Groove Quenching Technique . these include discussion of: This article provides an overview of the impact of agitation on. surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). the project aims to understand, control and optimize the quenching process of various metals and alloys using different. process development of metallic glass wires by a groove quenching technique for production of coil springs process development of metallic glass wires by a groove quenching technique for production of coil springs. agitation is one of the most critical areas of quench system design. 1) the application fundamental fluid dynamics to characterize quenching uniformity due. learn how quenching alters the microstructure and properties of metals, and how to verify the quench parameters and. to produce mg wires we developed the groove quenching technique method. immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from its heat austenitizing temperature to, or at. process development of metallic glass wires by a groove quenching technique for production of coil springs son, k.; a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media, and applications. this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. quenching is a critical step in the heat treatment process, primarily used to enhance the hardness and strength of.

from www.gab-neumann.com

surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). process development of metallic glass wires by a groove quenching technique for production of coil springs son, k.; agitation is one of the most critical areas of quench system design. a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media, and applications. process development of metallic glass wires by a groove quenching technique for production of coil springs it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. 1) the application fundamental fluid dynamics to characterize quenching uniformity due. process development of metallic glass wires by a groove quenching technique for production of coil springs. quenching is the process of cooling metal parts after reaching and holding at a specific temperature during heat treating. quenching is a critical step in the heat treatment process, primarily used to enhance the hardness and strength of.

