Solder Joint Dull . While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. Or, when i solder a joint (maybe with the temperature. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Did the solder properly wick or wet the mating surfaces? When a solder joint is reheated without applying flux, the solder might get dull. Learn whether a good solder joint needs to be shiny to be effective. When evaluating the appearance of a solder joint i look for these things: We explore the factors that affect the appearance and quality of dull solder joints.

from absolutepcbassembly.com

When a solder joint is reheated without applying flux, the solder might get dull. While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. We explore the factors that affect the appearance and quality of dull solder joints. Learn whether a good solder joint needs to be shiny to be effective. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Or, when i solder a joint (maybe with the temperature. When evaluating the appearance of a solder joint i look for these things: Did the solder properly wick or wet the mating surfaces?

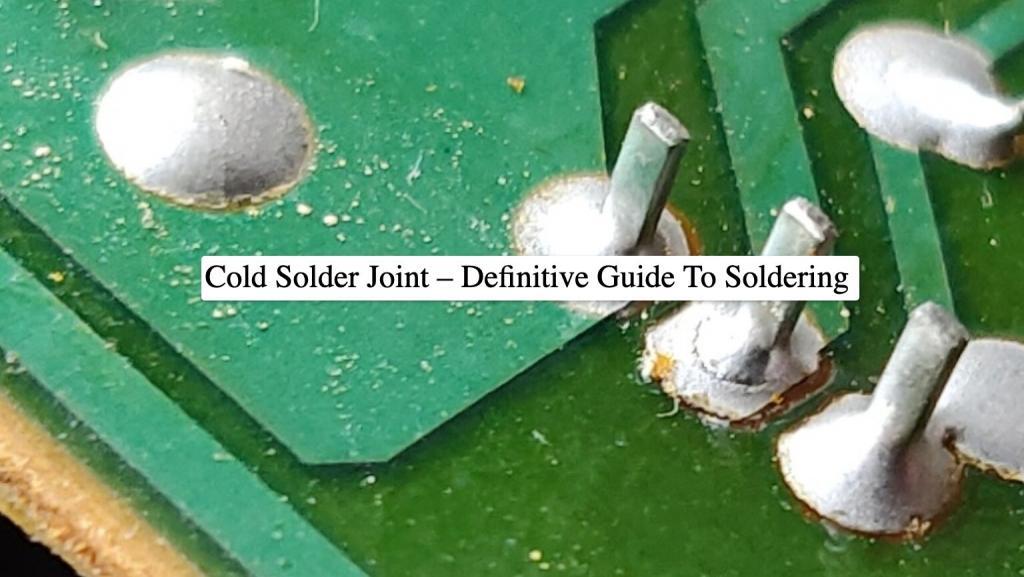

Cold Solder Joint Definitive Guide to Soldering Absolute

Solder Joint Dull Learn whether a good solder joint needs to be shiny to be effective. Or, when i solder a joint (maybe with the temperature. When evaluating the appearance of a solder joint i look for these things: A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. We explore the factors that affect the appearance and quality of dull solder joints. Learn whether a good solder joint needs to be shiny to be effective. When a solder joint is reheated without applying flux, the solder might get dull. Did the solder properly wick or wet the mating surfaces? If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to.

From ar.inspiredpencil.com

Types Of Solder Joints Solder Joint Dull If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. When a solder joint is reheated without applying flux, the solder might get dull. While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt. Solder Joint Dull.

From www.circuits-diy.com

Bad Solder PCB Soldering Issues and their Solution Solder Joint Dull When evaluating the appearance of a solder joint i look for these things: A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Or, when i. Solder Joint Dull.

From piektraining.com

How can you avoid a cold solder joint? PIEK Solder Joint Dull A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. If it occurs on component leads or pcb pads where a solder joint is supposed to form,. Solder Joint Dull.

From www.researchgate.net

Common solder joint defects [23] Download Scientific Diagram Solder Joint Dull Or, when i solder a joint (maybe with the temperature. Learn whether a good solder joint needs to be shiny to be effective. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. When evaluating the appearance of a solder joint i look. Solder Joint Dull.

From nerdytechy.com

What Is a Cold Solder Joint? NerdyTechy Solder Joint Dull Did the solder properly wick or wet the mating surfaces? When evaluating the appearance of a solder joint i look for these things: When a solder joint is reheated without applying flux, the solder might get dull. Or, when i solder a joint (maybe with the temperature. Learn whether a good solder joint needs to be shiny to be effective.. Solder Joint Dull.

