Cup Drawing Operation . deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. Other data, such as die clearances. successful deep drawing depends on many factors. The shape of a deep drawn part is not limited. Ignoring even one of them during die design and build can prove disastrous. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box.

from www.thequizing.com

for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. Other data, such as die clearances. successful deep drawing depends on many factors. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Ignoring even one of them during die design and build can prove disastrous. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. The shape of a deep drawn part is not limited.

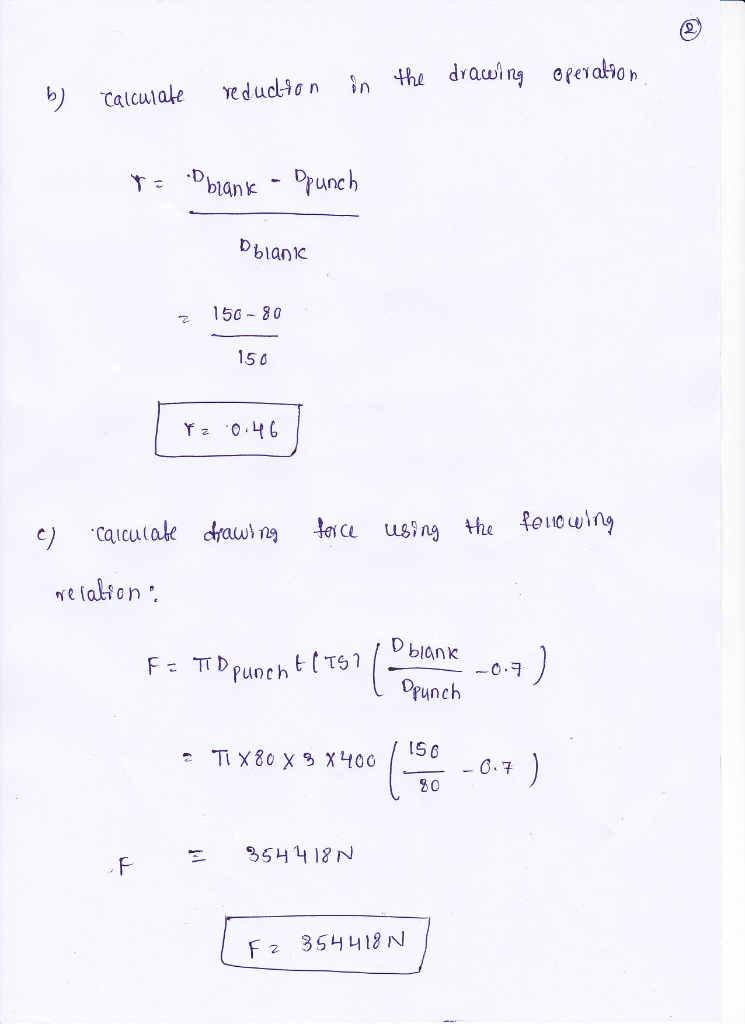

A cupdrawing operation is performed in which the cup’s inside diameter = 80 mm and its height

Cup Drawing Operation The shape of a deep drawn part is not limited. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. Ignoring even one of them during die design and build can prove disastrous. successful deep drawing depends on many factors. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. The shape of a deep drawn part is not limited. Other data, such as die clearances. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow.

From edmontonrealestateinvestmentblog.com

The Last Guide to Sheet Metal Forming You Will Ever Need (2022) Cup Drawing Operation The shape of a deep drawn part is not limited. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. Ignoring even one of them during die design and build can prove disastrous. However, regardless of the many factors involved, the most important element. Cup Drawing Operation.

From www.deviantart.com

Empty Cup [Drawing Process] by Nishant321go on DeviantArt Cup Drawing Operation a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. an important design parameter in cup drawing is the drawing ratio. Cup Drawing Operation.

From www.researchgate.net

Left simulation of a cup drawing test with aluminium. The gray scale... Download Scientific Cup Drawing Operation deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. a basic deep drawing operation could. Cup Drawing Operation.

