Types Of Rubber Moulding Defects . Here are 11 common injection molding defects, what the causes are and how you can avoid them. Here are five common problems and possible solutions. There are three main rubber molding processes: Various reasons, such as improper venting,. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Explore our injection molding troubleshooting guide! Each of these works in a slightly different way, which. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate the problem. Injection molding, transfer molding, and compression molding. A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber part. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! 26 august 2023 by autoplasticsworld.com.

from www.vem-tooling.com

Here are five common problems and possible solutions. A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber part. 26 august 2023 by autoplasticsworld.com. Explore our injection molding troubleshooting guide! Injection molding, transfer molding, and compression molding. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate the problem. There are three main rubber molding processes: An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Each of these works in a slightly different way, which.

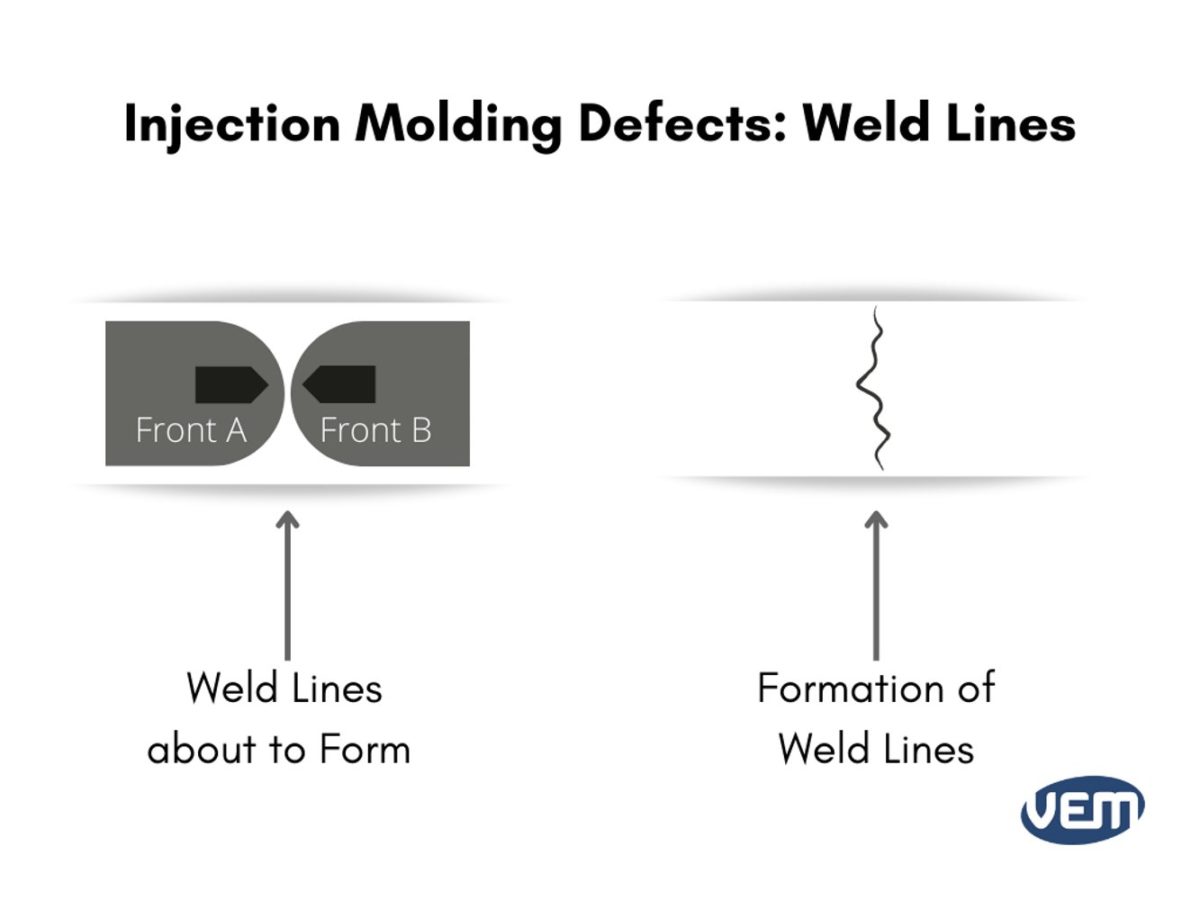

Molding Defects Weld Lines

Types Of Rubber Moulding Defects Explore our injection molding troubleshooting guide! A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber part. 26 august 2023 by autoplasticsworld.com. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate the problem. Explore our injection molding troubleshooting guide! Injection molding, transfer molding, and compression molding. There are three main rubber molding processes: Each of these works in a slightly different way, which. Here are five common problems and possible solutions. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Here are 11 common injection molding defects, what the causes are and how you can avoid them. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! Various reasons, such as improper venting,.

From slidetodoc.com

DEFECT IN PLASTIC INJECTION MOULDING PROCESS DEFECT IN Types Of Rubber Moulding Defects An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Here are five common problems and possible solutions. Explore our injection molding troubleshooting guide! Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! Here are 11 common injection molding. Types Of Rubber Moulding Defects.

From www.vem-tooling.com

Molding Defects Weld Lines Types Of Rubber Moulding Defects Explore our injection molding troubleshooting guide! Here are five common problems and possible solutions. Here are 11 common injection molding defects, what the causes are and how you can avoid them. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! There are three main rubber molding processes:. Types Of Rubber Moulding Defects.

From www.semanticscholar.org

