Feed Water Tank Deaerator . Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. The heat causes the dissolved gases to come out of the solution and be vented from the tank. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. By adhering to the surfaces of metal. Deaerators are critical components of many steam systems and have several functions: Deaerator tanks work by spraying the feedwater into a chamber where it is heated by steam. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive.

from aager.de

Deaerators are critical components of many steam systems and have several functions: On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. The heat causes the dissolved gases to come out of the solution and be vented from the tank. Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. Deaerator tanks work by spraying the feedwater into a chamber where it is heated by steam. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. By adhering to the surfaces of metal.

Deaerator Vessels & Feed Water Storage Tanks Äager

Feed Water Tank Deaerator The heat causes the dissolved gases to come out of the solution and be vented from the tank. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerator tanks work by spraying the feedwater into a chamber where it is heated by steam. Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. Deaerators are critical components of many steam systems and have several functions: The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. By adhering to the surfaces of metal. On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. The heat causes the dissolved gases to come out of the solution and be vented from the tank.

From aager.de

Deaerator Vessels & Feed Water Storage Tanks Äager Feed Water Tank Deaerator The heat causes the dissolved gases to come out of the solution and be vented from the tank. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. Deaerator tanks work by spraying. Feed Water Tank Deaerator.

From www.youtube.com

Deaerator working principle, Types and Process Control YouTube Feed Water Tank Deaerator On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Deaerators are critical components of many steam systems and have several functions: By adhering to the surfaces of metal. Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up. Feed Water Tank Deaerator.

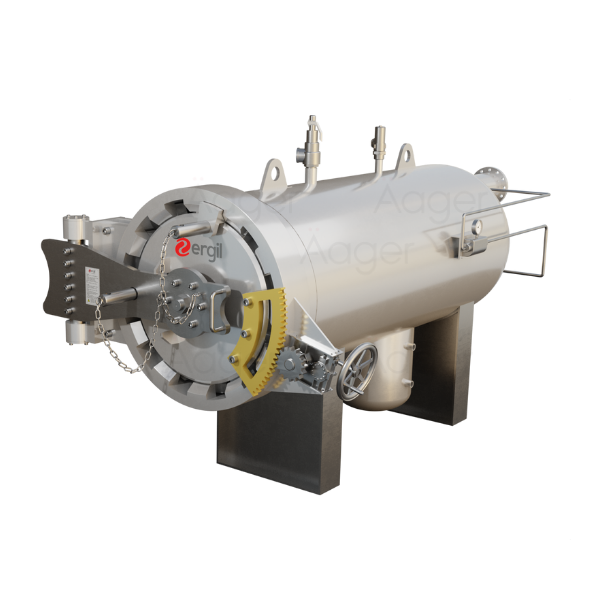

From ergil.com

Deaerator Vessels & Feed Water Storage Tanks Ergil World Leading Feed Water Tank Deaerator Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. By adhering to the surfaces of metal. Deaerators are critical components of many steam systems and have several functions: On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Find about the need to. Feed Water Tank Deaerator.

From smithhughes.com

Industrial Steam Feed Tanks & Deaerators Smith Hughes Feed Water Tank Deaerator On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Deaerator tanks work by spraying the feedwater into a chamber where. Feed Water Tank Deaerator.

From precisionboilers.com

Boiler Room Feedwater Tanks & Deaerators Precision Boilers Feed Water Tank Deaerator By adhering to the surfaces of metal. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerator tanks work by spraying the feedwater into a. Feed Water Tank Deaerator.

From ormandygroup.com

Feed Tanks, Hotwells & Deaerator Heads Ormandy Rycroft Engineering Feed Water Tank Deaerator The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Deaerators are critical components of many steam systems and have several functions: Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. Deaerator tanks work by spraying the feedwater into a chamber where. Feed Water Tank Deaerator.

From www.idmsteamboiler.co.id

Jual Fabrikasi Deaerator Tank boiler Feed Water Boiler Tangerang Feed Water Tank Deaerator The heat causes the dissolved gases to come out of the solution and be vented from the tank. Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen,. Feed Water Tank Deaerator.

