Welding Parameters For Saw . Because the operator cannot see the. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal.

from alumni.uod.ac

Because the operator cannot see the. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and.

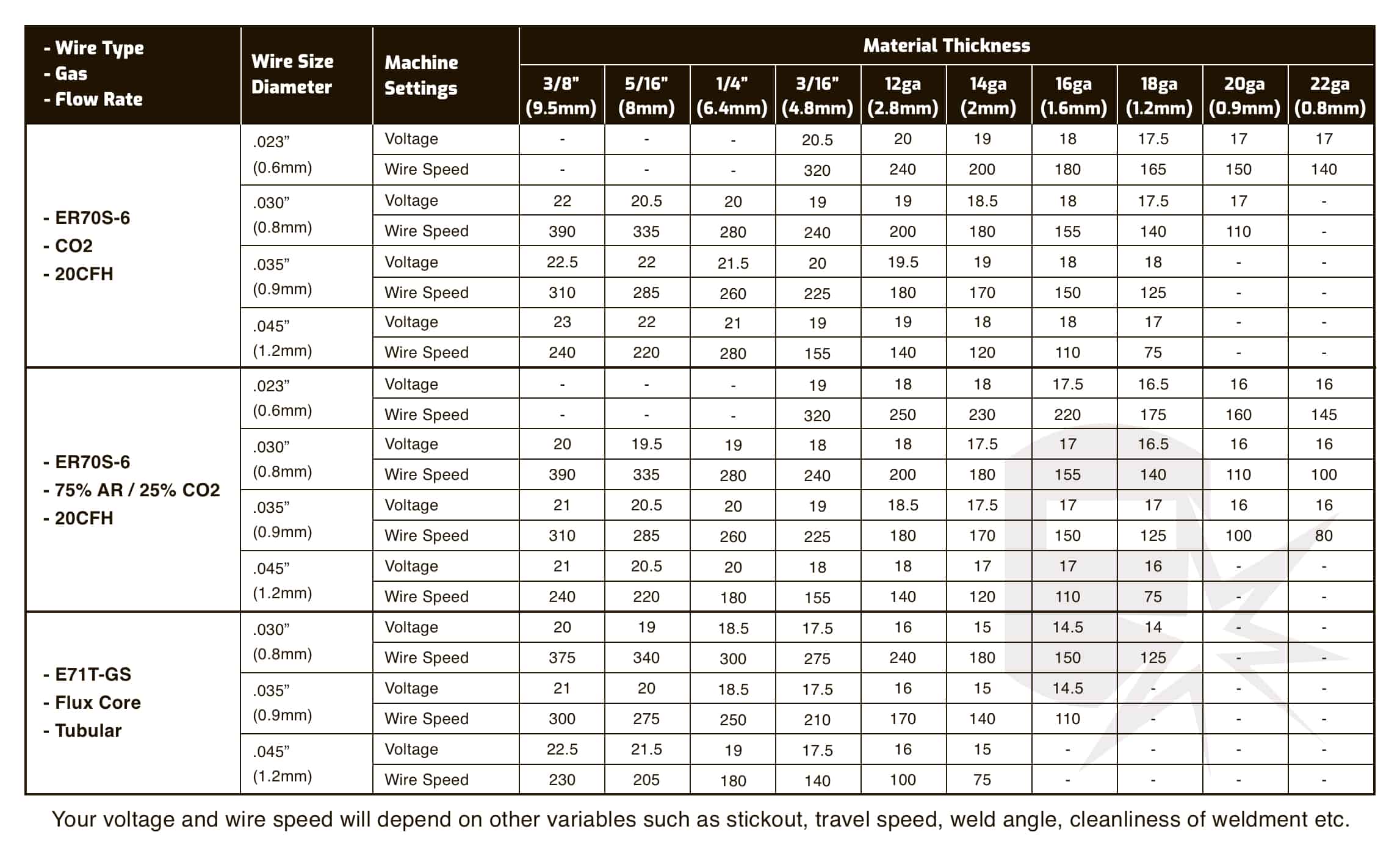

MIG Welder Settings Explained (with Chart) Weld Guru, 48 OFF

Welding Parameters For Saw Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Because the operator cannot see the. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and.

From www.scribd.com

QIR104Welding Parameters Record Sheet Welding Parameters For Saw Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean. Welding Parameters For Saw.

From www.researchgate.net

Welding parameters and responses for the full factorial design Welding Parameters For Saw Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals. Welding Parameters For Saw.

From www.slideshare.net

Submerged Arc Welding Welding Parameters For Saw Because the operator cannot see the. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously. Welding Parameters For Saw.

From www.slideserve.com

PPT One Side Welding Submerged Arc Welding Process PowerPoint Welding Parameters For Saw Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Because the operator cannot see the. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and. Welding Parameters For Saw.

From www.researchgate.net

Formula for determination of welding quality Download Scientific Diagram Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Because the operator. Welding Parameters For Saw.

From learnmech.com

What is welding procedure specification (wps) Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld.. Welding Parameters For Saw.

From www.scribd.com

Welding Calculations PDF Welding Construction Welding Parameters For Saw Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Current, arc. Welding Parameters For Saw.

From www.researchgate.net

Set of the welding parameters Download Table Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld.. Welding Parameters For Saw.

