Spray Dryer Cfd . To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. A key feature of the approach has been the systematic use of. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. After briefly covering the basics of.

from www.mdpi.com

A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. After briefly covering the basics of. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. A key feature of the approach has been the systematic use of.

Processes Free FullText Using CFD Simulations to Guide the

Spray Dryer Cfd This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. After briefly covering the basics of. A key feature of the approach has been the systematic use of. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying.

From www.ibu-tec.com

IBUtec Spray Dryer for Research and Development Spray Dryer Cfd A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. After briefly covering the basics of. A key feature of the approach has been the systematic. Spray Dryer Cfd.

From cfdconsultantsindia.com

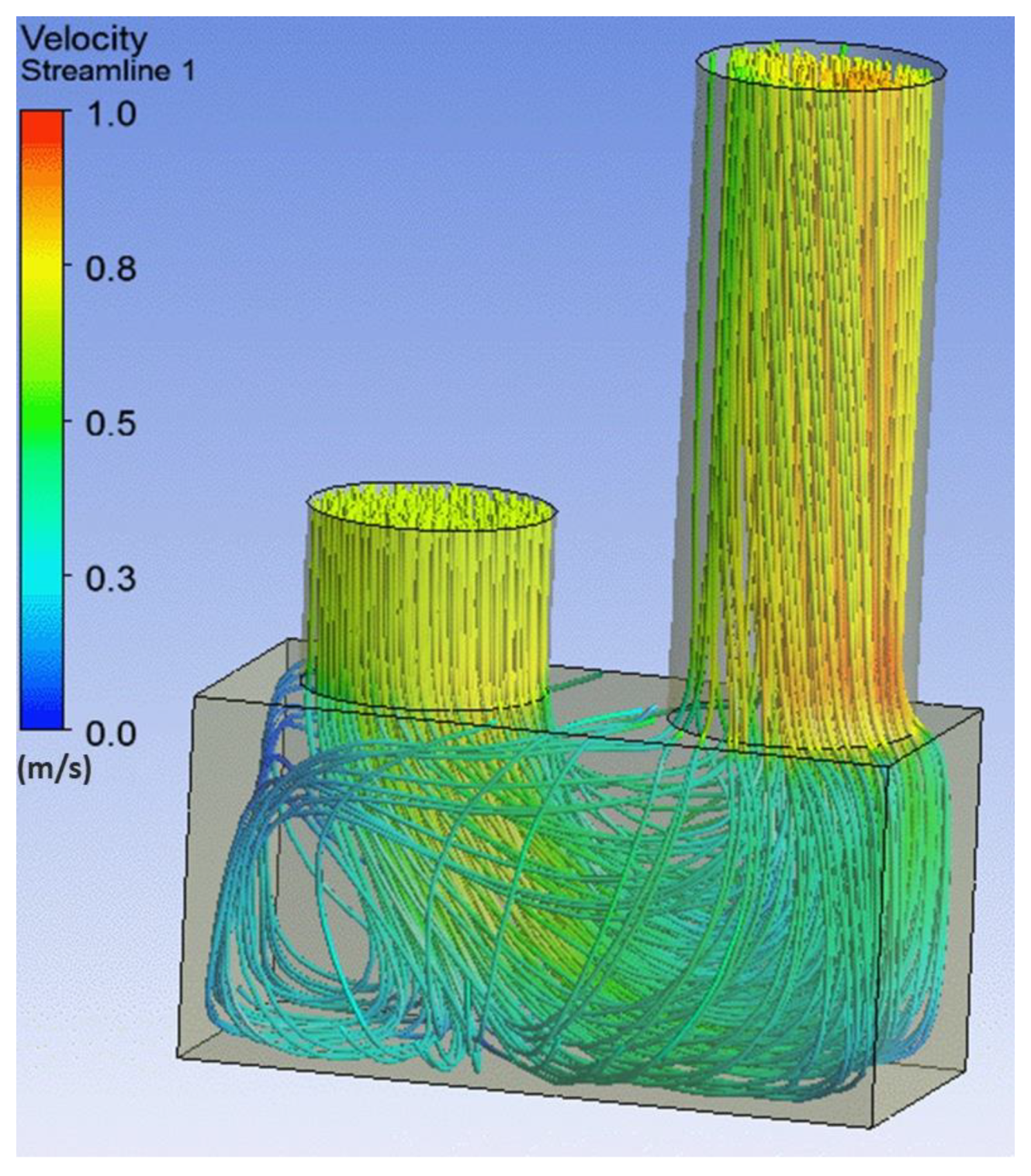

CFD Case Studies Spray Dryer Cfd Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. After briefly covering the basics of. A key feature of the approach has been the systematic use of. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering. Spray Dryer Cfd.

From www.researchgate.net

(PDF) CFD in Drying Technology Spray‐Dryer Simulation Spray Dryer Cfd After briefly covering the basics of. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. To predict the particle size accurately, this study. Spray Dryer Cfd.

From www.youtube.com

Spray Dryer CFD case Study by Saka Engineering YouTube Spray Dryer Cfd Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. A key feature of the approach has been the systematic use of. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. After briefly covering. Spray Dryer Cfd.

From www.cfdsource.com

CFD simulation of spray dryer by Ansys Fluent cfdsource Spray Dryer Cfd To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. A key feature of the approach has been the systematic use of. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. Along with showing how to set up. Spray Dryer Cfd.

From www.spray-dryer.com

European Spray Dry Technologies Spray Dryer Cfd Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. Now, with the increasing computing power cfd will be a valuable tool for the food. Spray Dryer Cfd.

From www.mdpi.com

Processes Free FullText Using CFD Simulations to Guide the Spray Dryer Cfd A key feature of the approach has been the systematic use of. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. To. Spray Dryer Cfd.

From www.youtube.com