Figure 2 from Evaluating the root causes of rubber molding defects Types Of Rubber Moulding Defects Explore our injection molding troubleshooting guide! 26 august 2023 by autoplasticsworld.com. Various reasons, such as improper venting,. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! Here are 11 common injection molding defects, what the causes are and how you can avoid them. Injection molding, transfer molding,. Types Of Rubber Moulding Defects.

From www.smlease.com

What are Injection Molding Defects and How to Control Them? SMLease Types Of Rubber Moulding Defects Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. There are three main rubber molding processes: Injection molding, transfer molding, and compression molding. Here are five common problems and. Types Of Rubber Moulding Defects.

From www.slideshare.net

Rubber moulding defects Types Of Rubber Moulding Defects Explore our injection molding troubleshooting guide! Here are five common problems and possible solutions. Injection molding, transfer molding, and compression molding. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s. Types Of Rubber Moulding Defects.

From dokumen.tips

(PDF) Evaluating the root causes of rubber molding defects Types Of Rubber Moulding Defects Each of these works in a slightly different way, which. Various reasons, such as improper venting,. There are three main rubber molding processes: Here are five common problems and possible solutions. 26 august 2023 by autoplasticsworld.com. Here are 11 common injection molding defects, what the causes are and how you can avoid them. Of course, the best way to ensure. Types Of Rubber Moulding Defects.

From ims-tex.com

The Most Common Injection Molding Defects Causes & Solutions Types Of Rubber Moulding Defects Injection molding, transfer molding, and compression molding. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! Various reasons, such as improper venting,. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect. Types Of Rubber Moulding Defects.

From slidetodoc.com

DEFECT IN PLASTIC INJECTION MOULDING PROCESS DEFECT IN Types Of Rubber Moulding Defects 26 august 2023 by autoplasticsworld.com. Explore our injection molding troubleshooting guide! Each of these works in a slightly different way, which. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on. Types Of Rubber Moulding Defects.

From www.mdpi.com

Applied Sciences Free FullText DualKernelBased Aggregated Types Of Rubber Moulding Defects Injection molding, transfer molding, and compression molding. Here are five common problems and possible solutions. Each of these works in a slightly different way, which. Explore our injection molding troubleshooting guide! Here are 11 common injection molding defects, what the causes are and how you can avoid them. Of course, the best way to ensure a positive outcome with your. Types Of Rubber Moulding Defects.

From www.vem-tooling.com

Molding Defects Sink Marks Types Of Rubber Moulding Defects Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber part. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes. Types Of Rubber Moulding Defects.

