Gear Position Definition . In this section we introduce the. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. The fundamental principle behind gears is the conservation of. The following order information is required for r, f, k and s gear units and gearmotors in addition to. By interlocking a pair of these. Gears are classified into 3 categories; In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Position of the output shaft and output flange. Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. Types of gears and quantities defining the relative position: A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Spur gears and helical gears are parallel axes.

from www.comsol.se

Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. Gears are classified into 3 categories; By interlocking a pair of these. In this section we introduce the. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. The following order information is required for r, f, k and s gear units and gearmotors in addition to. Types of gears and quantities defining the relative position: Position of the output shaft and output flange. Spur gears and helical gears are parallel axes. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces.

How to Build Gear Geometries in the Multibody Dynamics Module COMSOL Blog

Gear Position Definition A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Position of the output shaft and output flange. Spur gears and helical gears are parallel axes. Types of gears and quantities defining the relative position: In this section we introduce the. By interlocking a pair of these. The following order information is required for r, f, k and s gear units and gearmotors in addition to. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Gears are classified into 3 categories; In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. The fundamental principle behind gears is the conservation of. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears.

From medium.com

Gear Types, Definition, Terms Used, And The Law Of Gearing by LEARN Gear Position Definition Gears are classified into 3 categories; By interlocking a pair of these. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. In this section we introduce the. Types of gears and quantities defining the relative position: The following order information is required for r, f, k and s gear. Gear Position Definition.

From yzymis.blogspot.com

Gear Types Types of Gear Different Types of Gear Gear Position Definition Types of gears and quantities defining the relative position: In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. In this section we introduce the. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. The fundamental principle behind gears is the conservation of. A gear. Gear Position Definition.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Gear Position Definition Types of gears and quantities defining the relative position: By interlocking a pair of these. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Gears are classified into 3 categories; The fundamental principle behind gears is the conservation of. Position of the output shaft and output flange.. Gear Position Definition.

From www.iqsdirectory.com

Gear Drive What Is It? Types, Uses, Components, Design Gear Position Definition Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. Spur gears and helical gears are parallel axes. In this section we introduce the. Types of gears and quantities defining the relative position: The following order information is required for r, f, k and s gear units and gearmotors in addition to. Gears are classified into 3 categories;. Gear Position Definition.

From commercialdriving.weebly.com

Digital Handouts Chattanooga State Commercial Truck Driving Program Gear Position Definition A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. The fundamental principle behind gears is the conservation of. Gears are classified into 3 categories; Gears are mechanical devices consisting of toothed wheels that mesh with each other. Gear Position Definition.

From www.worksheetsplanet.com

What Is A Gear Gear Position Definition In this section we introduce the. The following order information is required for r, f, k and s gear units and gearmotors in addition to. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. Types of gears and quantities defining the relative position: Gears are classified into 3 categories; By interlocking a pair of these. Position of. Gear Position Definition.

From www.geartechnology.com

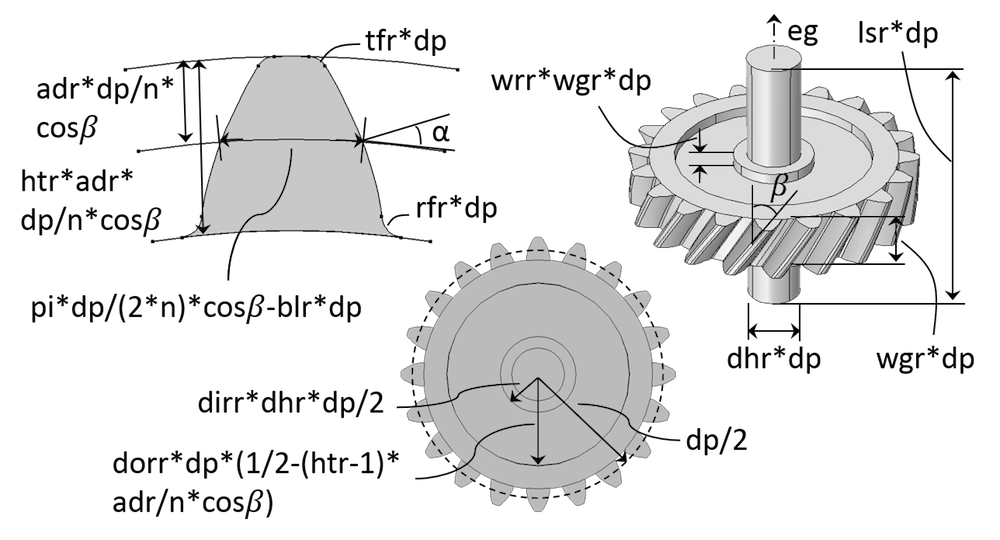

The Basics of Gear Theory Gear Technology Magazine Gear Position Definition Spur gears and helical gears are parallel axes. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Gears are classified into 3 categories; The fundamental principle behind gears is the conservation of. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth'. Gear Position Definition.

