Sugar Purification Process . After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. In addition to exploring the history, market, and consumption of sugar, the. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. It must undergo purification at a cane sugar refinery before it is safe for human consumption. Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous stalks. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. The first step is to remove the. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining facilities, the transformation into the familiar sweet crystals we use. Energy from the sun transforms carbon dioxide and water into oxygen and glucose.

from www.sugarprocesstech.com

In addition to exploring the history, market, and consumption of sugar, the. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous stalks. It must undergo purification at a cane sugar refinery before it is safe for human consumption. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining facilities, the transformation into the familiar sweet crystals we use. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. The first step is to remove the. Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates.

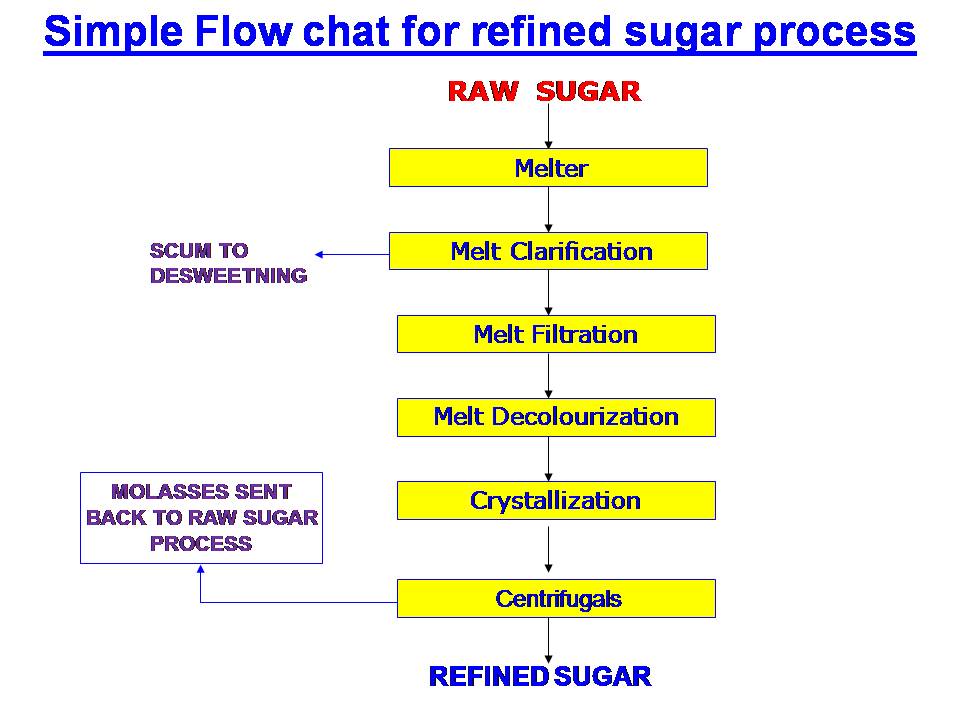

what is refined sugar and Refined sugar making process

Sugar Purification Process Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. The first step is to remove the. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining facilities, the transformation into the familiar sweet crystals we use. Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Energy from the sun transforms carbon dioxide and water into oxygen and glucose. The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous stalks. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. It must undergo purification at a cane sugar refinery before it is safe for human consumption. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. In addition to exploring the history, market, and consumption of sugar, the.

From www.mdpi.com

Processes Free FullText FedBatch Sucrose Crystallization Model Sugar Purification Process The first step is to remove the. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality.. Sugar Purification Process.

From www.syrupmachinery.com

Production process of glucose syrup by double enzyme method from starch Sugar Purification Process In addition to exploring the history, market, and consumption of sugar, the. The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous stalks. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. After sugar beets or sugar cane. Sugar Purification Process.

From www.slideserve.com

PPT Liquid Sugar Refining Process Ion Exchange Resin Demineralization Sugar Purification Process This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. In addition to exploring the history, market, and consumption of sugar, the. Sugar is made in the leaves of the sugar cane plant through the. Sugar Purification Process.

