What Is Helical Bevel . On a standard gear, the pitch surface (that carries the teeth) is. This angled tooth profile enables the gears to engage gradually, resulting in. A bevel gearbox, as its name suggests, contains two interlocking bevel gears. They are classified into two main types: Helical is the most commonly used gear in transmissions. They also generate large amounts of thrust and use bearings to help. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Helical gears distribute load across multiple teeth, reducing wear; Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. Spur gears concentrate load on a limited number of teeth; Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Those that transmit mechanical energy between.

from www.docsity.com

On a standard gear, the pitch surface (that carries the teeth) is. Helical gears distribute load across multiple teeth, reducing wear; Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Spur gears concentrate load on a limited number of teeth; Those that transmit mechanical energy between. They also generate large amounts of thrust and use bearings to help. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. They are classified into two main types:

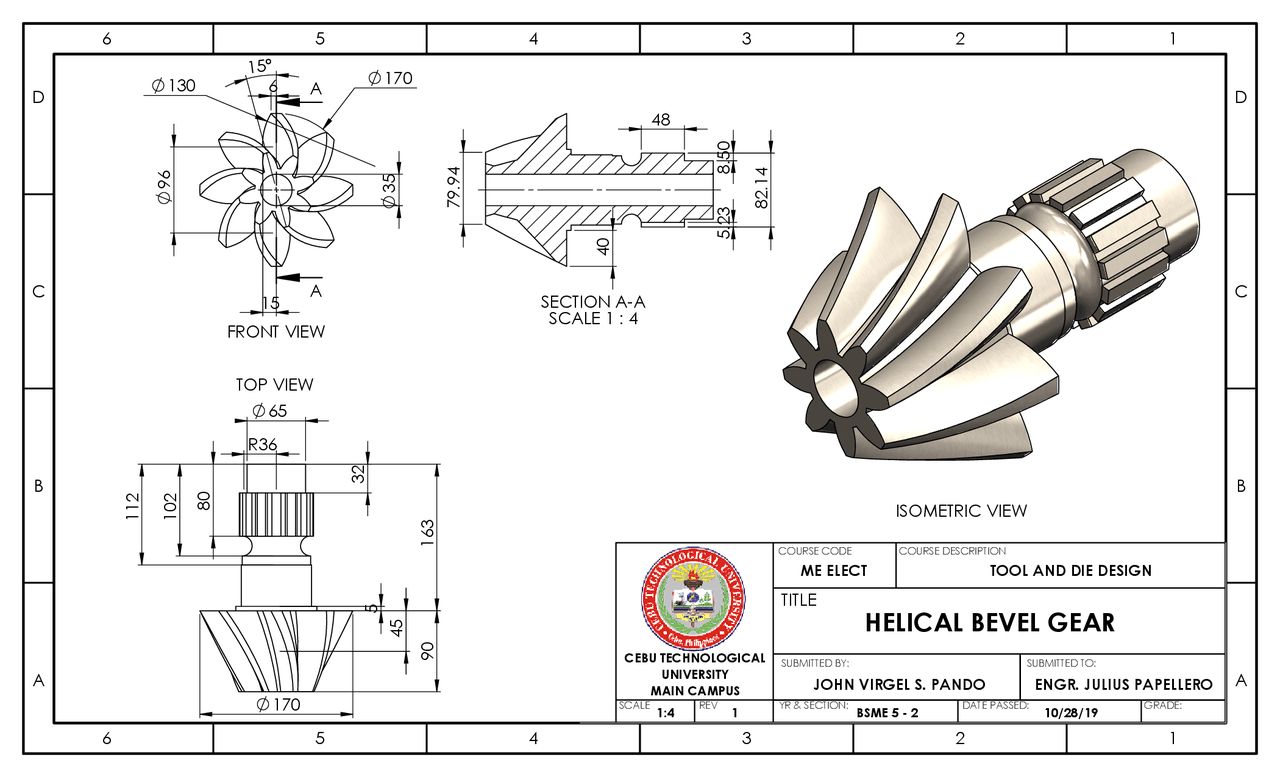

Helical Bevel Gear Design Docsity

What Is Helical Bevel They also generate large amounts of thrust and use bearings to help. Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. They are classified into two main types: They also generate large amounts of thrust and use bearings to help. Spur gears concentrate load on a limited number of teeth; Helical gears distribute load across multiple teeth, reducing wear; Helical is the most commonly used gear in transmissions. On a standard gear, the pitch surface (that carries the teeth) is. Those that transmit mechanical energy between. This angled tooth profile enables the gears to engage gradually, resulting in. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. A bevel gearbox, as its name suggests, contains two interlocking bevel gears.

