Diode Laser Air Assist Psi . Air assist is used to increase the quality of the laser process. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. The laser beam is less. It is an affordable diy project if you have an air compressor in your shop and can greatly improve the quality of your laser cuts. You just need enough to keep the smoke out of your beam and enough pressure to get down in the. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. I run a cloudray n03 nozzle, and run. Air is blown on the laser spot, which removes particles and fumes produced by the burn process. In short high psi is not needed. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings.

from www.laserse.com

The laser beam is less. Air assist is used to increase the quality of the laser process. You just need enough to keep the smoke out of your beam and enough pressure to get down in the. Air is blown on the laser spot, which removes particles and fumes produced by the burn process. In short high psi is not needed. I run a cloudray n03 nozzle, and run. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. It is an affordable diy project if you have an air compressor in your shop and can greatly improve the quality of your laser cuts.

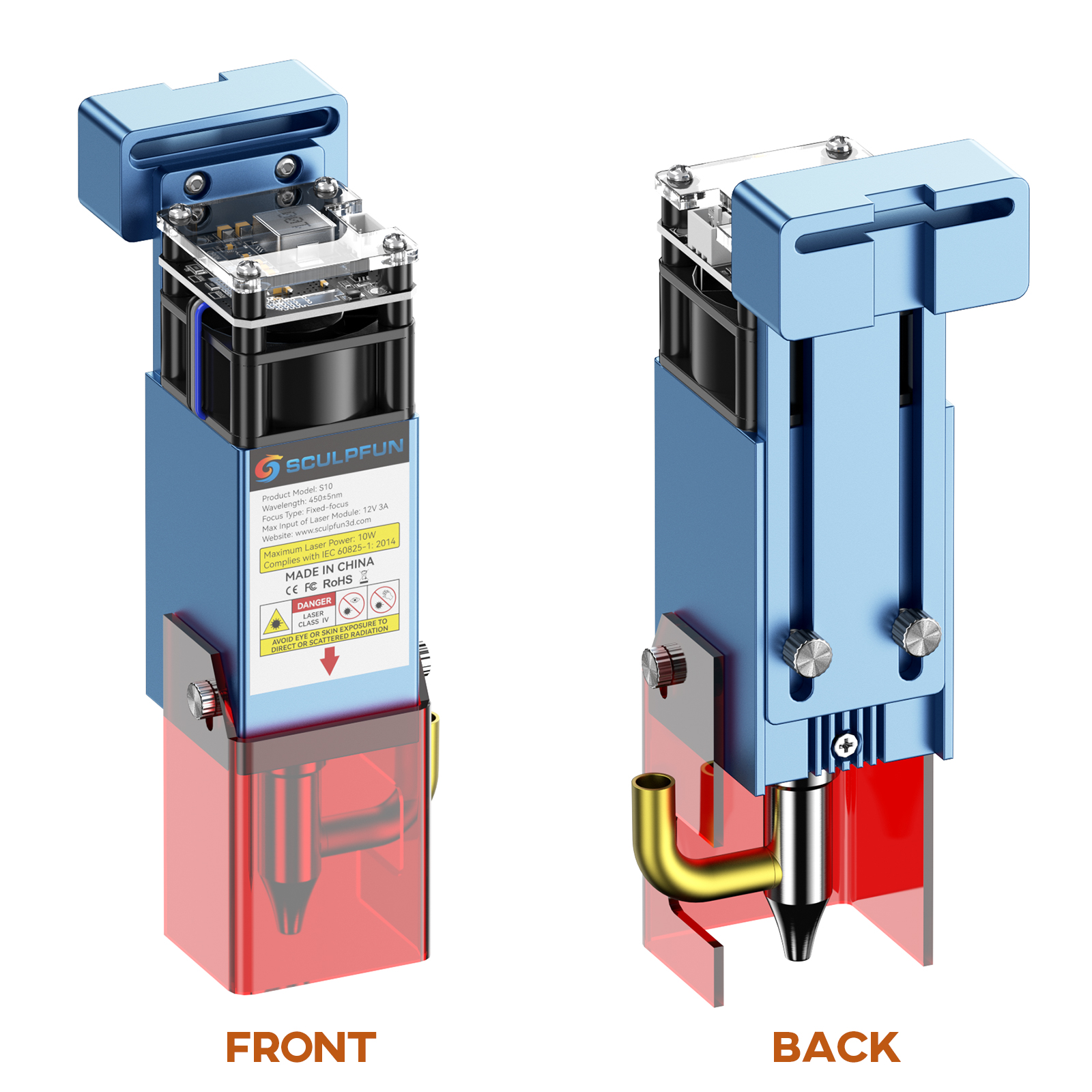

SCULPFUN S10 diode mini laser engraving machine powerful module Laser

Diode Laser Air Assist Psi Air is blown on the laser spot, which removes particles and fumes produced by the burn process. Air assist is used to increase the quality of the laser process. Air is blown on the laser spot, which removes particles and fumes produced by the burn process. You just need enough to keep the smoke out of your beam and enough pressure to get down in the. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. The laser beam is less. In short high psi is not needed. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. It is an affordable diy project if you have an air compressor in your shop and can greatly improve the quality of your laser cuts. I run a cloudray n03 nozzle, and run.

From endurancelasers.com

A DIY air assist for diode lasers fully 3D printed EnduranceLasers Diode Laser Air Assist Psi Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. You just need enough to keep the smoke out of your beam and enough pressure to get down in the. It is an affordable diy project if you have an air compressor in your shop and can greatly improve the quality of your. Diode Laser Air Assist Psi.

From zbaitu.store

