Etch Semiconductor Process . For example native oxide on polysilicon can be. Deposition, photoresist, lithography, etch, ionization and packaging. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. The process begins with a silicon. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. Let’s discuss six critical semiconductor manufacturing steps: In the semiconductor industry, etching is the process used to remove layers or slices of a material,. An etch system is used in manufacturing lines for semiconductors and.

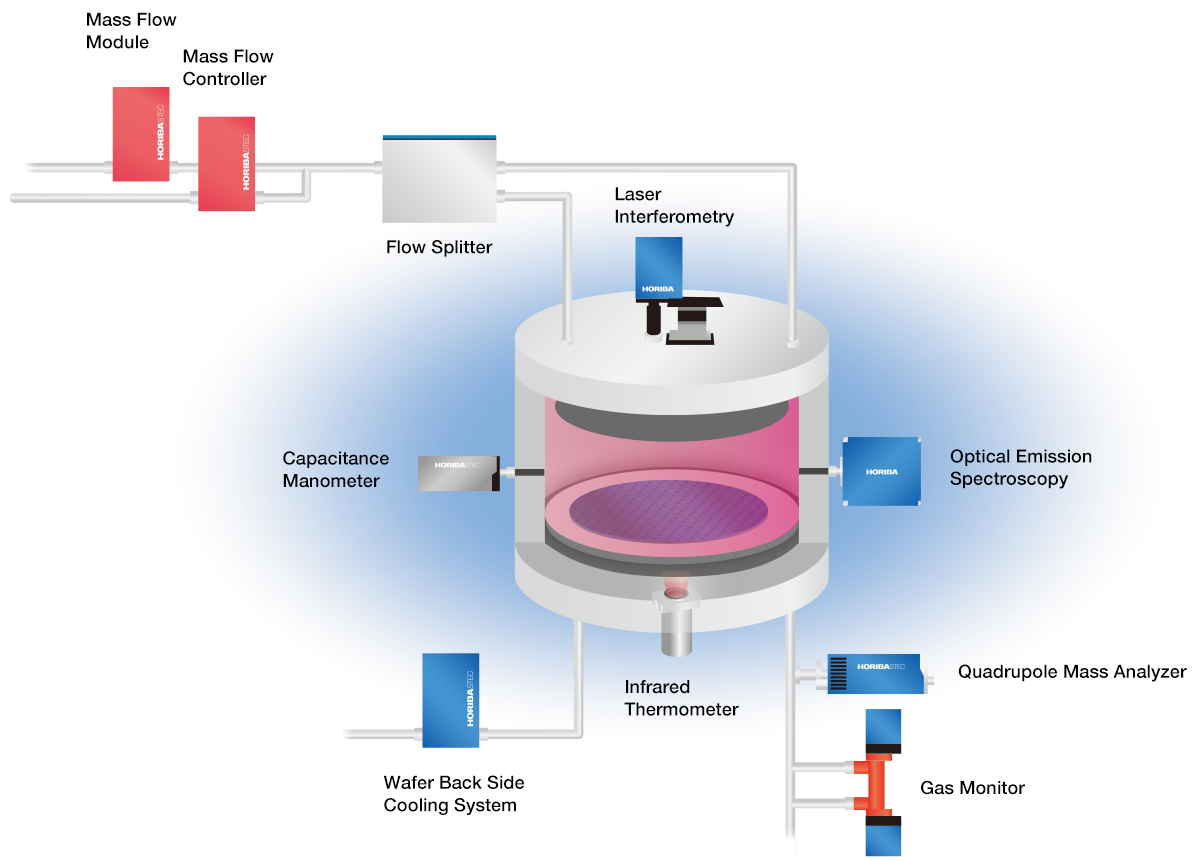

from www.horiba.com

An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. Deposition, photoresist, lithography, etch, ionization and packaging. The process begins with a silicon. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. In the semiconductor industry, etching is the process used to remove layers or slices of a material,. For example native oxide on polysilicon can be. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. Let’s discuss six critical semiconductor manufacturing steps:

Semiconductor Processing Etch

Etch Semiconductor Process Let’s discuss six critical semiconductor manufacturing steps: Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. The process begins with a silicon. For example native oxide on polysilicon can be. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. Deposition, photoresist, lithography, etch, ionization and packaging. An etch system is used in manufacturing lines for semiconductors and. Let’s discuss six critical semiconductor manufacturing steps: An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. In the semiconductor industry, etching is the process used to remove layers or slices of a material,.

From news.skhynix.com

Etching, Process to Complete Semiconductor Patterning 2 SK hynix Etch Semiconductor Process Deposition, photoresist, lithography, etch, ionization and packaging. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. An etch system shapes the thin film into. Etch Semiconductor Process.

From sites.utexas.edu

MetalAssisted Chemical Etching (MacEtch) Etch Semiconductor Process For example native oxide on polysilicon can be. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. The process begins with a silicon. An etch system is used in manufacturing lines. Etch Semiconductor Process.

