Boiler Feed Water Deaerator . A deaerator, generally, reduces the oxygen level to 7ppb. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Deaeration protects the steam system from the effects of. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Vacuum deaeration has been used successfully in water distribution systems. However, pressure deaeration (with steam as the purge gas) is. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Back to learn about steam.

from ar.inspiredpencil.com

Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Vacuum deaeration has been used successfully in water distribution systems. Back to learn about steam. Deaeration protects the steam system from the effects of. A deaerator, generally, reduces the oxygen level to 7ppb. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. However, pressure deaeration (with steam as the purge gas) is.

Boiler Feed Water Applications

Boiler Feed Water Deaerator Back to learn about steam. However, pressure deaeration (with steam as the purge gas) is. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Deaeration protects the steam system from the effects of. Back to learn about steam. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. A deaerator, generally, reduces the oxygen level to 7ppb. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Vacuum deaeration has been used successfully in water distribution systems. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam.

From www.wcrouse.com

Deaeration Overview of Deaerators and Their Role in Boilers WC Rouse Boiler Feed Water Deaerator Vacuum deaeration has been used successfully in water distribution systems. Back to learn about steam. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Deaeration protects the steam system from the effects of. However,. Boiler Feed Water Deaerator.

From instrumentationtools.com

Boiler Feed Water Circulation System Boiler Feed Water Deaerator Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. Deaerators are essential devices. Boiler Feed Water Deaerator.

From stock.adobe.com

Deaerator of a boiler room, thermal station. Open feed water heater Boiler Feed Water Deaerator Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Vacuum deaeration has been used successfully in water distribution systems. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Back to learn about steam. Deaerator equipment is designed to reduce dissolved corrosive. Boiler Feed Water Deaerator.

From qingdaopower.en.made-in-china.com

Boiler Feed Water Deoxygen Thermal Deaerator China Boiler and Deaerator Boiler Feed Water Deaerator Deaeration protects the steam system from the effects of. Back to learn about steam. A deaerator, generally, reduces the oxygen level to 7ppb. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam. Boiler Feed Water Deaerator.

From www.hurstboiler.com

Hurst Deaerating Feedwater System & Surge Tank Combination Boiler Feed Water Deaerator This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. A deaerator, generally, reduces the oxygen level to 7ppb. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds. Boiler Feed Water Deaerator.

From www.rasmech.com

Deaerator 101 And Considerations Before Buying RasMech Boiler Feed Water Deaerator Deaeration protects the steam system from the effects of. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. Vacuum deaeration has been used successfully in water distribution systems. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Back to learn about steam. The need to remove. Boiler Feed Water Deaerator.

From ar.inspiredpencil.com

Boiler Feed Water Applications Boiler Feed Water Deaerator Vacuum deaeration has been used successfully in water distribution systems. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. However, pressure deaeration (with steam as the purge gas) is. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Boiler deaerators commonly. Boiler Feed Water Deaerator.

From precisionboilers.com

SPDA Spray Deaerator Precision Boilers Boiler Feed Water Deaerator Deaeration protects the steam system from the effects of. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Vacuum deaeration has been used. Boiler Feed Water Deaerator.

From stock.adobe.com

Deaerator of a boiler room, thermal station principe of work. Open feed Boiler Feed Water Deaerator Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Back to learn about steam. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. A deaerator, generally, reduces the oxygen level to 7ppb. Vacuum deaeration has been used successfully in water distribution systems. This is. Boiler Feed Water Deaerator.

From atlanticfeedwatersystemsinc.com

Boiler Feedwater Systems Atlantic Feedwater Systems, Inc Boiler Feed Water Deaerator Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. A deaerator, generally, reduces the oxygen level to 7ppb. This is done at times by heating the water to. Boiler Feed Water Deaerator.

From watertreatmentbasics.com

Explained How Does a Deaerator Work? Boiler Water Treatment Boiler Feed Water Deaerator However, pressure deaeration (with steam as the purge gas) is. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Vacuum deaeration has been used successfully in water distribution systems. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerator equipment. Boiler Feed Water Deaerator.

