Dip Transfer Vs Spray Transfer . Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. It’s great for materials thicker than 3 mm. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. In spray transfer, the electrode.

from homepage.ufp.pt

It’s great for materials thicker than 3 mm. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In spray transfer, the electrode. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity.

SequentialStratigrapy7

Dip Transfer Vs Spray Transfer In spray transfer, the electrode. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In spray transfer, the electrode. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. It’s great for materials thicker than 3 mm. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc.

From weldguru.com

Welding Transfer Modes Spray, Global & Short Circuiting Dip Transfer Vs Spray Transfer In spray transfer, the electrode. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. The main difference between spray transfer and other types of. Dip Transfer Vs Spray Transfer.

From www.youtube.com

How to Hydro Dip or Water Transfer Printing Step by Step YouTube Dip Transfer Vs Spray Transfer In spray transfer, the electrode. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. The main difference between spray transfer and other types of. Dip Transfer Vs Spray Transfer.

From www.youtube.com

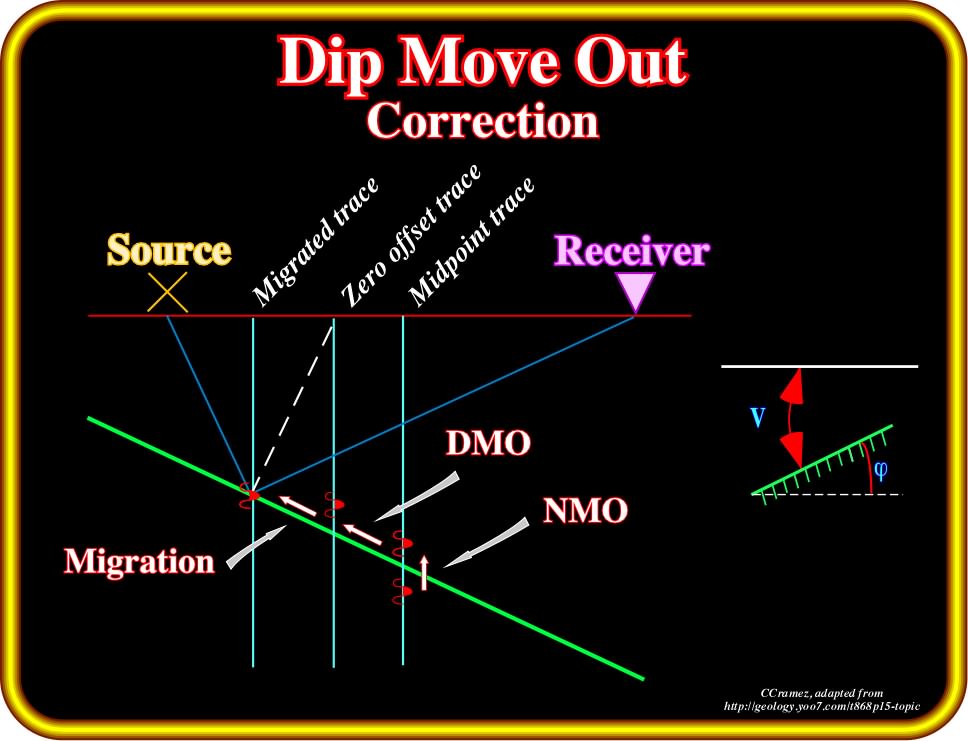

Normal Moveout (NMO), Dip moveout (DMO) and Linear Moveout (LMO) YouTube Dip Transfer Vs Spray Transfer It’s great for materials thicker than 3 mm. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In spray transfer, the electrode. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer. Dip Transfer Vs Spray Transfer.

From www.hobartbrothers.com

Welding Transfer Modes Tips for Achieving the Best Results Hobart Dip Transfer Vs Spray Transfer It’s great for materials thicker than 3 mm. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. In the spray transfer mode (also called axial. Dip Transfer Vs Spray Transfer.

From www.ubuy.co.in

Buy Hydrographic Film DIP Wizard Super Sized 16 Oz Aerosol Spray Can Dip Transfer Vs Spray Transfer It’s great for materials thicker than 3 mm. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In the spray transfer mode (also called axial spray transfer) the melting of the. Dip Transfer Vs Spray Transfer.