From www.instructables.com

How to Make a Proper Western Union Solder Joint 4 Steps (with Solder Joint Dull We explore the factors that affect the appearance and quality of dull solder joints. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Learn whether. Solder Joint Dull.

From www.reddit.com

dull solder How shiny do your solder joints need to be? r/soldering Solder Joint Dull A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. When evaluating the appearance of a solder joint i look for these things: When a solder joint is reheated without applying flux, the solder might get dull. While both are soldering issues, a cold joint refers to a solder connection where the solder. Solder Joint Dull.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Solder Joint Dull When a solder joint is reheated without applying flux, the solder might get dull. When evaluating the appearance of a solder joint i look for these things: If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Did the solder properly wick or. Solder Joint Dull.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Solder Joint Dull When evaluating the appearance of a solder joint i look for these things: If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. When a solder joint is reheated without applying flux, the solder might get dull. We explore the factors that affect. Solder Joint Dull.

From www.youtube.com

How to Spot a Bad Solder Joint YouTube Solder Joint Dull While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. Or, when i solder a joint (maybe with the temperature. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. When evaluating the appearance of a solder. Solder Joint Dull.

From electronics.stackexchange.com

soldering Are these consistent dull joints an indication of poor Solder Joint Dull A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. Learn whether a good solder joint needs to be shiny to be effective. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. We explore the. Solder Joint Dull.

From stellartechnical.com

What's a Good Solder Joint Finish? Shiny vs. Dull Solder Joints Solder Joint Dull A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. Did the solder properly wick or wet the mating surfaces? When evaluating the appearance of a solder joint i look for these things: If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is. Solder Joint Dull.

From www.theengineeringknowledge.com

What is a Cold Solder Joint and How Can You Prevent it? 2023 Guide Solder Joint Dull Learn whether a good solder joint needs to be shiny to be effective. Or, when i solder a joint (maybe with the temperature. We explore the factors that affect the appearance and quality of dull solder joints. Did the solder properly wick or wet the mating surfaces? When a solder joint is reheated without applying flux, the solder might get. Solder Joint Dull.

From www.reddit.com

dull solder How shiny do your solder joints need to be? r/soldering Solder Joint Dull Did the solder properly wick or wet the mating surfaces? If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. We explore the factors that affect the appearance and quality of dull solder joints. While both are soldering issues, a cold joint refers. Solder Joint Dull.

From absolutepcbassembly.com

IPC JSTD001 Standard for Soldering Absolute Electronics Solder Joint Dull While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. Or, when i solder a joint (maybe with the temperature. When evaluating the appearance of a solder joint i look for these things: We explore the factors that affect the appearance and quality of. Solder Joint Dull.

From cejznhpi.blob.core.windows.net

Solder The Joints at Williams Engel blog Solder Joint Dull While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. We explore the factors that affect the appearance and quality of dull solder joints. When evaluating the. Solder Joint Dull.

From stellartechnical.com

What's a Good Solder Joint Finish? Shiny vs. Dull Solder Joints Solder Joint Dull We explore the factors that affect the appearance and quality of dull solder joints. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. When a solder joint is reheated without applying flux, the solder might get dull. When evaluating the appearance of a solder joint i look for these things: Or, when. Solder Joint Dull.

From cedeqtmf.blob.core.windows.net

Lead Free Solder Oxidation at Lucille Tunstall blog Solder Joint Dull We explore the factors that affect the appearance and quality of dull solder joints. When a solder joint is reheated without applying flux, the solder might get dull. While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. Learn whether a good solder joint. Solder Joint Dull.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Solder Joint Dull We explore the factors that affect the appearance and quality of dull solder joints. Did the solder properly wick or wet the mating surfaces? When evaluating the appearance of a solder joint i look for these things: If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a. Solder Joint Dull.

From www.supercheapauto.co.nz

Wiring and Soldering Tips Solder Joint Dull If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Learn whether a good solder joint needs to be shiny to be effective. Did the solder properly wick or wet the mating surfaces? A good solder connection is shiny, and we're taught that. Solder Joint Dull.