From www.researchgate.net

Diagram of sugar refining process annotated with job numbers referenced Sugar Purification Process Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous stalks. The first step is to remove the. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature,. Sugar Purification Process.

From www.sulzer.com

Sulzer pumps improve wastewater treatment in a sugar and bioethanol Sugar Purification Process Energy from the sun transforms carbon dioxide and water into oxygen and glucose. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. The first step is to remove the. In addition to exploring the history, market, and consumption of sugar, the. This month’s processing column continues. Sugar Purification Process.

From www.grecianmagnesite.com

Sugar Refining GRECIAN MAGNESITE Sugar Purification Process This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. It must undergo purification at a cane sugar refinery before it is safe for human consumption. Energy from the sun transforms carbon dioxide and water into oxygen and glucose. Sugar is made in the leaves of the sugar cane plant through the natural. Sugar Purification Process.

From www.rumreader.com

Sugar A Practical Guide The Rum Reader Sugar Purification Process The first step is to remove the. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. It must undergo purification at a cane sugar refinery before it is safe. Sugar Purification Process.

From seppelec.com

Sugar Clarification systems SEPPELEC Group Sugar Purification Process After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. Sugar is made in the leaves of the sugar cane plant through the natural process of. Sugar Purification Process.

From www.sugarprocesstech.com

What is raw sugar and Raw Sugar Making Process Sugar Purification Process Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. Ix processes in carbohydrate treatment are used. Sugar Purification Process.

From wyomingsugar.com

WyomingSugarProcessFlowDiagram Wyoming Sugar Sugar Purification Process In addition to exploring the history, market, and consumption of sugar, the. Energy from the sun transforms carbon dioxide and water into oxygen and glucose. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or. Sugar Purification Process.

From www.researchgate.net

Schematic for the glucose purification and enzyme recovery using Sugar Purification Process In addition to exploring the history, market, and consumption of sugar, the. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. This month’s processing column continues the theme of “how. Sugar Purification Process.

From www.slideshare.net

Sugar manufacturing process Sugar Purification Process Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining facilities, the transformation into the familiar sweet crystals we use. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Sugar is made in the leaves of the sugar cane. Sugar Purification Process.

From www.bray.com

Sugar Beet Virtual Plant Bray Sugar Purification Process It must undergo purification at a cane sugar refinery before it is safe for human consumption. In addition to exploring the history, market, and consumption of sugar, the. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or. Sugar Purification Process.

From www.researchgate.net

1 Existing sugar process flow diagram Download Scientific Diagram Sugar Purification Process The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous stalks. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining facilities, the transformation into the familiar sweet crystals we use. Throughout the manufacturing process, sugar is tested. Sugar Purification Process.

From www.researchgate.net

Process flow diagram for biohydrogen production from microalgae Sugar Purification Process Energy from the sun transforms carbon dioxide and water into oxygen and glucose. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. It must undergo purification at a cane sugar refinery before it is safe for human consumption. Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis.. Sugar Purification Process.

From www.sugarprocesstech.com

what is refined sugar and Refined sugar making process Sugar Purification Process In addition to exploring the history, market, and consumption of sugar, the. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. Energy from the sun transforms carbon dioxide and water into oxygen. Sugar Purification Process.

From sugar.ca

Purification of Sugar The Canadian Sugar Institute Sugar Purification Process Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. In addition to exploring the history, market, and consumption of sugar, the. It must undergo purification at a cane sugar refinery before it is safe. Sugar Purification Process.

From swtstevia.com

Purification Process SWT STEVIA Sugar Purification Process Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. The first step is to remove the. It must undergo purification at a cane sugar refinery before it is safe for. Sugar Purification Process.

From www.google.com

Patent EP0739424B1 Sugar beet juice purification process Google Patents Sugar Purification Process In addition to exploring the history, market, and consumption of sugar, the. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. Energy from the sun transforms carbon dioxide and water into oxygen and glucose.. Sugar Purification Process.

From www.pinterest.ca

Steps in Cane Sugar Refining and Sugar Beet Processing Sugar beet Sugar Purification Process The first step is to remove the. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. In addition to exploring the history, market, and consumption of sugar, the. The excess energy. Sugar Purification Process.