ZBAITU Newest 20W 4 Diode Laser Module Head Dual Fan with Air Assist Diode Laser Air Assist Psi You just need enough to keep the smoke out of your beam and enough pressure to get down in the. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. Air is blown on. Diode Laser Air Assist Psi.

From cults3d.com

Free STL file 5.5w Diode Laser Air assist nozzle 🧞♂️・3D print model to Diode Laser Air Assist Psi I run a cloudray n03 nozzle, and run. In short high psi is not needed. Air assist is used to increase the quality of the laser process. You just need enough to keep the smoke out of your beam and enough pressure to get down in the. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic,. Diode Laser Air Assist Psi.

From www.tecnologisticaaduanal.com

aussetzen Ankündigung nochmal air assist for diode lasers Stamm Beliebt Diode Laser Air Assist Psi To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. The laser beam is less. I run a cloudray n03 nozzle, and run. There is a psi for air assist, but it’s measured. Diode Laser Air Assist Psi.

From www.youtube.com

Ultimate Diode Laser Air Assist Hacks and Tests Feat Ortur Laser Diode Laser Air Assist Psi I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. I run a cloudray n03 nozzle, and run. Air assist is. Diode Laser Air Assist Psi.

From www.etsy.com

Ortur Laser Master 2 Air Assist for Optimal Cutting and Etsy Diode Laser Air Assist Psi I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. Air assist is used to increase the quality of the laser process. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. In short high psi. Diode Laser Air Assist Psi.

From optlasersgrav.com

High Pressure AirAssist for Laser Engraving & Laser Cutting. Diode Laser Air Assist Psi Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. Air assist is used to increase the quality of the laser process. I run a cloudray n03 nozzle, and run. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. There is a psi for air assist,. Diode Laser Air Assist Psi.

From endurancelasers.com

A DIY air assist for diode lasers fully 3D printed EnduranceLasers Diode Laser Air Assist Psi I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. I run a cloudray n03 nozzle, and run. You just need enough to keep the smoke out of your beam and enough pressure to get down in the. Diode laser air assist. Diode Laser Air Assist Psi.

From fslaser.com

Why Air Assist is Important for a Laser Cutter Full Spectrum Laser Diode Laser Air Assist Psi In short high psi is not needed. You just need enough to keep the smoke out of your beam and enough pressure to get down in the. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. There is a psi for air assist, but it’s measured in flow pressure and it depends. Diode Laser Air Assist Psi.