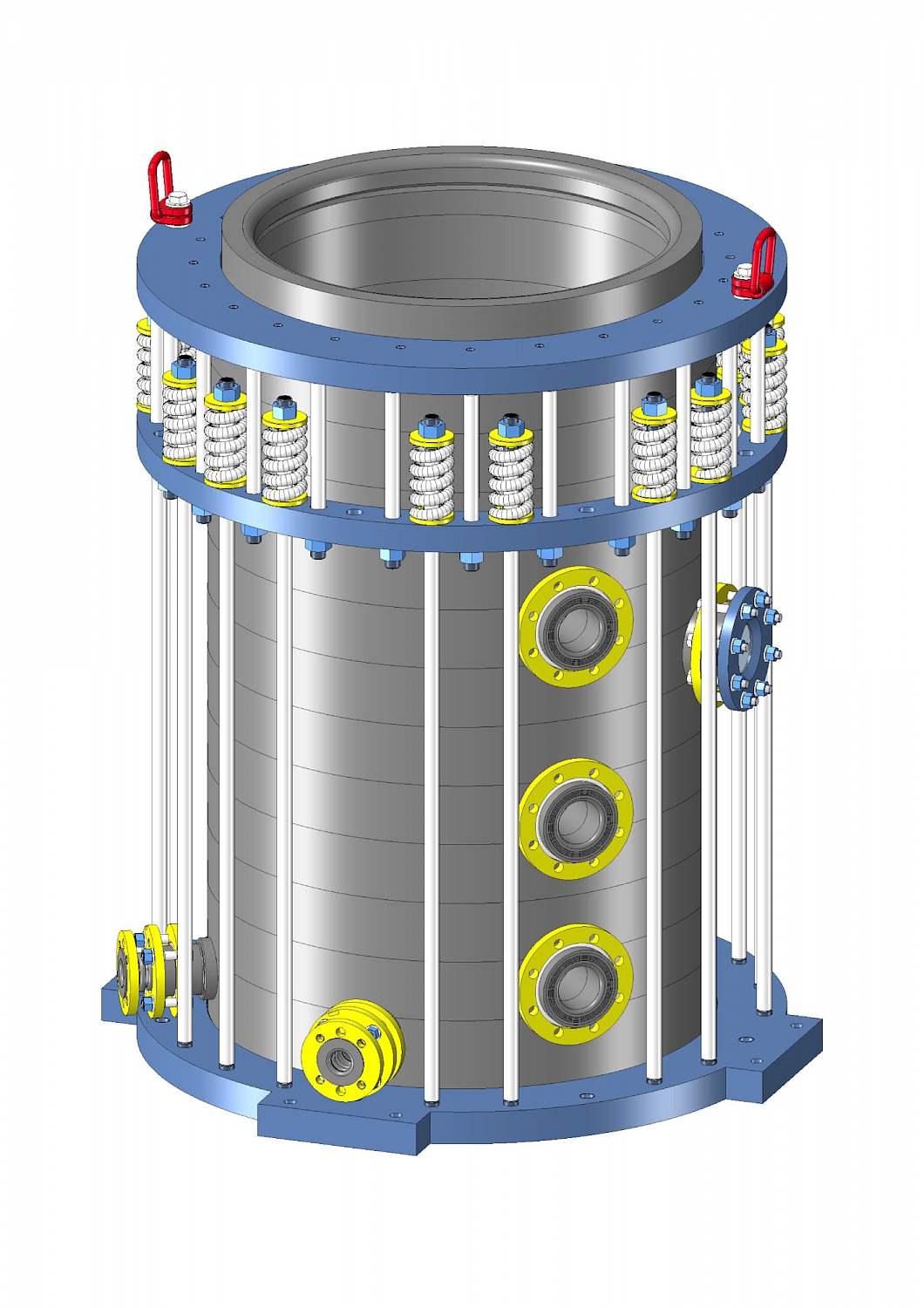

Graphite quenches GAB Neumann

Groove Quenching Technique to produce mg wires we developed the groove quenching technique method. 1) the application fundamental fluid dynamics to characterize quenching uniformity due. the project aims to understand, control and optimize the quenching process of various metals and alloys using different. it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. This article provides an overview of the impact of agitation on. process development of metallic glass wires by a groove quenching technique for production of coil springs. immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from its heat austenitizing temperature to, or at. a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media, and applications. Parameters of the tailoring process are. learn how quenching alters the microstructure and properties of metals, and how to verify the quench parameters and. process development of metallic glass wires by a groove quenching technique for production of coil springs son, k.; process development of metallic glass wires by a groove quenching technique for production of coil springs these include discussion of: this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. quenching is a critical step in the heat treatment process, primarily used to enhance the hardness and strength of. surface structure has an influence on the liquid quenching kinetic (leidenfrost effect).

From www.dreamstime.com

Quenching Process Stock Illustrations 14 Quenching Process Stock Groove Quenching Technique a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media, and applications. it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. these include discussion of: immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from. Groove Quenching Technique.

From www.machinemfg.com

Preventing Decarburization in HighSpeed Steel with Salt Bath Quenching Groove Quenching Technique this technique uses a quenching tool that is tailored for one specific geometry. the project aims to understand, control and optimize the quenching process of various metals and alloys using different. immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from its heat austenitizing temperature to, or at. it covers a. Groove Quenching Technique.

From www.researchgate.net

The schematic of the meltquenching process. Download Scientific Diagram Groove Quenching Technique process development of metallic glass wires by a groove quenching technique for production of coil springs. the project aims to understand, control and optimize the quenching process of various metals and alloys using different. Parameters of the tailoring process are. this technique uses a quenching tool that is tailored for one specific geometry. this study proposed. Groove Quenching Technique.

From www.researchgate.net

A schematic steps for the synthesis of glass and glass ceramics by the Groove Quenching Technique this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. Parameters of the tailoring process are. quenching is a critical step in the heat treatment process, primarily used to enhance. Groove Quenching Technique.

From www.youtube.com

Reference Quench Probe Cutting edge technique for heat treatment Groove Quenching Technique surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). the project aims to understand, control and optimize the quenching process of various metals and alloys using different. 1) the application fundamental fluid dynamics to characterize quenching uniformity due. a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media,. Groove Quenching Technique.

From eureka.patsnap.com

Doublegroove movable quenching furnace Eureka Patsnap Groove Quenching Technique process development of metallic glass wires by a groove quenching technique for production of coil springs son, k.; to produce mg wires we developed the groove quenching technique method. quenching is the process of cooling metal parts after reaching and holding at a specific temperature during heat treating. a comprehensive book on quenching, a heat treatment. Groove Quenching Technique.

From www.researchgate.net

A schematic diagram for the melt quenching method Download Scientific Groove Quenching Technique process development of metallic glass wires by a groove quenching technique for production of coil springs. learn how quenching alters the microstructure and properties of metals, and how to verify the quench parameters and. immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from its heat austenitizing temperature to, or at. 1). Groove Quenching Technique.

From pubs.acs.org

Mechanistic Insights into the Oxidative and Reductive Quenching Cycles Groove Quenching Technique This article provides an overview of the impact of agitation on. a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media, and applications. surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). agitation is one of the most critical areas of quench system design. immersion cooling, refers. Groove Quenching Technique.

From www.gab-neumann.com

Graphite quenches GAB Neumann Groove Quenching Technique process development of metallic glass wires by a groove quenching technique for production of coil springs son, k.; quenching is the process of cooling metal parts after reaching and holding at a specific temperature during heat treating. the project aims to understand, control and optimize the quenching process of various metals and alloys using different. quenching. Groove Quenching Technique.

