Abrasive Wheel Making Process . In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding wheels, regardless of their manufacturer, are made up of three main components: These particles may be in bonded wheels, coated belts, or simply loose. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics.

from www.iqsdirectory.com

Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. These particles may be in bonded wheels, coated belts, or simply loose.

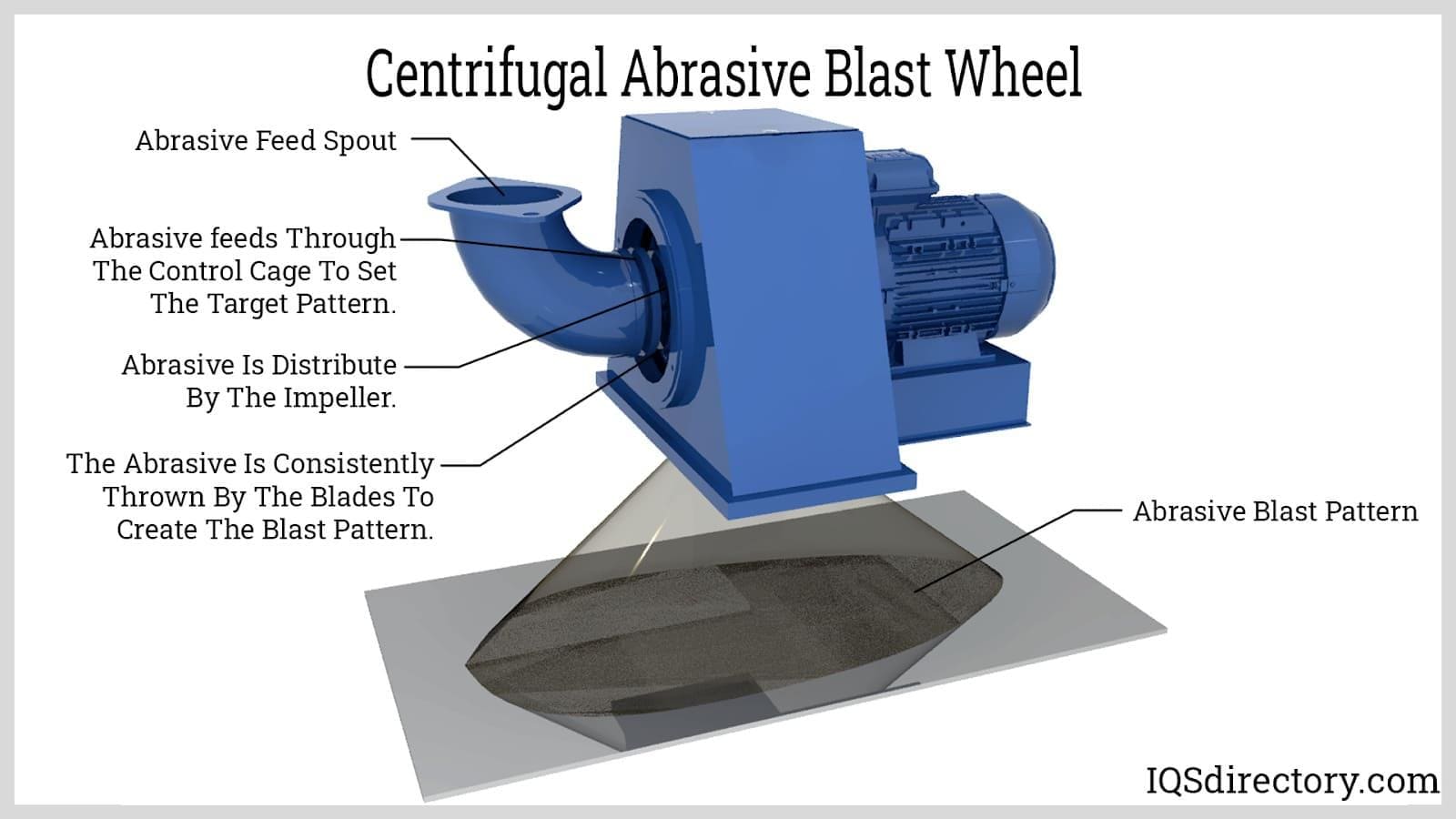

Abrasive Blast Equipment What Is It? How Does It Work? Uses

Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded wheels, coated belts, or simply loose. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding wheels, regardless of their manufacturer, are made up of three main components:

From www.youtube.com

Dressing and Trueing of Grinding wheel YouTube Abrasive Wheel Making Process Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive. Abrasive Wheel Making Process.