From www.animalia-life.club

Helical Bevel Gearbox What Is Helical Bevel On a standard gear, the pitch surface (that carries the teeth) is. They are classified into two main types: They also generate large amounts of thrust and use bearings to help. Those that transmit mechanical energy between. This angled tooth profile enables the gears to engage gradually, resulting in. A helical gearbox works by using helical gears, which have teeth. What Is Helical Bevel.

From www.rundles.co.uk

Motovario Helical Bevel Aluminium 100 Gearbox What Is Helical Bevel They also generate large amounts of thrust and use bearings to help. Helical is the most commonly used gear in transmissions. On a standard gear, the pitch surface (that carries the teeth) is. Helical gears distribute load across multiple teeth, reducing wear; A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Those that transmit mechanical energy between.. What Is Helical Bevel.

From www.animalia-life.club

Helical Bevel Gearbox What Is Helical Bevel They are classified into two main types: Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. Those that transmit mechanical energy between. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. A bevel gearbox, as its name suggests, contains two interlocking bevel gears. They also. What Is Helical Bevel.

From hvhindustrial.com

Right Angle Helical Bevel Gearmotors and Units A Bonfiglioli What Is Helical Bevel Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. They also generate large amounts of thrust and use bearings to help. Spur gears concentrate load on a limited number of teeth; Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. They are classified into two. What Is Helical Bevel.

From ar.inspiredpencil.com

Helical Bevel Gearbox What Is Helical Bevel Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. They are classified into two main types: Helical is the most commonly used gear in transmissions. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. On a standard gear, the pitch surface (that carries. What Is Helical Bevel.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations What Is Helical Bevel Helical is the most commonly used gear in transmissions. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Those that transmit mechanical energy between. Spur gears concentrate load on a limited number of teeth;. What Is Helical Bevel.

From www.torkdrive.com

K helical bevel geared motor,helical bevel What Is Helical Bevel Those that transmit mechanical energy between. They are classified into two main types: Spur gears concentrate load on a limited number of teeth; Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. A bevel gearbox, as its name suggests, contains two interlocking bevel gears. They also generate large amounts of. What Is Helical Bevel.

From premium-transmission.com

Difference Between Bevel Helical Gearbox & Worm Gearboxes Premium What Is Helical Bevel This angled tooth profile enables the gears to engage gradually, resulting in. They also generate large amounts of thrust and use bearings to help. Those that transmit mechanical energy between. Helical is the most commonly used gear in transmissions. They are classified into two main types: Helical gears are primarily used to enhance torque and reduce speed between rotating shafts.. What Is Helical Bevel.

From en.wikipedia.org

Spiral bevel gear Wikipedia What Is Helical Bevel They are classified into two main types: On a standard gear, the pitch surface (that carries the teeth) is. This angled tooth profile enables the gears to engage gradually, resulting in. A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Helical gears distribute load across multiple teeth, reducing wear; They also generate large amounts of thrust and. What Is Helical Bevel.

From www.docsity.com

Helical Bevel Gear Design Docsity What Is Helical Bevel They also generate large amounts of thrust and use bearings to help. This angled tooth profile enables the gears to engage gradually, resulting in. On a standard gear, the pitch surface (that carries the teeth) is. Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. A helical gearbox works by. What Is Helical Bevel.

From www.eqm.co.nz

CleanGeartech Stainless Steel Helical Bevel Gearboxes EQM Industrial NZ What Is Helical Bevel A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. On a standard gear, the pitch surface (that carries the teeth) is. A helical gearbox works by using helical gears, which have teeth that are cut at an angle. What Is Helical Bevel.