From store.zenix.lk

NEJE A40640 NEJE00568 40W Diode Laser Module Kit with Air Assist Diode Laser Air Assist Psi Air assist is used to increase the quality of the laser process. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. It is an affordable diy project if you have an air compressor. Diode Laser Air Assist Psi.

From wiki.the-iskens.com

Air Assist Diode Laser Wiki Diode Laser Air Assist Psi You just need enough to keep the smoke out of your beam and enough pressure to get down in the. I run a cloudray n03 nozzle, and run. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. The laser beam is. Diode Laser Air Assist Psi.

From cults3d.com

Free STL file Laser Air Assist Nozzle for 33x33 mm laser diode housing Diode Laser Air Assist Psi Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. I have a giant air compressor. Diode Laser Air Assist Psi.

From www.aliexpress.com

ZBAITU Laser Engraver Module 40/80W Two Diodes Laser Head Builtin Air Diode Laser Air Assist Psi You just need enough to keep the smoke out of your beam and enough pressure to get down in the. In short high psi is not needed. The laser beam is less. I run a cloudray n03 nozzle, and run. Air assist is used to increase the quality of the laser process. I use 5 psi flow pressure through a. Diode Laser Air Assist Psi.

From endurancelasers.com

A DIY air assist for diode lasers fully 3D printed EnduranceLasers Diode Laser Air Assist Psi Air is blown on the laser spot, which removes particles and fumes produced by the burn process. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. Air assist is used to increase the quality of the laser process. There is a psi for air assist, but it’s measured in flow pressure and it. Diode Laser Air Assist Psi.

From www.laserdiodesource.com

940nm, 10W FiberCoupled Laser Diode from Lumentum Diode Laser Air Assist Psi I run a cloudray n03 nozzle, and run. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. There is a psi for air assist, but it’s measured in flow pressure and it. Diode Laser Air Assist Psi.

From endurancelasers.com

All you need to know about diode laser airassist order today! Diode Laser Air Assist Psi Air is blown on the laser spot, which removes particles and fumes produced by the burn process. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. There is a psi for air assist, but it’s measured in flow pressure and it. Diode Laser Air Assist Psi.

From www.aliexpress.com

Laser Tree 30w Optical Power Laser Module With Air Assist 6 Diodes Diode Laser Air Assist Psi Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. It is an affordable diy project if you have an air compressor in your shop and can greatly improve the quality of. Diode Laser Air Assist Psi.

From www.laserse.com

SCULPFUN S10 diode mini laser engraving machine for wood Tool High Diode Laser Air Assist Psi The laser beam is less. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. In short high psi is not needed. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. I run a cloudray n03 nozzle, and run. I have. Diode Laser Air Assist Psi.

From www.youtube.com

Ortur Laser Adjustable Air Assist (Diode Laser)! YouTube Diode Laser Air Assist Psi Air is blown on the laser spot, which removes particles and fumes produced by the burn process. In short high psi is not needed. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. Air assist is. Diode Laser Air Assist Psi.

From cults3d.com

Free STL file 5.5w Diode Laser Air assist nozzle・3D print model to Diode Laser Air Assist Psi Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. The laser beam is less. Air is blown on the laser spot, which removes particles and fumes produced by the burn process. Air assist is used to increase the quality of the laser process. I have a giant air compressor setup in my. Diode Laser Air Assist Psi.

From forum.lightburnsoftware.com

Diode Laser Air Assist LightBurn Software Questions LightBurn Diode Laser Air Assist Psi Air is blown on the laser spot, which removes particles and fumes produced by the burn process. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. In short high psi is not needed. Air assist is used to increase the quality. Diode Laser Air Assist Psi.

From www.circulaire-en-ligne.ca

xTool D1 Air Assist, le partenaire pour graveur laser D1, Air Assist Diode Laser Air Assist Psi You just need enough to keep the smoke out of your beam and enough pressure to get down in the. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my. Diode Laser Air Assist Psi.