From www.alamy.com

Rough grinding, metalworking process, grinding machine with Abrasive Wheel Making Process Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. These particles may be in bonded. Abrasive Wheel Making Process.

From echo-3.co.uk

Guide to Abrasive Wheels What you need to know to work safely Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded wheels, coated belts, or simply loose. Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining process used to produce smooth. Abrasive Wheel Making Process.

From www.alamy.com

Machine abrasive wheel Stock Photo Alamy Abrasive Wheel Making Process Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. These particles may be in bonded wheels, coated belts, or simply loose. In summary, the digitalisation and iot integration in abrasive wheel technology. Abrasive Wheel Making Process.

From encyclopedia.pub

Texturing Methods of Abrasive Grinding Wheels Encyclopedia MDPI Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Surface grinding is a precision machining process. Abrasive Wheel Making Process.

From www.forturetools.com

Two necessary steps for grinding wheel dressing Forture Tools Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles.. Abrasive Wheel Making Process.

From www.okuma.com

What is Dressing and Why Does Your Grinding Wheel Need It? Abrasive Wheel Making Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining. Abrasive Wheel Making Process.

From www.slideserve.com

PPT ABRASIVE WHEEL MACHINERY OSHA 29 CFR 1910.215 PowerPoint Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. In summary, the digitalisation and iot integration in abrasive wheel technology brings. Abrasive Wheel Making Process.

From www.dreamstime.com

The Drilling Tool Regrinding Process with Abrasive Wheel Stock Photo Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded wheels, coated belts, or simply loose. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Surface grinding is a precision machining process. Abrasive Wheel Making Process.

From www.optimatraining.ie

Category Health, Safety & Environment Abrasive Wheel Making Process Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action. Abrasive Wheel Making Process.

From www.youtube.com

Abrasive Cutting Wheel And Grinding Wheel Manufacturing Hands on Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding wheels, regardless of their manufacturer, are made up of three main components: In summary, the digitalisation and iot integration in abrasive wheel technology. Abrasive Wheel Making Process.

From encyclopedia.pub

Texturing Methods of Abrasive Grinding Wheels Encyclopedia MDPI Abrasive Wheel Making Process Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. In summary, the digitalisation and iot integration in abrasive wheel technology brings. Abrasive Wheel Making Process.

From www.slideserve.com

PPT Abrasive Processes PowerPoint Presentation, free download ID Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. Grinding wheels, regardless of their manufacturer, are made up of three main components: In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the. Abrasive Wheel Making Process.

From www.youtube.com

Safety Series How to mount an abrasive wheel YouTube Abrasive Wheel Making Process Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. These particles may be in bonded wheels, coated belts, or simply loose. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding wheels, regardless of their manufacturer, are. Abrasive Wheel Making Process.

From trimmers-pro.com

Wheel Abrasive Test Abrasive Wheel Making Process Grinding wheels, regardless of their manufacturer, are made up of three main components: These particles may be in bonded wheels, coated belts, or simply loose. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Surface grinding is a precision machining process used to produce smooth. Abrasive Wheel Making Process.

From shoal-safetyinnumbers.com

Abrasive Wheels with Practical Cutting/Grinding Training Shoal Abrasive Wheel Making Process Grinding wheels, regardless of their manufacturer, are made up of three main components: In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded. Abrasive Wheel Making Process.

From www.dreamstime.com

Editing the Grinding Abrasive Wheel by the Process of Removing Abrasive Wheel Making Process Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded wheels, coated belts, or simply loose.. Abrasive Wheel Making Process.

From www.ivorking.co.uk

Abrasive Wheels Handheld Cut Off Saw (N017) Ivor King Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. In summary, the digitalisation and iot integration in abrasive wheel technology brings. Abrasive Wheel Making Process.