From smithhughes.com

Industrial Steam Feed Tanks & Deaerators Smith Hughes Feed Water Tank Deaerator On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. Deaerators are critical components of many. Feed Water Tank Deaerator.

From www.coalhandlingplants.com

Deaerator in Thermal Power Plant Feed Water Tank Deaerator The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. By adhering to the surfaces of metal. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerator tanks work by spraying the feedwater into a. Feed Water Tank Deaerator.

From www.directindustry.com

Boiler feed water degasser DG ATTSU TERMICA S.L. for water Feed Water Tank Deaerator Deaerators are critical components of many steam systems and have several functions: The heat causes the dissolved gases to come out of the solution and be vented from the tank. On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Deaerators are pressurised feedwater tanks also. Feed Water Tank Deaerator.

From ergil.com

Deaerator Vessels & Feed Water Storage Tanks Ergil World Leading Feed Water Tank Deaerator The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerator tanks work by spraying the feedwater into a chamber where it is heated by steam.. Feed Water Tank Deaerator.

From precisionboilers.com

Boiler Room Feedwater Tanks & Deaerators Precision Boilers Feed Water Tank Deaerator Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerators are critical components of many steam systems and have several functions: The heat causes the dissolved gases to come out of the solution and be vented from the. Feed Water Tank Deaerator.

From www.shipcopumps.com

Type .03 DA Deaerators Shipco® Pumps Feed Water Tank Deaerator Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. The heat causes the dissolved gases to come out of the solution and be vented from the tank. Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. Deaerator tanks work by spraying the feedwater into a chamber where. Feed Water Tank Deaerator.

From aager.de

Deaerator Vessels & Feed Water Storage Tanks Äager Feed Water Tank Deaerator Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. By adhering to the surfaces of metal. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring. Feed Water Tank Deaerator.

From goesheatingsystems.com

Industrial Steam Deaerators & Feed Water Systems Feed Water Tank Deaerator Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. By adhering to the surfaces of metal. Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. The purpose of a deaerator is to reduce dissolved gases, particularly. Feed Water Tank Deaerator.

From ormandygroup.com

Feed Tanks, Hotwells & Deaerator Heads Ormandy Rycroft Engineering Feed Water Tank Deaerator Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Deaerators are pressurised feedwater tanks. Feed Water Tank Deaerator.

From econtrol.com

Boiler Feed Systems Energy Control Feed Water Tank Deaerator The heat causes the dissolved gases to come out of the solution and be vented from the tank. Deaerator tanks work by spraying the feedwater into a chamber where it is heated by steam. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. The purpose of a deaerator is to. Feed Water Tank Deaerator.

From www.ewt-wasser.de

Deaerator, Boiler Feed Water Tank EWT Water Technology Feed Water Tank Deaerator Deaerators are critical components of many steam systems and have several functions: On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising. Feed Water Tank Deaerator.

From bryanboilers.com

Separable Tank Tray Type Feedwater Deaerator Feed Water Tank Deaerator Deaerators are critical components of many steam systems and have several functions: By adhering to the surfaces of metal. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency. Feed Water Tank Deaerator.

From ormandygroup.com

Feed Tanks, Hotwells & Deaerator Heads Ormandy Rycroft Engineering Feed Water Tank Deaerator On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid. Feed Water Tank Deaerator.

From www.ewt-wasser.de

Boiler Feed Water Treatment EWT Water Technology Feed Water Tank Deaerator Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. The heat causes the dissolved gases to come out of the solution and be vented from the tank. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. By adhering to the surfaces of metal. The purpose of a. Feed Water Tank Deaerator.

From precisionboilers.com

Boiler Room Feedwater Tanks & Deaerators Precision Boilers Feed Water Tank Deaerator Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. By adhering to the surfaces of metal. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerator tanks work by. Feed Water Tank Deaerator.