From www.researchgate.net

Growth and transfer of 2D materials and fabrication steps of cavities Dip Transfer Vs Spray Transfer Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In spray transfer, the electrode. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. It’s great for materials thicker than 3 mm. The main. Dip Transfer Vs Spray Transfer.

From www.desertcart.ae

Hydrographic Film Water Transfer Printing Hydro Dipping 6 oz Dip Transfer Vs Spray Transfer Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. It’s great for materials thicker than 3 mm. In spray transfer, the electrode.. Dip Transfer Vs Spray Transfer.

From www.youtube.com

Miller Explains Pulse Spray Transfer in MIG Welding YouTube Dip Transfer Vs Spray Transfer Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to. Dip Transfer Vs Spray Transfer.

From www.youtube.com

Vertical Pulse Spray Transfer YouTube Dip Transfer Vs Spray Transfer Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In spray transfer, the electrode. It’s great for materials thicker than 3 mm. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc.. Dip Transfer Vs Spray Transfer.

From www.desertcart.com.eg

Buy Hydrographic Film Water Transfer Printing Film Hydro Dipping Dip Dip Transfer Vs Spray Transfer Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. It’s great for materials thicker than 3 mm. Spray transfer is named for. Dip Transfer Vs Spray Transfer.

From weldinganswers.com

Modes of Metal Transfer Spray WELDING ANSWERS Dip Transfer Vs Spray Transfer It’s great for materials thicker than 3 mm. In spray transfer, the electrode. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The main. Dip Transfer Vs Spray Transfer.

From apr-rework.descoindustries.com

APR DTPCSP Flux Dip Transfer Plates for CSP, Pack of 3 Plates Dip Transfer Vs Spray Transfer Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. It’s great for materials thicker than 3 mm. Spray transfer mode requires a high current density pulse to. Dip Transfer Vs Spray Transfer.

From github.com

GitHub solareclipse27/DIP_ColorTransferbetweenImages Digital Dip Transfer Vs Spray Transfer In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In spray transfer, the electrode. It’s great for materials thicker than 3 mm. Spray transfer. Dip Transfer Vs Spray Transfer.

From cymiss.com

Water Transfer Printing Tanks (2022) Dip Transfer Vs Spray Transfer It’s great for materials thicker than 3 mm. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The main difference between spray transfer and. Dip Transfer Vs Spray Transfer.

From dippros.com

10' FOOT STAINLESS HYDROGRAPHIC WATER TRANSFER DIP TANK Dip Pros Dip Transfer Vs Spray Transfer It’s great for materials thicker than 3 mm. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. In spray transfer, the electrode. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity.. Dip Transfer Vs Spray Transfer.

From bahamas.desertcart.com

Hydrographic Film Activator DIP APE Super Sized 16 Oz Aerosol Spray Dip Transfer Vs Spray Transfer In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The main difference between spray transfer and other types of metal transfer is the size. Dip Transfer Vs Spray Transfer.

From www.youtube.com

MIG Welding Basics What is Spray Arc Transfer? YouTube Dip Transfer Vs Spray Transfer Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. In spray transfer, the electrode. The main difference between spray transfer and other. Dip Transfer Vs Spray Transfer.

From weldguru.com

Welding Transfer Modes Spray, Global & Short Circuiting Dip Transfer Vs Spray Transfer Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. It’s great for materials thicker than 3 mm. Spray transfer mode requires a high current density pulse to. Dip Transfer Vs Spray Transfer.

From homepage.ufp.pt

SequentialStratigrapy7 Dip Transfer Vs Spray Transfer In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. It’s great for materials thicker than 3 mm. In spray transfer, the electrode.. Dip Transfer Vs Spray Transfer.

From www.indiamart.com

Water Transfer Printing Hydrographic Hydro Dip Film Activators Aerosol Dip Transfer Vs Spray Transfer In spray transfer, the electrode. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. It’s great for materials thicker than 3 mm. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer. Dip Transfer Vs Spray Transfer.