From news.skhynix.com

Semiconductor FrontEnd Process Episode 6 Metallization Etch Semiconductor Process Let’s discuss six critical semiconductor manufacturing steps: For example native oxide on polysilicon can be. The process begins with a silicon. An etch system is used in manufacturing lines for semiconductors and. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. Deposition, photoresist, lithography, etch, ionization and packaging. An etch system. Etch Semiconductor Process.

From kremesti.com

The Semiconductor Chip Manufacturing Process Etch Semiconductor Process In the semiconductor industry, etching is the process used to remove layers or slices of a material,. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. An etch system is used in manufacturing lines for semiconductors and. Deposition, photoresist, lithography, etch, ionization and packaging.. Etch Semiconductor Process.

From www.semanticscholar.org

Pulsed plasma etching for semiconductor manufacturing Semantic Scholar Etch Semiconductor Process For example native oxide on polysilicon can be. In the semiconductor industry, etching is the process used to remove layers or slices of a material,. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. An etch system is used in manufacturing lines for semiconductors and. Reactive ion etching is currently the. Etch Semiconductor Process.

From pv-manufacturing.org

Etch Semiconductor Process In the semiconductor industry, etching is the process used to remove layers or slices of a material,. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. The process begins with a silicon. For example native oxide on polysilicon can be. Deposition, photoresist, lithography, etch,. Etch Semiconductor Process.

From inquivixtech.com

What Is Dry Etch Semiconductor Processing? Inquivix Technologies Etch Semiconductor Process Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. The process begins with a silicon. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Deposition,. Etch Semiconductor Process.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of Etch Semiconductor Process An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. For example native oxide on polysilicon can be. Etch processes can be devided into wet and dry etching while there is a further separation into. Etch Semiconductor Process.

From engineering.nyu.edu

Researchers find novel way to “EtchaSketch” critical pn nano Etch Semiconductor Process Let’s discuss six critical semiconductor manufacturing steps: The process begins with a silicon. For example native oxide on polysilicon can be. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. An etch process is not limited to one gas,. Etch Semiconductor Process.

From www.coventor.com

A Deposition and Etch Technique to Lower Resistance of Semiconductor Etch Semiconductor Process Let’s discuss six critical semiconductor manufacturing steps: An etch system is used in manufacturing lines for semiconductors and. For example native oxide on polysilicon can be. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. In the semiconductor industry, etching is the process used. Etch Semiconductor Process.

From www.horiba.com

Semiconductor Processing Etch Etch Semiconductor Process Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. The process begins with a silicon. In the semiconductor industry, etching is the process used to remove layers or slices of a material,. For example native oxide on polysilicon can. Etch Semiconductor Process.

From www.elaboreluxury.com

Wet PCB Etching Using Acidic Alkaline Sierra Circuits, 59 OFF Etch Semiconductor Process For example native oxide on polysilicon can be. Let’s discuss six critical semiconductor manufacturing steps: In the semiconductor industry, etching is the process used to remove layers or slices of a material,. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. Etch processes can be devided into wet and dry etching while there is. Etch Semiconductor Process.

From www.thierry-corp.com

Reactive Ion Etching Thierry Corporation Etch Semiconductor Process For example native oxide on polysilicon can be. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. The process begins with a silicon. Let’s discuss six critical semiconductor manufacturing steps: An etch process is not limited to one gas,. Etch Semiconductor Process.

From www.youtube.com

Etching Process in semiconductor manufacturing! YouTube Etch Semiconductor Process The process begins with a silicon. Let’s discuss six critical semiconductor manufacturing steps: In the semiconductor industry, etching is the process used to remove layers or slices of a material,. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. Deposition, photoresist, lithography, etch, ionization and packaging. Describes the types and plasma generation mechanism of. Etch Semiconductor Process.

From www.coventor.com

A Deposition and Etch Technique to Lower Resistance of Semiconductor Etch Semiconductor Process An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. An etch system is used in manufacturing lines for semiconductors and. The process begins with a silicon. For example native oxide on polysilicon can be. Deposition, photoresist, lithography, etch, ionization and packaging. Describes the types and plasma generation mechanism of etching equipment. Etch Semiconductor Process.

From www.samco.co.jp

Compound Semiconductor Etching|Samco Inc. Etch Semiconductor Process The process begins with a silicon. Let’s discuss six critical semiconductor manufacturing steps: An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. For example native oxide on polysilicon can be. An etch system is used in manufacturing lines for semiconductors and. An etch system shapes the thin film into a desired. Etch Semiconductor Process.

From www.cambridge.org

Photoelectrochemical etch enables damagefree device fabrication Etch Semiconductor Process Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. An etch system is used in manufacturing lines for semiconductors and. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. For example native oxide on polysilicon can be. Describes the types and plasma generation mechanism of. Etch Semiconductor Process.