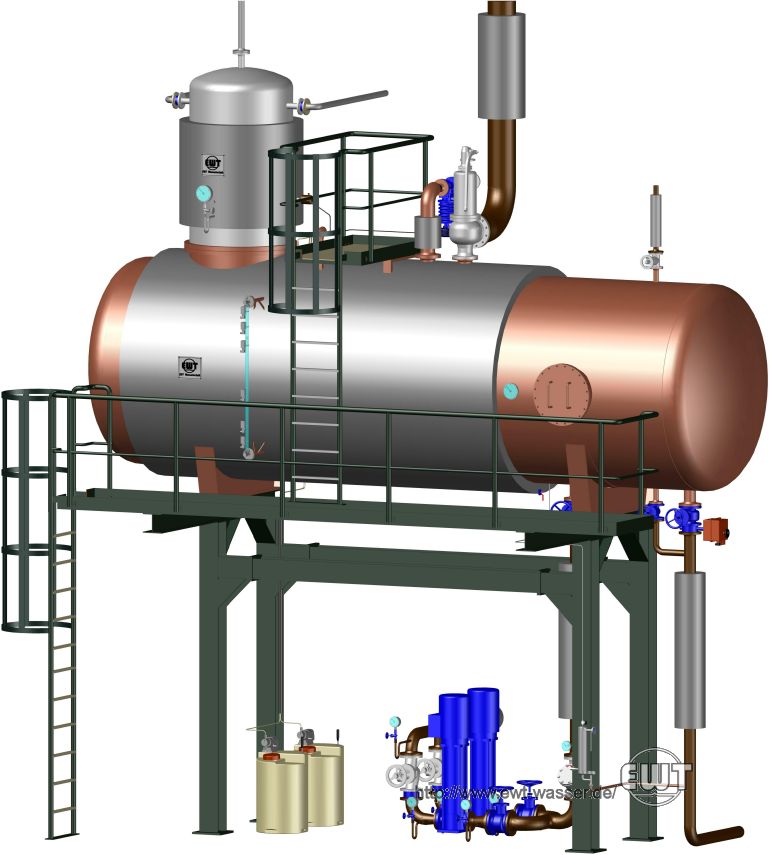

From www.ewt-wasser.de

Deaerator, Boiler Feed Water Tank EWT Water Technology Boiler Feed Water Deaerator The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaeration protects the steam system from the effects of. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. A deaerator, generally, reduces the oxygen level to 7ppb. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater.. Boiler Feed Water Deaerator.

From simtronics.com

SPM5400 Boiler Feedwater System (BFW) Simtronics SPM Series Boiler Feed Water Deaerator However, pressure deaeration (with steam as the purge gas) is. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Vacuum deaeration has been used successfully in water distribution systems. Back to. Boiler Feed Water Deaerator.

From atlanticfeedwatersystemsinc.com

P5 .005 cc/liter Horizontal & Vertical Pressurized Deaerators Boiler Feed Water Deaerator Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Vacuum deaeration has been used. Boiler Feed Water Deaerator.

From qingdaopower.en.made-in-china.com

Power Plant Boiler Feed Water Deoxygen Thermal Deaerator Boiler and Boiler Feed Water Deaerator Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. A deaerator, generally, reduces the oxygen level to 7ppb. Vacuum deaeration has been used successfully in water distribution systems. Back to learn about steam. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. The need. Boiler Feed Water Deaerator.

From www.powerhx.com

POWER HX TECH CO., LTD. Boiler Feed Water Deaerator The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Vacuum deaeration has been used successfully in water distribution systems. This is done at times by heating the water to the temperature closed. Boiler Feed Water Deaerator.

From www.linkedin.com

Gas Removal Methods from Water Boiler Feed Water Deaerator However, pressure deaeration (with steam as the purge gas) is. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Vacuum deaeration has been used successfully in water distribution systems. Back to learn about steam. A deaerator, generally, reduces the oxygen level to 7ppb. Deaerators are mechanical devices that remove dissolved gases from. Boiler Feed Water Deaerator.

From www.wcrouse.com

Deaeration Overview of Deaerators and Their Role in Boilers WC Rouse Boiler Feed Water Deaerator Back to learn about steam. However, pressure deaeration (with steam as the purge gas) is. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. A deaerator, generally, reduces the oxygen level to 7ppb. Deaeration protects the steam system from the effects of. This is done at times by. Boiler Feed Water Deaerator.

From www.coalhandlingplants.com

Deaerator in Thermal Power Plant Boiler Feed Water Deaerator Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. A deaerator, generally, reduces the oxygen level to 7ppb. Deaeration protects the steam system from the effects of. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Back to learn about steam. Deaerators are essential devices in chemical process industries or facilities where boilers. Boiler Feed Water Deaerator.

From cleanboiler.org

Deaerator_Spray2 Boiler Feed Water Deaerator Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Vacuum deaeration has been used successfully in water distribution systems. A deaerator, generally, reduces the oxygen level to 7ppb. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerator equipment is. Boiler Feed Water Deaerator.