From sybridge.com

7 Injection Molding Defects and How to Avoid Types Of Rubber Moulding Defects An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Here are 11 common injection molding defects, what the causes are and how you can avoid them. There are three main rubber molding processes: A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber. Types Of Rubber Moulding Defects.

From www.topgrid.co

5 Common Problems in Compression Molding Process Topgrid Types Of Rubber Moulding Defects Injection molding, transfer molding, and compression molding. There are three main rubber molding processes: An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Each of these works in a slightly different way, which. Various reasons, such as improper venting,. Explore our injection molding troubleshooting guide! 26 august 2023 by autoplasticsworld.com. Of. Types Of Rubber Moulding Defects.

From www.pioneerplastics.com

Injection Molding Defects and How to Avoid Them Types Of Rubber Moulding Defects Injection molding, transfer molding, and compression molding. Explore our injection molding troubleshooting guide! Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect. Types Of Rubber Moulding Defects.

From www.rpmindinc.com

Defects that can Occur in a Product after Rubber Compression Molding Types Of Rubber Moulding Defects Various reasons, such as improper venting,. There are three main rubber molding processes: Here are 11 common injection molding defects, what the causes are and how you can avoid them. Explore our injection molding troubleshooting guide! An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Here are five common problems and. Types Of Rubber Moulding Defects.

From www.slideshare.net

Rubber moulding defects Types Of Rubber Moulding Defects An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Here are five common problems and possible solutions. Injection molding, transfer molding, and compression molding. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and. Types Of Rubber Moulding Defects.

From www.vem-tooling.com

Molding Defects Sink Marks Types Of Rubber Moulding Defects Injection molding, transfer molding, and compression molding. Here are 11 common injection molding defects, what the causes are and how you can avoid them. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! Here are five common problems and possible solutions. Various reasons, such as improper venting,.. Types Of Rubber Moulding Defects.

From slidetodoc.com

DEFECT IN PLASTIC INJECTION MOULDING PROCESS DEFECT IN Types Of Rubber Moulding Defects Various reasons, such as improper venting,. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate. Types Of Rubber Moulding Defects.

From dokumen.tips

(PDF) Plastic Defects How to Avoid Common Injection Molding Part Types Of Rubber Moulding Defects A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber part. Here are 11 common injection molding defects, what the causes are and how you can avoid them. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of. Types Of Rubber Moulding Defects.

From www.vrogue.co

Top 10 Injection Molding Defects And How To Fix Them vrogue.co Types Of Rubber Moulding Defects Each of these works in a slightly different way, which. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Injection molding, transfer molding, and compression molding. There are three main rubber molding processes: Here are 11 common injection molding defects, what the causes are and how you can avoid them. Of. Types Of Rubber Moulding Defects.

From www.vrogue.co

Injection Molding Process Materials Cycle Defects vrogue.co Types Of Rubber Moulding Defects Here are five common problems and possible solutions. Various reasons, such as improper venting,. 26 august 2023 by autoplasticsworld.com. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type. Types Of Rubber Moulding Defects.

From www.elastron.com

11 Injection Molding Defects and Troubleshooting Elastron TPE Types Of Rubber Moulding Defects Here are five common problems and possible solutions. Explore our injection molding troubleshooting guide! Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. The key to troubleshooting rubber compression. Types Of Rubber Moulding Defects.

From resources.cadimensions.com

5 Common Injection Molding Problems & How to Fix It CADimensions Types Of Rubber Moulding Defects 26 august 2023 by autoplasticsworld.com. There are three main rubber molding processes: Various reasons, such as improper venting,. Here are five common problems and possible solutions. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Each of these works in a slightly different way, which. The key to troubleshooting rubber compression. Types Of Rubber Moulding Defects.

From www.topgrid.co

Common Injection Moulding Defects Causes, Remedies Types Of Rubber Moulding Defects An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate the problem. Injection molding, transfer molding,. Types Of Rubber Moulding Defects.