From www.eurotherm.com

Semiconductor Fabrication Dry Etch Processing Solution Eurotherm Etch Semiconductor Process In the semiconductor industry, etching is the process used to remove layers or slices of a material,. An etch system is used in manufacturing lines for semiconductors and. The process begins with a silicon. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. Reactive ion etching is currently the most widely. Etch Semiconductor Process.

From news.skhynix.com

Semiconductor FrontEnd Process Episode 4 Etching Etch Semiconductor Process Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. In the semiconductor industry, etching is the process used to remove layers or slices of a material,. For example native oxide on polysilicon can be.. Etch Semiconductor Process.

From www.tofwerk.com

Sensitive, RealTime Monitoring of Etch Processes with Semicon Process Etch Semiconductor Process Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six. Etch Semiconductor Process.

From www.samcointl.com

Compound Semiconductor Etching Samco Inc. Etch Semiconductor Process An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. In the semiconductor industry, etching is the process used to remove layers or slices of a material,. Let’s discuss six critical semiconductor manufacturing steps: Etch. Etch Semiconductor Process.

From www.researchgate.net

A schematic illustration of plasma etching process and multiwavelength Etch Semiconductor Process Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction.. Etch Semiconductor Process.

From www.samcointl.com

What is the Bosch Process (Deep Reactive Ion Etching)? Samco Inc. Etch Semiconductor Process An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch system is used in manufacturing lines for semiconductors and. Let’s discuss six critical semiconductor manufacturing steps: The process begins with a silicon. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor. Etch Semiconductor Process.

From www.researchgate.net

1 Semiconductor etching process of surface micromachine [2.1 Etch Semiconductor Process Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. In the semiconductor industry, etching is the process used to remove layers or slices of a material,. For example native oxide on polysilicon can be. Etch processes can be devided into wet and dry etching. Etch Semiconductor Process.

From spie.org

Plasma etch challenges for nextgeneration semiconductor manufacturing Etch Semiconductor Process In the semiconductor industry, etching is the process used to remove layers or slices of a material,. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters.. Etch Semiconductor Process.

From www.mdpi.com

Applied Sciences Free FullText Factor Design for the Oxide Etching Etch Semiconductor Process Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. For example native oxide on polysilicon can be. In the semiconductor industry, etching is the process used to remove layers or slices of a material,. An etch system shapes the. Etch Semiconductor Process.

From www.led-professional.com

New Developed Technique Makes it Easier To Etch Semiconductors Etch Semiconductor Process Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. An etch system is used in manufacturing lines for semiconductors and. Deposition, photoresist, lithography, etch, ionization and packaging. For example native oxide on polysilicon can be. Etch processes can be devided into wet and dry. Etch Semiconductor Process.

From www.protoexpress.com

Wet PCB Etching Using Acidic & Alkaline Sierra Circuits Etch Semiconductor Process Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. The process begins with a silicon. Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: An etch system is used in manufacturing lines for semiconductors. Etch Semiconductor Process.

From www.electronicsandyou.com

waferetchingprocess Electronics Tutorial The Best Electronics Etch Semiconductor Process Let’s discuss six critical semiconductor manufacturing steps: An etch system is used in manufacturing lines for semiconductors and. For example native oxide on polysilicon can be. An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Describes the types and plasma generation mechanism of etching equipment which are actually used. Etch Semiconductor Process.

From www.samco.co.jp

Compound Semiconductor Etching|Samco Inc. Etch Semiconductor Process Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. The process begins with a silicon. Let’s discuss six critical semiconductor manufacturing steps: An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or. Etch Semiconductor Process.

From mavink.com

Semiconductor Process Steps Etch Semiconductor Process An etch system is used in manufacturing lines for semiconductors and. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. In the semiconductor industry,. Etch Semiconductor Process.

From news.skhynix.com

Etching, Process to Complete Semiconductor Patterning 2 SK hynix Etch Semiconductor Process Deposition, photoresist, lithography, etch, ionization and packaging. Reactive ion etching is currently the most widely used dry etching process in semiconductor technology. Describes the types and plasma generation mechanism of etching equipment which are actually used in semiconductor fabs, such as ccp (capacitively coupled plasma), magnetron rie. The process begins with a silicon. An etch process is not limited to. Etch Semiconductor Process.

From www.youtube.com

Semiconductor MultiZone Etch System Machine Control YouTube Etch Semiconductor Process Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and packaging. The process begins with a silicon. An etch system is used in manufacturing lines for semiconductors. Etch Semiconductor Process.

From www.researchgate.net

Schema of the fabrication process followed for the etching of thin Etch Semiconductor Process The process begins with a silicon. An etch process is not limited to one gas, a mixture of gases or to fixed process parameters. Deposition, photoresist, lithography, etch, ionization and packaging. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical. Etch Semiconductor Process.

From www.researchgate.net

Schematic diagram of the semiconductor etch equipment used in this Etch Semiconductor Process An etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. Etch processes can be devided into wet and dry etching while there is a further separation into isotropic and anisotropic processes and also a separation in chemical and physical etch. In the semiconductor industry, etching is the process used to. Etch Semiconductor Process.