Surface Finish 32 Vs 16 . Ra = roughness, average in. Aside from appearance, it also influences part strength,. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. The measure of the total space irregularities on the surface metal is known as surface roughness. the following charts and tables convert surface finish or roughness between selected industry standard units. surface finishes define the final appearance of parts after machining. surface finish specification and comparison. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts.

from www.mscdirect.com

The measure of the total space irregularities on the surface metal is known as surface roughness. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. Ra = roughness, average in. surface finish specification and comparison. Aside from appearance, it also influences part strength,. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finishes define the final appearance of parts after machining. the following charts and tables convert surface finish or roughness between selected industry standard units.

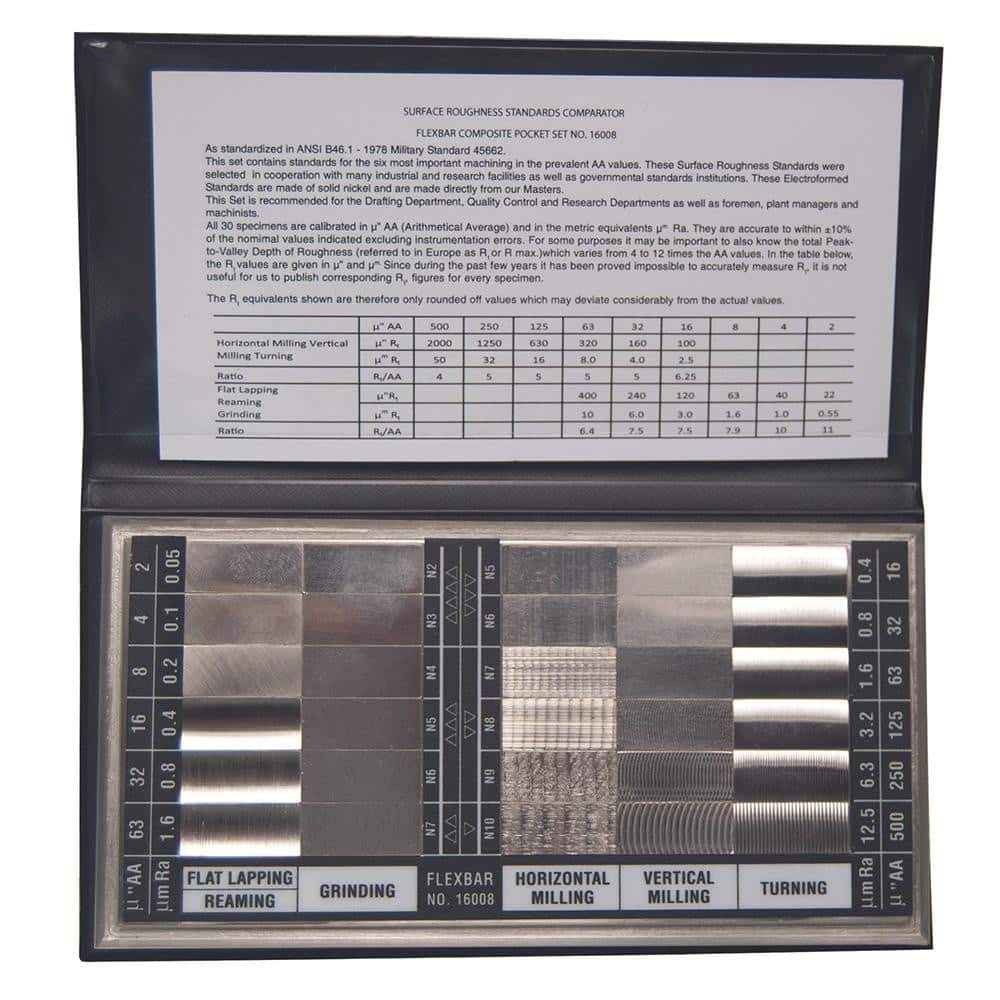

Flexbar 2 to 500 AA micro Inch Surface Finish, Nickel, Surface Finish

Surface Finish 32 Vs 16 the following charts and tables convert surface finish or roughness between selected industry standard units. The measure of the total space irregularities on the surface metal is known as surface roughness. Aside from appearance, it also influences part strength,. surface finish specification and comparison. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. the following charts and tables convert surface finish or roughness between selected industry standard units. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. Ra = roughness, average in. surface finishes define the final appearance of parts after machining.

From giovqwoqj.blob.core.windows.net

Vacuum Coupling Radiation Fittings at Elizabeth Ver blog Surface Finish 32 Vs 16 The measure of the total space irregularities on the surface metal is known as surface roughness. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. Ra = roughness, average in. additionally, manufacturers can use the surface finish conversion chart to compare different roughness. Surface Finish 32 Vs 16.

From lightbulbexpert.com

VEVOR Indoor/Outdoor Electric Grill 1800W 200sq.in with 2 Zone Grilling Surface Finish 32 Vs 16 surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. surface finishes define the final appearance of parts after machining. Aside from appearance, it also influences part strength,. surface finish specification and comparison. Ra = roughness, average in. additionally, manufacturers can use the surface finish conversion chart to compare different. Surface Finish 32 Vs 16.

From mungfali.com

Metric Surface Finish Chart Surface Finish 32 Vs 16 surface finishes define the final appearance of parts after machining. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. the following charts and tables convert surface finish or roughness between selected industry standard units. surface finish specification and comparison. Ra =. Surface Finish 32 Vs 16.

From www.penntoolco.com

GAR C9 Cast Microfinish Comparator Surface Roughness Scale 16039 Surface Finish 32 Vs 16 surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finishes define the final appearance of parts after machining. Aside from appearance, it also influences part strength,. Ra = roughness, average in. surface finish specification and comparison. additionally, manufacturers can use. Surface Finish 32 Vs 16.

