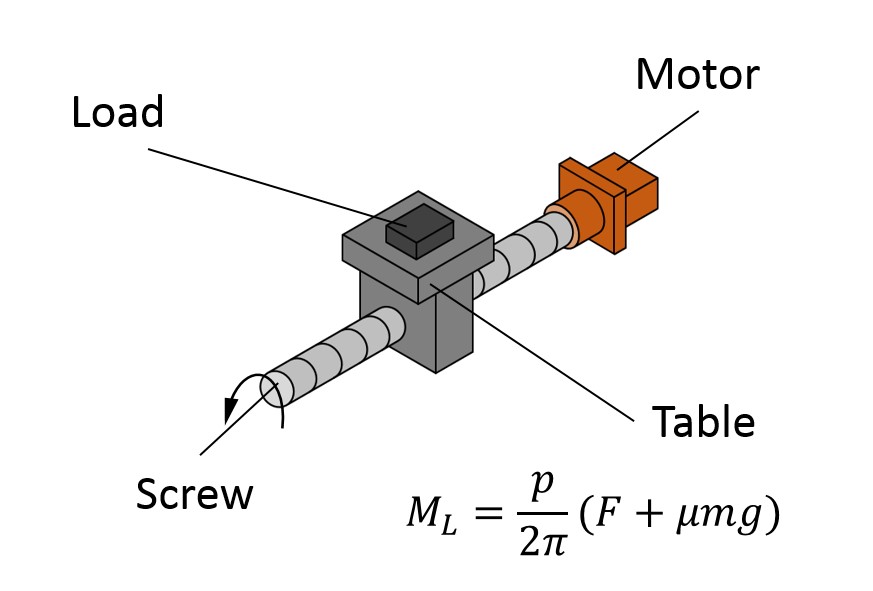

Lead Screw Motor Sizing . Proper sizing of a motor requires that 3 criteria must be met: Torque, load inertia, and speed. For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. The performance of a lead screw depends on the coefficient of friction between. While many factors are involved in the selection of a specific lead screw assembly, lead screw sizing — choosing the right diameter and lead for the application — can be done in. Required lead is calculated based on the motor max. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Speed and maximum speed requirement. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead. Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load capacity, speed, and back driving torque for the application. But there are hundreds — maybe thousands — of lead screw designs on the market.

from www.e-motionsupply.com

The performance of a lead screw depends on the coefficient of friction between. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load capacity, speed, and back driving torque for the application. For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. Proper sizing of a motor requires that 3 criteria must be met: But there are hundreds — maybe thousands — of lead screw designs on the market. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead. While many factors are involved in the selection of a specific lead screw assembly, lead screw sizing — choosing the right diameter and lead for the application — can be done in. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Speed and maximum speed requirement.

Ball Screw

Lead Screw Motor Sizing For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead. Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load capacity, speed, and back driving torque for the application. Proper sizing of a motor requires that 3 criteria must be met: But there are hundreds — maybe thousands — of lead screw designs on the market. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. The performance of a lead screw depends on the coefficient of friction between. While many factors are involved in the selection of a specific lead screw assembly, lead screw sizing — choosing the right diameter and lead for the application — can be done in. Speed and maximum speed requirement. Required lead is calculated based on the motor max. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Torque, load inertia, and speed.

From www.holrymotor.com

Non Captive NEMA 23 ACME Tr8 Lead Screw Stepper Motor Tr8 57mmx56mm Lead Screw Motor Sizing When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead. While many factors are involved in the selection of a specific lead screw assembly, lead screw sizing — choosing the right diameter and lead for the application — can be done. Lead Screw Motor Sizing.

From www.bidorbuy.co.za

Test Equipment Hanpose 17hs4401s T8x8 Nema 17 Lead Screw Stepper Lead Screw Motor Sizing Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Speed and maximum speed requirement. While many factors are involved in the selection of a specific lead screw assembly, lead screw sizing — choosing the right diameter and lead for the application — can be done in. Once you’ve gone through the process of. Lead Screw Motor Sizing.

From fractory.com

Lead Screws Explained Fractory Lead Screw Motor Sizing For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. Speed and maximum speed requirement. Required lead is calculated based on the motor max. Once you’ve gone through the process of sizing a lead screw, you know. Lead Screw Motor Sizing.

From blog.igus.eu

Lead screws terms and definitions igus Blog Lead Screw Motor Sizing Torque, load inertia, and speed. But there are hundreds — maybe thousands — of lead screw designs on the market. Speed and maximum speed requirement. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Proper sizing of a motor requires that 3 criteria. Lead Screw Motor Sizing.

From www.littlebird.com.au

Stepper Motor with 38cm Lead Screw Bipolar, 200 Steps/Rev, 42x38mm, 2 Lead Screw Motor Sizing Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Required lead is calculated based on the motor max. For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. When designing. Lead Screw Motor Sizing.

