Threading Material Meaning . Including, cold forming, rolling, tapping, milling, threading and grinding. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. A short description of the main thread production methods. Threads can generally be categorized into. * list and definition of symbols. Thread sizes are given in nominal sizes, not in actual measurement. A screw assembly with a small. The thread class defines it, and it indicates how tight or loose the thread is when assembled. This technique is used to produce intricate. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread milling refers to a metalworking process. The main document for iso metric threads:

from alwepo.com

In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. The main document for iso metric threads: A short description of the main thread production methods. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. A screw assembly with a small. * list and definition of symbols. This technique is used to produce intricate. Thread milling refers to a metalworking process. The thread class defines it, and it indicates how tight or loose the thread is when assembled. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled.

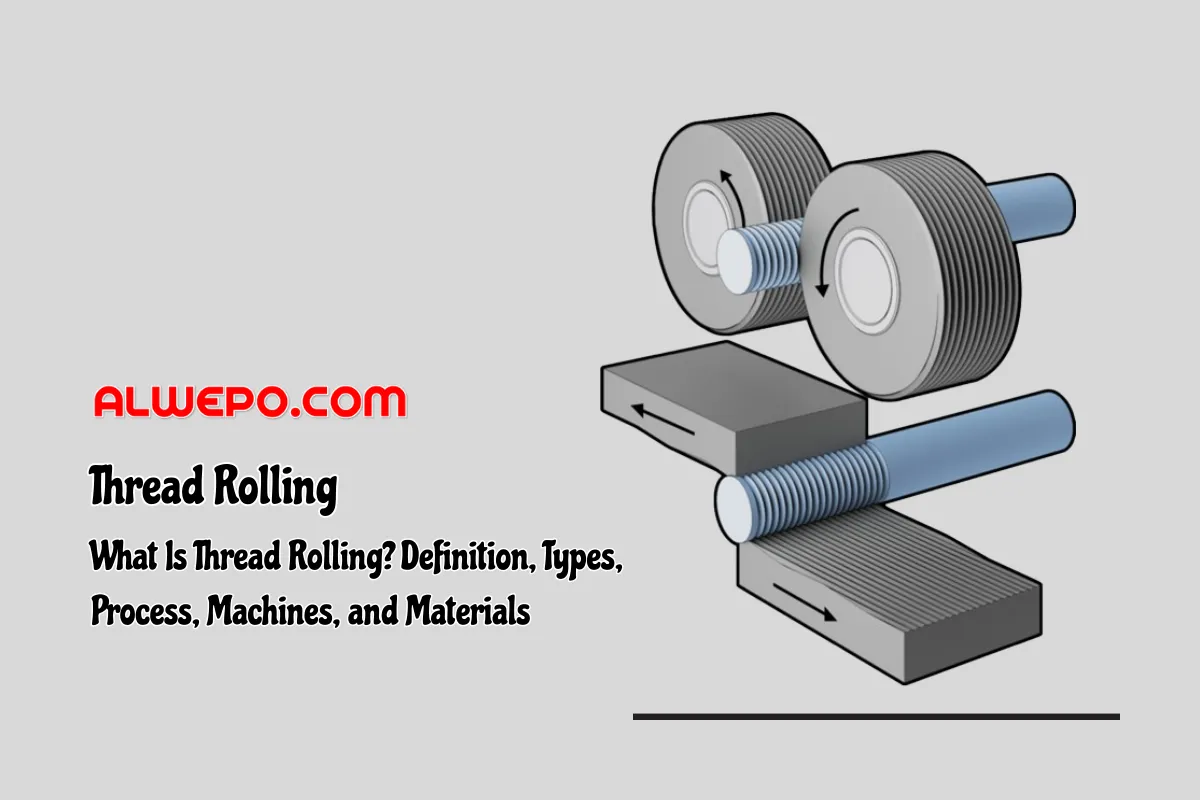

What Is Thread Rolling? Definition, Types, Process, Machines, And

Threading Material Meaning Threads can generally be categorized into. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. This technique is used to produce intricate. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread milling refers to a metalworking process. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. The main document for iso metric threads: The thread class defines it, and it indicates how tight or loose the thread is when assembled. * list and definition of symbols. Threads can generally be categorized into. Including, cold forming, rolling, tapping, milling, threading and grinding. A screw assembly with a small. Thread sizes are given in nominal sizes, not in actual measurement. A short description of the main thread production methods.

From www.depatie.com

Thread Identification & Types Guide Threading Material Meaning Threads can generally be categorized into. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. * list and definition of symbols. The thread class defines it, and it indicates how tight or loose the thread is when assembled. The main document for iso metric threads: Thread milling refers to a metalworking process. This. Threading Material Meaning.

From www.aquacure.co.uk

A User Guide to Thread Types Aqua Cure Threading Material Meaning Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. The thread class defines it, and it indicates how tight or loose the thread is when. Threading Material Meaning.