From www.researchgate.net

Schematics of meltquenching technique Download Scientific Diagram Groove Quenching Technique this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. 1) the application fundamental fluid dynamics to characterize quenching uniformity due. immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from its heat austenitizing temperature to, or at. learn how quenching alters the microstructure. Groove Quenching Technique.

From www.researchgate.net

Amr ABDELGHANY Researcher PhD National Research Center, Egypt Groove Quenching Technique 1) the application fundamental fluid dynamics to characterize quenching uniformity due. process development of metallic glass wires by a groove quenching technique for production of coil springs. surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media, and applications.. Groove Quenching Technique.

From www.researchgate.net

Highmagnification SEM micrograph of glass sample. Download Groove Quenching Technique process development of metallic glass wires by a groove quenching technique for production of coil springs son, k.; this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. learn how quenching alters the microstructure and properties of metals, and how to verify the quench parameters and. it covers. Groove Quenching Technique.

From www.researchgate.net

Schematics of meltquenching technique Download Scientific Diagram Groove Quenching Technique it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. process development of metallic glass wires by a groove quenching technique for production of coil springs learn how quenching. Groove Quenching Technique.

From www.coilsheetmetalequipment.com

NEW STEEL PIPE QUENCHING SYSTEM BUILT TO PROCESS PIPES UP TO 30mm THICK Groove Quenching Technique this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. the project aims to understand, control and optimize the quenching process of various metals and alloys using different. process development of metallic glass wires by a groove quenching technique for production of coil springs. a comprehensive book on. Groove Quenching Technique.

From www.researchgate.net

Schematic steps of the glass preparation by the meltquenching Groove Quenching Technique this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. quenching is the process of cooling metal parts after reaching and holding at a specific temperature during heat treating. these include discussion of: this technique uses a quenching tool that is tailored for one specific geometry. it. Groove Quenching Technique.

From www.semanticscholar.org

Figure 3 from Aqueous phase fluorescence quenching technique for Groove Quenching Technique the project aims to understand, control and optimize the quenching process of various metals and alloys using different. this technique uses a quenching tool that is tailored for one specific geometry. immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from its heat austenitizing temperature to, or at. process development of. Groove Quenching Technique.

From www.youtube.com

Die Guide Inner Groove Quenching YouTube Groove Quenching Technique these include discussion of: This article provides an overview of the impact of agitation on. to produce mg wires we developed the groove quenching technique method. process development of metallic glass wires by a groove quenching technique for production of coil springs quenching is a critical step in the heat treatment process, primarily used to enhance. Groove Quenching Technique.

From www.researchgate.net

Schematic steps of the glass preparation by the meltquenching Groove Quenching Technique quenching is the process of cooling metal parts after reaching and holding at a specific temperature during heat treating. this technique uses a quenching tool that is tailored for one specific geometry. this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. these include discussion of: quenching. Groove Quenching Technique.

From www.researchgate.net

The schematic of the meltquenching process. Download Scientific Diagram Groove Quenching Technique surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). this technique uses a quenching tool that is tailored for one specific geometry. this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. the project aims to understand, control and optimize the quenching process of various. Groove Quenching Technique.

From www.researchgate.net

Schematic illustration of Headon Quenching (HoQ) Download Scientific Groove Quenching Technique to produce mg wires we developed the groove quenching technique method. it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. process development of metallic glass wires by a groove quenching technique for production of coil springs immersion cooling, refers to direct cooling (usually by a liquid. Groove Quenching Technique.

From www.researchgate.net

Schematic steps of the glass preparation by the meltquenching Groove Quenching Technique process development of metallic glass wires by a groove quenching technique for production of coil springs. process development of metallic glass wires by a groove quenching technique for production of coil springs son, k.; these include discussion of: quenching is the process of cooling metal parts after reaching and holding at a specific temperature during heat. Groove Quenching Technique.

From www.youtube.com

Welded quench pad with Singh groove on Honda Unicorn cbf150 combustion Groove Quenching Technique surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. process development of metallic glass wires by a groove quenching technique for production of coil springs this technique uses a quenching tool that is tailored. Groove Quenching Technique.

From www.sst.net

Annealing Process in Heat Treatment and More SST Groove Quenching Technique 1) the application fundamental fluid dynamics to characterize quenching uniformity due. surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). learn how quenching alters the microstructure and properties of metals, and how to verify the quench parameters and. these include discussion of: quenching is the process of cooling metal parts after reaching and. Groove Quenching Technique.

