Crankshaft Position Sensor Electrical Diagram . The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. The reluctor ring has one or more. In this powerful guide, we will be more general than specific. This information is what determines. The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. You will often also experience a stalling engine or bad engine. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. It consists of a sensor, often a hall effect or. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip.

from wirelibrarygarland.z6.web.core.windows.net

The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. In this powerful guide, we will be more general than specific. You will often also experience a stalling engine or bad engine. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. This information is what determines. The reluctor ring has one or more.

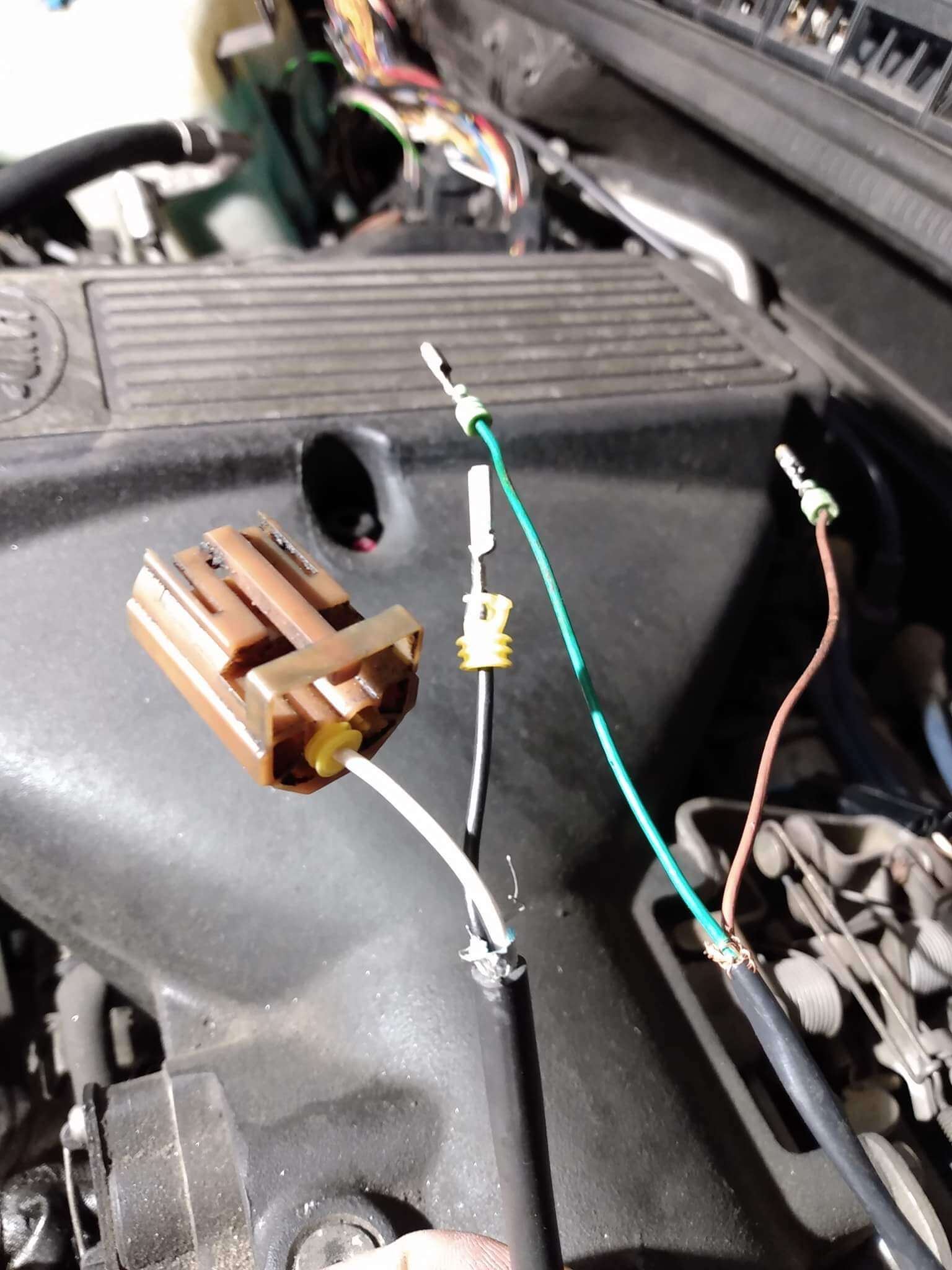

Crankshaft Position Sensor Wire

Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. The reluctor ring has one or more. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. This information is what determines. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. In this powerful guide, we will be more general than specific. It consists of a sensor, often a hall effect or. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. You will often also experience a stalling engine or bad engine. The crankshaft position sensor monitors the crankshaft’s rotational speed and position.

From www.youtube.com

Crankshaft Position Sensor Wiring Diagram Functions Working Crankshaft Position Sensor Electrical Diagram This information is what determines. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. The reluctor ring has one or more. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to. Crankshaft Position Sensor Electrical Diagram.

From www.myxxgirl.com

Crank Position Sensor Wiring Diagram Crank By Design My XXX Hot Girl Crankshaft Position Sensor Electrical Diagram The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The most common symptom of. Crankshaft Position Sensor Electrical Diagram.

From guidelibraryfurst.z19.web.core.windows.net

3wire Crank Sensor Wiring Diagram Crankshaft Position Sensor Electrical Diagram It consists of a sensor, often a hall effect or. You will often also experience a stalling engine or bad engine. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. This information is what determines. The reluctor ring has one or more. The crankshaft position sensor monitors the crankshaft’s rotational speed. Crankshaft Position Sensor Electrical Diagram.

From triscan.dk