From gamesmartz.com

Position Definition & Image GameSmartz Gear Position Definition Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. Types of gears and quantities defining the relative position: Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. The fundamental principle behind gears is the conservation of. By interlocking a pair of these. Spur gears and helical gears. Gear Position Definition.

From www.wisegeek.com

What Is a Crank Angle? (with picture) Gear Position Definition Position of the output shaft and output flange. Gears are classified into 3 categories; The following order information is required for r, f, k and s gear units and gearmotors in addition to. Spur gears and helical gears are parallel axes. In this section we introduce the. Types of gears and quantities defining the relative position: The fundamental principle behind. Gear Position Definition.

From www.chegg.com

Position analysis of a landing gear; the coordinates Gear Position Definition A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. The fundamental principle behind gears is the conservation of. Position of the output shaft and output flange. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. In. Gear Position Definition.

From www.mech4study.com

Gear Terminology Basic Definition Used in Gear mech4study Gear Position Definition Gears are classified into 3 categories; By interlocking a pair of these. Position of the output shaft and output flange. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. Spur gears and helical gears are parallel axes. The following order information is required for r, f, k and s gear units and gearmotors in addition to. The. Gear Position Definition.

From www.engineeringchoice.com

What is Gear? Definition, Parts, Types, and Benefits Engineering Choice Gear Position Definition The fundamental principle behind gears is the conservation of. The following order information is required for r, f, k and s gear units and gearmotors in addition to. Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. In. Gear Position Definition.

From www.sodialed.com

gear ratio definition RC Car Glossary Gear Position Definition Gears are classified into 3 categories; In this section we introduce the. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. The fundamental principle behind gears is the conservation of. Position of the output shaft and output flange. By interlocking a pair of these. Spur gears and. Gear Position Definition.

From saabwisonline.com

Checking and adjusting the gear position 95 2003 SAAB Gear Position Definition The following order information is required for r, f, k and s gear units and gearmotors in addition to. Position of the output shaft and output flange. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Gears are mechanical devices consisting of toothed wheels that mesh with. Gear Position Definition.

From www.youtube.com

BICYCLE BASICS Low vs High Gear Which Gear is Easier and Which is Gear Position Definition Spur gears and helical gears are parallel axes. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. By interlocking a pair of these. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. Gears are classified into 3 categories; The following order information is required. Gear Position Definition.

From studylib.net

Gears Gear Position Definition Spur gears and helical gears are parallel axes. Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. The fundamental principle behind gears is the conservation of. Position of the output shaft and output flange. The following order information is required for r, f, k and s gear units and gearmotors. Gear Position Definition.

From www.marysrosaries.com

FileDifferential Gear (PSF).png The Work of God's Children Gear Position Definition Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. Gears are classified into 3 categories; In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. The fundamental principle behind gears is the conservation of. Types of gears and quantities defining the relative position: A gear. Gear Position Definition.

From www.investopedia.com

Gearing Ratios Definition, Types of Ratios, and How to Calculate Gear Position Definition The fundamental principle behind gears is the conservation of. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Types of gears and quantities defining the relative position: Spur gears and helical gears are parallel axes. Position of the output shaft and output flange. By interlocking a pair of these.. Gear Position Definition.

From differenttypesofengineering.blogspot.com

Introduction to Steering Gear Different Types of Engineering Gear Position Definition Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. Gears are classified into 3 categories; The fundamental principle behind gears is the conservation of. By interlocking a pair of these. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth. Gear Position Definition.

From www.comsol.se

How to Build Gear Geometries in the Multibody Dynamics Module COMSOL Blog Gear Position Definition Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. Types of gears and quantities defining the relative position: In this section we introduce the. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. By interlocking a pair of these.. Gear Position Definition.

From saabwisonline.com

Checking and adjusting gear positions 95 2003 SAAB Gear Position Definition The fundamental principle behind gears is the conservation of. Spur gears and helical gears are parallel axes. Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. By interlocking a pair of these. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or. Gear Position Definition.