From alwepo.com

What Is Thread Rolling? Definition, Types, Process, Machines, And Threading Material Meaning The main document for iso metric threads: Thread sizes are given in nominal sizes, not in actual measurement. The thread class defines it, and it indicates how tight or loose the thread is when assembled. A screw assembly with a small. * list and definition of symbols. This technique is used to produce intricate. In this blog post, we’ll delve. Threading Material Meaning.

From mavink.com

Thread Types Chart Threading Material Meaning Thread sizes are given in nominal sizes, not in actual measurement. Thread milling refers to a metalworking process. The thread class defines it, and it indicates how tight or loose the thread is when assembled. A short description of the main thread production methods. Because in all threads, either the crest or the root must be relieved, the height is. Threading Material Meaning.

From www.parktool.com

Basic Thread Concepts Park Tool Threading Material Meaning Thread sizes are given in nominal sizes, not in actual measurement. The thread class defines it, and it indicates how tight or loose the thread is when assembled. Thread milling refers to a metalworking process. Threads can generally be categorized into. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a. Threading Material Meaning.

From slideplayer.com

Metalwork Threading. ppt download Threading Material Meaning Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. Threads can generally be categorized into. A screw assembly with a small. In this blog post,. Threading Material Meaning.

From www.hoseassemblytips.com

How do you identify fitting thread types? Hose Assembly Tips Threading Material Meaning Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread milling refers to a metalworking process. Threads can generally be categorized into. Including, cold forming, rolling, tapping, milling, threading and grinding. A screw assembly with a small. Thread sizes are given in nominal sizes, not in actual measurement. The. Threading Material Meaning.

From www.electrician-1.com

Screw Thread Terminology electrical and electronics technology degree Threading Material Meaning A screw assembly with a small. The thread class defines it, and it indicates how tight or loose the thread is when assembled. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. The main document for iso metric threads: Thread milling refers to a metalworking. Threading Material Meaning.

From learnmech.com

Nomenclature of Mechanical Threads Diagram Of Threads Threading Material Meaning A short description of the main thread production methods. Threads can generally be categorized into. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. The thread class defines it, and it indicates how. Threading Material Meaning.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Material Meaning A screw assembly with a small. Threads can generally be categorized into. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. A short description of the main thread production methods. Thread milling refers to a metalworking process. The thread class defines it, and it indicates how tight or loose the thread is when. Threading Material Meaning.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Material Meaning Thread milling refers to a metalworking process. Thread sizes are given in nominal sizes, not in actual measurement. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. This technique is used to produce intricate. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for. Threading Material Meaning.

From www.artofit.org

Sewing thread information types of thread materials Artofit Threading Material Meaning In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. Thread milling refers to a metalworking process. Including, cold forming, rolling, tapping, milling, threading and grinding. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Threads can generally be categorized into. Because in. Threading Material Meaning.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Material Meaning Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. This technique is used to produce intricate. The thread class defines it, and it indicates how tight or loose the thread is when assembled. A screw assembly with a small. The main document for iso metric. Threading Material Meaning.

From www.youtube.com

[ English ] What is Thread Pitch ? / How to measure thread pitch Threading Material Meaning A screw assembly with a small. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. Including, cold forming, rolling, tapping, milling, threading and grinding. Thread sizes are given in nominal sizes, not in actual measurement. Thread milling refers to a metalworking process. Because in all threads, either the crest or the root must. Threading Material Meaning.

From www.slideserve.com

PPT ME311 Machine Design PowerPoint Presentation ID468279 Threading Material Meaning A short description of the main thread production methods. Threads can generally be categorized into. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. The main document for iso metric threads: * list. Threading Material Meaning.

From www.oxfordlearnersdictionaries.com

thread noun Definition, pictures, pronunciation and usage notes Threading Material Meaning Including, cold forming, rolling, tapping, milling, threading and grinding. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. Thread sizes are given in nominal sizes, not in actual measurement. Threads can generally be categorized into. Threading is a crucial process in manufacturing that involves creating. Threading Material Meaning.

From blog.bernina.com

Sewing tips for beginners Important info about needle and thread Threading Material Meaning The thread class defines it, and it indicates how tight or loose the thread is when assembled. The main document for iso metric threads: Threads can generally be categorized into. A short description of the main thread production methods. Thread sizes are given in nominal sizes, not in actual measurement. Because in all threads, either the crest or the root. Threading Material Meaning.

From mysewingmall.blogspot.com

What Types of Thread To Use? Threading Material Meaning * list and definition of symbols. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. Thread milling refers to a metalworking process. Threads can generally be categorized into. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. The. Threading Material Meaning.

From www.electricsolenoidvalves.com

NPT Threading Explained Threading Material Meaning A short description of the main thread production methods. The thread class defines it, and it indicates how tight or loose the thread is when assembled. Thread sizes are given in nominal sizes, not in actual measurement. Including, cold forming, rolling, tapping, milling, threading and grinding. Thread milling refers to a metalworking process. A screw assembly with a small. Threading. Threading Material Meaning.

From mechasource.blogspot.com

An IntroductionTo Fasteners,Bolt Types ,Materials ,Threads And Selection Threading Material Meaning This technique is used to produce intricate. Thread sizes are given in nominal sizes, not in actual measurement. Threads can generally be categorized into. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. In this blog post, we’ll delve into the fundamentals of threading, offering. Threading Material Meaning.