From www.wcrouse.com

Deaeration Overview of Deaerators and Their Role in Boilers WC Rouse Feed Water Tank Deaerator The heat causes the dissolved gases to come out of the solution and be vented from the tank. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the. Feed Water Tank Deaerator.

From www.caesarvery.com

Feed Water System PLTU Sains, Teknologi dan Ekonomi Bisnis Feed Water Tank Deaerator Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. By adhering to the surfaces of metal. The heat causes the. Feed Water Tank Deaerator.

From atlanticfeedwatersystemsinc.com

P5 .005 cc/liter Horizontal & Vertical Pressurized Deaerators Feed Water Tank Deaerator Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. By adhering to the surfaces. Feed Water Tank Deaerator.

From www.hurstboiler.com

Feedwater Deaerators Oxymiser Hurst Boiler Feed Water Tank Deaerator On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and. Feed Water Tank Deaerator.

From goesheatingsystems.com

Industrial Steam Deaerators & Feed Water Systems Feed Water Tank Deaerator On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. The heat causes the dissolved gases to come out of the solution and be vented from the tank. The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve. Feed Water Tank Deaerator.

From lockwoodproducts.com

Model SS Deaerator (Spray Type) Lockwood Products Feed Water Tank Deaerator By adhering to the surfaces of metal. On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Deaerators are critical components of many steam systems and have several functions: The heat causes the dissolved gases to come out of the solution and be vented from the. Feed Water Tank Deaerator.

From precisionboilers.com

Boiler Room Feedwater Tanks & Deaerators Precision Boilers Feed Water Tank Deaerator On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Deaerators are critical components of many steam systems and have several functions: Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. By adhering to the surfaces of metal. The purpose of a deaerator. Feed Water Tank Deaerator.

From ormandygroup.com

Feed Tanks, Hotwells & Deaerator Heads Ormandy Rycroft Engineering Feed Water Tank Deaerator Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. The heat causes the dissolved gases to come out of the solution and be vented from the tank. Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters.. Feed Water Tank Deaerator.

From www.scribd.com

Deaerator, Boiler Feed Water Tank EWT Water Technology Boiler Steam Feed Water Tank Deaerator By adhering to the surfaces of metal. Deaerators are critical components of many steam systems and have several functions: Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. The heat causes the dissolved gases to come out of the solution and be vented from the tank. Find about the need to remove gases from boiler feedwater and. Feed Water Tank Deaerator.

From www.ydboilerpart.com

Horizontal Boiler Feed Water Storage Tank Deaerators Images & Photos Feed Water Tank Deaerator The purpose of a deaerator is to reduce dissolved gases, particularly oxygen, to a low level and improve a plant's thermal efficiency by raising the. Find about the need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. The heat causes the dissolved gases to come out of the solution and be vented from. Feed Water Tank Deaerator.

From www.oceanproperty.co.th

Feed Water Tank An Overview ScienceDirect Topics, 44 OFF Feed Water Tank Deaerator Deaerators are critical components of many steam systems and have several functions: Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Find about the need to remove gases from boiler feedwater and the. Feed Water Tank Deaerator.

From precisionboilers.com

Boiler Room Feedwater Tanks & Deaerators Precision Boilers Feed Water Tank Deaerator On larger boiler plants, pressurised deaerators are sometimes installed and live steam is used to bring the feedwater up to approximately 105°c to drive. Deaerators are pressurised feedwater tanks also referred to as open feedwater heaters. Deaerators are critical components of many steam systems and have several functions: By adhering to the surfaces of metal. The heat causes the dissolved. Feed Water Tank Deaerator.

From www.pro-sonix.com

Boiler Feedwater Tank Heating Steam Sparger for Oxygen Removal to Feed Water Tank Deaerator Deaerator and feedwater storage tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater. The heat causes the dissolved gases to come out of the solution and be vented from the tank. On larger boiler plants, pressurised deaerators are sometimes installed and live steam. Feed Water Tank Deaerator.