Surface Grinding Dressing Process . The surface grinder is mainly used in the finishing process. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. It removes clogs, dulled abrasive grains, and excess bonding.

from autoplasticsworld.com

It removes clogs, dulled abrasive grains, and excess bonding. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. The surface grinder is mainly used in the finishing process. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),.

Surface Grinding Machine Techniques, Technologies & Trends

Surface Grinding Dressing Process Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It removes clogs, dulled abrasive grains, and excess bonding. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. The surface grinder is mainly used in the finishing process.

From www.stahliusa.com

Grinding Applications Stahli USA Worldwide Leader Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. It removes clogs, dulled abrasive grains, and excess bonding. Dressing returns. Surface Grinding Dressing Process.

From orbray.com

Summary of “Grinding” and “Polishing”A brief introduction to these Surface Grinding Dressing Process Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. The surface grinder is mainly used in the finishing process. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. In order to keep the surface of the. Surface Grinding Dressing Process.

From autoplasticsworld.com

Surface Grinding Machine Techniques, Technologies & Trends Surface Grinding Dressing Process In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. It removes clogs, dulled abrasive grains, and excess bonding. The dressing parameters including dressing. Surface Grinding Dressing Process.

From www.forturetools.com

Two necessary steps for grinding wheel dressing Forture Tools Surface Grinding Dressing Process Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. The surface grinder is mainly used in the finishing process. Grinding is an abrasive machining process used for. Surface Grinding Dressing Process.

From www.researchgate.net

Process layout of the performed surface grinding experiments Surface Grinding Dressing Process It removes clogs, dulled abrasive grains, and excess bonding. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. Grinding is an abrasive machining process used for almost every manufacturing process. Surface Grinding Dressing Process.

From indianaprecisiongrinding.com

The Importance of Dressing a Grinding Wheel Indiana Precision Grinding Surface Grinding Dressing Process It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. It removes clogs, dulled abrasive grains, and excess bonding. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal. Surface Grinding Dressing Process.

From www.researchgate.net

Flow chart of grinding procedure. Download Scientific Diagram Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It removes clogs, dulled abrasive grains, and excess. Surface Grinding Dressing Process.

From www.ctemag.com

Optimizing grinding and dressing with 'dressing speed ratio' parameter Surface Grinding Dressing Process In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of. Surface Grinding Dressing Process.

From www.youtube.com

STUNNING Process of Grinding a Flawless Surface Finish on a STUDER S41 Surface Grinding Dressing Process Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. It is a very precise tool which uses a stationary, abrasive, rotating wheel to. Surface Grinding Dressing Process.

From www.youtube.com

SURFACE GRINDING part 1, basic principals, wheel dressing, prepping for Surface Grinding Dressing Process It removes clogs, dulled abrasive grains, and excess bonding. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr),. Surface Grinding Dressing Process.

From www.youtube.com

Grinding Wheel Dressing Process YouTube Surface Grinding Dressing Process Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it. Surface Grinding Dressing Process.

From www.youtube.com

Honing Process Surface Finishing Process Abrasive Machining PPT Surface Grinding Dressing Process The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. It removes clogs, dulled abrasive grains, and excess bonding. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. In order to keep the surface of the grinding wheel with sufficient. Surface Grinding Dressing Process.

From www.slideserve.com

PPT Grinding PowerPoint Presentation, free download ID2175456 Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. Dressing returns the grinding wheel to its original sharpness by removing. Surface Grinding Dressing Process.

From youtube.com

How to dress an angle or radius on a surface grinder wheel YouTube Surface Grinding Dressing Process Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It removes clogs, dulled abrasive grains, and excess bonding. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. The surface grinder is mainly used in the finishing. Surface Grinding Dressing Process.

From www.forturetools.com

8 points common knowledge of grinding wheel safety Forture Tools Surface Grinding Dressing Process Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. It removes clogs, dulled abrasive grains, and excess bonding. The dressing parameters including dressing feed rate (s), rough. Surface Grinding Dressing Process.

From forturetools.com

How to use diamond dresser to dress and true grinding wheelMrbrianzhao Surface Grinding Dressing Process Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. The surface grinder is mainly used in the finishing process. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. It removes clogs, dulled abrasive grains, and. Surface Grinding Dressing Process.