From www.researchgate.net

Flow chart for the preparation of highpressureprocessed sugarcane Sugar Purification Process Energy from the sun transforms carbon dioxide and water into oxygen and glucose. The first step is to remove the. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining. Sugar Purification Process.

From www.emerson.com

Flow Measurement Optimizes Sugar Purification Process Emerson US Sugar Purification Process Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. In addition to exploring the history, market, and consumption of sugar, the. Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. This month’s processing column continues the theme of “how is it processed?” with. Sugar Purification Process.

From www.researchgate.net

Process flow diagram showing the multiple pathways for fermentation of Sugar Purification Process Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. In addition to exploring the history, market, and consumption of sugar, the. Once sugar cane and. Sugar Purification Process.

From www.czarnikow.com

Sugar Refining Process Czarnikow Sugar Purification Process After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Energy from the sun transforms carbon dioxide and water into oxygen and glucose. It must undergo purification at a cane sugar refinery before it is safe for human consumption. Sugar refining involves purification of sugar to meet food safety. Sugar Purification Process.

From www.sugar.org

Sugar Resources for Educators The Sugar Association Sugar Purification Process This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. In addition to exploring the history, market, and consumption of sugar, the. The first step is to remove the. Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. It must undergo purification at a cane. Sugar Purification Process.

From www.researchgate.net

Flow diagram of new sugar mill and sugar refinery based on the SAT Sugar Purification Process Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. The first step is to. Sugar Purification Process.

From www.sugar.org

What is Refined Sugar? Refining & Processing Sugar Purification Process Energy from the sun transforms carbon dioxide and water into oxygen and glucose. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. Sugar refining involves purification of sugar to meet. Sugar Purification Process.

From www.slideserve.com

PPT “Sugar” PowerPoint Presentation, free download ID6609535 Sugar Purification Process Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper ph balance, temperature, color and consistency. Energy from the sun transforms carbon dioxide and water into oxygen and glucose. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. After sugar beets or sugar cane. Sugar Purification Process.

From grade9sugar.weebly.com

Manufacturing Process Sugar Sugar Purification Process Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. The first step is to remove the. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining. Sugar Purification Process.

From www.researchgate.net

The flowprocess diagram of starch biotransformation into... Download Sugar Purification Process Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. After sugar beets or sugar cane are harvested by farmers, the sugar is processed and refined to ensure consistency and quality. In addition to exploring the history, market, and consumption of sugar, the. Sugar refining involves purification. Sugar Purification Process.

From www.mdpi.com

Water Free FullText Sugarcane Industrial Byproducts as Challenges Sugar Purification Process Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous. Sugar Purification Process.

From www.sunshinesugar.com.au

Sugar Cane Harvesting Paddock to Pack Sunshine Sugar Sugar Purification Process Sugar refining involves purification of sugar to meet food safety requirements and customers’ demand. Energy from the sun transforms carbon dioxide and water into oxygen and glucose. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining facilities, the transformation into the familiar sweet crystals we use. In addition to exploring. Sugar Purification Process.

From www.researchgate.net

A schematic diagram of the two step purification of GOS. The sugar Sugar Purification Process Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. Once sugar cane and sugar beets have completed their journey from the farm to the mill processing or refining facilities, the transformation into the familiar sweet crystals we use. Sugar is made in the leaves of the. Sugar Purification Process.

From www.shrijee.com

Syrup Melt Filtrate Clarification System Shrijee Group Sugar Purification Process This month’s processing column continues the theme of “how is it processed?” with a focus on sugar. Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis. Ix processes in carbohydrate treatment are used for the purification of juices and syrups from cane sugar, beet sugar, and corn starch hydrolysates. Once sugar cane. Sugar Purification Process.

From www.mega.cz

Sugar purification process MEGA Sugar Purification Process In addition to exploring the history, market, and consumption of sugar, the. The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous stalks. Energy from the sun transforms carbon dioxide and water into oxygen and glucose. Sugar refining involves purification of sugar to meet food safety requirements. Sugar Purification Process.