From www.echosupply.com

Injection Molding Basics Common Surface Defects Echo Supply Types Of Rubber Moulding Defects 26 august 2023 by autoplasticsworld.com. Injection molding, transfer molding, and compression molding. Here are 11 common injection molding defects, what the causes are and how you can avoid them. A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber part. The key to troubleshooting rubber compression molding is to carefully analyze the. Types Of Rubber Moulding Defects.

From www.rpmrubberparts.com

Compression Molding Defects What Can Go Wrong? Types Of Rubber Moulding Defects 26 august 2023 by autoplasticsworld.com. Injection molding, transfer molding, and compression molding. Each of these works in a slightly different way, which. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection. Types Of Rubber Moulding Defects.

From www.vem-tooling.com

Mold Life Expectancy Types Of Rubber Moulding Defects A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber part. Various reasons, such as improper venting,. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! Here are five common problems and possible solutions. Injection molding, transfer molding, and. Types Of Rubber Moulding Defects.

From www.semanticscholar.org

Figure 1 from Evaluating the root causes of rubber molding defects Types Of Rubber Moulding Defects The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate the problem. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber!. Types Of Rubber Moulding Defects.

From www.vem-tooling.com

Molding Defects Weld Lines Types Of Rubber Moulding Defects 26 august 2023 by autoplasticsworld.com. Here are five common problems and possible solutions. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate the problem. Here are 11 common injection molding defects, what the. Types Of Rubber Moulding Defects.

From sybridge.com

7 Injection Molding Defects and How to Avoid Types Of Rubber Moulding Defects There are three main rubber molding processes: A short shot is the incomplete filling of a mould cavity, resulting in an incomplete injection moulded rubber part. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Here are five common problems and possible solutions. Here are 11 common injection molding defects, what. Types Of Rubber Moulding Defects.

From www.mechanicalbooster.com

What is Casting Defects Types, Causes and Remedies? Mechanical Booster Types Of Rubber Moulding Defects The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate the problem. An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. A short shot is. Types Of Rubber Moulding Defects.

From www.topgrid.co

5 Common Problems in Compression Molding Process Topgrid Types Of Rubber Moulding Defects Various reasons, such as improper venting,. Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! Here are 11 common injection molding defects, what the causes are and how you can avoid them. Each of these works in a slightly different way, which. There are three main rubber. Types Of Rubber Moulding Defects.

From www.plasticmoulds.net

Troubleshooting Product Defects In Injection Moldingflash,short Shot Types Of Rubber Moulding Defects Various reasons, such as improper venting,. Here are 11 common injection molding defects, what the causes are and how you can avoid them. 26 august 2023 by autoplasticsworld.com. Explore our injection molding troubleshooting guide! There are three main rubber molding processes: An injection moulding defect is an imperfection or unwanted mark, bump, or gap left on the final part. Each. Types Of Rubber Moulding Defects.

From makenica.com

Preventing Voids, Bubbles, and other part defects in injection molding Types Of Rubber Moulding Defects Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! Here are 11 common injection molding defects, what the causes are and how you can avoid them. Explore our injection molding troubleshooting guide! Each of these works in a slightly different way, which. An injection moulding defect is. Types Of Rubber Moulding Defects.

From reliantplastics.com

Injection Molding Defects Causes and Solutions Reliant Worldwide Types Of Rubber Moulding Defects 26 august 2023 by autoplasticsworld.com. There are three main rubber molding processes: Injection molding, transfer molding, and compression molding. The key to troubleshooting rubber compression molding is to carefully analyze the specific defect, identify the potential root causes based on the type of defect observed, and then systematically adjust the relevant molding parameters to eliminate the problem. A short shot. Types Of Rubber Moulding Defects.

From www.elastron.com

11 Injection Molding Defects and Troubleshooting Elastron TPE Types Of Rubber Moulding Defects Here are 11 common injection molding defects, what the causes are and how you can avoid them. Explore our injection molding troubleshooting guide! There are three main rubber molding processes: Of course, the best way to ensure a positive outcome with your moulded rubber is to employ an expert, like martin’s rubber! The key to troubleshooting rubber compression molding is. Types Of Rubber Moulding Defects.