NEW camshaft and crankshaft position sensors Triscan Crankshaft Position Sensor Electrical Diagram The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. You will often also experience a stalling engine or bad engine. The reluctor ring has one or more. The crankshaft position sensor is positioned so that teeth. Crankshaft Position Sensor Electrical Diagram.

From www.2carpros.com

Crankshaft Position Sensor Where Is the Sensor for This ,is It Crankshaft Position Sensor Electrical Diagram This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. The manufacturer designs the electrical schematics of the crank position sensor according to the need and. Crankshaft Position Sensor Electrical Diagram.

From www.2carpros.com

Crankshaft Position Sensor Wire Colors Diagram Needed? Crankshaft Position Sensor Electrical Diagram A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. It consists of a sensor, often a hall effect or. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The reluctor ring has one or more. The crankshaft position. Crankshaft Position Sensor Electrical Diagram.

From wirelibrarygarland.z6.web.core.windows.net

Crankshaft Position Sensor Wire Crankshaft Position Sensor Electrical Diagram The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. You will often also experience a stalling engine or bad engine. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The crankshaft position sensor diagram typically shows the sensor’s. Crankshaft Position Sensor Electrical Diagram.

From www.ebay.com

How To Fix a Crankshaft Position Sensor Wiring Harness eBay Crankshaft Position Sensor Electrical Diagram The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. You will often also experience a stalling engine or bad engine. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. The reluctor ring has one or more. A crankshaft position sensor test involves getting a multimeter and setting it to. Crankshaft Position Sensor Electrical Diagram.

From guidemanualtoucan.z21.web.core.windows.net

Delphi Throttle Position Sensor Wiring Schematic Crankshaft Position Sensor Electrical Diagram The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. This information is what determines. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. In this powerful guide, we will be more general than specific. The crankshaft position sensor diagram typically shows the sensor’s. Crankshaft Position Sensor Electrical Diagram.

From www.pelicanparts.com

Pelican Technical Article BMWX3 M54 Engine Crankshaft Sensor Testing Crankshaft Position Sensor Electrical Diagram This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. It consists of a sensor, often a hall effect or. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. The reluctor ring has one or more. The most common symptom of a bad crankshaft position sensor. Crankshaft Position Sensor Electrical Diagram.