From www.basicwelding.co.uk

What is Dip Transfer Welding? BWS Ltd Dip Transfer Vs Spray Transfer Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. In spray transfer, the electrode. The main difference between spray transfer and other types of. Dip Transfer Vs Spray Transfer.

From www.aedmetals.com

MIG Welding Transfer Methods A.E.D. Motorsport Products Dip Transfer Vs Spray Transfer In spray transfer, the electrode. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. It’s great for materials thicker than 3 mm. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. Spray transfer mode requires a. Dip Transfer Vs Spray Transfer.

From weldguru.com

Welding Transfer Modes Spray, Global & Short Circuiting Dip Transfer Vs Spray Transfer Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. It’s great for materials thicker than 3 mm. In spray transfer, the electrode.. Dip Transfer Vs Spray Transfer.

From weldingpros.net

Dual Shield Welding Fundamentals, Tips, Tricks, & Pros Dip Transfer Vs Spray Transfer The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. It’s great for materials thicker than 3 mm. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In the spray transfer mode (also called axial. Dip Transfer Vs Spray Transfer.

From weldingpros.net

Spray Transfer MIG Welding Techniques & Tips Dip Transfer Vs Spray Transfer Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. The main difference between spray transfer and other types of metal transfer is. Dip Transfer Vs Spray Transfer.

From www.researchgate.net

Schematics of phosphor diptransfer coating on a cuboid bump structure Dip Transfer Vs Spray Transfer The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. It’s great for materials thicker than 3 mm. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray. Dip Transfer Vs Spray Transfer.

From www.youtube.com

Welding Modes Short Circuit vs Spray vs Globular YouTube Dip Transfer Vs Spray Transfer In spray transfer, the electrode. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. It’s great for materials thicker than 3 mm. The main. Dip Transfer Vs Spray Transfer.

From www.perfectpowerwelders.com

Spray Transfer MIG Welding Tips & Tricks Mig Welder, Mma Welder Dip Transfer Vs Spray Transfer The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In spray transfer, the electrode. Spray transfer mode requires a high current density pulse to send tiny droplets. Dip Transfer Vs Spray Transfer.

From www.twi-global.com

MIG/MAG Developments in Low Heat Input Transfer Modes TWI Dip Transfer Vs Spray Transfer The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to. Dip Transfer Vs Spray Transfer.

From www.youtube.com

🔥 Spray Transfer MIG Welding YouTube Dip Transfer Vs Spray Transfer It’s great for materials thicker than 3 mm. In spray transfer, the electrode. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are. Dip Transfer Vs Spray Transfer.

From www.youtube.com

[English] Types of Metal Transfer in MIG/MAG Welding YouTube Dip Transfer Vs Spray Transfer In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. In spray transfer, the electrode. It’s great for materials thicker than 3 mm. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity.. Dip Transfer Vs Spray Transfer.

From www.youtube.com

Miller Explains Globular Transfer in MIG Welding YouTube Dip Transfer Vs Spray Transfer In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. In spray transfer, the electrode. The main difference between spray transfer and other. Dip Transfer Vs Spray Transfer.

From www.hobartbrothers.com

Welding Transfer Modes Tips for Achieving the Best Results Hobart Dip Transfer Vs Spray Transfer Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. In spray transfer, the electrode. Spray transfer mode requires a high current density pulse to send tiny droplets into the weld pool with high velocity. The main difference between spray transfer and other types of metal transfer is the size of the. Dip Transfer Vs Spray Transfer.

From weldinganswers.com

Modes of Metal Transfer Short Circuit WELDING ANSWERS Dip Transfer Vs Spray Transfer In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The main difference between spray transfer and other types of metal transfer is the size. Dip Transfer Vs Spray Transfer.

From small-town-shirt-shack.myshopify.com

Dip Dip Hooray Transfer Small Town Shirt Shack Dip Transfer Vs Spray Transfer It’s great for materials thicker than 3 mm. In the spray transfer mode (also called axial spray transfer) the melting of the consumable electrode wire is driven mainly by the heat of the welding arc. The main difference between spray transfer and other types of metal transfer is the size of the droplets that are released from the electrode. Spray. Dip Transfer Vs Spray Transfer.