From www.fastenerdata.co.uk

Fastenerdata THREAD BASICS knf Fastener Specifications Threading Material Meaning The thread class defines it, and it indicates how tight or loose the thread is when assembled. Thread sizes are given in nominal sizes, not in actual measurement. A screw assembly with a small. Threads can generally be categorized into. This technique is used to produce intricate. A short description of the main thread production methods. The main document for. Threading Material Meaning.

From www.aatprod.com

Thread Pitch and Pitch Diameter All America Threaded Products Threading Material Meaning A short description of the main thread production methods. * list and definition of symbols. A screw assembly with a small. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. Threads can generally be categorized into. Including, cold forming, rolling, tapping, milling, threading and grinding. The main document for iso metric threads: Thread. Threading Material Meaning.

From engineeringlearn.com

13 Types of Threads Definition, Parts and Thread Identifying Tools Threading Material Meaning Thread milling refers to a metalworking process. * list and definition of symbols. This technique is used to produce intricate. Threads can generally be categorized into. A screw assembly with a small. The main document for iso metric threads: Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. In. Threading Material Meaning.

From www.youtube.com

Screw Thread Terminology in a simple way YouTube Threading Material Meaning * list and definition of symbols. Thread sizes are given in nominal sizes, not in actual measurement. A short description of the main thread production methods. This technique is used to produce intricate. Including, cold forming, rolling, tapping, milling, threading and grinding. Threads can generally be categorized into. The thread class defines it, and it indicates how tight or loose. Threading Material Meaning.

From www.rmgtech.in

Metric Thread Data Threading Material Meaning A screw assembly with a small. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. A short description of the main thread production methods. Threads can generally be categorized into. Because in all. Threading Material Meaning.

From www.themetalcompany.co.nz

Our Range Of NPT Threaded Fittings Threading Material Meaning Thread sizes are given in nominal sizes, not in actual measurement. Thread milling refers to a metalworking process. A short description of the main thread production methods. Including, cold forming, rolling, tapping, milling, threading and grinding. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. * list and definition of symbols. This technique. Threading Material Meaning.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Material Meaning Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread milling refers to a metalworking process. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. A screw assembly with a small. In this blog. Threading Material Meaning.

From www.slideserve.com

PPT Chapter 5 Threads and Fasteners PowerPoint Presentation, free Threading Material Meaning Threads can generally be categorized into. Thread sizes are given in nominal sizes, not in actual measurement. A short description of the main thread production methods. The thread class defines it, and it indicates how tight or loose the thread is when assembled. This technique is used to produce intricate. In this blog post, we’ll delve into the fundamentals of. Threading Material Meaning.

From casper.com

Best Thread Count For Sheets (Based on Material) Casper Threading Material Meaning The main document for iso metric threads: A screw assembly with a small. Thread sizes are given in nominal sizes, not in actual measurement. This technique is used to produce intricate. The thread class defines it, and it indicates how tight or loose the thread is when assembled. Because in all threads, either the crest or the root must be. Threading Material Meaning.

From www.allfreesewing.com

The Ultimate Thread Guide Types of Thread Materials Threading Material Meaning Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. This technique is used to produce intricate. Including, cold forming, rolling, tapping, milling, threading and grinding. The thread class defines it, and it indicates how tight or loose the thread is when assembled. A short description of the main thread. Threading Material Meaning.

From www.apollointernational.in

British Standard Fine Thread BSF Thread Chart Apollo International Threading Material Meaning Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. * list and definition of symbols. Including, cold forming, rolling, tapping, milling, threading and grinding. This technique is used to produce intricate. Because in all threads, either the crest or the root must be relieved, the height is a reference. Threading Material Meaning.

From blog.treasurie.com

Sewing Thread Types Best Threads for Sewing Projects TREASURIE Threading Material Meaning The main document for iso metric threads: A screw assembly with a small. Thread sizes are given in nominal sizes, not in actual measurement. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. Threads can generally be categorized into. Because in all threads, either the crest or the root must be relieved, the. Threading Material Meaning.

From waykenrm.com

Make Threaded Holes Considerations For Tapped A Hole WayKen Threading Material Meaning The main document for iso metric threads: A screw assembly with a small. * list and definition of symbols. A short description of the main thread production methods. Including, cold forming, rolling, tapping, milling, threading and grinding. In this blog post, we’ll delve into the fundamentals of threading, offering practical tips for engineers. Thread sizes are given in nominal sizes,. Threading Material Meaning.

From www.ageberry.com

Sewing thread types and uses Threading Material Meaning This technique is used to produce intricate. * list and definition of symbols. A short description of the main thread production methods. The thread class defines it, and it indicates how tight or loose the thread is when assembled. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread. Threading Material Meaning.

From www.allfreesewing.com

Sewing Thread Information Types of Thread Materials Threading Material Meaning * list and definition of symbols. This technique is used to produce intricate. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. Including, cold forming, rolling, tapping, milling, threading and grinding. The main document for iso metric threads: The thread class defines it, and it. Threading Material Meaning.