From www.isel-us.com

Ball Screws and ball nuts Isel USA Lead Screw Motor Sizing The performance of a lead screw depends on the coefficient of friction between. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Required lead is calculated based on the motor max. Lead screws use the helix angle of the thread to convert rotary. Lead Screw Motor Sizing.

From www.holrymotor.com

Motorized Lead Screw Stepper Motor Linear Actuator HOLRY Lead Screw Motor Sizing Proper sizing of a motor requires that 3 criteria must be met: Required lead is calculated based on the motor max. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load capacity,. Lead Screw Motor Sizing.

From www.iqsdirectory.com

Lead Screw What Is It? How Is It Used? Types, Threads Lead Screw Motor Sizing The performance of a lead screw depends on the coefficient of friction between. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed. Lead Screw Motor Sizing.

From www.pololu.com

Pololu Dimension diagram for the NEMA 17 stepper motors with lead Lead Screw Motor Sizing Lead screws use the helix angle of the thread to convert rotary motion to linear motion. The performance of a lead screw depends on the coefficient of friction between. Torque, load inertia, and speed. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application.. Lead Screw Motor Sizing.

From core-electronics.com.au

Stepper Motor with 28cm Lead Screw Bipolar, 200 Steps/Rev, 42×38mm, 2 Lead Screw Motor Sizing For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. The performance of a lead screw depends on the coefficient of friction between. Torque, load inertia, and speed. Lead screws use the helix angle of the thread. Lead Screw Motor Sizing.

From www.manufacturingtomorrow.com

Guide to Lead Screws and Integrated Motor Assemblies Lead Screw Motor Sizing The performance of a lead screw depends on the coefficient of friction between. Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load capacity, speed, and back driving torque for the application. But there are hundreds — maybe thousands — of lead screw designs on the market. For. Lead Screw Motor Sizing.

From openbuilds.com

Sizing a custom lead screw and 4 post motor mount OpenBuilds Lead Screw Motor Sizing Torque, load inertia, and speed. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead. Proper sizing of a motor requires that 3 criteria must be met: Speed and maximum speed requirement. But there are hundreds — maybe thousands — of. Lead Screw Motor Sizing.

From www.youtube.com

Calculating Lead Screw Efficiency and Required Lifting Torque YouTube Lead Screw Motor Sizing Required lead is calculated based on the motor max. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead. Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load. Lead Screw Motor Sizing.

From www.dec-motor.com

NEMA23 hybrid Linear lead screw Stepper Motor with nut factory and Lead Screw Motor Sizing For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Speed and maximum speed requirement. Required lead is calculated based on. Lead Screw Motor Sizing.

From blog.engineeringpaper.xyz

Lead Screw Torque and Efficiency Calculations The Official Lead Screw Motor Sizing Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Speed and maximum speed requirement. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. For the first part of this motor sizing basics series, i will be. Lead Screw Motor Sizing.

From www.automotioncomponents.co.uk

Lead Screws and Ball Screws from Automotion Automotion Lead Screw Motor Sizing Speed and maximum speed requirement. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. While many factors are involved in the selection of a specific lead screw. Lead Screw Motor Sizing.

From www.iqsdirectory.com

Lead Screw What Is It? How Is It Used? Types, Threads Lead Screw Motor Sizing But there are hundreds — maybe thousands — of lead screw designs on the market. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. The performance of a lead screw depends on the coefficient of friction between. Once you’ve gone through the process of sizing a lead screw, you know what diameter and. Lead Screw Motor Sizing.

From www.slideshare.net

Thomson lead screws_ballscrews_ballsplines_catalog Lead Screw Motor Sizing Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Speed and maximum speed requirement. Proper sizing of a motor requires that 3 criteria must be met: For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into. Lead Screw Motor Sizing.

From www.linearmotiontips.com

How to account for ball and lead screw inertia during system design Lead Screw Motor Sizing For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. Proper sizing of a motor requires that 3 criteria must be met: But there are hundreds — maybe thousands — of lead screw designs on the market.. Lead Screw Motor Sizing.

From www.amazon.co.uk

17HS4401S T8x8 Nema 17 Lead Screw Stepper Motor Linear Actuators 40mm Lead Screw Motor Sizing While many factors are involved in the selection of a specific lead screw assembly, lead screw sizing — choosing the right diameter and lead for the application — can be done in. The performance of a lead screw depends on the coefficient of friction between. Torque, load inertia, and speed. Proper sizing of a motor requires that 3 criteria must. Lead Screw Motor Sizing.

From www.velmex.com

UniSlide Lead Screws Lead Screw Motor Sizing But there are hundreds — maybe thousands — of lead screw designs on the market. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead. Lead screws use the helix angle of the thread to convert rotary motion to linear motion.. Lead Screw Motor Sizing.