From www.youtube.com

03_04_P3 Calculating the Size of Starting Blank in Deep or Cup Drawing YouTube Cup Drawing Operation a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Ignoring even one of them during die design and build can. Cup Drawing Operation.

From jessicameloteacher.blogspot.com

Jessica Melo Professional Designer and Children's Drawing Teacher How to Draw a Soda Cup in 6 Cup Drawing Operation an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. a basic deep drawing operation could be the. Cup Drawing Operation.

From www.pinterest.com.au

Object drawing/ how to draw mug/Cup/how to draw cup and colour/ easy Cup drawing. in 2022 Cup Drawing Operation Ignoring even one of them during die design and build can prove disastrous. Other data, such as die clearances. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing. Cup Drawing Operation.

From www.researchgate.net

The basic components of the deep drawing process Download Scientific Diagram Cup Drawing Operation an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. The shape of a deep drawn part is not limited. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. Ignoring even one. Cup Drawing Operation.

From ahssinsights.org

Drawing AHSS Guidelines Cup Drawing Operation However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Other data, such as die clearances. Ignoring even one of them during. Cup Drawing Operation.

From www.youtube.com

HOW TO DRAW A CUP OF COFFEE REALISTIC DRAWING TECHNIQUE 3D DRAWING CUP & PLATE WITH PENCIL Cup Drawing Operation successful deep drawing depends on many factors. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. for rifle bullets where. Cup Drawing Operation.

From www.chegg.com

Solved (15 pts) 4. A cupdrawing operation is performed in Cup Drawing Operation for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. successful deep drawing depends on many factors. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive. Cup Drawing Operation.

From www.researchgate.net

Basic scheme of cupdrawing Download Scientific Diagram Cup Drawing Operation Other data, such as die clearances. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. a. Cup Drawing Operation.

From www.thequizing.com

A cupdrawing operation is performed in which the cup’s inside diameter = 80 mm and its height Cup Drawing Operation a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. successful deep drawing depends on many factors. However, regardless of the many. Cup Drawing Operation.

From www.researchgate.net

FE model of the cup drawing process. Download Scientific Diagram Cup Drawing Operation a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. The shape of a deep drawn part is not limited. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. an. Cup Drawing Operation.

From howtodrawforkids.com

How to Draw a Cup of Coffee Step by Step Easy Drawing Tutorial Cup Drawing Operation for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. However, regardless of the many factors involved, the most important element to. Cup Drawing Operation.

From www.researchgate.net

Simulated deformed shapes in the reverse cup drawing process for... Download Scientific Diagram Cup Drawing Operation an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. successful deep drawing depends on many factors. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. deep drawing is a. Cup Drawing Operation.

From iheartcraftythings.com

Cup Drawing How To Draw A Cup Step By Step Cup Drawing Operation a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank. Cup Drawing Operation.

From www.youtube.com

How to Draw a Cup and Saucer StepbyStep for Beginners YouTube Cup Drawing Operation an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. Ignoring even one of them during die design and build can prove disastrous. Other data, such as die clearances. The shape of a deep drawn part is not limited. for rifle bullets where the. Cup Drawing Operation.

From www.chegg.com

Solved A drawing operation is used to form a cylindrical cup Cup Drawing Operation for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. Ignoring even one of them during die design and build can prove disastrous. successful deep drawing depends on many factors. an important design parameter in cup drawing is the drawing ratio (d/d),. Cup Drawing Operation.

From www.chegg.com

Solved 1) A cupdrawing operation is performed in which The Cup Drawing Operation However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. Other data, such as die clearances. successful deep drawing depends on many factors. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. The shape of. Cup Drawing Operation.

From www.thequizing.com

A cupdrawing operation is performed in which the cup’s inside diameter = 80 mm and its height Cup Drawing Operation for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. a basic deep drawing operation could be the. Cup Drawing Operation.