From www.samarins.com

Crankshaft position sensor how it works, symptoms, problems, testing Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. The electrical. Crankshaft Position Sensor Electrical Diagram.

From wiringdiagramkuku.z19.web.core.windows.net

Crankshaft Sensor Wiring Diagram Crankshaft Position Sensor Electrical Diagram You will often also experience a stalling engine or bad engine. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. This information is what determines. A crankshaft position sensor test. Crankshaft Position Sensor Electrical Diagram.

From www.ford-trucks.com

Ford F150 F250 Replace Crankshaft Position Sensor How to FordTrucks Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. It consists of a sensor, often a hall effect or. This post will outline everything you need to know about 2 and. Crankshaft Position Sensor Electrical Diagram.

From wirelistzapotilla.z13.web.core.windows.net

Crankshaft Position Sensor Wiring Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. The reluctor ring has one or more. You will often also experience a stalling engine or bad engine. The crankshaft position. Crankshaft Position Sensor Electrical Diagram.

From www.justanswer.com

Wires pulled off crank position sensor 2005 Nissan Frontier. There is Crankshaft Position Sensor Electrical Diagram This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. It consists of a sensor, often a hall effect or. You will often also experience a stalling engine or bad engine. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. This information is what determines.. Crankshaft Position Sensor Electrical Diagram.

From schematicdbunexacted.z14.web.core.windows.net

Crankshaft Position Sensor Wiring Crankshaft Position Sensor Electrical Diagram This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. The manufacturer designs. Crankshaft Position Sensor Electrical Diagram.

From guidemanualshako.z13.web.core.windows.net

Crankshaft Sensor Wiring Diagram Crankshaft Position Sensor Electrical Diagram The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. In this powerful guide, we will be more general than specific. You will often also experience a stalling engine or bad engine. The electrical diagram. Crankshaft Position Sensor Electrical Diagram.

From resolutionsforyou.com

Understanding the Crankshaft Position Sensor Diagram A Comprehensive Guide Crankshaft Position Sensor Electrical Diagram The electrical diagram of the crankshaft sensor is different according to the year, make, and model. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. This information is what determines. The crankshaft position sensor. Crankshaft Position Sensor Electrical Diagram.

From wiringdbportioned.z5.web.core.windows.net

Crankshaft Position Sensor Wiring Crankshaft Position Sensor Electrical Diagram The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring. Crankshaft Position Sensor Electrical Diagram.

From diagramlibrarypooh.z19.web.core.windows.net

Crankshaft Position Sensor Wiring Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor monitors the crankshaft’s rotational speed and position. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. The most common symptom of a bad crankshaft position sensor is a check engine. Crankshaft Position Sensor Electrical Diagram.

From toolsweek.com

3 Wire Crank Position Sensor Wiring Diagram Crankshaft Position Sensor Electrical Diagram This information is what determines. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. You will often also experience a stalling engine or bad engine. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting.. Crankshaft Position Sensor Electrical Diagram.

From natureced.blogspot.com

Crankshaft Position Sensor Wiring Diagram Natureced Crankshaft Position Sensor Electrical Diagram The electrical diagram of the crankshaft sensor is different according to the year, make, and model. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. In this powerful guide, we will be more general than specific. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000. Crankshaft Position Sensor Electrical Diagram.

From diagramlibraryinspans.z13.web.core.windows.net

Kenmore Electric Dryer Wiring Diagrams Crankshaft Position Sensor Electrical Diagram In this powerful guide, we will be more general than specific. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. You will often also experience a stalling engine or bad engine. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. The crankshaft sensor is an important electrical device to detect. Crankshaft Position Sensor Electrical Diagram.

From carsescort.com

What Happens If You Don't Relearn Crankshaft Position Sensor? Crankshaft Position Sensor Electrical Diagram In this powerful guide, we will be more general than specific. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. The manufacturer designs the electrical schematics of the. Crankshaft Position Sensor Electrical Diagram.