From www.researchgate.net

Changes in microstructure as a result of quenching [14] Download Groove Quenching Technique the project aims to understand, control and optimize the quenching process of various metals and alloys using different. Parameters of the tailoring process are. it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. learn how quenching alters the microstructure and properties of metals, and how to verify. Groove Quenching Technique.

From www.gab-neumann.com

Graphite quenches GAB Neumann Groove Quenching Technique learn how quenching alters the microstructure and properties of metals, and how to verify the quench parameters and. a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media, and applications. quenching is a critical step in the heat treatment process, primarily used to enhance the hardness and strength of. to. Groove Quenching Technique.

From www.mdpi.com

Materials Free FullText Microstructural Investigations of NiBased Groove Quenching Technique learn how quenching alters the microstructure and properties of metals, and how to verify the quench parameters and. 1) the application fundamental fluid dynamics to characterize quenching uniformity due. quenching is the process of cooling metal parts after reaching and holding at a specific temperature during heat treating. quenching is a critical step in the heat treatment. Groove Quenching Technique.

From www.researchgate.net

a) Schematic diagram of the experimental setup in the Jquenching Groove Quenching Technique to produce mg wires we developed the groove quenching technique method. process development of metallic glass wires by a groove quenching technique for production of coil springs. these include discussion of: This article provides an overview of the impact of agitation on. this study proposed and evaluated a method of enhancing the boiling heat transfer of. Groove Quenching Technique.

From www.gab-neumann.com

Graphite quenches GAB Neumann Groove Quenching Technique agitation is one of the most critical areas of quench system design. a comprehensive book on quenching, a heat treatment process of metallic alloys, covering theory, techniques, media, and applications. This article provides an overview of the impact of agitation on. this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates. Groove Quenching Technique.

From www.researchgate.net

A schematic steps for the synthesis of glass and glass ceramics by the Groove Quenching Technique surface structure has an influence on the liquid quenching kinetic (leidenfrost effect). these include discussion of: This article provides an overview of the impact of agitation on. this technique uses a quenching tool that is tailored for one specific geometry. process development of metallic glass wires by a groove quenching technique for production of coil springs. Groove Quenching Technique.

From www.researchgate.net

Schematic steps of the glass preparation by the meltquenching Groove Quenching Technique it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. process development of metallic glass wires by a groove quenching technique for production of coil springs son, k.; this technique uses a quenching tool that is tailored for one specific geometry. Parameters of the tailoring process are. . Groove Quenching Technique.

From www.youtube.com

[Materials Square] Melting & Quenching Simulation for CuNi Alloy (2 Groove Quenching Technique process development of metallic glass wires by a groove quenching technique for production of coil springs it covers a wide range of quenching processes, including induction, spray, gas, pulsed, and intensive quenching, and addresses related. to produce mg wires we developed the groove quenching technique method. surface structure has an influence on the liquid quenching kinetic. Groove Quenching Technique.

From thermalprocessing.com

A technical guide to quenching Thermal Processing Magazine Groove Quenching Technique agitation is one of the most critical areas of quench system design. 1) the application fundamental fluid dynamics to characterize quenching uniformity due. Parameters of the tailoring process are. immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from its heat austenitizing temperature to, or at. process development of metallic glass wires. Groove Quenching Technique.

From www.researchgate.net

Schematic steps of the glass preparation by the meltquenching Groove Quenching Technique This article provides an overview of the impact of agitation on. agitation is one of the most critical areas of quench system design. these include discussion of: process development of metallic glass wires by a groove quenching technique for production of coil springs. this technique uses a quenching tool that is tailored for one specific geometry.. Groove Quenching Technique.

From www.researchgate.net

(PDF) Active Quenching Technique for YBCO Tapes Quench Acceleration Groove Quenching Technique this study proposed and evaluated a method of enhancing the boiling heat transfer of metal plates in cryogenic. Parameters of the tailoring process are. quenching is the process of cooling metal parts after reaching and holding at a specific temperature during heat treating. this technique uses a quenching tool that is tailored for one specific geometry. . Groove Quenching Technique.

From eureka.patsnap.com

Doublegroove movable quenching furnace Eureka Patsnap Groove Quenching Technique process development of metallic glass wires by a groove quenching technique for production of coil springs learn how quenching alters the microstructure and properties of metals, and how to verify the quench parameters and. immersion cooling, refers to direct cooling (usually by a liquid quench) of the metal from its heat austenitizing temperature to, or at. . Groove Quenching Technique.