Light Gauge Steel Vs Structural Steel . In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. The structural steel fabricators working at baker steel trading recommend the latter. Light gauge steel and structural steel. Structural steel requires thicker and heavier fastening. The longer spans means less fastening and faster construction. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. The pros and cons of structural steel vs. In this case, most projects use one of two options: Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. It is extremely durable and trusted as a primary steel framing system for tall buildings.

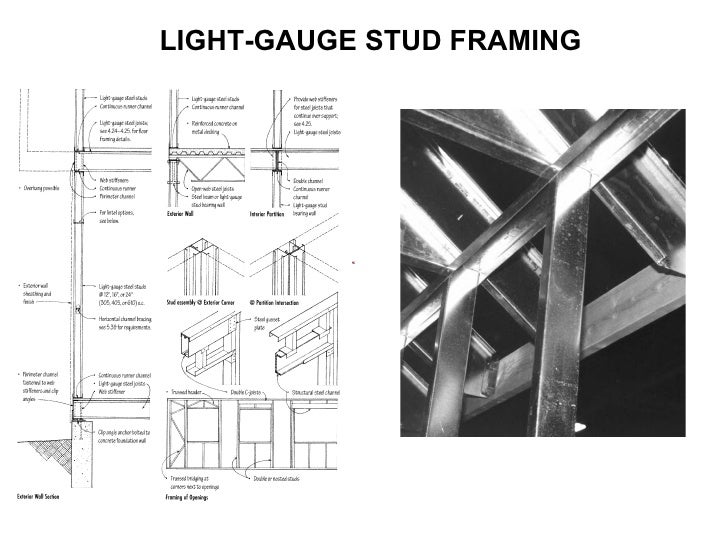

from www.slideshare.net

Structural steel requires thicker and heavier fastening. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. Light gauge steel and structural steel. In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. The pros and cons of structural steel vs. Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. The structural steel fabricators working at baker steel trading recommend the latter. In this case, most projects use one of two options: As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. The longer spans means less fastening and faster construction.

Light Gauge Steel

Light Gauge Steel Vs Structural Steel Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. In this case, most projects use one of two options: Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. Light gauge steel and structural steel. It is extremely durable and trusted as a primary steel framing system for tall buildings. The pros and cons of structural steel vs. The structural steel fabricators working at baker steel trading recommend the latter. Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. The longer spans means less fastening and faster construction. Structural steel requires thicker and heavier fastening.

From www.pinterest.co.uk

Using hot rolled steel sections in Light gauge steel framing Light Gauge Steel Vs Structural Steel In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. It is extremely durable and trusted as a primary steel framing system for tall buildings. The longer spans means less fastening and faster construction. Structural steel and light gauge framing are quite different in both production of the steel, application and. Light Gauge Steel Vs Structural Steel.

From s3da-design.com

Using hot rolled steel sections in Light gauge steel framing Light Gauge Steel Vs Structural Steel As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. In this case, most projects use one of two options: The pros and cons of structural steel vs. The structural steel fabricators working at. Light Gauge Steel Vs Structural Steel.

From yumi-steel.en.made-in-china.com

Engineered Light Gauge Steel Framing System for Steel Structure Steel Light Gauge Steel Vs Structural Steel Structural steel requires thicker and heavier fastening. The pros and cons of structural steel vs. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. It is extremely durable and trusted as a primary steel framing system for tall buildings. The longer spans means less fastening and faster construction. In the dynamic. Light Gauge Steel Vs Structural Steel.

From www.lgsf.co.uk

Products & Systems Light Gauge Steel Framing (LGSF) Light Gauge Steel Vs Structural Steel The longer spans means less fastening and faster construction. Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. It is extremely durable and trusted as a primary steel framing system for tall buildings. In the dynamic landscape of construction, the choice between structural. Light Gauge Steel Vs Structural Steel.

From www.base-4.com

ColdFormed Steel vs Structural Steel BASE4 Light Gauge Steel Vs Structural Steel As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. It is extremely durable and trusted as a primary steel framing system for tall buildings. The pros and cons of structural steel vs. Structural steel requires thicker and heavier fastening. Structural steel has many uses, but the most common are large projects such. Light Gauge Steel Vs Structural Steel.

From usframefactory.com

Light Gauge Steel vs Red Iron Light Gauge Steel Vs Structural Steel Structural steel requires thicker and heavier fastening. The longer spans means less fastening and faster construction. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. In this case, most projects use one of two options: Structural steel and light gauge framing are quite different in both production of the steel, application and. Light Gauge Steel Vs Structural Steel.

From usframefactory.com

Light Gauge Steel vs Red Iron Light Gauge Steel Vs Structural Steel The structural steel fabricators working at baker steel trading recommend the latter. In this case, most projects use one of two options: Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. Light gauge steel and structural steel. Structural steel requires thicker and heavier fastening. The pros and cons of structural steel. Light Gauge Steel Vs Structural Steel.