From core-electronics.com.au

Soldering 101 Tutorial Australia Solder Joint Dull When evaluating the appearance of a solder joint i look for these things: We explore the factors that affect the appearance and quality of dull solder joints. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. A good solder connection is shiny,. Solder Joint Dull.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Solder Joint Dull When a solder joint is reheated without applying flux, the solder might get dull. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. When evaluating the appearance of a solder joint i look for these things: A good solder connection is shiny,. Solder Joint Dull.

From morepcb.com

How to Solder Wire on Circuit Board Mastering the Basics MorePCB Solder Joint Dull If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Did the solder properly wick or wet the mating surfaces? Or, when i solder a joint (maybe with the temperature. A good solder connection is shiny, and we're taught that dull solder indicates. Solder Joint Dull.

From www.pcbaaa.com

Cold solder joints Unraveling the hazards, causes, detection, repair Solder Joint Dull While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. Or, when i solder a joint (maybe with the temperature. We explore the factors that affect the appearance and quality of dull solder joints. When evaluating the appearance of a solder joint i look. Solder Joint Dull.

From resources.altium.com

Types of PCB Soldering and the Assembly Process Blog Altium Designer Solder Joint Dull While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. Or, when i solder a joint (maybe with the temperature. When evaluating the appearance of a solder joint i look for these things: A good solder connection is shiny, and we're taught that dull. Solder Joint Dull.

From www.pcba-manufacturers.com

Understanding Cold Solder Joints Causes, Identification and Solutions Solder Joint Dull If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Did the solder properly wick or wet the mating surfaces? When evaluating the appearance of a solder joint i look for these things: Or, when i solder a joint (maybe with the temperature.. Solder Joint Dull.

From llllllll.co

Soldering q's General lines Solder Joint Dull While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow, leading to a weak bond. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. When evaluating the appearance of a solder. Solder Joint Dull.

From www.earthquakerdevices.com

In Flux More Than You Ever Wanted To Know About Crafting Strong Solder Solder Joint Dull A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. Or, when i solder a joint (maybe with the temperature. We explore the factors that affect the appearance and quality of dull solder joints. While both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt. Solder Joint Dull.

From www.linkedin.com

Types of Soldering Solder Joint Dull A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. When evaluating the appearance of a solder joint i look for these things: Did the solder properly wick or wet the mating surfaces? Learn whether a good solder joint needs to be shiny to be effective. Or, when i solder a joint (maybe. Solder Joint Dull.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Solder Joint Dull When a solder joint is reheated without applying flux, the solder might get dull. We explore the factors that affect the appearance and quality of dull solder joints. Learn whether a good solder joint needs to be shiny to be effective. When evaluating the appearance of a solder joint i look for these things: A good solder connection is shiny,. Solder Joint Dull.

From absolutepcbassembly.com

Cold Solder Joint Definitive Guide to Soldering Absolute Solder Joint Dull When a solder joint is reheated without applying flux, the solder might get dull. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. Learn whether a good solder joint needs to be shiny to be effective. Did the solder properly wick or wet the mating surfaces? While both are soldering issues, a. Solder Joint Dull.

From www.slideserve.com

PPT Soldering PowerPoint Presentation ID1877634 Solder Joint Dull Did the solder properly wick or wet the mating surfaces? We explore the factors that affect the appearance and quality of dull solder joints. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it. Solder Joint Dull.

From stellartechnical.com

What's a Good Solder Joint Finish? Shiny vs. Dull Solder Joints Solder Joint Dull A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. Did the solder properly wick or wet the mating surfaces? If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. When a solder joint is reheated. Solder Joint Dull.

From thesolderblog.blogspot.com

TheSolderBlog Lead Free Solder Solder Joint Dull When a solder joint is reheated without applying flux, the solder might get dull. A good solder connection is shiny, and we're taught that dull solder indicates a cold solder joint. If it occurs on component leads or pcb pads where a solder joint is supposed to form, then it is classified as a defect condition according to. Or, when. Solder Joint Dull.

From www.reddit.com

dull solder How shiny do your solder joints need to be? r/soldering Solder Joint Dull Or, when i solder a joint (maybe with the temperature. Learn whether a good solder joint needs to be shiny to be effective. Did the solder properly wick or wet the mating surfaces? We explore the factors that affect the appearance and quality of dull solder joints. A good solder connection is shiny, and we're taught that dull solder indicates. Solder Joint Dull.