How To Set Drive Roller Tension . • releasing all tension on the drive rolls first. Mig welder troubleshooting and how to set drive roll tension. • taking the wire between your thumb and. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Setting the tension correctly involves: Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. Correct drive roll size and type: Also, they offer a knurled drive roll for use with flux core wire. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. The instructions seem pretty clear about how to set up tension. In this video i demonstrate how to. To set the proper tension, begin by releasing all tension on the drive rolls.

from www.youtube.com

To set the proper tension, begin by releasing all tension on the drive rolls. • releasing all tension on the drive rolls first. Correct drive roll size and type: Setting the tension correctly involves: Also, they offer a knurled drive roll for use with flux core wire. In this video i demonstrate how to. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. The instructions seem pretty clear about how to set up tension.

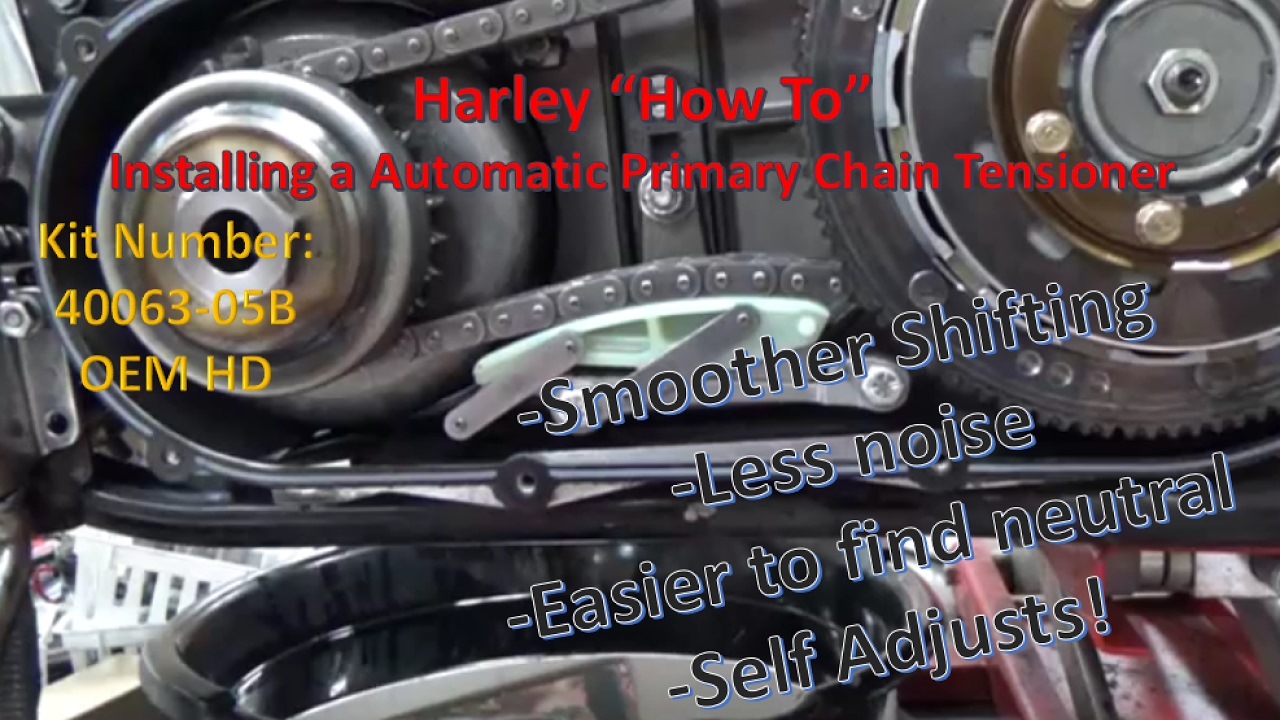

How to Install a Harley Davidson Automatic Primary Chain Tensioner Kit

How To Set Drive Roller Tension To set the proper tension, begin by releasing all tension on the drive rolls. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. • releasing all tension on the drive rolls first. The instructions seem pretty clear about how to set up tension. Also, they offer a knurled drive roll for use with flux core wire. To set the proper tension, begin by releasing all tension on the drive rolls. Mig welder troubleshooting and how to set drive roll tension. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Setting the tension correctly involves: • taking the wire between your thumb and. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. In this video i demonstrate how to. Correct drive roll size and type:

From www.roll-ring.com

Installation Chain Tensioner Chain Drive How To Set Drive Roller Tension To set the proper tension, begin by releasing all tension on the drive rolls. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. In this video i demonstrate how to. Setting the tension correctly involves: • taking the wire between your thumb and. Ensure the drive roll tension is not. How To Set Drive Roller Tension.

