Evaporation Test Boiler . The low water cutoff on the boiler makes certain that the water never drops lower than the. Separately, the first and second low alarms are tested. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Prevent low water conditions in. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge.

from www.slideshare.net

Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Separately, the first and second low alarms are tested. The low water cutoff on the boiler makes certain that the water never drops lower than the. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Prevent low water conditions in. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point.

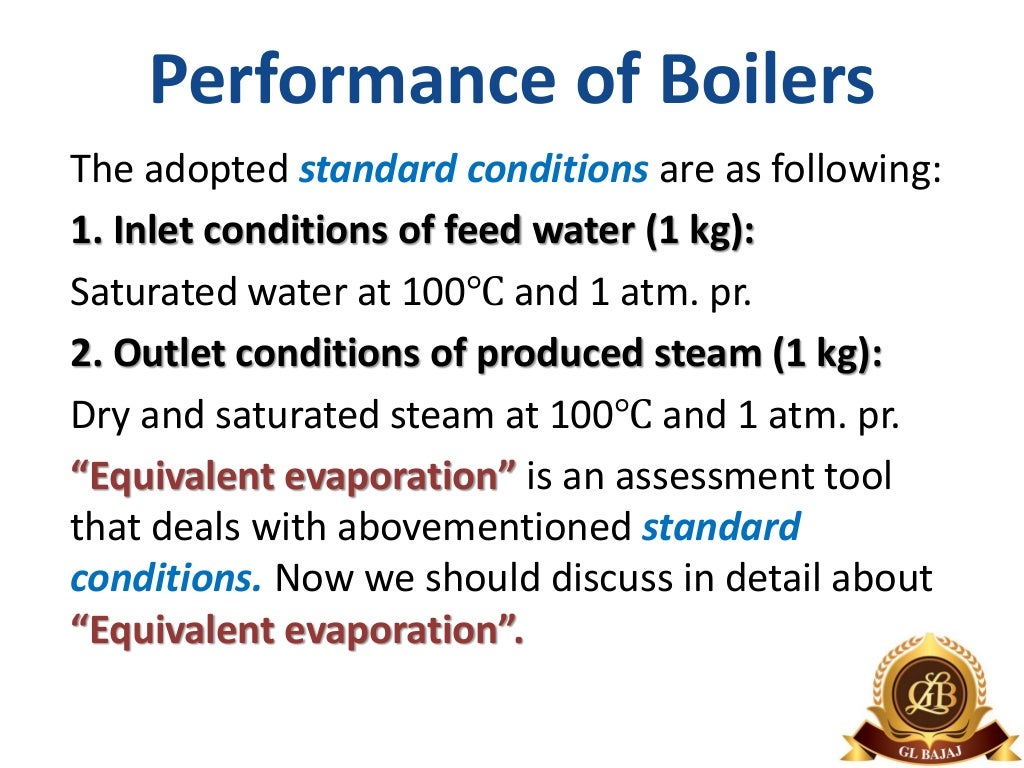

Boiler performance (Part 1) Equivalent evaporation Notes

Evaporation Test Boiler Separately, the first and second low alarms are tested. Separately, the first and second low alarms are tested. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. The low water cutoff on the boiler makes certain that the water never drops lower than the. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Prevent low water conditions in. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge.

From www.studypool.com

SOLUTION Smoke tube boilers tank boiler scotch boiler modern Evaporation Test Boiler Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Prevent low water conditions in. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. The low water cutoff on the boiler makes certain that the water never drops lower than. Evaporation Test Boiler.

From www.slideshare.net

Boiler performance (Part 1) Equivalent evaporation Notes Evaporation Test Boiler Separately, the first and second low alarms are tested. The low water cutoff on the boiler makes certain that the water never drops lower than the. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff. Evaporation Test Boiler.

From www.youtube.com

Find boiler efficiency, find actual evaporation, boiler power Evaporation Test Boiler Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. The low water. Evaporation Test Boiler.

From www.researchgate.net

(a) Schematic of the homemade interfacial evaporation testing system Evaporation Test Boiler Prevent low water conditions in. Separately, the first and second low alarms are tested. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. The low water cutoff on the boiler makes certain that the water never drops lower than the. Conduct an evaporation test on the. Evaporation Test Boiler.