Spray Dryer CFD Animation STARCCM+ Simulation YouTube Spray Dryer Cfd This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. Along with showing how to set up models, the book helps readers identify the capabilities and. Spray Dryer Cfd.

From www.semanticscholar.org

Figure 8 from CFD Analysis of Cocurrent Spray Dryer with Swirler at Spray Dryer Cfd To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. After briefly covering the basics of. A key feature of the approach has been the systematic use of. This chapter provides. Spray Dryer Cfd.

From relco.net

Parvus™ Pilot Spray Dryer RELCO Spray Dryer Cfd This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes. Spray Dryer Cfd.

From www.aerotak.dk

Spray Drying simulation — Aerotak Spray Dryer Cfd A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a. Spray Dryer Cfd.

From www.youtube.com

Parametric CFD simulations on spray dryers YouTube Spray Dryer Cfd To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering. Spray Dryer Cfd.

From www.ansysfluent.ir

Spray Dryer CFD Simulation Training Spray Dryer Cfd A key feature of the approach has been the systematic use of. To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. A combined approach has been taken here, using. Spray Dryer Cfd.

From www.mr-cfd.com

Spray Dryer CFD Simulation Training Spray Dryer Cfd After briefly covering the basics of. A key feature of the approach has been the systematic use of. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes. Spray Dryer Cfd.

From www.mr-cfd.com

Spray Dryer CFD Simulation Training Spray Dryer Cfd Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. A combined approach has been taken here, using cfd and physical testing, due to. Spray Dryer Cfd.

From www.researchgate.net

(PDF) Using CFD Simulations to Guide the Development of a New Spray Spray Dryer Cfd Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. After briefly covering the basics of. Along with showing how to set up models, the book helps. Spray Dryer Cfd.

From www.dryingresearch.org

Center for Advanced Research in Drying » A CFDBased Numerical Tool to Spray Dryer Cfd A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. To predict the particle size accurately, this study presents a cfd model of particle agglomeration. Spray Dryer Cfd.

From www.griffinmachinery.com

Introduction To The Composition And Characteristics Of Spray Dryer Spray Dryer Cfd A key feature of the approach has been the systematic use of. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. Now, with the increasing. Spray Dryer Cfd.

From www.aerotak.dk

Spray Drying simulation — Aerotak Spray Dryer Cfd After briefly covering the basics of. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. A key feature of the approach has been the systematic use of. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes. Spray Dryer Cfd.