From www.researchgate.net

Parameters of welding process Download Table Welding Parameters For Saw Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Because the operator cannot see the. Welding current is the most influential process parameter for saw because it determines. Welding Parameters For Saw.

From www.semanticscholar.org

Table 2 from Effects of Various Process Parameters by Tensile and Welding Parameters For Saw Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid.. Welding Parameters For Saw.

From www.weldingandndt.com

(SAW) Submerged Arc Welding Welding & NDT Welding Parameters For Saw Because the operator cannot see the. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited. Welding Parameters For Saw.

From www.semanticscholar.org

Table 6 from Determination of submerged arc welding process parameters Welding Parameters For Saw Because the operator cannot see the. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Submerged arc welding uses a powdered flux layer, generating shielding and slag while. Welding Parameters For Saw.

From www.researchgate.net

Welding Parameters Parameter Value Download Table Welding Parameters For Saw Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals. Welding Parameters For Saw.

From www.researchgate.net

Submerged arc welding (SAW) conditions for the 70 mm thick plate Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Because the operator cannot see the. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously. Welding Parameters For Saw.

From www.hobartbrothers.com

TIG Welding Parameters Hobart Brothers Welding Parameters For Saw Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Because the operator cannot see the. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable. Welding Parameters For Saw.

From www.scribd.com

Parameters Submerged Arc Welding Handbook Welding Alternating Current Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited. Welding Parameters For Saw.

From www.researchgate.net

Welding parameter map with points indicating minimum power and energy Welding Parameters For Saw Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld. Welding Parameters For Saw.

From www.researchgate.net

Welding process parameters in different cases Download Scientific Diagram Welding Parameters For Saw Because the operator cannot see the. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously. Welding Parameters For Saw.

From www.pinterest.ca

Weld Setup and Parts Information Chart Welding set, Welding table Welding Parameters For Saw Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Welding current is the most. Welding Parameters For Saw.

From www.westweld.com

Parameter Selection of Drawn Arc Stud Welding Machine Welding Parameters For Saw Because the operator cannot see the. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously. Welding Parameters For Saw.

From www.slideserve.com

PPT TIG Welding Introduction PowerPoint Presentation, free download Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Because the operator cannot see the. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the. Welding Parameters For Saw.

From infoweldings.blogspot.com

Projection Welding Parameters Info Welding Welding Parameters For Saw Because the operator cannot see the. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding (saw) is an arc welding process that forms an. Welding Parameters For Saw.

From ahssinsights.org

Spot Weld Strength Improvement by PWHT AHSS Guidelines Welding Parameters For Saw Because the operator cannot see the. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Submerged arc welding uses a powdered flux layer, generating shielding and slag. Welding Parameters For Saw.

From infoweldings.blogspot.com

Projection Welding Parameters Info Welding Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Because the operator cannot see the. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Submerged arc welding (saw) is a welding process where the tubular electrode is. Welding Parameters For Saw.

From www.scribd.com

Welding Chart the complete reference guide to welding Pipe (Fluid Welding Parameters For Saw Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc. Welding Parameters For Saw.

From vdocuments.mx

Sample Form (GMAW FCAW) WELDING PROCEDURE SPECIFICATION (WPS) Form Welding Parameters For Saw Because the operator cannot see the. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of. Welding Parameters For Saw.

From www.researchgate.net

Welding process parameters for each layer. Download Scientific Diagram Welding Parameters For Saw Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Current, arc voltage and travel. Welding Parameters For Saw.

From www.researchgate.net

SAW procedure welding parameters for horizontal joints. Download Welding Parameters For Saw Because the operator cannot see the. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Submerged arc welding (saw) is a welding process where the tubular electrode. Welding Parameters For Saw.

From alumni.uod.ac

MIG Welder Settings Explained (with Chart) Weld Guru, 48 OFF Welding Parameters For Saw Because the operator cannot see the. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Welding current is the most influential process parameter for saw because it determines. Welding Parameters For Saw.

From www.researchgate.net

Welding parameters used in DC PGMAW Download Table Welding Parameters For Saw Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited. Welding Parameters For Saw.

From weldinganswers.com

14 Welding Procedure Specification Variables WELDING ANSWERS Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Because the operator cannot see. Welding Parameters For Saw.

From www.researchgate.net

Welding parameters used in this study. Download Scientific Diagram Welding Parameters For Saw Welding current is the most influential process parameter for saw because it determines the melting rate of electrode, penetration depth and. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc. Welding Parameters For Saw.

From www.researchgate.net

Values of Welding Parameters Download Table Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Current, arc voltage and travel speed all affect bead shape, depth of penetration and chemical composition of the deposited weld metal. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals. Welding Parameters For Saw.

From www.cruxweld.com

Submerged Arc Welding (SAW) Working Process, Equipment, Parts, and Its Welding Parameters For Saw Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously fed consumable solid. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating.. Welding Parameters For Saw.

From www.hobartbrothers.com

Welding Procedures Typical TIG Parameters For Groove Welds In Welding Parameters For Saw Because the operator cannot see the. Welding parameters, namely electrode size, welding voltage, welding current and welding speed are four most important. Submerged arc welding (saw) is a welding process where the tubular electrode is fed continuously to join two metals by generating. Submerged arc welding (saw) is an arc welding process that forms an electric arc between a continuously. Welding Parameters For Saw.