From zaribo.com

Zaribo 210220 Z Axis Nema 17 (320mm) Integrated Lead Screw Stepper Lead Screw Motor Sizing Required lead is calculated based on the motor max. Proper sizing of a motor requires that 3 criteria must be met: When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead. The performance of a lead screw depends on the coefficient. Lead Screw Motor Sizing.

From blog.orientalmotor.com

Motor Sizing Basics Part 3 How to Calculate Speed, Acceleration Torque Lead Screw Motor Sizing Lead screws use the helix angle of the thread to convert rotary motion to linear motion. Proper sizing of a motor requires that 3 criteria must be met: Torque, load inertia, and speed. The performance of a lead screw depends on the coefficient of friction between. Speed and maximum speed requirement. Once you’ve gone through the process of sizing a. Lead Screw Motor Sizing.

From alexnld.com

HANPOSE 17HS3401S T8x8 Nema 17 Lead Screw Stepper Motor Linear Lead Screw Motor Sizing Speed and maximum speed requirement. The performance of a lead screw depends on the coefficient of friction between. Proper sizing of a motor requires that 3 criteria must be met: While many factors are involved in the selection of a specific lead screw assembly, lead screw sizing — choosing the right diameter and lead for the application — can be. Lead Screw Motor Sizing.

From www.linearmotiontips.com

What options are there for integrated motor and screw designs? Lead Screw Motor Sizing Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load capacity, speed, and back driving torque for the application. Required lead is calculated based on the motor max. Proper sizing of a motor requires that 3 criteria must be met: Torque, load inertia, and speed. For the first. Lead Screw Motor Sizing.

From learnmech.com

Lead Screw Mechanism Types , Advantages, Applications Lead Screw Motor Sizing Speed and maximum speed requirement. Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load capacity, speed, and back driving torque for the application. Lead screws use the helix angle of the thread to convert rotary motion to linear motion. For the first part of this motor sizing. Lead Screw Motor Sizing.

From hxettprap.blob.core.windows.net

Servo Motor Lead Screw at Robert Barron blog Lead Screw Motor Sizing Required lead is calculated based on the motor max. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Once you’ve gone through the process of sizing a lead screw, you know what diameter and lead will provide the required load capacity, speed, and. Lead Screw Motor Sizing.

From www.alibaba.com

Siheng Nema23 Hybrid Lead Screw Stepper Motor With Copper Nut Lead 8mm Lead Screw Motor Sizing For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. Torque, load inertia, and speed. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to. Lead Screw Motor Sizing.

From www.pinterest.com

Ball / lead screw motor sizing forms calculate the necessary Torque Lead Screw Motor Sizing Speed and maximum speed requirement. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead.. Lead Screw Motor Sizing.

From blog.igus.eu

Construction and assembly of lead screw motors the basics igus Blog Lead Screw Motor Sizing Lead screws use the helix angle of the thread to convert rotary motion to linear motion. For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. Speed and maximum speed requirement. But there are hundreds — maybe. Lead Screw Motor Sizing.

From pixelelectric.com

4lead NEMA 17 Linear Stepper Motor T8 Lead Screw 2 Pitch 110mm Lead Lead Screw Motor Sizing The performance of a lead screw depends on the coefficient of friction between. While many factors are involved in the selection of a specific lead screw assembly, lead screw sizing — choosing the right diameter and lead for the application — can be done in. Speed and maximum speed requirement. Once you’ve gone through the process of sizing a lead. Lead Screw Motor Sizing.

From store.allied-automation.com

Quick Tip Using Mitsubishi Motor Sizing Software (Motorizer) Allied Lead Screw Motor Sizing Proper sizing of a motor requires that 3 criteria must be met: The performance of a lead screw depends on the coefficient of friction between. Speed and maximum speed requirement. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. For the first part. Lead Screw Motor Sizing.

From www.iqsdirectory.com

Lead Screw What Is It? How Is It Used? Types, Threads Lead Screw Motor Sizing For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Lead. Lead Screw Motor Sizing.

From en.nanotec.com

Lead Screws for Stepper Motor Linear Actuators NANOTEC Lead Screw Motor Sizing Required lead is calculated based on the motor max. Torque, load inertia, and speed. Proper sizing of a motor requires that 3 criteria must be met: But there are hundreds — maybe thousands — of lead screw designs on the market. Speed and maximum speed requirement. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy. Lead Screw Motor Sizing.

From www.e-motionsupply.com

Ball Screw Lead Screw Motor Sizing Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. For the first part of this motor sizing basics series, i will be explaining what load torque is, how to calculate it, and how it fits into the torque requirement for the application. Lead. Lead Screw Motor Sizing.