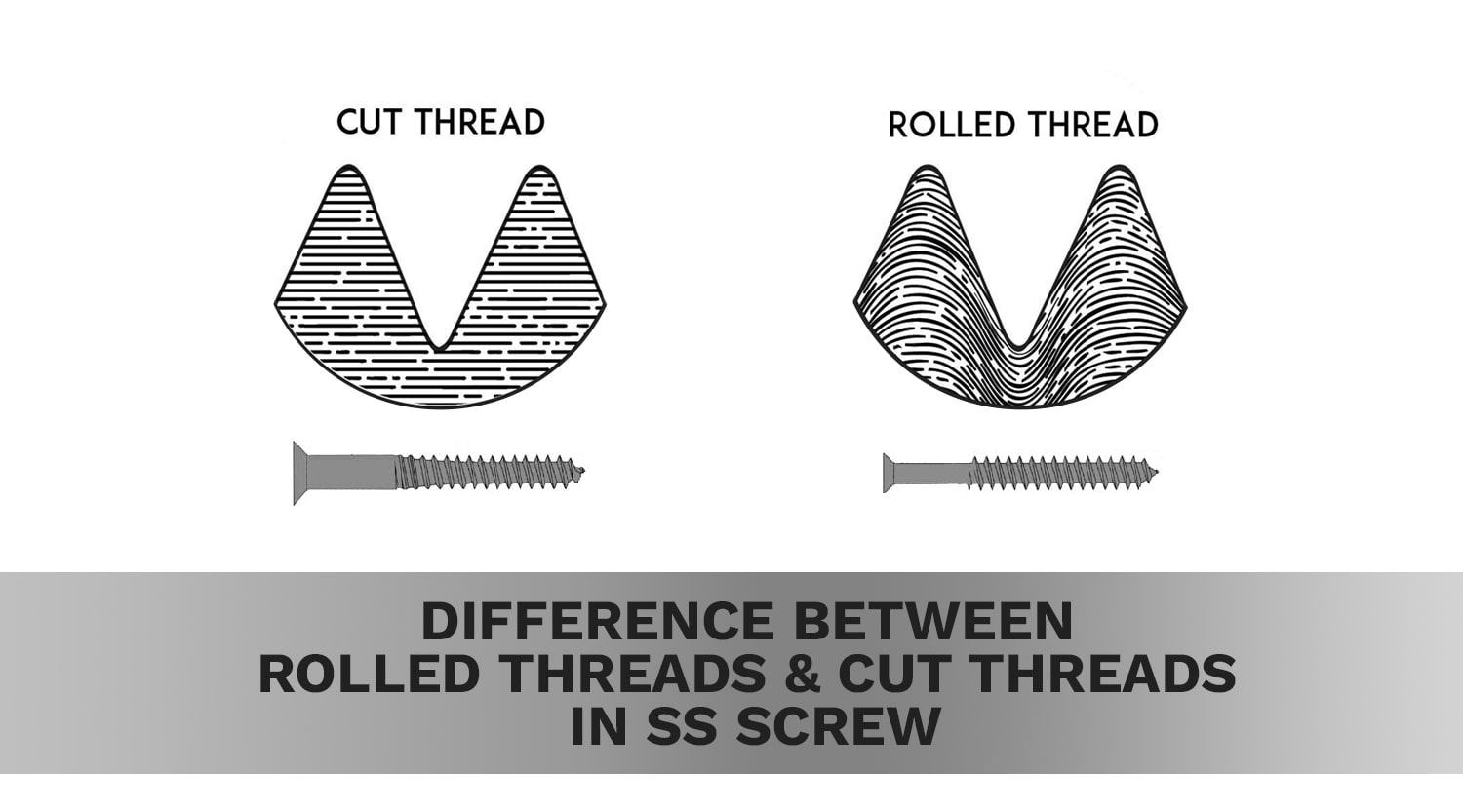

Difference Between Thread Rolling And Thread Cutting . Which works best for your application? Wondering which one may be best for your application? Rolled threads have higher strength compared to those with. Two prevalent techniques in the industry are thread rolling and thread cutting. The main difference between rolling threads vs. Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Many manufacturers prefer thread rolling to. Both methods have their unique advantages and. Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Rolled threads are significantly more economical to produce, with. Generally speaking, there are two main methods of producing external threads on a fastener: For many applications both cut threads and rolled threads are interchangeable. Cut threading takes a steel bar and cuts the threads.

from lpscrew.com

Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. Rolled threads have higher strength compared to those with. Generally speaking, there are two main methods of producing external threads on a fastener: Many manufacturers prefer thread rolling to. Rolled threads are significantly more economical to produce, with. Both methods have their unique advantages and. Wondering which one may be best for your application? The main difference between rolling threads vs. Cut threading takes a steel bar and cuts the threads. Two prevalent techniques in the industry are thread rolling and thread cutting.