From www.studypool.com

SOLUTION Smoke tube boilers tank boiler scotch boiler modern Evaporation Test Boiler Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Separately, the first and second low alarms are tested. Blow through of the chambers is required, using the sequencing purge. Evaporation Test Boiler.

From www.youtube.com

Performance Analysis of Boilers, Equivalent evaporation, Boiler thermal Evaporation Test Boiler The low water cutoff on the boiler makes certain that the water never drops lower than the. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Low water conditions occur. Evaporation Test Boiler.

From www.slideshare.net

Boiler performance (Part 1) Equivalent evaporation Notes Evaporation Test Boiler The low water cutoff on the boiler makes certain that the water never drops lower than the. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Separately, the first and second low alarms are tested. Low water conditions occur when a boiler is insufficiently replacing the water. Evaporation Test Boiler.

From www.researchgate.net

CarbonZrO2/PDA/PU evaporator in a) evaporation test under different Evaporation Test Boiler The low water cutoff on the boiler makes certain that the water never drops lower than the. Prevent low water conditions in. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated. Evaporation Test Boiler.

From www.youtube.com

Boiler Performance Boiler Efficiency Step by Step Calculations Evaporation Test Boiler Separately, the first and second low alarms are tested. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Conduct an evaporation test on the low water level control(s) to. Evaporation Test Boiler.

From www.labthinkinternational.com

Evaporation Residue Test Labthink Evaporation Test Boiler The low water cutoff on the boiler makes certain that the water never drops lower than the. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Separately, the first and second low alarms are tested. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge.. Evaporation Test Boiler.

From www.slideserve.com

PPT EVAP System testing using a Smoke Machine PowerPoint Presentation Evaporation Test Boiler The low water cutoff on the boiler makes certain that the water never drops lower than the. Separately, the first and second low alarms are tested. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Prevent low water conditions in. Once the boiler reaches 2 to. Evaporation Test Boiler.

From www.youtube.com

Equivalent Evaporation Boiler Efficiency Applied Thermodynamics Evaporation Test Boiler Separately, the first and second low alarms are tested. The low water cutoff on the boiler makes certain that the water never drops lower than the. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate. Evaporation Test Boiler.

From www.youtube.com

How to find out boiler efficiency and equivalent evaporation SPPU Evaporation Test Boiler Prevent low water conditions in. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Separately, the first and second low alarms are tested. Conduct an evaporation test on the. Evaporation Test Boiler.

From steamboilerpitsujiku.blogspot.com

Steam Boiler Steam Boiler Evaporation Rate Evaporation Test Boiler Prevent low water conditions in. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Separately, the first and second low alarms are tested. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Low water conditions occur when a boiler. Evaporation Test Boiler.

From www.studypool.com

SOLUTION Dual pressure double evaporation boilers Studypool Evaporation Test Boiler Separately, the first and second low alarms are tested. The low water cutoff on the boiler makes certain that the water never drops lower than the. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Prevent low water conditions in. Low water conditions occur when a boiler. Evaporation Test Boiler.

From steamboilerpitsujiku.blogspot.com

Steam Boiler Steam Boiler Evaporation Rate Evaporation Test Boiler Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Blow through of the chambers is required, using the sequencing purge valves to remove any. Evaporation Test Boiler.

From www.meoexamnotes.in

Double evaporation boilers Evaporation Test Boiler Prevent low water conditions in. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. The low water cutoff on the boiler makes certain that the water never drops lower than the. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Conduct an evaporation test. Evaporation Test Boiler.

From www.studypool.com

SOLUTION Dual pressure double evaporation boilers Studypool Evaporation Test Boiler The low water cutoff on the boiler makes certain that the water never drops lower than the. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Prevent low water conditions in. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents. Evaporation Test Boiler.

From inproheat.com

Submerged Combustion Evaporation Boiler Systems Inproheat Evaporation Test Boiler Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. The low water cutoff on the boiler makes certain that the water never drops lower than the. Low water conditions occur. Evaporation Test Boiler.

From fluidhandlingpro.com

Best Practice For Evaporation Processes • Fluid Handling Pro Evaporation Test Boiler Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. The low water cutoff on the boiler makes certain that the water never drops lower than the. Separately, the first. Evaporation Test Boiler.

