Semiconductor Wafer Production . semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. Deposition, photoresist, lithography, etch, ionization and packaging. Started out with the semiconductor industry and eventually. Silicon valley in the u.s. let’s discuss six critical semiconductor manufacturing steps: Abrasive chemicals and machines polish the uneven surface of the wafer for a. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. most wafers are made of silicon extracted from sand.

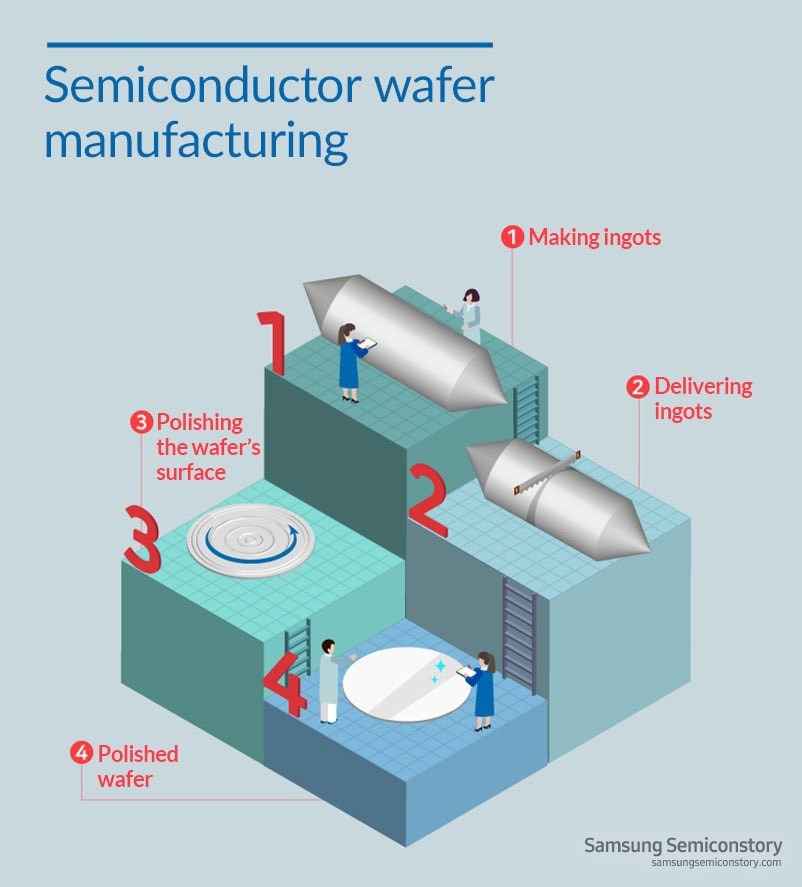

from semiconductor.samsung.com

most wafers are made of silicon extracted from sand. Deposition, photoresist, lithography, etch, ionization and packaging. Abrasive chemicals and machines polish the uneven surface of the wafer for a. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. Started out with the semiconductor industry and eventually. Silicon valley in the u.s. let’s discuss six critical semiconductor manufacturing steps: In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon.

Creating the wafer Samsung Semiconductor USA

Semiconductor Wafer Production In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. Abrasive chemicals and machines polish the uneven surface of the wafer for a. most wafers are made of silicon extracted from sand. Deposition, photoresist, lithography, etch, ionization and packaging. Silicon valley in the u.s. Started out with the semiconductor industry and eventually. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. let’s discuss six critical semiconductor manufacturing steps:

From hayden-bogspotcarrillo.blogspot.com

Wafer Fabrication Process Flow Semiconductor Wafer Production In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. let’s discuss six critical semiconductor manufacturing steps: most wafers are made of silicon extracted from sand. Abrasive chemicals and machines polish the uneven surface of the wafer for a. Started out with the semiconductor industry and eventually.. Semiconductor Wafer Production.

From ar.inspiredpencil.com

Semiconductor Wafer Fabrication Semiconductor Wafer Production the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. Silicon valley in the u.s. Deposition, photoresist, lithography, etch, ionization and packaging. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. Started out with the semiconductor industry and eventually. let’s discuss six critical. Semiconductor Wafer Production.

From ar.inspiredpencil.com

Semiconductor Wafer Fabrication Semiconductor Wafer Production let’s discuss six critical semiconductor manufacturing steps: most wafers are made of silicon extracted from sand. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. Silicon valley in the u.s. Abrasive chemicals and machines polish the uneven surface of the wafer for. Semiconductor Wafer Production.

From mavink.com

Silicon Wafer Fabrication Process Semiconductor Wafer Production In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. Abrasive chemicals and machines polish the uneven surface of the wafer for a. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. let’s discuss six critical semiconductor manufacturing steps: most wafers are. Semiconductor Wafer Production.

From mungfali.com

Wafer Fabrication Process Flow Semiconductor Wafer Production most wafers are made of silicon extracted from sand. Abrasive chemicals and machines polish the uneven surface of the wafer for a. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. Deposition, photoresist, lithography, etch, ionization and packaging. Silicon valley in the u.s.. Semiconductor Wafer Production.