From ergil.com

Deaerator Vessels & Feed Water Storage Tanks Ergil World Leading Boiler Feed Water Deaerator Vacuum deaeration has been used successfully in water distribution systems. However, pressure deaeration (with steam as the purge gas) is. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Back to learn. Boiler Feed Water Deaerator.

From www.wareinc.com

Testing & Maintaining a Healthy Deaerator WARE Boiler Feed Water Deaerator Back to learn about steam. A deaerator, generally, reduces the oxygen level to 7ppb. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. However, pressure deaeration (with steam as the purge gas) is. Vacuum deaeration has been used successfully in water distribution systems. Deaerators. Boiler Feed Water Deaerator.

From econtrol.com

Boiler Feed Systems Energy Control Boiler Feed Water Deaerator This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator,. Boiler Feed Water Deaerator.

From en.idmsteamboiler.co.id

Sell Deaerator Tank boiler Feed Water Boiler Indira Mitra Boiler Boiler Feed Water Deaerator Vacuum deaeration has been used successfully in water distribution systems. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. However, pressure deaeration (with steam as the purge gas) is. A deaerator,. Boiler Feed Water Deaerator.

From www.thermalpowertech.com

Basic Deaerator and Working Thermal Power Tech Boiler Feed Water Deaerator However, pressure deaeration (with steam as the purge gas) is. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Vacuum deaeration has been used successfully in water distribution systems. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Back to learn about steam. This. Boiler Feed Water Deaerator.

From www.pro-sonix.com

Boiler Feedwater Tank Heating Steam Sparger for Oxygen Removal to Boiler Feed Water Deaerator Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Back to learn about steam. However, pressure deaeration (with steam as the purge gas) is. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment.. Boiler Feed Water Deaerator.

From www.hurstboiler.com

Feedwater Deaerators Oxymiser Hurst Boiler Boiler Feed Water Deaerator Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Back to. Boiler Feed Water Deaerator.

From precisionboilers.com

Boiler Room Feedwater Tanks & Deaerators Precision Boilers Boiler Feed Water Deaerator Deaeration protects the steam system from the effects of. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. A deaerator, generally, reduces the oxygen level to 7ppb. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Deaerators are essential devices. Boiler Feed Water Deaerator.

From www.idmsteamboiler.co.id

Jual Fabrikasi Deaerator Tank boiler Feed Water Boiler Tangerang Boiler Feed Water Deaerator Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. A deaerator, generally, reduces the oxygen level to 7ppb. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus. Boiler Feed Water Deaerator.

From www.dreamstime.com

Deaerator of a Boiler Room, Thermal Station Principe of Work Stock Boiler Feed Water Deaerator The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Boiler deaerators commonly are used to remove oxygen and other gases from the water that feeds into boilers that generate steam. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Deaerator equipment. Boiler Feed Water Deaerator.

From smithhughes.com

Industrial Steam Feed Tanks & Deaerators Smith Hughes Boiler Feed Water Deaerator The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Back to learn about steam. However, pressure deaeration (with steam as the purge gas) is. Deaeration protects the steam system from the effects of. Deaerator equipment is designed to reduce dissolved corrosive gases in the boiler feed water. Deaerators are mechanical devices that. Boiler Feed Water Deaerator.

From patriotboiler.com

What Is a Boiler Deaerator Patriot Boiler Boiler Feed Water Deaerator However, pressure deaeration (with steam as the purge gas) is. A deaerator, generally, reduces the oxygen level to 7ppb. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerators are essential devices in chemical process industries or facilities where boilers are. Boiler Feed Water Deaerator.

From instrumentationtools.com

What is a Deaerator? Working Principle Boiler Feed Water Deaerator This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Deaerators are mechanical devices that remove dissolved gases from boiler feedwater. Deaerators are essential devices in chemical process industries or facilities where boilers are used for steam production from boiler feedwater. Vacuum deaeration has been used. Boiler Feed Water Deaerator.

From lockwoodproducts.com

Model SS Deaerator (Spray Type) Lockwood Products Boiler Feed Water Deaerator Back to learn about steam. Vacuum deaeration has been used successfully in water distribution systems. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. The need to remove gases from boiler feedwater and the operation of a pressurised deaerator, plus calculations. Deaerators are mechanical devices. Boiler Feed Water Deaerator.

From www.directindustry.com

Boiler feed water degasser DG ATTSU TERMICA S.L. for water Boiler Feed Water Deaerator Back to learn about steam. However, pressure deaeration (with steam as the purge gas) is. Deaeration protects the steam system from the effects of. This is done at times by heating the water to the temperature closed to the saturated temperature at the pressure within the deaerating equipment. Vacuum deaeration has been used successfully in water distribution systems. Deaerator equipment. Boiler Feed Water Deaerator.