From www.structure1.com

Structural Design of Light Gauge Steel / Coldformed Steel PSE Light Gauge Steel Vs Structural Steel In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. It is extremely durable and trusted as a primary steel framing system for tall buildings. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. The longer spans means less fastening and faster. Light Gauge Steel Vs Structural Steel.

From www.slideshare.net

Light Gauge Steel Light Gauge Steel Vs Structural Steel The pros and cons of structural steel vs. In this case, most projects use one of two options: In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. The structural steel fabricators working. Light Gauge Steel Vs Structural Steel.

From shellysavonlea.net

Light Gauge Steel Buildings India Shelly Lighting Light Gauge Steel Vs Structural Steel Light gauge steel and structural steel. The structural steel fabricators working at baker steel trading recommend the latter. Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. The longer spans means less fastening and faster construction. Structural steel has many uses, but the. Light Gauge Steel Vs Structural Steel.

From www.summitengineeringinc.com

Structural Design of Light Gauge Steel Summit Engineering Inc Light Gauge Steel Vs Structural Steel Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. Light gauge steel and structural steel. In the dynamic landscape of construction, the choice between structural. Light Gauge Steel Vs Structural Steel.

From shellysavonlea.net

Light Gauge Steel Building Design Shelly Lighting Light Gauge Steel Vs Structural Steel In this case, most projects use one of two options: As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. The pros and cons of structural steel vs. Light gauge steel and structural steel.. Light Gauge Steel Vs Structural Steel.

From www.structure1.com

Light Gauge Steel Framing PSE Consulting Engineers, Inc. Light Gauge Steel Vs Structural Steel Structural steel requires thicker and heavier fastening. It is extremely durable and trusted as a primary steel framing system for tall buildings. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. Light gauge. Light Gauge Steel Vs Structural Steel.

From liongarages.com

Light Gauge vs. Structural Steel Construction Liongarages Light Gauge Steel Vs Structural Steel The structural steel fabricators working at baker steel trading recommend the latter. Light gauge steel and structural steel. The longer spans means less fastening and faster construction. In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. Structural steel and light gauge framing are quite different in both production of the. Light Gauge Steel Vs Structural Steel.

From www.youtube.com

Light gauge steel framing construction system for your new house YouTube Light Gauge Steel Vs Structural Steel The longer spans means less fastening and faster construction. In this case, most projects use one of two options: Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. Light gauge steel and structural steel. Structural steel has many uses, but the most common are large projects such as ships and. Light Gauge Steel Vs Structural Steel.

From www.smarthousing.cn

Light Gauge Steel Framing House Structure , Quick Installation Light Light Gauge Steel Vs Structural Steel Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. The longer spans means less fastening and faster construction. It is extremely durable and trusted as a primary steel framing system for tall buildings. The. Light Gauge Steel Vs Structural Steel.

From www.structure1.com

Structural Design of Light Gauge Steel / Coldformed Steel PSE Light Gauge Steel Vs Structural Steel Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. The longer spans means less fastening and faster construction. In this case, most projects use one of two options: Light gauge steel and structural steel. Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230. Light Gauge Steel Vs Structural Steel.

From www.slideshare.net

Comparison Presentation Between Light Gauge Steel Frame Construction Light Gauge Steel Vs Structural Steel Structural steel requires thicker and heavier fastening. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. It is extremely durable and trusted as a primary steel framing system for tall buildings. The structural steel fabricators working at baker steel trading recommend the latter. The longer spans means less fastening and. Light Gauge Steel Vs Structural Steel.

From www.structure1.com

Pros and Cons of Light Gauge Steel Framing PSE Consulting Engineers, Inc. Light Gauge Steel Vs Structural Steel In this case, most projects use one of two options: Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. The pros and cons of structural steel vs. The longer spans means less fastening and faster construction. The structural steel fabricators working at baker steel trading recommend the latter. As a. Light Gauge Steel Vs Structural Steel.

From www.structure1.com

Structural Design of Light Gauge Steel / Coldformed Steel PSE Light Gauge Steel Vs Structural Steel It is extremely durable and trusted as a primary steel framing system for tall buildings. The pros and cons of structural steel vs. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. Structural steel requires thicker and heavier fastening. As a metal, light gauge steel won’t rot, split, warp, shrink twist,. Light Gauge Steel Vs Structural Steel.

From www.totaljoist.com

LightGauge Steel 101 A Lesson on the Ultimate LoadBearing Structural Light Gauge Steel Vs Structural Steel Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. The pros and cons of structural steel vs. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. The structural steel fabricators working at baker. Light Gauge Steel Vs Structural Steel.