From www.researchgate.net

Carlino techniqueunderstanding gear position within vessel Gear Position Definition Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. The following order information is required for r, f, k and s gear units and gearmotors in addition to. Gears are classified into 3 categories; Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. In the previous pages,. Gear Position Definition.

From www.gauravindustries.com

Gaurav Industries Gears Gear Position Definition Types of gears and quantities defining the relative position: Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. The following order information is required for r, f, k and s gear units and gearmotors in addition to. In this section we introduce the. Spur gears and helical gears are parallel axes. Gears are mechanical devices consisting of. Gear Position Definition.

From www.jaredzone.info

Gears and Gearing Definitions Mechanical Reviews Gear Position Definition The following order information is required for r, f, k and s gear units and gearmotors in addition to. Gears are classified into 3 categories; A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. The fundamental principle behind gears is the conservation of. Position of the output shaft and. Gear Position Definition.

From saabwisonline.com

Checking and adjusting the gear position 95 2003 SAAB Gear Position Definition In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Types of gears and quantities defining the relative position: Position of the output shaft and output flange. In. Gear Position Definition.

From www.dreamstime.com

Gear Position Symbol with Manual Mode Shifting on Automatic Gear Position Definition Position of the output shaft and output flange. The fundamental principle behind gears is the conservation of. In this section we introduce the. The following order information is required for r, f, k and s gear units and gearmotors in addition to. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or. Gear Position Definition.

From www.yourmechanic.com

How to Figure Out the Gear Ratio of Your Car YourMechanic Advice Gear Position Definition A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Types of gears and quantities defining the relative position: Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting axes gears. Position of the output shaft and output flange. The fundamental principle behind gears is the conservation of. The following. Gear Position Definition.

From www.tutorix.com

Types of Gears Gear Position Definition Spur gears and helical gears are parallel axes. By interlocking a pair of these. Types of gears and quantities defining the relative position: In this section we introduce the. Gears are classified into 3 categories; Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. Parallel axis gears, intersecting axes gears,. Gear Position Definition.

From 3d-mds-academy.com

Gear Fundamentals 3DMDS Academy Gear Position Definition In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Position of the output shaft and output flange. A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Gears are mechanical devices consisting of toothed wheels that mesh. Gear Position Definition.

From www.youtube.com

How To Understand Gear Position Gear Sifting Practice Gear Gear Position Definition A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Position of the output shaft and output flange. The following order information is required for r, f, k and s gear units and gearmotors in addition to. Types of gears and quantities defining the relative position: Gears are mechanical devices. Gear Position Definition.

From www.engineeringchoice.com

What is Gear? Definition, Parts, Types, and Benefits Gear Position Definition Position of the output shaft and output flange. By interlocking a pair of these. Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. Gears are classified into 3 categories; Spur gears and helical gears are parallel axes. The following order information is required for r, f, k and s gear. Gear Position Definition.

From www.slideserve.com

PPT Gears PowerPoint Presentation, free download ID9271971 Gear Position Definition A gear is a type of machine element in which evenly spaced teeth are cut around cylindrical or conical surfaces. Spur gears and helical gears are parallel axes. In this section we introduce the. By interlocking a pair of these. Position of the output shaft and output flange. The fundamental principle behind gears is the conservation of. Types of gears. Gear Position Definition.

From mectips.com

Gear Train Definition, Types, Applications Mechanical Engineering Gear Position Definition The following order information is required for r, f, k and s gear units and gearmotors in addition to. Position of the output shaft and output flange. By interlocking a pair of these. Gears are mechanical devices consisting of toothed wheels that mesh with each other to transmit torque and rotational motion. A gear is a type of machine element. Gear Position Definition.

From www.alamy.com

Automatic transmission gear of vehicle on a 2nd lower gear position Gear Position Definition Spur gears and helical gears are parallel axes. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. By interlocking a pair of these. Types of gears and quantities defining the relative position: In this section we introduce the. The following order information is required for r, f,. Gear Position Definition.

From www.investopedia.com

Gearing Definition, How It’s Measured, and Example Gear Position Definition In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Types of gears and quantities defining the relative position: The following order information is required for r, f, k and s gear units and gearmotors in addition to. Parallel axis gears, intersecting axes gears, and nonparallel and nonintersecting. Gear Position Definition.