How Can You Test The Hardness Of A Material . Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the. It is used in a number of industries for. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. The most common test for this is the shore scleroscope.

from whatispiping.com

It is used in a number of industries for. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. The most common test for this is the shore scleroscope. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods.

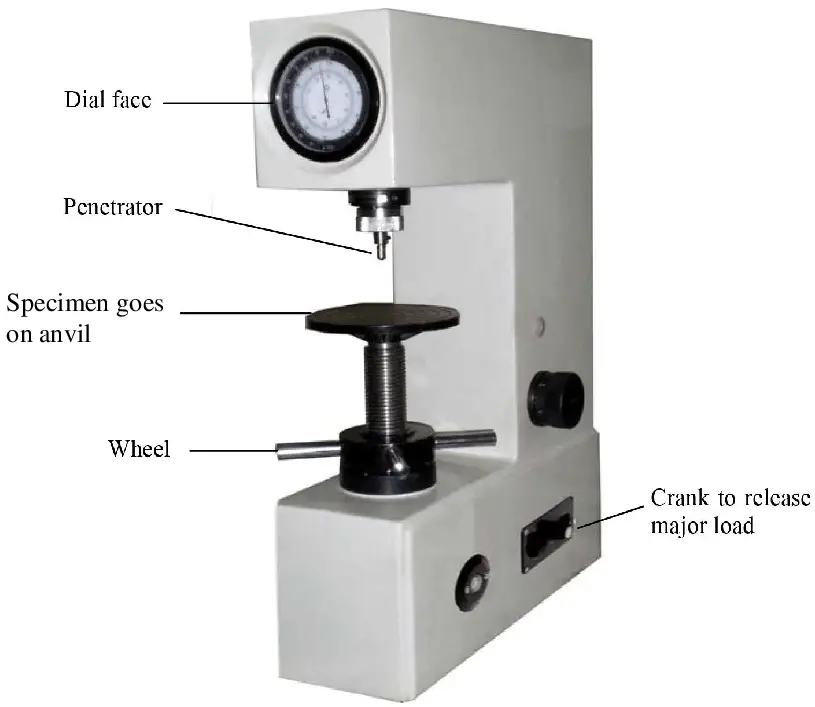

Rockwell Hardness Scale for Hardness Test What Is Piping

How Can You Test The Hardness Of A Material Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. The most common test for this is the shore scleroscope. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. It is used in a number of industries for. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it.

From www.hardnessgauge.com

Hardness Testing Basics Hardness Tester How Can You Test The Hardness Of A Material It is used in a number of industries for. The most common test for this is the shore scleroscope. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and. How Can You Test The Hardness Of A Material.

From www.scribd.com

Rockwell Hardness Test PDF Hardness Chemical Product Engineering How Can You Test The Hardness Of A Material The most common test for this is the shore scleroscope. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Various. How Can You Test The Hardness Of A Material.

From www.wikihow.com

How to Test Hardness of a Mineral 10 Steps (with Pictures) How Can You Test The Hardness Of A Material The most common test for this is the shore scleroscope. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. How Can You Test The Hardness Of A Material.

From amesportablehardnesstesters.com

The Rockwell Metal Hardness Scales Explained How Can You Test The Hardness Of A Material The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. Hardness testing is an essential aid in the differentiation of materials, as well as for the. How Can You Test The Hardness Of A Material.

From fractory.com

Material Hardness from Types of Hardness to Testing & Units How Can You Test The Hardness Of A Material Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. In this article we shall explore five of the most common test methods. How Can You Test The Hardness Of A Material.

From www.youtube.com

Hardness of materials (Metals, Plastics and Ceramics) (Theory and How Can You Test The Hardness Of A Material Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the. How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical.. How Can You Test The Hardness Of A Material.

From www.practicalmachinist.com

A Primer on Rockwell Hardness Testing Practical Machinist Practical How Can You Test The Hardness Of A Material In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined. How Can You Test The Hardness Of A Material.

From www.youtube.com

Measuring Hardness of Materials (Experimental) YouTube How Can You Test The Hardness Of A Material Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. The most common test for this is the shore scleroscope. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests.. How Can You Test The Hardness Of A Material.

From www.youtube.com

Types of hardness tester ? Rockwell hardness tester YouTube How Can You Test The Hardness Of A Material Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. The most common test for this is the shore scleroscope. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests.. How Can You Test The Hardness Of A Material.

From www.wikihow.com

How to Test Hardness of a Mineral 10 Steps (with Pictures) How Can You Test The Hardness Of A Material It is used in a number of industries for. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. The most common test for this is the shore scleroscope. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. Various hardness testing methods exist,. How Can You Test The Hardness Of A Material.

From www.educationalstuffs.in

STRENGTH OF MATERIALS Brinell Hardness Test How Can You Test The Hardness Of A Material Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Rebound hardness is. How Can You Test The Hardness Of A Material.

From www.tec-science.com

Brinell hardness test tecscience How Can You Test The Hardness Of A Material Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. Rebound hardness. How Can You Test The Hardness Of A Material.

