au

What are Roller Rockers? Rocker Arms Engine Roller Rockers But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. The rocker can handle engine speeds in excess of. These components help to decrease. Rocker Arms Engine Roller Rockers.

From www.cxracing.com

Aluminum Roller Rocker Arms For 4BT 3.9L 12V Cummins Engine Rocker Arms Engine Roller Rockers Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. Roller rockers and standard rockers. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. When installing adjustable roller rockers on this engine, you. Rocker Arms Engine Roller Rockers.

From www.onallcylinders.com

Rocker Rolling with Jesel's Sportsman ShaftMounted Rocker Technology Rocker Arms Engine Roller Rockers The rocker can handle engine speeds in excess of. But engine masters ’ david freiburger and steve dulcich are always willing to question conventional wisdom and will leave no horsepower sacred cow untouched. There are two primary types of rocker arms commonly used in automotive engines: When installing adjustable roller rockers on this engine, you will need to restrict the. Rocker Arms Engine Roller Rockers.