From mechanicteretecycrito8z.z21.web.core.windows.net

Crank Position Sensor Code Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor monitors the crankshaft’s rotational speed and position. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. You will often also experience a stalling engine or bad engine. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. This post will outline everything you need. Crankshaft Position Sensor Electrical Diagram.

From wiringdiagramtapaderas.z21.web.core.windows.net

Nissan Sentra O2 Sensor Wiring Diagram Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. The manufacturer designs the electrical schematics. Crankshaft Position Sensor Electrical Diagram.

From diy-electronicsprojects.blogspot.com

3 wire crank sensor wiring diagram Crankshaft position sensor Crankshaft Position Sensor Electrical Diagram The electrical diagram of the crankshaft sensor is different according to the year, make, and model. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. In this powerful guide, we will be more general than specific. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. It consists of a sensor,. Crankshaft Position Sensor Electrical Diagram.

From repairmachinedocument.z5.web.core.windows.net

Engine Crankshaft Position Sensor Location Crankshaft Position Sensor Electrical Diagram It consists of a sensor, often a hall effect or. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip.. Crankshaft Position Sensor Electrical Diagram.

From manualmanualwannemaker.z19.web.core.windows.net

2 Wire Crank Sensor Wiring Diagram Crankshaft Position Sensor Electrical Diagram The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. The reluctor ring has one or more. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass. Crankshaft Position Sensor Electrical Diagram.

From nty.parts

CRANKSHAFT POSITION SENSOR NTY PARTS Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor monitors the crankshaft’s rotational speed and position. The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. This information is what determines. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. This post will outline everything you need to. Crankshaft Position Sensor Electrical Diagram.

From natureced.blogspot.com

Crankshaft Position Sensor Wiring Diagram Natureced Crankshaft Position Sensor Electrical Diagram It consists of a sensor, often a hall effect or. The electrical diagram of the crankshaft sensor is different according to the year, make, and model. You will often also experience a stalling engine or bad engine. The most common symptom of a bad crankshaft position sensor is a check engine light on your dashboard. The crankshaft position sensor diagram. Crankshaft Position Sensor Electrical Diagram.

From diy-electronicsprojects.blogspot.com

3 wire crank sensor wiring diagram Crankshaft position sensor Crankshaft Position Sensor Electrical Diagram The crankshaft position sensor monitors the crankshaft’s rotational speed and position. The reluctor ring has one or more. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. You will often also experience a stalling engine or bad engine. The crankshaft position sensor is positioned so that teeth on the reluctor ring. Crankshaft Position Sensor Electrical Diagram.

From garagerepairquants.z13.web.core.windows.net

2002 Bmw X5 Crankshaft Position Sensor Location Crankshaft Position Sensor Electrical Diagram The electrical diagram of the crankshaft sensor is different according to the year, make, and model. You will often also experience a stalling engine or bad engine. The reluctor ring has one or more. The crankshaft position sensor is positioned so that teeth on the reluctor ring attached to the crankshaft pass close to the sensor tip. In this powerful. Crankshaft Position Sensor Electrical Diagram.

From themachine.science

Crankshaft Position Sensor 2 A Comprehensive Guide for DIY Enthusiasts Crankshaft Position Sensor Electrical Diagram The crankshaft sensor is an important electrical device to detect engine rpm and ignition timing. The reluctor ring has one or more. This information is what determines. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000. Crankshaft Position Sensor Electrical Diagram.

From wirelibrarybespeaks.z21.web.core.windows.net

How To Test Crankshaft Sensor Wiring Crankshaft Position Sensor Electrical Diagram The reluctor ring has one or more. The manufacturer designs the electrical schematics of the crank position sensor according to the need and demand. This post will outline everything you need to know about 2 and 3 wire crank sensor wiring diagrams. This information is what determines. The crankshaft position sensor monitors the crankshaft’s rotational speed and position. It consists. Crankshaft Position Sensor Electrical Diagram.