From www.aerotak.dk

Spray Drying simulation — Aerotak Spray Dryer Cfd After briefly covering the basics of. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. A key feature of the approach has been the systematic use. Spray Dryer Cfd.

From www.taylorfrancis.com

Computational Fluid Dynamics Simulation of Spray Dryers Taylor Spray Dryer Cfd Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. A key feature of the approach has been the systematic use of. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. After. Spray Dryer Cfd.

From www.youtube.com

Spray Dryer CFD Simulation YouTube Spray Dryer Cfd A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. To predict the particle size accurately, this study presents a cfd model of particle agglomeration. Spray Dryer Cfd.

From www.youtube.com

Spray Dryer CFD analysis Saka Engineering YouTube Spray Dryer Cfd Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. After briefly covering the basics of. This chapter provides a detailed case study of the application of. Spray Dryer Cfd.

From fluent-es.in

CFD Simulation of ‘Spray Dryer’ System ⋆ Fluent Engineering Solutions Spray Dryer Cfd This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. A key feature of the approach has been the systematic use of. A combined approach has been taken here,. Spray Dryer Cfd.

From www.mr-cfd.com

Spray Dryer CFD Simulation Training Spray Dryer Cfd This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. Along with showing how to set up models, the book helps readers identify the capabilities. Spray Dryer Cfd.

From www.mdpi.com

Processes Free FullText Using CFD Simulations to Guide the Spray Dryer Cfd To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. A combined approach has been taken here, using cfd and physical testing, due to the variations in the. Spray Dryer Cfd.

From www.mr-cfd.com

Spray Dryer CFD Simulation Training Spray Dryer Cfd A key feature of the approach has been the systematic use of. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. After briefly covering the basics of. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex. Spray Dryer Cfd.

From www.mr-cfd.com

Spray Dryer CFD Simulation Training Spray Dryer Cfd A key feature of the approach has been the systematic use of. To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. After briefly covering the basics of. This chapter. Spray Dryer Cfd.

From www.mdpi.com

Processes Free FullText Using CFD Simulations to Guide the Spray Dryer Cfd A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. After briefly covering the basics of. A key feature of the approach has been the systematic. Spray Dryer Cfd.

From www.researchgate.net

(PDF) CFD SIMULATION OF COCURRENT SPRAY DRYER Spray Dryer Cfd To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. After briefly covering the basics of. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. Now, with the increasing computing power cfd will be a valuable tool for the food. Spray Dryer Cfd.

From www.researchgate.net

(PDF) DESIGN AND MATHEMATICAL MODELING OF SPRAY DRYER USING CFD. Spray Dryer Cfd Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. This chapter provides a detailed case study of the application of cfd modelling to the drying of. Spray Dryer Cfd.

From www.shachiengineering.com

Industrial 4.0 spray dryer CFD Shachi Engineering Spray Dryer Cfd After briefly covering the basics of. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. A combined approach has been taken here, using. Spray Dryer Cfd.

From www.mr-cfd.com

Spray Dryer CFD Simulation Training Spray Dryer Cfd This chapter provides a detailed case study of the application of cfd modelling to the drying of skimmed milk in a spray dryer,. A key feature of the approach has been the systematic use of. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties of the cfd technique for spray drying. Now,. Spray Dryer Cfd.

From www.mr-cfd.com

Spray Dryer CFD Simulation Training Spray Dryer Cfd To predict the particle size accurately, this study presents a cfd model of particle agglomeration and droplet coalescence. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. After briefly covering the basics of. A key feature of the approach has been the systematic use of. A combined. Spray Dryer Cfd.

From www.researchgate.net

Computational Fluid Dynamics (CFD) Simulations of Spray Drying Linking Spray Dryer Cfd A combined approach has been taken here, using cfd and physical testing, due to the variations in the outcomes of using. Now, with the increasing computing power cfd will be a valuable tool for the food industry in answering complex fluid flow, heat. Along with showing how to set up models, the book helps readers identify the capabilities and uncertainties. Spray Dryer Cfd.