From www.summitengineeringinc.com

Structural Design of Light Gauge Steel Summit Engineering Inc Light Gauge Steel Vs Structural Steel In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. The longer spans means less fastening and faster construction. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. Structural steel and light gauge framing are quite different in both production of the steel,. Light Gauge Steel Vs Structural Steel.

From www.smartbuild.ae

Light Gauge Steel in Construction The way forward Smart Build Light Gauge Steel Vs Structural Steel Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. The longer spans means less fastening and faster construction. In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. Structural steel and light gauge framing are quite different in both production of the. Light Gauge Steel Vs Structural Steel.

From qdjiahexin.en.made-in-china.com

Light Gauge Steel Structure Framing Truss China Steel Framing and Light Gauge Steel Vs Structural Steel Light gauge steel and structural steel. The structural steel fabricators working at baker steel trading recommend the latter. The pros and cons of structural steel vs. Structural steel requires thicker and heavier fastening. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. In the dynamic landscape of construction, the choice between structural. Light Gauge Steel Vs Structural Steel.

From alpineitw.com

LightGauge Steel Versus Wood Framing Alpine An ITW Company Light Gauge Steel Vs Structural Steel Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. Structural steel requires thicker and heavier fastening. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. The pros and cons of structural steel vs. The longer spans means less fastening and faster construction. The. Light Gauge Steel Vs Structural Steel.

From shellysavonlea.net

Light Gauge Steel Building Design Shelly Lighting Light Gauge Steel Vs Structural Steel Light gauge steel and structural steel. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. The longer spans means less fastening and faster construction. In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. Structural steel requires thicker and heavier fastening. Structural steel. Light Gauge Steel Vs Structural Steel.

From www.pbctoday.co.uk

Is light gauge steel framing the most advanced material in offsite Light Gauge Steel Vs Structural Steel The pros and cons of structural steel vs. Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. It is extremely durable and trusted as a. Light Gauge Steel Vs Structural Steel.

From usframefactory.com

Light Gauge Steel vs Red Iron Light Gauge Steel Vs Structural Steel Light gauge steel and structural steel. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. The pros and cons of structural steel vs. The longer spans means less fastening and faster construction. In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision.. Light Gauge Steel Vs Structural Steel.

From steelframesolutions.co.nz

Why Consider Light Gauge Steel Framing In Your Next Project Steel Light Gauge Steel Vs Structural Steel The longer spans means less fastening and faster construction. Light gauge steel and structural steel. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. The pros and cons of structural steel vs. It is extremely durable and trusted as a primary steel framing system for tall buildings. Structural steel has. Light Gauge Steel Vs Structural Steel.

From liongarages.com

Light Gauge vs. Structural Steel Construction Liongarages Light Gauge Steel Vs Structural Steel In this case, most projects use one of two options: Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. Structural steel requires thicker and. Light Gauge Steel Vs Structural Steel.

From portacabinsuae.com

Light Gauge Steel Structure Emirates Portacabins UAE Light Gauge Steel Vs Structural Steel Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. The structural steel fabricators working at baker steel trading recommend the latter. It is extremely durable and trusted as a primary steel framing system for tall buildings. Structural steel requires thicker and heavier fastening. Light gauge steel, as the name implies,. Light Gauge Steel Vs Structural Steel.

From galvastrong.com

Why Light Gauge Steel Frame Construction is the Best option in Rapid Light Gauge Steel Vs Structural Steel In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. Structural steel requires thicker and heavier fastening. The pros and cons of structural steel vs. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. As a metal, light gauge steel won’t rot,. Light Gauge Steel Vs Structural Steel.

From mexisteel.com

MEXI® Steel Light Gauge Steel Framing LGSF system produced with Light Gauge Steel Vs Structural Steel The longer spans means less fastening and faster construction. It is extremely durable and trusted as a primary steel framing system for tall buildings. Structural steel requires thicker and heavier fastening. In the dynamic landscape of construction, the choice between structural steel and light gauge steel presents a critical decision. In this case, most projects use one of two options:. Light Gauge Steel Vs Structural Steel.

From tatabluescopesteel.com

Light Gauge Framing System (LGFS) A Smart and sustainable Steel Light Gauge Steel Vs Structural Steel The longer spans means less fastening and faster construction. Structural steel and light gauge framing are quite different in both production of the steel, application and fastening methods. Light gauge steel, as the name implies, is much lighter and thinner, ranging from 0.0157 to 0.230 inches thick, while structural steel starts at 0.23 inches. In this case, most projects use. Light Gauge Steel Vs Structural Steel.

From strucsoftsolutions.com

Understanding Construction What is Light Gauge Steel Framing Light Gauge Steel Vs Structural Steel The pros and cons of structural steel vs. Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. As a metal, light gauge steel won’t rot, split, warp, shrink twist, burn or become termite food. The structural steel fabricators working at baker steel trading recommend the latter. Light gauge steel and structural. Light Gauge Steel Vs Structural Steel.