From www.alamy.com

Belt transmission mechanism with two pulleys drive part automobile How To Set Drive Roller Tension Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. • releasing all tension on the drive rolls first. In this video i demonstrate how to. To set the proper tension, begin by releasing all tension on the drive rolls. Also, they offer a knurled drive roll for use with flux. How To Set Drive Roller Tension.

From www.youtube.com

How to Check if your VBelt is Properly Tensioned YouTube How To Set Drive Roller Tension Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. To set the proper tension, begin by releasing all tension on the drive rolls. Correct drive roll size and type: Mig welder troubleshooting and how to set drive roll tension. Then increase the tension while feeding the wire into a block. How To Set Drive Roller Tension.

From www.youtube.com

The Mechanics of Tension Control YouTube How To Set Drive Roller Tension Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. In this video i demonstrate how to. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. Mig welder troubleshooting and how to set drive roll tension. Ben romenesko, product manager at. How To Set Drive Roller Tension.

From www.eng-tips.com

Conveyor Belt Tension with Sliding Rollers Gear & Pulley engineering How To Set Drive Roller Tension To set the proper tension, begin by releasing all tension on the drive rolls. In this video i demonstrate how to. • taking the wire between your thumb and. • releasing all tension on the drive rolls first. Mig welder troubleshooting and how to set drive roll tension. Setting the tension correctly involves: The instructions seem pretty clear about how. How To Set Drive Roller Tension.

From weldingmachinery.ie

MIG Drive roller tension what it does and how to set it correctly How To Set Drive Roller Tension In this video i demonstrate how to. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. • taking the wire between your thumb and. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. To set the proper tension, begin by releasing. How To Set Drive Roller Tension.

From www.pinterest.com.mx

How to do a rollerset You need to apply great tension. A great hair How To Set Drive Roller Tension Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Setting the tension correctly involves: Mig welder troubleshooting and how to set drive roll tension. Ben romenesko, product manager at miller, explains. How To Set Drive Roller Tension.

From www.youtube.com

How to Install a Harley Davidson Automatic Primary Chain Tensioner Kit How To Set Drive Roller Tension To set the proper tension, begin by releasing all tension on the drive rolls. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. • taking the wire between your thumb and. In this video i demonstrate how to. The instructions seem pretty clear about how to set up tension.. How To Set Drive Roller Tension.

From fyowayltb.blob.core.windows.net

Drive Chain Tension Guide at Cleo Ellis blog How To Set Drive Roller Tension Mig welder troubleshooting and how to set drive roll tension. To set the proper tension, begin by releasing all tension on the drive rolls. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. Also, they offer a knurled drive roll for use with flux core wire. Ensure the drive. How To Set Drive Roller Tension.

From www.bearingsrus.co.uk

R38 Dunlop Tensioner Roller for Belt Drives How To Set Drive Roller Tension Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. • taking the wire between your thumb and. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll. How To Set Drive Roller Tension.

From www.youtube.com

HVAC Belt Tension YouTube How To Set Drive Roller Tension Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. • releasing all tension on the drive rolls first. Setting the tension correctly involves: Mig welder troubleshooting and how to set drive roll tension. In this video i demonstrate how to. Correct drive roll size and type: The instructions seem pretty. How To Set Drive Roller Tension.

From www.colliermiller.com.au

TENSIONING ROLLER 30MM Collier & Miller How To Set Drive Roller Tension To set the proper tension, begin by releasing all tension on the drive rolls. Mig welder troubleshooting and how to set drive roll tension. • taking the wire between your thumb and. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. Setting the tension correctly involves: Correct drive roll. How To Set Drive Roller Tension.