From www.researchgate.net

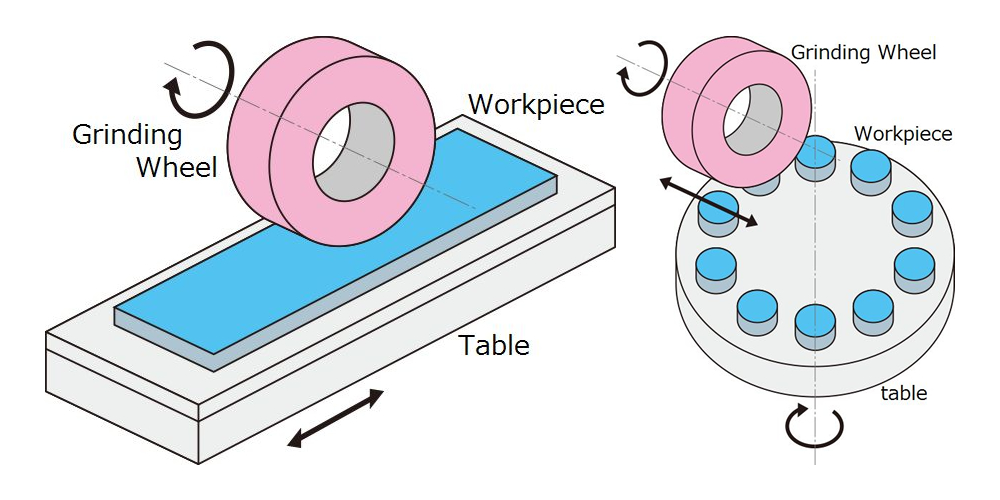

1 Schematic diagram of surface grinding. Download Scientific Diagram Surface Grinding Dressing Process The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. The surface grinder is mainly used in the finishing process. It removes clogs, dulled abrasive grains, and. Surface Grinding Dressing Process.

From thetoolanddieguy.com

SURFACE GRINDING Surface Grinding Dressing Process In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. The surface grinder is mainly used in the finishing process. It removes clogs, dulled. Surface Grinding Dressing Process.

From csmsheetmetal.co.uk

Surface Preparation CSM Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. The dressing parameters including dressing feed rate (s), rough dressing depth. Surface Grinding Dressing Process.

From www.youtube.com

How Surface Grinding Works Part 1? YouTube Surface Grinding Dressing Process Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. Dressing returns the grinding wheel to its original sharpness by removing old grains to. Surface Grinding Dressing Process.

From www.researchgate.net

(PDF) Electrolytic InProcess Dressing (ELID) Grinding for NanoSurface Surface Grinding Dressing Process Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. Grinding is. Surface Grinding Dressing Process.

From www.researchgate.net

The schematic illustration of grinding wheel dressing Download Surface Grinding Dressing Process In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. It removes clogs, dulled abrasive grains, and excess bonding. The surface grinder is mainly used in the. Surface Grinding Dressing Process.

From pgisteel.com

Surface Grinding Precision Grinding, Inc. Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. The dressing parameters including dressing feed rate (s), rough dressing depth. Surface Grinding Dressing Process.

From mechanicalenotes.com

Surface Grinding Machine Definition, Parts, Working, Advantages Surface Grinding Dressing Process Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. The surface grinder is mainly used in the finishing process. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. Dressing returns the grinding wheel to its. Surface Grinding Dressing Process.

From extrudesign.com

What is Grinding Process? ExtruDesign Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. It is a very precise tool which. Surface Grinding Dressing Process.

From www.mdpi.com

Applied Sciences Free FullText Research and Progress on Truing and Surface Grinding Dressing Process Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the. Surface Grinding Dressing Process.

From www.multigrind.co.uk

Surface Grinding Services For Surfaces Up To 300mm x 650mm Surface Grinding Dressing Process The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. It removes clogs, dulled abrasive grains, and excess bonding. The surface grinder is mainly used in the. Surface Grinding Dressing Process.

From www.forturetools.com

Two necessary steps for grinding wheel dressing Forture Tools Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. Grinding is an abrasive machining process used for almost every manufacturing process to improve the. Surface Grinding Dressing Process.

From www.okuma.com

What is Dressing and Why Does Your Grinding Wheel Need It? Surface Grinding Dressing Process In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. It removes clogs, dulled abrasive grains, and excess bonding. It is a very precise tool which uses a. Surface Grinding Dressing Process.

From finemetalworking.com

Surface Grinder Types of Grinders & How They Work Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. Dressing returns the grinding wheel to its. Surface Grinding Dressing Process.

From www.hazellj.co.uk

Surface Dressing What you Need to Know Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. The dressing parameters including dressing feed rate (s), rough dressing depth. Surface Grinding Dressing Process.

From www.youtube.com

Surface grinding process YouTube Surface Grinding Dressing Process The surface grinder is mainly used in the finishing process. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. In order to keep the surface of the grinding wheel with sufficient sharpness and correct geometry during the grinding process, it must be. Dressing returns the grinding. Surface Grinding Dressing Process.

From www.youtube.com

SURFACE GRINDING part 2, accurate grinding, squaring up a block Surface Grinding Dressing Process The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or. Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. It. Surface Grinding Dressing Process.

From www.youtube.com

wheel dressing of surface grinding machine YouTube Surface Grinding Dressing Process It removes clogs, dulled abrasive grains, and excess bonding. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing depth (af),. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. The surface grinder is mainly used in the finishing process. It is. Surface Grinding Dressing Process.

From www.precision-surface.com

What is Surface Grinding & Reciprocating grinding? Surface Grinding Dressing Process Grinding is an abrasive machining process used for almost every manufacturing process to improve the surface finish with the help of abrasive grits. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal the fresh grain underneath. The dressing parameters including dressing feed rate (s), rough dressing depth (ar), rough dressing times (nr), fine dressing. Surface Grinding Dressing Process.