Brass Hardness Brinell . Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). The large size of indentation and. The test is achieved by. Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy.

from samanthalong.z19.web.core.windows.net

Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. The test is achieved by. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The large size of indentation and.

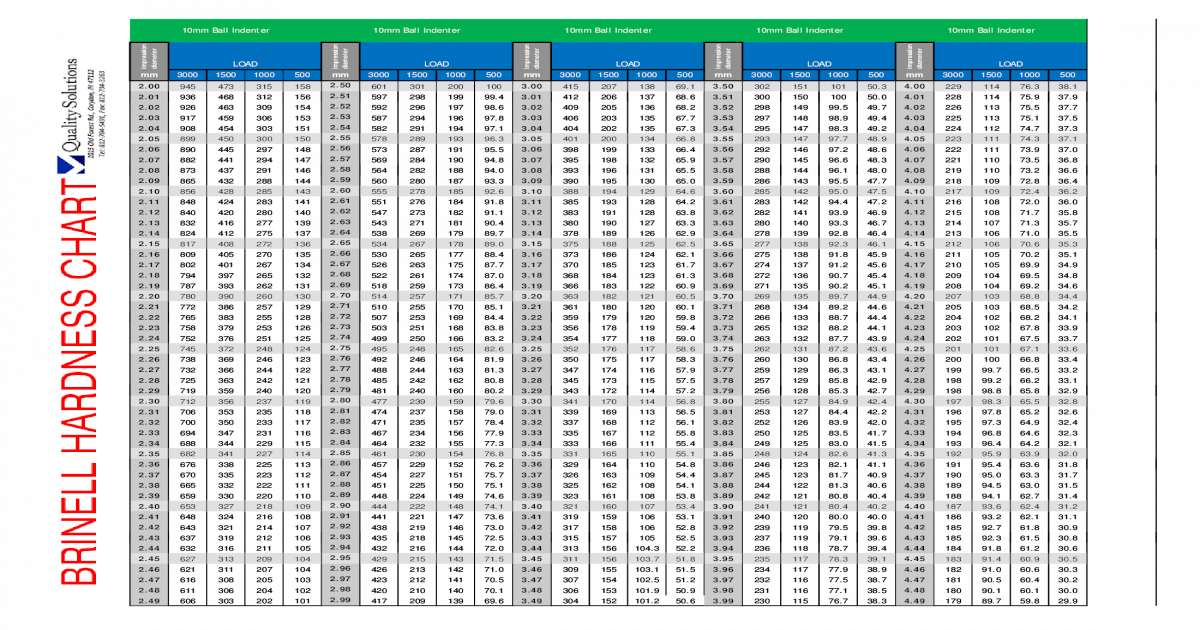

Brinell Hardness Chart For Metals

Brass Hardness Brinell Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The test is achieved by. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The large size of indentation and. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys.

From www.tessshebaylo.com

Brinell Hardness Equation Tessshebaylo Brass Hardness Brinell 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The large size of indentation and. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The test is achieved by. The brinell hardness of brass constant displays. Brass Hardness Brinell.

From www.practicalmachinist.com

Brinell Hardness Testing Machine Brass Hardness Brinell The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. The large size of indentation. Brass Hardness Brinell.

From www.vrogue.co

Rockwell Brinell Hardness Conversion Chart vrogue.co Brass Hardness Brinell 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and. Brass Hardness Brinell.

From www.yumpu.com

Hardness Conversion Chart provides values for Brinell Kelly Pipe Brass Hardness Brinell Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The large size of indentation and. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness. Brass Hardness Brinell.

From www.sfckoenig.com

Technical Information Hardness Conversion Table SFC KOENIG Brass Hardness Brinell The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these. Brass Hardness Brinell.

From payscalechart.z28.web.core.windows.net

rockwell scale conversion chart Rockwell hardness chart metals brinell Brass Hardness Brinell Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. 53 rows the. Brass Hardness Brinell.

From gamma.app

Brinell Hardness Test Brass Hardness Brinell Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Understanding the relationship between hardness scales (such as. Brass Hardness Brinell.

From slashk.blogspot.com

Slash K Reloading Lead Bullet Hardness Brass Hardness Brinell The test is achieved by. Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. 53 rows the brinell hardness test is commonly used. Brass Hardness Brinell.

From www.solutionspile.com

[Solved] Estimate the Brinell and Rockwell hardness for t Brass Hardness Brinell The large size of indentation and. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The test is achieved by. Overview of materials for brass, this property data is a summary of. Brass Hardness Brinell.

From mavink.com

Rockwell B Hardness Scale Chart Brass Hardness Brinell Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. The large size of indentation and. The test is achieved by. The brinell hardness of brass constant displays the value of the. Brass Hardness Brinell.

From www.enggstudy.com

Metallurgy EnggStudy Brass Hardness Brinell 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The test is achieved. Brass Hardness Brinell.