From essentialsiteskills.co.uk

The ESS Guide to Abrasive Wheels Training Essential Site Skills Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Grinding wheels, regardless of their manufacturer, are made up of three main components: These particles may be in bonded wheels, coated belts, or simply loose. In summary, the digitalisation and iot integration in abrasive wheel technology. Abrasive Wheel Making Process.

From encyclopedia.pub

Texturing Methods of Abrasive Grinding Wheels Encyclopedia MDPI Abrasive Wheel Making Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Surface grinding is a precision machining. Abrasive Wheel Making Process.

From mjksafety.com

Abrasive Wheel MJK Safety Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and. Abrasive Wheel Making Process.

From www.dreamstime.com

Abrasive Wheel on the Mandrel on the Machine in Front of the Abrasive Wheel Making Process Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive. Abrasive Wheel Making Process.

From www.1training.org

Abrasive Wheels Training Course Online 1Training Abrasive Wheel Making Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. These particles may be in bonded wheels, coated belts, or simply loose. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the. Abrasive Wheel Making Process.

From quick-reach.co.uk

Abrasive Wheel Course Quick Reach Abrasive Wheel Making Process Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded wheels, coated belts, or simply loose. Surface grinding is a precision machining process used to produce smooth. Abrasive Wheel Making Process.

From www.camarossaudio.com

abrasive grinding wheel manufacturers exclusive designs Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Grinding wheels, regardless of their manufacturer, are made up of three main components: In summary, the digitalisation and iot integration in abrasive wheel technology. Abrasive Wheel Making Process.

From www.iqsdirectory.com

Abrasive Blast Equipment What Is It? How Does It Work? Uses Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics.. Abrasive Wheel Making Process.

From pd-training.co.uk

A guide to abrasive wheel training PD Training Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. Grinding wheels, regardless of their manufacturer, are made up of three main components: These particles may be in bonded wheels, coated belts, or simply loose. Surface grinding is a precision machining process used to produce smooth. Abrasive Wheel Making Process.

From www.superabrasivetools.com

2019 The Tips of Grinding Wheel Selection Diamond Grinding tools Abrasive Wheel Making Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. These particles may be in bonded. Abrasive Wheel Making Process.

From www.foleysafetysolutions.ie

Abrasive Wheel Training Courses Abrasive Wheel Making Process Grinding wheels, regardless of their manufacturer, are made up of three main components: These particles may be in bonded wheels, coated belts, or simply loose. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. In summary, the digitalisation and iot integration in abrasive wheel technology. Abrasive Wheel Making Process.

From www.dreamstime.com

Editing the Grinding Abrasive Wheel by the Process of Removing Abrasive Wheel Making Process Grinding wheels, regardless of their manufacturer, are made up of three main components: Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive. Abrasive Wheel Making Process.

From toolnotes.com

Abrasive Machining and Finishing ToolNotes Abrasive Wheel Making Process Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded wheels, coated belts, or simply loose. Grinding wheels, regardless of their manufacturer, are made up of three main components: In summary, the digitalisation and iot integration in abrasive wheel technology. Abrasive Wheel Making Process.

From extrudesign.com

Grinding Wheel Abrasives, Properties, Shape and Structures Abrasive Wheel Making Process Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles. These particles may be in bonded wheels, coated belts, or simply loose.. Abrasive Wheel Making Process.

From www.dreamstime.com

The Lathe Tool Regrind Process with Abrasive Stone Wheel Stock Photo Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding wheels, regardless of their manufacturer, are. Abrasive Wheel Making Process.

From www.slideserve.com

PPT Abrasive Processes PowerPoint Presentation, free download ID Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of materials, including metals, plastics, and ceramics. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by the action of irregularly shaped abrasive particles.. Abrasive Wheel Making Process.

From complisafe.co.uk

Abrasive Wheels Complisafe Abrasive Wheel Making Process These particles may be in bonded wheels, coated belts, or simply loose. Grinding wheels, regardless of their manufacturer, are made up of three main components: In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Surface grinding is a precision machining process used to produce smooth and flat surfaces on a variety of. Abrasive Wheel Making Process.