From www.youtube.com

Adjusting the Rear Roller Drive Belt tension on an Allett Liberty 43 How To Set Drive Roller Tension In this video i demonstrate how to. Setting the tension correctly involves: Correct drive roll size and type: Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. To set the proper tension, begin by releasing all tension on the drive rolls. Ben romenesko, product manager at miller, explains how. How To Set Drive Roller Tension.

From baartgroup.com

How to Extend the Life of Roller Chain Drives Baart Industrial Group How To Set Drive Roller Tension • taking the wire between your thumb and. Also, they offer a knurled drive roll for use with flux core wire. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. The instructions seem pretty clear about how to set up tension. Mig welder troubleshooting and how to set drive roll tension.. How To Set Drive Roller Tension.

From www.mig-welding.co.uk

Installing MIG Wire and Setting Wire Feed Tension How To Set Drive Roller Tension • taking the wire between your thumb and. • releasing all tension on the drive rolls first. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. Also, they offer a knurled drive roll for use with flux core wire. Then increase the tension while feeding the wire into a block. How To Set Drive Roller Tension.

From www.mig-welding.co.uk

Installing MIG Wire and Setting Wire Feed Tension How To Set Drive Roller Tension • releasing all tension on the drive rolls first. In this video i demonstrate how to. Correct drive roll size and type: • taking the wire between your thumb and. Mig welder troubleshooting and how to set drive roll tension. Also, they offer a knurled drive roll for use with flux core wire. Ensure the drive roll tension is not. How To Set Drive Roller Tension.

From webshop.packtti.com

Tension roller assembly curved Shop PackTTI How To Set Drive Roller Tension Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. • taking the wire between your thumb and. Correct drive roll size and type: Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. Ensure the drive roll tension is not. How To Set Drive Roller Tension.

From www.grainger.com

B/A PRODUCTS CO. Cable Tensioner Roller Guide, For Use With 10 to 14 in How To Set Drive Roller Tension In this video i demonstrate how to. • releasing all tension on the drive rolls first. Correct drive roll size and type: Mig welder troubleshooting and how to set drive roll tension. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. The instructions seem pretty clear about how to. How To Set Drive Roller Tension.

From www.youtube.com

LEWCO Conveyor Belt Tension and Tracking YouTube How To Set Drive Roller Tension The instructions seem pretty clear about how to set up tension. Correct drive roll size and type: • taking the wire between your thumb and. Setting the tension correctly involves: Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Also, they offer a knurled drive roll for use with flux core. How To Set Drive Roller Tension.

From www.crownparts.pk

ROLLER TENSIONER SET CROWN PARTS How To Set Drive Roller Tension Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. • taking the wire between your thumb and. The instructions seem pretty clear about how to set up tension. Correct drive roll size and type: Also, they offer a knurled drive roll for use with flux core wire. • releasing all. How To Set Drive Roller Tension.

From www.aliexpress.com

Drive Chain Roller Tensioner Bike Pulley Wheel Slider Guide For Street How To Set Drive Roller Tension Also, they offer a knurled drive roll for use with flux core wire. The instructions seem pretty clear about how to set up tension. Mig welder troubleshooting and how to set drive roll tension. • releasing all tension on the drive rolls first. • taking the wire between your thumb and. In this video i demonstrate how to. Setting the. How To Set Drive Roller Tension.

From www.chiefdelphi.com

How to design efficient Tensioners for long or irregular Belt, Chain How To Set Drive Roller Tension Also, they offer a knurled drive roll for use with flux core wire. • taking the wire between your thumb and. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Mig welder troubleshooting and how to set drive roll tension. To set the proper tension, begin by releasing all tension on. How To Set Drive Roller Tension.

From www.youtube.com

SureShade ATF Adding Tension to Roller Instructions YouTube How To Set Drive Roller Tension • releasing all tension on the drive rolls first. To set the proper tension, begin by releasing all tension on the drive rolls. • taking the wire between your thumb and. The instructions seem pretty clear about how to set up tension. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension. How To Set Drive Roller Tension.