From www.youtube.com

What is the Difference Between Boiling and Evaporation Thermodynamics Evaporation Test Boiler Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. The low water cutoff on the boiler makes certain that the water never drops lower than the. Prevent low water conditions in. Conduct an evaporation test on the low water level control(s) to ensure proper operation and. Evaporation Test Boiler.

From www.youtube.com

boiler performances, Evaporation Rate , Equivalent Evaporation , Boiler Evaporation Test Boiler Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Separately, the first and second low alarms are tested. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Once the boiler reaches 2 to 3 psig on the steam. Evaporation Test Boiler.

From www.youtube.com

Equivalent of Evaporation Boiler Efficiency Boiler Performance Evaporation Test Boiler Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Prevent low water conditions in. Separately, the first and second low alarms are tested. Low water conditions occur when a boiler. Evaporation Test Boiler.

From www.researchgate.net

Schematic diagram of water evaporation test. Download Scientific Diagram Evaporation Test Boiler Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Prevent low water conditions in. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation. Evaporation Test Boiler.

From www.youtube.com

Equivalent Evaporation of Boiler What is Equivalent Evaporation of Evaporation Test Boiler Separately, the first and second low alarms are tested. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. The low water cutoff on the boiler makes certain that the water never drops lower than the.. Evaporation Test Boiler.

From www.intechopen.com

Chromia Evaporation in Advanced UltraSupercritical Steam Boilers and Evaporation Test Boiler Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. The low water cutoff on the boiler makes certain that the water never drops lower than the. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Conduct an evaporation test on the low water level. Evaporation Test Boiler.

From www.chegg.com

Solved During a test on a boiler the following data were Evaporation Test Boiler Separately, the first and second low alarms are tested. Prevent low water conditions in. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. The low water cutoff on the boiler. Evaporation Test Boiler.

From www.youtube.com

Boiler efficiency / Equivalent evaporation YouTube Evaporation Test Boiler Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Separately, the first. Evaporation Test Boiler.

From petroleum-lab-equipment.com

Evaporation Loss Tester Petroleum Laboratory Testing Equipment Evaporation Test Boiler Prevent low water conditions in. The low water cutoff on the boiler makes certain that the water never drops lower than the. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Conduct an evaporation test on the low water level control(s) to ensure proper operation and. Evaporation Test Boiler.

From www.industrial-steamboiler.com

1t/H Rated Evaporation Gas Steam Boiler For Pharmaceutical Textile Industry Evaporation Test Boiler Separately, the first and second low alarms are tested. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. The low water cutoff on the boiler makes certain that the water never drops lower than the. Prevent low water conditions in. Blow through of the chambers is required,. Evaporation Test Boiler.

From steamboilerpitsujiku.blogspot.com

Steam Boiler Steam Boiler Evaporation Rate Evaporation Test Boiler Prevent low water conditions in. Separately, the first and second low alarms are tested. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Once the boiler reaches 2 to 3 psig on the steam gauge, close the vents and drains. Low water conditions occur when a boiler is insufficiently replacing the water. Evaporation Test Boiler.

From www.chegg.com

Solved 4.12. The following data were obtained from a boiler Evaporation Test Boiler Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Separately, the first and second low alarms are tested. Once the boiler reaches 2 to 3 psig on the steam gauge,. Evaporation Test Boiler.

From www.researchgate.net

Detailed diagram of the evaporator (test section) Download Scientific Evaporation Test Boiler Separately, the first and second low alarms are tested. Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Prevent low water conditions in. Once. Evaporation Test Boiler.

From www.slideshare.net

Boiler performance (Part 1) Equivalent evaporation Notes Evaporation Test Boiler The low water cutoff on the boiler makes certain that the water never drops lower than the. Low water conditions occur when a boiler is insufficiently replacing the water to meet the evaporation rate and the control doesn’t respond accordingly. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Separately, the first. Evaporation Test Boiler.

From www.researchgate.net

Photos before and after the preliminary evaporation test Download Evaporation Test Boiler Conduct an evaporation test on the low water level control(s) to ensure proper operation and burner shutoff at the low water point. Separately, the first and second low alarms are tested. Blow through of the chambers is required, using the sequencing purge valves to remove any accumulated sludge. Once the boiler reaches 2 to 3 psig on the steam gauge,. Evaporation Test Boiler.