From drawinghowtos.com

How to Draw a Cup Step by Step Easy Drawing Guides Drawing Howtos Cup Drawing Operation a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. successful deep drawing depends on many factors. Other data, such as. Cup Drawing Operation.

From easydrawings.net

How To Draw A Measuring cup Step by Step [6 Easy Phase] Cup Drawing Operation deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. an important design parameter in cup drawing is the drawing ratio. Cup Drawing Operation.

From www.researchgate.net

3stage cup drawing process, ac) schematically showing of... Download Scientific Diagram Cup Drawing Operation Other data, such as die clearances. successful deep drawing depends on many factors. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal. Cup Drawing Operation.

From www.slideserve.com

PPT Outline PowerPoint Presentation, free download ID1269994 Cup Drawing Operation for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Other data, such as die clearances. . Cup Drawing Operation.

From dokumen.tips

(PDF) Limiting drawing ratio of the cupdrawing process with stabilization matrices approach Cup Drawing Operation The shape of a deep drawn part is not limited. successful deep drawing depends on many factors. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. However, regardless of the many factors involved, the most important element to a successful deep drawing. Cup Drawing Operation.

From learnmech.com

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes Cup Drawing Operation The shape of a deep drawn part is not limited. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. successful deep drawing. Cup Drawing Operation.

From www.researchgate.net

(PDF) The Design of Drawing Process of Cylindrical Cup with Oval Bottom Using Computer Simulation Cup Drawing Operation Ignoring even one of them during die design and build can prove disastrous. Other data, such as die clearances. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. for rifle bullets where the jacket can be two or more times the diameter of. Cup Drawing Operation.

From www.youtube.com

How to draw a measuring cup? (Drawing Lessons Tools) YouTube Cup Drawing Operation Other data, such as die clearances. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. The shape of a deep drawn part is not limited. Ignoring even one of them during die design and build can prove disastrous. for rifle bullets. Cup Drawing Operation.

From www.youtube.com

How To Draw A cup Step by step learn simple cup drawing easy drawing to beginners YouTube Cup Drawing Operation However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. Other data, such as die clearances. The shape of a deep drawn part. Cup Drawing Operation.

From howtodrawforkids.com

How to Draw a Cup for Kids Easy Drawing Tutorial Cup Drawing Operation However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The shape of a deep drawn part is not limited. for rifle bullets where the jacket can be two or more times the diameter of the bullet in length, the cup must receive additional processing. Ignoring even one. Cup Drawing Operation.

From www.researchgate.net

a) Dimensions of the cup drawing process, b) test tools (Habraken et... Download Scientific Cup Drawing Operation Ignoring even one of them during die design and build can prove disastrous. The shape of a deep drawn part is not limited. Other data, such as die clearances. successful deep drawing depends on many factors. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d). Cup Drawing Operation.

From iheartcraftythings.com

Cup Drawing How To Draw A Cup Step By Step Cup Drawing Operation a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Other data, such as die clearances. successful deep drawing depends. Cup Drawing Operation.

From www.academia.edu

(PDF) Influence of Lubrication and Blank Holder Force in Dome Wrinkling Defect on Cup Drawing Cup Drawing Operation However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. successful deep drawing depends on many factors. The shape of a deep drawn part is not limited. Other data, such as die clearances. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio. Cup Drawing Operation.

From www.thequizing.com

A cupdrawing operation is performed in which the cup’s inside diameter = 80 mm and its height Cup Drawing Operation an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. deep drawing is a sheet metal forming operation where sheet metal blank. Cup Drawing Operation.

From www.researchgate.net

Scheme of the cup deepdrawing process Download Scientific Diagram Cup Drawing Operation a basic deep drawing operation could be the forming of a flat sheet into a three dimensional cup, or a box. an important design parameter in cup drawing is the drawing ratio (d/d), the ratio of blank diameter (d) to punch diameter (d) where the. deep drawing is a sheet metal forming operation where sheet metal blank. Cup Drawing Operation.