From mavink.com

Brinell Hardness Chart Printable Brass Hardness Brinell The large size of indentation and. The test is achieved by. Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and. Brass Hardness Brinell.

From katherinewall.z13.web.core.windows.net

Brinell Hardness Chart For Metals Brass Hardness Brinell Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). The large size of indentation and. The test is achieved by. 53 rows the brinell hardness test. Brass Hardness Brinell.

From samanthalong.z19.web.core.windows.net

Brinell Hardness Chart For Metals Brass Hardness Brinell 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The test is achieved by. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and. Brass Hardness Brinell.

From web.calce.umd.edu

Hardness Brass Hardness Brinell Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile. Brass Hardness Brinell.

From allsteelchoices.blogspot.com

Stainless Steel Hardness Scale Steel Choices Brass Hardness Brinell Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The large size of indentation and. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering. Brass Hardness Brinell.

From payscalechart.z28.web.core.windows.net

brinell hardness scale chart Brinell scale hbw 10/3000 chart Brass Hardness Brinell The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Overview of materials for brass, this property data is a summary of similar materials in the matweb database. Brass Hardness Brinell.

From www.chegg.com

Solved SCOPE The Brinell Hardness Test measures the Brass Hardness Brinell Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for. Brass Hardness Brinell.

From www.iqualitrol.com

China Dongguan Quality Control Technology Co., Ltd. latest company news Brass Hardness Brinell 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. Overview of materials. Brass Hardness Brinell.

From www.tradeindia.com

Truemet Poldi Hardness Tester For Measuring The Brinell Hardness Of Brass Hardness Brinell Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The brinell hardness of brass constant displays the value of the brinell hardness for brass. Brass Hardness Brinell.

From hxeyernyc.blob.core.windows.net

Rockwell Hardness C Scale Chart at Tabitha Moore blog Brass Hardness Brinell The test is achieved by. Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile. Brass Hardness Brinell.

From www.impacttestingmachine.com

HB3000C Brinell hardness tester Brass Hardness Brinell Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for. Brass Hardness Brinell.

From www.youtube.com

Determining Brinell Hardness Using a Standard Non Destructive Brinell Brass Hardness Brinell The large size of indentation and. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for. Brass Hardness Brinell.

From liamhowells.z19.web.core.windows.net

Material Hardness Comparison Chart Brass Hardness Brinell Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The test is achieved by. The large size of indentation and. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Overview of materials for brass, this property data is a summary of similar materials in the. Brass Hardness Brinell.

From extrudesign.com

How Brinell Hardness Test is conducted? ExtruDesign Brass Hardness Brinell The large size of indentation and. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. The test is achieved by. Standard industry hardness testing methods, including. Brass Hardness Brinell.

From mavink.com

Metal Hardness Scale Brass Hardness Brinell The large size of indentation and. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and. Brass Hardness Brinell.

From www.struers.com

Brinell Hardness Testing. Brass Hardness Brinell Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Understanding the relationship between. Brass Hardness Brinell.

From mavink.com

Brinell Hardness Chart Printable Brass Hardness Brinell Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The large size of indentation and. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. The test is achieved by. 53 rows the brinell hardness test is commonly used to determine. Brass Hardness Brinell.

From justdownloadandgo.blogspot.com

Just Download And Go CONVERT BRINELL TO ROCKWELL C Brass Hardness Brinell Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for. Brass Hardness Brinell.

From www.brystartools.com

Hardness Conversion Chart Rockwell "C" Hardness Range Brass Hardness Brinell Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. The large size of indentation and. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering. Brass Hardness Brinell.

From www.metalsupermarkets.com

What are Brinell and Rockwell Hardness Measurements? Metal Supermarkets Brass Hardness Brinell Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. The test is achieved by. Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. 53 rows the brinell hardness test is commonly used. Brass Hardness Brinell.

From www.pinnaxis.com

Determining Brinell Hardness Using A Standard Non, 45 OFF Brass Hardness Brinell The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Understanding the relationship between hardness scales (such as. Brass Hardness Brinell.

From www.azahner.com

Metal Hardness Zahner — Innovation and Collaboration to Achieve the Brass Hardness Brinell Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass. Proposed by swedish. Brass Hardness Brinell.

From pdfslide.net

BrinellRockwell Hardness Chart JP CHART Visit us at http/ Brinell Brass Hardness Brinell Overview of materials for brass, this property data is a summary of similar materials in the matweb database for the category brass. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection. Standard industry hardness testing methods, including rockwell, brinell, or vickers, will suffice for brass.. Brass Hardness Brinell.

From jodielambert.z13.web.core.windows.net

Aluminium Hardness Scale Comparison Brass Hardness Brinell Proposed by swedish engineer johan august brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The test is achieved by. The large size of indentation and. The brinell hardness of brass constant displays the value of the brinell hardness for brass uns c26000 (100 bhn). Understanding the relationship between hardness scales (such. Brass Hardness Brinell.