From www.sogears.com

bevel gearbox motor helical bevel gear motor SEW type GEARMOTOR What Is Helical Bevel A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Helical is the most commonly used gear in transmissions. This angled tooth profile enables the gears to engage gradually, resulting in. They also generate large amounts of thrust and use bearings to help. A helical gearbox works by using helical gears, which have teeth that are cut at. What Is Helical Bevel.

From uni-associates.com

Helical, Bevel Helical Gearboxes What Is Helical Bevel Helical gears distribute load across multiple teeth, reducing wear; They are classified into two main types: A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Spur gears concentrate load on a limited number of teeth; Helical. What Is Helical Bevel.

From www.animalia-life.club

Helical Bevel Gearbox What Is Helical Bevel A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. They also generate large amounts of thrust and use bearings to help. Helical is the most commonly used gear in transmissions. They are classified into two main types: Spur gears concentrate load on a limited number of teeth; This. What Is Helical Bevel.

From www.vogel-antriebe.de

Bevel helical gearboxes What Is Helical Bevel A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Those that transmit mechanical energy between. This angled tooth profile enables the gears to engage gradually, resulting in. They also generate large amounts of thrust and use bearings to help. Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between. What Is Helical Bevel.

From www.weg.net

WG20 Helical Bevel Geared Motors Helical Bevel Geared Motors WG20 What Is Helical Bevel They also generate large amounts of thrust and use bearings to help. Helical is the most commonly used gear in transmissions. They are classified into two main types: A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Those that transmit mechanical energy between. Helical gears distribute load across. What Is Helical Bevel.

From hvhindustrial.com

Helical & bevel helical gear reducers H Series Rossi What Is Helical Bevel This angled tooth profile enables the gears to engage gradually, resulting in. They are classified into two main types: A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Those that transmit mechanical energy between. Spur gears concentrate load on a limited number of teeth; Helical gears distribute load. What Is Helical Bevel.

From www.sgrgear.com

Helical Bevel Gearbox SGR What Is Helical Bevel Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Helical is the most commonly used gear in transmissions. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. On a standard gear, the pitch surface (that carries the teeth) is. Helical gears distribute load. What Is Helical Bevel.

From tech-center-eg.com

Helical Bevel Gear Reducers Aluminium Technology Center What Is Helical Bevel Spur gears concentrate load on a limited number of teeth; A bevel gearbox, as its name suggests, contains two interlocking bevel gears. They also generate large amounts of thrust and use bearings to help. On a standard gear, the pitch surface (that carries the teeth) is. Helical gears distribute load across multiple teeth, reducing wear; A helical gearbox works by. What Is Helical Bevel.

From gearjuli.com

Industrial Robot Helical spiral bevel gear Juli What Is Helical Bevel Helical is the most commonly used gear in transmissions. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. They also generate large amounts of thrust and use bearings to help. Spur gears concentrate load on a limited number of teeth; A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Helical gears distribute. What Is Helical Bevel.

From www.ien.eu

Helical Bevel Gear Units What Is Helical Bevel Those that transmit mechanical energy between. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Helical is the most commonly used gear in transmissions. Spur gears concentrate load on a limited number of teeth; They are classified into two main types: On a standard gear, the pitch surface (that carries the teeth) is. Helical gears. What Is Helical Bevel.

From www.torkdrive.com

Helical bevel gearbox,Helical bevel gear What Is Helical Bevel They are classified into two main types: Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. Spur gears concentrate load on a limited number of teeth; Helical is the most commonly used gear in transmissions. Helical gears distribute load across multiple teeth, reducing wear; Helical gears are primarily used to. What Is Helical Bevel.

From kumera.com

Kumera Multi Stage Helical and BevelHelical Gearboxes What Is Helical Bevel They are classified into two main types: On a standard gear, the pitch surface (that carries the teeth) is. A bevel gearbox, as its name suggests, contains two interlocking bevel gears. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Helical gears are primarily used to enhance torque. What Is Helical Bevel.