From www.slideserve.com

PPT IC Fabrication Overview Procedure of Silicon Wafer Production Semiconductor Wafer Production Abrasive chemicals and machines polish the uneven surface of the wafer for a. Started out with the semiconductor industry and eventually. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,.. Semiconductor Wafer Production.

From mungfali.com

Semiconductor Production Process Semiconductor Wafer Production most wafers are made of silicon extracted from sand. let’s discuss six critical semiconductor manufacturing steps: Abrasive chemicals and machines polish the uneven surface of the wafer for a. Silicon valley in the u.s. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. In the manufacturing process of ic, electronic circuits with components. Semiconductor Wafer Production.

From stock.adobe.com

Inside Bright Advanced Semiconductor Production Fab Cleanroom with Semiconductor Wafer Production Deposition, photoresist, lithography, etch, ionization and packaging. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. Silicon valley in the u.s. Started out with the semiconductor industry and eventually. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. In. Semiconductor Wafer Production.

From www.waferworld.com

Die Preparation Process Essential Guide Semiconductor Wafer Production In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. Abrasive chemicals and machines polish the uneven surface of the wafer for a. Silicon valley in the u.s. Started out with the semiconductor industry and eventually. semiconductor device manufacturing has since spread from texas and california in the. Semiconductor Wafer Production.

From www.wevolver.com

Wafer Thinning Investigating an essential part of semiconductor Semiconductor Wafer Production Silicon valley in the u.s. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. most wafers are made of silicon extracted from sand. Deposition, photoresist, lithography, etch, ionization and packaging. Started out with the semiconductor industry and eventually. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on. Semiconductor Wafer Production.

From mungfali.com

Semiconductor Wafer Sizes Semiconductor Wafer Production let’s discuss six critical semiconductor manufacturing steps: Started out with the semiconductor industry and eventually. most wafers are made of silicon extracted from sand. Abrasive chemicals and machines polish the uneven surface of the wafer for a. Silicon valley in the u.s. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. semiconductor. Semiconductor Wafer Production.

From www.chetanpatil.in

The Evolving Semiconductor Wafer Size chetanpatil Chetan Arvind Patil Semiconductor Wafer Production Deposition, photoresist, lithography, etch, ionization and packaging. Abrasive chemicals and machines polish the uneven surface of the wafer for a. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the. Semiconductor Wafer Production.

From jahaemmahughes.blogspot.com

Wafer Fabrication Process Flow Emma Hughes Semiconductor Wafer Production most wafers are made of silicon extracted from sand. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. Deposition, photoresist, lithography, etch, ionization and packaging. let’s discuss six critical semiconductor manufacturing steps: In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon.. Semiconductor Wafer Production.

From mungfali.com

Semiconductor Wafer Fabrication Semiconductor Wafer Production the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. most wafers are made of silicon extracted from sand. let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and packaging. Silicon valley in the u.s. Abrasive chemicals and machines polish the uneven surface of the wafer for a. semiconductor device. Semiconductor Wafer Production.

From semiconductor.samsung.com

Creating the wafer Samsung Semiconductor USA Semiconductor Wafer Production In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. Silicon valley in the u.s. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. Started out with the semiconductor industry and eventually. Abrasive chemicals and machines polish the uneven surface of the wafer for. Semiconductor Wafer Production.

From www.piezosystem.com

Piezo Solutions for Semiconductor Wafer Production Piezosystem Semiconductor Wafer Production In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the.. Semiconductor Wafer Production.

From mungfali.com

Wafer Fabrication Process Flow Semiconductor Wafer Production Deposition, photoresist, lithography, etch, ionization and packaging. Abrasive chemicals and machines polish the uneven surface of the wafer for a. Started out with the semiconductor industry and eventually. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of. Semiconductor Wafer Production.

From www.electronicsandyou.com

waferetchingprocess Electronics Tutorial The Best Electronics Semiconductor Wafer Production Started out with the semiconductor industry and eventually. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. Deposition, photoresist, lithography, etch, ionization and packaging. Silicon valley in the u.s. most wafers are made of silicon extracted from sand. let’s discuss six critical semiconductor manufacturing steps: . Semiconductor Wafer Production.

From www.missouripartnership.com

Global Leaders in Advanced Manufacturing Partner to Expand Semiconductor Wafer Production In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and. Semiconductor Wafer Production.

From mungfali.com

Wafer Fabrication Process Flow Chart Semiconductor Wafer Production let’s discuss six critical semiconductor manufacturing steps: most wafers are made of silicon extracted from sand. Silicon valley in the u.s. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. In the manufacturing process of ic, electronic circuits with components such as. Semiconductor Wafer Production.

From www.sputtertargets.net

How is the Semiconductor Wafer Manufactured? (With Infographic) Semiconductor Wafer Production Started out with the semiconductor industry and eventually. Deposition, photoresist, lithography, etch, ionization and packaging. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a. Semiconductor Wafer Production.