Difference Between Rolled Threads and Cut Threads in SS Screw

Difference Between Thread Rolling And Thread Cutting Cut threading takes a steel bar and cuts the threads. Two prevalent techniques in the industry are thread rolling and thread cutting. Both methods have their unique advantages and. For many applications both cut threads and rolled threads are interchangeable. The main difference between rolling threads vs. Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Which works best for your application? What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Wondering which one may be best for your application? Generally speaking, there are two main methods of producing external threads on a fastener: Cut threading takes a steel bar and cuts the threads. Rolled threads have higher strength compared to those with. Rolled threads are significantly more economical to produce, with. Many manufacturers prefer thread rolling to.

From www.ultrasonic-resonators.org

Threads and threaded fasteners Ultrasonic Resonators Difference Between Thread Rolling And Thread Cutting Rolled threads are significantly more economical to produce, with. Wondering which one may be best for your application? Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. Many manufacturers prefer thread rolling to.. Difference Between Thread Rolling And Thread Cutting.

From www.accu.co.uk

Rolled Thread vs Cut Thread The Differences And Benefits Of Each Difference Between Thread Rolling And Thread Cutting Which works best for your application? The main difference between rolling threads vs. Rolled threads have higher strength compared to those with. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Wondering which one may be best for your application? Generally. Difference Between Thread Rolling And Thread Cutting.

From accu-components.com

Rolled Thread vs Cut Thread The Differences And Benefits Of Each Difference Between Thread Rolling And Thread Cutting The main difference between rolling threads vs. Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Which works best for your application?. Difference Between Thread Rolling And Thread Cutting.

From bhavyaindustriesldh.com

What is the Difference Between Rolled Threads and Cut Threads Difference Between Thread Rolling And Thread Cutting Cut threading takes a steel bar and cuts the threads. Two prevalent techniques in the industry are thread rolling and thread cutting. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Generally speaking, there are two main methods of producing external. Difference Between Thread Rolling And Thread Cutting.

From blog.thepipingmart.com

Self Tapping vs Thread Cutting Screws What's the Difference Difference Between Thread Rolling And Thread Cutting Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Many manufacturers prefer thread rolling to. Which works best for your application? Rolled threads are significantly more economical to produce, with. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with. Difference Between Thread Rolling And Thread Cutting.

From www.manufacturingguide.com

Thread Rolling Find suppliers, processes & material Difference Between Thread Rolling And Thread Cutting What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Wondering which one may be best for your application? Rolled threads have higher strength compared to those with. Cutting threads is that cut thread bolts and screws have the same body diameter. Difference Between Thread Rolling And Thread Cutting.

From klavcahys.blob.core.windows.net

What Tool Is Used To Cut Internal Threads at Billy Dunn blog Difference Between Thread Rolling And Thread Cutting Both methods have their unique advantages and. Wondering which one may be best for your application? Many manufacturers prefer thread rolling to. Rolled threads are significantly more economical to produce, with. Cut threading takes a steel bar and cuts the threads. Two prevalent techniques in the industry are thread rolling and thread cutting. What is the difference between a bolt. Difference Between Thread Rolling And Thread Cutting.

From www.jerpbakbayless.com

Rolled vs. Cut Threads JerpbakBayless Company Difference Between Thread Rolling And Thread Cutting Two prevalent techniques in the industry are thread rolling and thread cutting. Rolled threads are significantly more economical to produce, with. Wondering which one may be best for your application? Many manufacturers prefer thread rolling to. Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. The main difference between rolling. Difference Between Thread Rolling And Thread Cutting.

From whirlingmachines.com

Thread whirling vs thread rolling What are the differences between Difference Between Thread Rolling And Thread Cutting What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. For many applications both cut threads and rolled threads are interchangeable. Wondering which one may be best for your application? Two prevalent techniques in the industry are thread rolling and thread cutting.. Difference Between Thread Rolling And Thread Cutting.

From londonspokes.com

Spoke Machine London Spokes Difference Between Thread Rolling And Thread Cutting For many applications both cut threads and rolled threads are interchangeable. Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Cut threading takes a steel bar and cuts the threads. Rolled threads are significantly more economical to produce, with. The main difference between rolling threads vs. Wondering which one may. Difference Between Thread Rolling And Thread Cutting.

From mikehardware.com

Thread Rolling Process of Screws The Basics MIKEHARDWARE Difference Between Thread Rolling And Thread Cutting Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Which works best for your application? Wondering which one may be best for your application? Cut threading takes a steel bar and cuts the threads. Two prevalent techniques in the industry are thread rolling and thread cutting. The main difference between. Difference Between Thread Rolling And Thread Cutting.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Difference Between Thread Rolling And Thread Cutting Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Which works best for your application? Wondering which one may be best for your application? Many manufacturers prefer thread rolling to. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with. Difference Between Thread Rolling And Thread Cutting.