From mavink.com

Types Of Bevel Gears What Is Helical Bevel Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Those that transmit mechanical energy between. Helical gears distribute load across multiple teeth, reducing wear; On a standard gear, the pitch surface (that carries the teeth) is. Helical is the most commonly used gear in transmissions. This angled tooth profile enables the gears to engage gradually,. What Is Helical Bevel.

From www.indiantradebird.com

Helical Bevel Gear Reducer In Valsad What Is Helical Bevel Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. Those that transmit mechanical energy between. Helical gears distribute load across multiple teeth, reducing wear; They also generate large amounts of thrust and use bearings to help. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts.. What Is Helical Bevel.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations What Is Helical Bevel Spur gears concentrate load on a limited number of teeth; This angled tooth profile enables the gears to engage gradually, resulting in. They also generate large amounts of thrust and use bearings to help. On a standard gear, the pitch surface (that carries the teeth) is. Helical gears distribute load across multiple teeth, reducing wear; Helical gears have teeth angled. What Is Helical Bevel.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria What Is Helical Bevel Helical gears distribute load across multiple teeth, reducing wear; They are classified into two main types: They also generate large amounts of thrust and use bearings to help. Helical is the most commonly used gear in transmissions. On a standard gear, the pitch surface (that carries the teeth) is. This angled tooth profile enables the gears to engage gradually, resulting. What Is Helical Bevel.

From www.researchgate.net

Assembly schematic of the helical bevel gearbox. Download Scientific What Is Helical Bevel Helical is the most commonly used gear in transmissions. Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Helical gears are primarily used to enhance torque and reduce speed. What Is Helical Bevel.

From www.ien.eu

Helical Bevel Gear Units What Is Helical Bevel A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Those that transmit mechanical energy between. Helical is the most commonly used gear in transmissions. Helical gears distribute load across multiple teeth, reducing wear; Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. They are classified into two main types: They also generate. What Is Helical Bevel.

From www.rehfuss.com

Bevel helical gearbox Rehfuss Drive Solutions GmbH What Is Helical Bevel Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. Spur gears concentrate load on a limited number of teeth; They are classified into two main types: Those that transmit mechanical energy between. This angled tooth profile enables the gears to engage gradually, resulting in. They also generate large amounts of. What Is Helical Bevel.

From www.youtube.com

Helical Gearbox Bevel gearbox Three Stage Gearbox Gearbox What Is Helical Bevel On a standard gear, the pitch surface (that carries the teeth) is. A bevel gearbox, as its name suggests, contains two interlocking bevel gears. Helical is the most commonly used gear in transmissions. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. Spur gears concentrate load on a. What Is Helical Bevel.

From www.ien.eu

Helical Bevel Gear Units What Is Helical Bevel Helical is the most commonly used gear in transmissions. On a standard gear, the pitch surface (that carries the teeth) is. Helical gears have teeth angled to the gear axis, allowing for a more gradual and smoother engagement between the. Spur gears concentrate load on a limited number of teeth; They are classified into two main types: Helical gears distribute. What Is Helical Bevel.

From tech-center-eg.com

Helical Bevel Gear Reducers Aluminium Technology Center What Is Helical Bevel On a standard gear, the pitch surface (that carries the teeth) is. Helical gears distribute load across multiple teeth, reducing wear; Those that transmit mechanical energy between. A helical gearbox works by using helical gears, which have teeth that are cut at an angle to the gear axis. This angled tooth profile enables the gears to engage gradually, resulting in.. What Is Helical Bevel.

From www.indiamart.com

Helical Bevel Gears at Rs 625 Helical Gears in Pune ID 15239550388 What Is Helical Bevel This angled tooth profile enables the gears to engage gradually, resulting in. Spur gears concentrate load on a limited number of teeth; Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. They also generate large amounts of thrust and use bearings to help. Helical gears distribute load across multiple teeth, reducing wear; A helical gearbox. What Is Helical Bevel.

From www.cpaltd.net

Helical Bevel Gearboxes What Is Helical Bevel Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Spur gears concentrate load on a limited number of teeth; They are classified into two main types: Helical is the most commonly used gear in transmissions. On a standard gear, the pitch surface (that carries the teeth) is. This angled tooth profile enables the gears to. What Is Helical Bevel.