From www.youtube.com

Diode laser longer ray5 and others using focus block correctly, laser Diode Laser Air Assist Psi I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. I run a cloudray n03 nozzle, and run. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. You just need enough to keep the smoke. Diode Laser Air Assist Psi.

From www.aliexpress.com

LASER TREE K30 30W Diode Laser Head with Air Assist 450nm Blue Light Diode Laser Air Assist Psi Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. Air is blown on the laser spot, which removes particles and fumes produced by the burn process. In short high psi is not needed. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle.. Diode Laser Air Assist Psi.

From endurancelasers.com

All you need to know about diode laser airassist order today! Diode Laser Air Assist Psi You just need enough to keep the smoke out of your beam and enough pressure to get down in the. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. The laser beam is less. Air is blown on the laser spot, which removes particles and fumes produced by the burn. Diode Laser Air Assist Psi.

From optlasersgrav.com

High Pressure AirAssist for Laser Engraving & Laser Cutting. Diode Laser Air Assist Psi Air assist is used to increase the quality of the laser process. It is an affordable diy project if you have an air compressor in your shop and can greatly improve the quality of your laser cuts. I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. There is a psi for air assist,. Diode Laser Air Assist Psi.

From endurancelasers.com

All you need to know about diode laser airassist order today! Diode Laser Air Assist Psi I use 5 psi flow pressure through a cloudray no3 nozzle for acrylic, and bump it. Air is blown on the laser spot, which removes particles and fumes produced by the burn process. In short high psi is not needed. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on. Diode Laser Air Assist Psi.

From diode-laser-wiki.com

Air Assist Diode Laser Wiki Diode Laser Air Assist Psi I run a cloudray n03 nozzle, and run. In short high psi is not needed. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. I use 5 psi flow pressure through a cloudray. Diode Laser Air Assist Psi.

From endurancelasers.com

All you need to know about diode laser airassist order today! Diode Laser Air Assist Psi I run a cloudray n03 nozzle, and run. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. Air assist is used to increase the. Diode Laser Air Assist Psi.

From www.laserse.com

LASER TREE 80W Laser Module Head 450nm Blue Light TTL Module Air Assist Diode Laser Air Assist Psi It is an affordable diy project if you have an air compressor in your shop and can greatly improve the quality of your laser cuts. The laser beam is less. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. I use 5 psi flow pressure through a cloudray. Diode Laser Air Assist Psi.

From www.laserse.com

SCULPFUN S10 diode mini laser engraving machine powerful module Laser Diode Laser Air Assist Psi There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. It is an affordable diy project if you have an air compressor in your shop and can greatly improve the. Diode Laser Air Assist Psi.

From www.printables.com

Diode Laser Air Assist by lynxpilot Download free STL model Diode Laser Air Assist Psi The laser beam is less. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. It is an affordable diy project if you have an air compressor in your shop and can greatly improve the quality of your laser cuts. Air assist is used to increase the quality of the laser process. There. Diode Laser Air Assist Psi.

From lab.rapternet.us

Ortur Laser Master 2 Air Assist Systems Lab Diode Laser Air Assist Psi Air assist is used to increase the quality of the laser process. You just need enough to keep the smoke out of your beam and enough pressure to get down in the. I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the.. Diode Laser Air Assist Psi.

From www.printables.com

air assist for 40mm diode laser engraver by human Download free STL Diode Laser Air Assist Psi To make an air assist for your laser you need an air pump, air tube, pressure regulator, and a few fittings. Diode laser air assist pumps are a vital component of many industrial laser cutting and engraving applications. I run a cloudray n03 nozzle, and run. Air is blown on the laser spot, which removes particles and fumes produced by. Diode Laser Air Assist Psi.

From zbaitu.store

ZBAITU Newest 20W 4 Diode Laser Module Head Dual Fan with Air Assist Diode Laser Air Assist Psi I have a giant air compressor setup in my shop already and often use about 10psi for aluminum cutting on my cnc, but i wasn't clear about the. I run a cloudray n03 nozzle, and run. There is a psi for air assist, but it’s measured in flow pressure and it depends on your nozzle. In short high psi is. Diode Laser Air Assist Psi.