From www.cutwel.co.uk

Roll Tapping vs Conventional (Cut) Tapping Cutwel Ltd Difference Between Thread Rolling And Thread Cutting Cut threading takes a steel bar and cuts the threads. Wondering which one may be best for your application? Generally speaking, there are two main methods of producing external threads on a fastener: Two prevalent techniques in the industry are thread rolling and thread cutting. For many applications both cut threads and rolled threads are interchangeable. Rolled threads are significantly. Difference Between Thread Rolling And Thread Cutting.

From lpscrew.com

Difference Between Rolled Threads and Cut Threads in SS Screw Difference Between Thread Rolling And Thread Cutting Which works best for your application? Both methods have their unique advantages and. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Two prevalent techniques in the industry are thread rolling and thread cutting. The main difference between rolling threads vs.. Difference Between Thread Rolling And Thread Cutting.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Difference Between Thread Rolling And Thread Cutting Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Both methods have their unique advantages and. Which works best for your application? Many manufacturers prefer thread rolling to. Generally speaking, there are two main methods of producing external threads on a fastener: Rolled threads have higher strength compared to those. Difference Between Thread Rolling And Thread Cutting.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Difference Between Thread Rolling And Thread Cutting Wondering which one may be best for your application? Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. Two prevalent techniques in the industry are thread rolling and thread cutting. Generally speaking, there are two main methods of producing external threads on a fastener: The main difference between rolling threads vs. Which. Difference Between Thread Rolling And Thread Cutting.

From engineeringcheatsheet.com

The Science of The Rolling Process Engineering Cheat Sheet Difference Between Thread Rolling And Thread Cutting Cut threading takes a steel bar and cuts the threads. Generally speaking, there are two main methods of producing external threads on a fastener: The main difference between rolling threads vs. Which works best for your application? Many manufacturers prefer thread rolling to. For many applications both cut threads and rolled threads are interchangeable. Two prevalent techniques in the industry. Difference Between Thread Rolling And Thread Cutting.

From www.youtube.com

THREAD CUTTING on a LATHE YouTube Difference Between Thread Rolling And Thread Cutting Which works best for your application? Rolled threads have higher strength compared to those with. Cut threading takes a steel bar and cuts the threads. Generally speaking, there are two main methods of producing external threads on a fastener: Rolled threads are significantly more economical to produce, with. Many manufacturers prefer thread rolling to. Two prevalent techniques in the industry. Difference Between Thread Rolling And Thread Cutting.

From www.tfgusa.com

Unraveling The Advantage of Thread Rolling The Federal Group USA Difference Between Thread Rolling And Thread Cutting Many manufacturers prefer thread rolling to. Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Generally speaking, there are two main methods of producing external threads on a fastener: Cut threading takes a steel bar and cuts the threads. Both methods have their unique advantages and. Which works best for. Difference Between Thread Rolling And Thread Cutting.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Difference Between Thread Rolling And Thread Cutting Wondering which one may be best for your application? Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. For many applications both cut threads and rolled threads are interchangeable. Cut threading takes a steel bar and cuts the threads. Rolled threads have higher strength compared to those with. Two prevalent techniques in. Difference Between Thread Rolling And Thread Cutting.

From halifaxrs.com

Rolled Thread vs Cut Thread Differences and Benefits of Each Thread Difference Between Thread Rolling And Thread Cutting Rolled threads have higher strength compared to those with. Wondering which one may be best for your application? For many applications both cut threads and rolled threads are interchangeable. Two prevalent techniques in the industry are thread rolling and thread cutting. Rolled threads are significantly more economical to produce, with. The main difference between rolling threads vs. Both methods have. Difference Between Thread Rolling And Thread Cutting.

From www.fastening-solutions.co.uk

Fast What are the differences between cut and rolled threads? Difference Between Thread Rolling And Thread Cutting What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. Rolled threads are significantly more economical to produce, with. Rolled threads have higher strength compared. Difference Between Thread Rolling And Thread Cutting.

From www.slideserve.com

PPT Rolled Thread vs Cut Thread Differences and Benefits of Each Difference Between Thread Rolling And Thread Cutting Which works best for your application? What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Rolled threads have higher strength compared to those with. Rolled threads are formed by displacing the material, while cut threads are created by removing the material. Difference Between Thread Rolling And Thread Cutting.