From www.okmetic.com

Silicon wafer manufacturing Okmetic Semiconductor Wafer Production most wafers are made of silicon extracted from sand. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. Deposition, photoresist, lithography, etch, ionization and packaging. Started out with the semiconductor industry and eventually. Silicon valley in the u.s. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on. Semiconductor Wafer Production.

From recipepes.com

semiconductor wafer fabrication Semiconductor Wafer Production most wafers are made of silicon extracted from sand. Silicon valley in the u.s. Started out with the semiconductor industry and eventually. Abrasive chemicals and machines polish the uneven surface of the wafer for a. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. let’s discuss six critical semiconductor manufacturing steps: semiconductor. Semiconductor Wafer Production.

From sklep.foteks.pl

Naklejka Silicon Wafer during Photolithography Process inside Complex Semiconductor Wafer Production the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. Deposition, photoresist, lithography, etch, ionization and packaging. Started out with the semiconductor industry and eventually. Silicon valley in the u.s. . Semiconductor Wafer Production.

From ar.inspiredpencil.com

Semiconductor Wafer Fabrication Semiconductor Wafer Production Silicon valley in the u.s. let’s discuss six critical semiconductor manufacturing steps: most wafers are made of silicon extracted from sand. Abrasive chemicals and machines polish the uneven surface of the wafer for a. Deposition, photoresist, lithography, etch, ionization and packaging. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. In the manufacturing. Semiconductor Wafer Production.

From www.wevolver.com

Wafer Thinning Investigating an essential part of semiconductor Semiconductor Wafer Production Abrasive chemicals and machines polish the uneven surface of the wafer for a. let’s discuss six critical semiconductor manufacturing steps: the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. Started out with the semiconductor industry and eventually. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest. Semiconductor Wafer Production.

From proper-cooking.info

Semiconductor Wafer Fabrication Semiconductor Wafer Production Silicon valley in the u.s. Deposition, photoresist, lithography, etch, ionization and packaging. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. most wafers are made of silicon extracted from sand. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and. Semiconductor Wafer Production.

From melissaexhartman.blogspot.com

Wafer Fabrication Process Flow MelissaexHartman Semiconductor Wafer Production Started out with the semiconductor industry and eventually. Abrasive chemicals and machines polish the uneven surface of the wafer for a. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. Deposition, photoresist, lithography, etch, ionization and packaging. most wafers are made of silicon. Semiconductor Wafer Production.

From news.samsung.com

Eight Major Steps to Semiconductor Fabrication, Part 1 Creating the Semiconductor Wafer Production Started out with the semiconductor industry and eventually. Silicon valley in the u.s. let’s discuss six critical semiconductor manufacturing steps: most wafers are made of silicon extracted from sand. Abrasive chemicals and machines polish the uneven surface of the wafer for a. the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition,. In the. Semiconductor Wafer Production.

From suireng.ie

Semiconductor Wafer Fabrication Facility Suir Engineering Semiconductor Wafer Production Started out with the semiconductor industry and eventually. Silicon valley in the u.s. let’s discuss six critical semiconductor manufacturing steps: most wafers are made of silicon extracted from sand. Deposition, photoresist, lithography, etch, ionization and packaging. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia,. Semiconductor Wafer Production.

From www.michigansthumb.com

New semiconductor wafer manufacturing, research facility coming to Bay City Semiconductor Wafer Production Silicon valley in the u.s. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. most wafers are made of silicon extracted from sand. Deposition, photoresist, lithography, etch, ionization and packaging. In the manufacturing process of ic, electronic circuits with components such as transistors. Semiconductor Wafer Production.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Semiconductor Wafer Production Silicon valley in the u.s. Started out with the semiconductor industry and eventually. Deposition, photoresist, lithography, etch, ionization and packaging. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. most wafers are made of silicon extracted from sand. Abrasive chemicals and machines polish. Semiconductor Wafer Production.

From www.electronicsandyou.com

Top Silicon Wafer Manufacturing Companies in the World Semiconductor Wafer Production Started out with the semiconductor industry and eventually. semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of the world, including asia, europe, and the. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. Deposition, photoresist, lithography, etch, ionization and. Semiconductor Wafer Production.

From mavink.com

Silicon Wafer Processing Steps Semiconductor Wafer Production Abrasive chemicals and machines polish the uneven surface of the wafer for a. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. let’s discuss six critical semiconductor manufacturing steps: semiconductor device manufacturing has since spread from texas and california in the 1960s to the rest of. Semiconductor Wafer Production.

From img.tweakpc.de

Tsmc wafer semiconductor chip 300mm fab 4 TweakPC.de Semiconductor Wafer Production Deposition, photoresist, lithography, etch, ionization and packaging. Silicon valley in the u.s. most wafers are made of silicon extracted from sand. Abrasive chemicals and machines polish the uneven surface of the wafer for a. In the manufacturing process of ic, electronic circuits with components such as transistors are formed on the surface of a silicon. semiconductor device manufacturing. Semiconductor Wafer Production.