From baartgroup.com

Roller Chain Climbing Sprockets? Causes and Solutions Baart Group How To Set Drive Roller Tension • taking the wire between your thumb and. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. In this video i demonstrate how to. Correct drive roll size and type: Then increase. How To Set Drive Roller Tension.

From www.youtube.com

Design & Solve How to Properly Tension Chain Drives YouTube How To Set Drive Roller Tension The instructions seem pretty clear about how to set up tension. • taking the wire between your thumb and. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. Correct drive roll size. How To Set Drive Roller Tension.

From grabcad.com

Tension roller 3D CAD Model Library GrabCAD How To Set Drive Roller Tension Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. Correct drive roll size and type: In this video i demonstrate how to. • taking the wire between your thumb and. • releasing all tension on the drive rolls first. Then increase the tension while feeding the wire into a block. How To Set Drive Roller Tension.

From www.vrogue.co

All About Roller Conveyors Types Design And Uses vrogue.co How To Set Drive Roller Tension Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Mig welder troubleshooting and how to set drive roll tension. Setting the tension correctly involves: Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. The instructions seem pretty clear about how to. How To Set Drive Roller Tension.

From www.transdev.co.uk

Tension Rollers TransDev How To Set Drive Roller Tension In this video i demonstrate how to. Also, they offer a knurled drive roll for use with flux core wire. The instructions seem pretty clear about how to set up tension. Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. To set the proper tension, begin by releasing all tension. How To Set Drive Roller Tension.

From www.pelicanparts.com

Porsche Drive Belt Tension Roller Hamburg Technic 99610211757 996 102 How To Set Drive Roller Tension Correct drive roll size and type: Setting the tension correctly involves: Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. Also, they offer a knurled drive roll for use with flux core wire. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate. How To Set Drive Roller Tension.

From www.youtube.com

How to Retension Cordless Spring Roller Shades YouTube How To Set Drive Roller Tension Also, they offer a knurled drive roll for use with flux core wire. In this video i demonstrate how to. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. • taking the wire between your thumb and. Setting the tension correctly involves: Ben romenesko, product manager at miller, explains how to. How To Set Drive Roller Tension.

From www.alamy.com

Belt transmission mechanism with three pulleys drive part automobile How To Set Drive Roller Tension Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. To set the proper tension, begin by releasing all tension on the drive rolls. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. Setting the tension correctly involves: Mig welder troubleshooting and. How To Set Drive Roller Tension.

From www.slideshare.net

tension control loadcells vs. dancer rollers How To Set Drive Roller Tension The instructions seem pretty clear about how to set up tension. Also, they offer a knurled drive roll for use with flux core wire. • taking the wire between your thumb and. Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. • releasing all tension on the drive rolls first. Correct. How To Set Drive Roller Tension.

From www.parktool.com

BDT2 Belt Drive Tension and Alignment Tool Park Tool How To Set Drive Roller Tension In this video i demonstrate how to. Correct drive roll size and type: Mig welder troubleshooting and how to set drive roll tension. Setting the tension correctly involves: Also, they offer a knurled drive roll for use with flux core wire. • releasing all tension on the drive rolls first. Ensure the drive roll tension is not too tight or. How To Set Drive Roller Tension.

From www.linearmotiontips.com

How to measue synchronous (toothed) belt tension How To Set Drive Roller Tension Ben romenesko, product manager at miller, explains how to properly adjust your drive roll tension to ensure consistent wire. Then increase the tension while feeding the wire into a block of wood, continuing to increase the tension one half. In this video i demonstrate how to. The instructions seem pretty clear about how to set up tension. To set the. How To Set Drive Roller Tension.

From baartgroup.com

How to Extend the Life of Roller Chain Drives Baart Industrial Group How To Set Drive Roller Tension Ensure the drive roll tension is not too tight or loose, adjusting the spring pressure to appropriate levels. • releasing all tension on the drive rolls first. Mig welder troubleshooting and how to set drive roll tension. To set the proper tension, begin by releasing all tension on the drive rolls. Setting the tension correctly involves: Correct drive roll size. How To Set Drive Roller Tension.