From www.earnestmachine.com

What are the differences between cut and rolled threads? Earnest Difference Between Thread Rolling And Thread Cutting Which works best for your application? Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. The main difference between rolling threads vs. Generally speaking, there are two main methods of producing external threads on a fastener: Wondering which one may be best for your application? Rolled threads have higher strength compared to. Difference Between Thread Rolling And Thread Cutting.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Difference Between Thread Rolling And Thread Cutting Rolled threads are significantly more economical to produce, with. Both methods have their unique advantages and. Many manufacturers prefer thread rolling to. Generally speaking, there are two main methods of producing external threads on a fastener: Rolled threads have higher strength compared to those with. Rolled threads are formed by displacing the material, while cut threads are created by removing. Difference Between Thread Rolling And Thread Cutting.

From www.slideserve.com

PPT Difference Between Rolled and Cut Thread Bolts PowerPoint Difference Between Thread Rolling And Thread Cutting Cut threading takes a steel bar and cuts the threads. Wondering which one may be best for your application? Two prevalent techniques in the industry are thread rolling and thread cutting. The main difference between rolling threads vs. Generally speaking, there are two main methods of producing external threads on a fastener: Many manufacturers prefer thread rolling to. Rolled threads. Difference Between Thread Rolling And Thread Cutting.

From classicmetallicsheetfactory.blogspot.com

What's the Difference Between Rolled and Cut Thread Bolts Classic Difference Between Thread Rolling And Thread Cutting What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Many manufacturers prefer thread rolling to. Two prevalent techniques in the industry are thread rolling and thread cutting. Rolled threads have higher strength compared to those with. The main difference between rolling. Difference Between Thread Rolling And Thread Cutting.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Difference Between Thread Rolling And Thread Cutting Many manufacturers prefer thread rolling to. Which works best for your application? Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. The main difference between rolling threads vs. Cut threading takes a steel bar and cuts the threads. Rolled threads are significantly more economical to produce, with. Both methods have their unique. Difference Between Thread Rolling And Thread Cutting.

From loetbkgbj.blob.core.windows.net

Threaded Rod Cut To Size at Mark Newby blog Difference Between Thread Rolling And Thread Cutting Both methods have their unique advantages and. Two prevalent techniques in the industry are thread rolling and thread cutting. The main difference between rolling threads vs. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Generally speaking, there are two main. Difference Between Thread Rolling And Thread Cutting.

From www.nejireo.com

เจาะลึกข้อมูล "การกลึงเกลียว" และ "การรีดเกลียว" มีแตกต่างกันอย่างไร Blog Difference Between Thread Rolling And Thread Cutting Cutting threads is that cut thread bolts and screws have the same body diameter as thread diameter. Many manufacturers prefer thread rolling to. Two prevalent techniques in the industry are thread rolling and thread cutting. Rolled threads are significantly more economical to produce, with. Generally speaking, there are two main methods of producing external threads on a fastener: Which works. Difference Between Thread Rolling And Thread Cutting.

From www.ygmtools.com

What are the Differences Between Thread Rolling and Thread Cutting Difference Between Thread Rolling And Thread Cutting Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. Two prevalent techniques in the industry are thread rolling and thread cutting. Rolled threads are significantly more economical to produce, with. Both methods have their unique advantages and. Cut threading takes a steel bar and cuts the threads. Cutting threads is. Difference Between Thread Rolling And Thread Cutting.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Difference Between Thread Rolling And Thread Cutting Both methods have their unique advantages and. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Rolled threads have higher strength compared to those with. Cut threading takes a steel bar and cuts the threads. Many manufacturers prefer thread rolling to.. Difference Between Thread Rolling And Thread Cutting.

From www.youtube.com

Rolled vs Cut threads what's the difference? YouTube Difference Between Thread Rolling And Thread Cutting The main difference between rolling threads vs. Which works best for your application? Many manufacturers prefer thread rolling to. For many applications both cut threads and rolled threads are interchangeable. Rolled threads are significantly more economical to produce, with. Both methods have their unique advantages and. Cutting threads is that cut thread bolts and screws have the same body diameter. Difference Between Thread Rolling And Thread Cutting.

From taptite.com

ThreadRolling Screws or ThreadForming… REMINC & CONTI Fasteners Difference Between Thread Rolling And Thread Cutting Rolled threads are significantly more economical to produce, with. Many manufacturers prefer thread rolling to. Rolled threads are formed by displacing the material, while cut threads are created by removing the material through cutting. The main difference between rolling threads vs. Cut threading takes a steel bar and cuts the threads. What is the difference between a bolt with rolled. Difference Between Thread Rolling And Thread Cutting.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Difference Between Thread Rolling And Thread Cutting Wondering which one may be best for your application? Which works best for your application? Rolled threads have higher strength compared to those with. What is the difference between a bolt with rolled threads and one with cut threads and does a fastener with a reduced body and rolled threads meet astm. Rolled threads are formed by displacing the material,. Difference Between Thread Rolling And Thread Cutting.