From machiningtoday.com

Material Hardness A Comprehensive Guide to You MachiningToday How Can You Test The Hardness Of A Material The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Various hardness. How Can You Test The Hardness Of A Material.

From www.penntoolco.com

How To Measure the Hardness of Materials Penn Tool Co., Inc How Can You Test The Hardness Of A Material Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. It is used in a number of industries for. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and. How Can You Test The Hardness Of A Material.

From www.corrosionpedia.com

5 Ways to Measure the Hardness of Materials How Can You Test The Hardness Of A Material How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. Rebound hardness is particularly. How Can You Test The Hardness Of A Material.

From www.metalsupermarkets.com

What are Brinell and Rockwell Hardness Measurements? Metal Supermarkets How Can You Test The Hardness Of A Material Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the. How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with. How Can You Test The Hardness Of A Material.

From dl-uk.apowersoft.com

Printable Mohs Hardness Scale How Can You Test The Hardness Of A Material The most common test for this is the shore scleroscope. It is used in a number of industries for. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Rigorous metal hardness testing involves using a probe to indent. How Can You Test The Hardness Of A Material.

From www.youtube.com

Calculate the hardness of material using Brinell Hardness Tester in How Can You Test The Hardness Of A Material Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. The most common test for this is the shore scleroscope. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Rebound hardness is particularly useful for. How Can You Test The Hardness Of A Material.

From whatispiping.com

Rockwell Hardness Scale for Hardness Test What Is Piping How Can You Test The Hardness Of A Material Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material. The most common test for this is the shore scleroscope. Rebound hardness is particularly. How Can You Test The Hardness Of A Material.

From www.youtube.com

Hardness Of Materials Hardness Testing Methods Basic Concepts How Can You Test The Hardness Of A Material Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. How Can You Test The Hardness Of A Material.

From www.tec-science.com

Rockwell hardness test tecscience How Can You Test The Hardness Of A Material In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. Rebound hardness is particularly useful for large and irregularly shaped. How Can You Test The Hardness Of A Material.

From fractory.com

Material Hardness from Types of Hardness to Testing & Units How Can You Test The Hardness Of A Material In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a. How Can You Test The Hardness Of A Material.

From www.youtube.com

Hardness of Materials The Scratch Test Science Experiment YouTube How Can You Test The Hardness Of A Material Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder. How Can You Test The Hardness Of A Material.

From www.geologyin.com

The Mohs Hardness Scale Geology In How Can You Test The Hardness Of A Material How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas. How Can You Test The Hardness Of A Material.

From mavink.com

Hardness Testing Methods How Can You Test The Hardness Of A Material Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable.. How Can You Test The Hardness Of A Material.

From www.struers.com

Hardness Testing Knowledge. How Can You Test The Hardness Of A Material Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. It is used in a number of industries for. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. The most common. How Can You Test The Hardness Of A Material.

From www.mechical.com

Types of Hardness Testing Methods and Impact Testing How Can You Test The Hardness Of A Material How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations. How Can You Test The Hardness Of A Material.

From www.youtube.com

Rockwell Hardness test to find the BHN(Rockwell hardness number) of How Can You Test The Hardness Of A Material Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional. How Can You Test The Hardness Of A Material.

From www.hardnessgauge.com

Brinell Hardness Testing Hardness Tester How Can You Test The Hardness Of A Material Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in. How Can You Test The Hardness Of A Material.

From www.tecquipment.com

Hardness Testing Materials Testing TecQuipment How Can You Test The Hardness Of A Material How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into. How Can You Test The Hardness Of A Material.

From www.aeromarineproducts.com

Durometer Shore Hardness Scale Explained AeroMarine How Can You Test The Hardness Of A Material How to test the hardness of your material, using brinell, rockwell, vickers or leeb testing methods. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for. Hardness testing is an essential aid in the differentiation of materials, as well as for the. How Can You Test The Hardness Of A Material.

From www.btsa.in

Hardness Testing Bombay Tools Supplying Agency How Can You Test The Hardness Of A Material In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. The most common test for this is the shore scleroscope.. How Can You Test The Hardness Of A Material.

From toolboxmagazine.com

Rockwell Hardness Testpage Toolbox MagazineHow Hard Should The How Can You Test The Hardness Of A Material In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Rebound hardness is particularly useful for large and irregularly shaped materials where traditional indentation tests might be impractical. Materials are tested using various methods, with each test expressing hardness. How Can You Test The Hardness Of A Material.

From www.engineeringclicks.com

Vickers Hardness Test What it is and how it's measured EngineeringClicks How Can You Test The Hardness Of A Material Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine. How Can You Test The Hardness Of A Material.

From theconstructor.org

How To Perform Rockwell Hardness Test? The Constructor How Can You Test The Hardness Of A Material Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the. Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. Various hardness testing methods exist, including the brinell, rockwell, and vickers hardness tests. Rebound hardness is particularly. How Can You Test The Hardness Of A Material.