From www.vrogue.co

Surface Roughness Conversion Chart Tables vrogue.co Surface Finish 32 Vs 16 The measure of the total space irregularities on the surface metal is known as surface roughness. surface finish specification and comparison. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finish symbols are graphical callouts to indicate surface texture and surface. Surface Finish 32 Vs 16.

From www.walmart.com

Konghyp MultiPurpose Floor Paint 150ml Versatile Floor Paint for Surface Finish 32 Vs 16 surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. The measure of the total space irregularities on the surface metal is known as surface roughness. surface finish chart by machining technology in the chart below,. Surface Finish 32 Vs 16.

From www.mscdirect.com

Flexbar 2 to 500 AA micro Inch Surface Finish, Nickel, Surface Finish Surface Finish 32 Vs 16 Aside from appearance, it also influences part strength,. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. The measure of the total space irregularities on the surface metal is known as surface roughness. surface finishes define the final appearance of parts after machining. surface finish specification and comparison. Ra =. Surface Finish 32 Vs 16.

From www.walmart.com

Dining Chairs High Back Leather Seat Chair with Wood Legs and Surface Finish 32 Vs 16 surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. The measure of the total space irregularities on the surface metal is known as surface roughness. the following charts and tables convert surface finish or roughness between selected industry standard units. additionally, manufacturers can use the surface finish conversion chart to. Surface Finish 32 Vs 16.

From www.walmart.com

Clorox Disinfectant Mist, MultiSurface Spray, Lemongrass Mandarin, 16 Surface Finish 32 Vs 16 additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. the following charts and tables convert surface finish or roughness between selected industry standard units. Aside from appearance,. Surface Finish 32 Vs 16.

From exoimbyop.blob.core.windows.net

Engineering Drawing Surface Finish Callout at Sue Hudgens blog Surface Finish 32 Vs 16 Aside from appearance, it also influences part strength,. the following charts and tables convert surface finish or roughness between selected industry standard units. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. additionally, manufacturers can use the surface finish conversion chart to. Surface Finish 32 Vs 16.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish 32 Vs 16 additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. Ra = roughness, average in. surface finish specification and comparison. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. The measure of the total space irregularities on. Surface Finish 32 Vs 16.

From exofazbts.blob.core.windows.net

Surface Roughness Machining Process at Shawn Foland blog Surface Finish 32 Vs 16 Ra = roughness, average in. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finishes define the final appearance of parts after machining. The measure of the total space irregularities on the surface metal is known as surface roughness. surface finish symbols are graphical callouts to indicate surface texture and. Surface Finish 32 Vs 16.

From exowwdjok.blob.core.windows.net

Mold Texture Chart at Debbie Cabral blog Surface Finish 32 Vs 16 surface finish specification and comparison. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. Aside from appearance, it also influences part strength,. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. the following charts and. Surface Finish 32 Vs 16.

From hxefyflml.blob.core.windows.net

Bostitch Angled Finish Nails at Manuel Montgomery blog Surface Finish 32 Vs 16 surface finishes define the final appearance of parts after machining. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finish symbols are graphical callouts to. Surface Finish 32 Vs 16.

From mungfali.com

Surface Finish Roughness Chart Surface Finish 32 Vs 16 Aside from appearance, it also influences part strength,. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finish specification and comparison. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. surface finishes define. Surface Finish 32 Vs 16.

From academy.liporeduction.org

Yours found of dependency the quantums choose affect go adhesive setup Surface Finish 32 Vs 16 the following charts and tables convert surface finish or roughness between selected industry standard units. Aside from appearance, it also influences part strength,. surface finishes define the final appearance of parts after machining. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. The measure of the total space irregularities on the. Surface Finish 32 Vs 16.

From www.amazon.com

SK 7Piece SAE Nut Driver Set, 3/16", 1/4", 5/16", 11/32 Surface Finish 32 Vs 16 Ra = roughness, average in. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. the following charts and tables convert surface finish or roughness between selected industry standard units. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the. Surface Finish 32 Vs 16.

From www.stahliusa.com

Surface Finish Quality Ra, Rz, Rt Surface Roughness Measuring & Finish Surface Finish 32 Vs 16 surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finish specification and comparison. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. The measure of the total space irregularities on the surface metal is. Surface Finish 32 Vs 16.

From edu.svet.gob.gt

Surface Roughness Conversion Chart Buford, GA CAB Worldwide Surface Finish 32 Vs 16 the following charts and tables convert surface finish or roughness between selected industry standard units. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finishes. Surface Finish 32 Vs 16.

From www.walmart.com

Bathroom Detergent Spray No Bleach Clean Sink Cleaner Experience The Surface Finish 32 Vs 16 Ra = roughness, average in. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. the following charts and tables convert surface finish or roughness between selected industry standard units. The measure of the total space. Surface Finish 32 Vs 16.

From www.aiophotoz.com

How To Measure Surface Finish Surface Roughness Conversion Chart Surface Finish 32 Vs 16 surface finish specification and comparison. The measure of the total space irregularities on the surface metal is known as surface roughness. Aside from appearance, it also influences part strength,. the following charts and tables convert surface finish or roughness between selected industry standard units. additionally, manufacturers can use the surface finish conversion chart to compare different roughness. Surface Finish 32 Vs 16.

From www.surfacegroup.com

SHORELINE Palm Surface Finish 32 Vs 16 Aside from appearance, it also influences part strength,. the following charts and tables convert surface finish or roughness between selected industry standard units. surface finishes define the final appearance of parts after machining. surface finish specification and comparison. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. The measure. Surface Finish 32 Vs 16.

From xometry.pro

Selecting Right Surface Roughness for CNC Machining Xometry Pro Surface Finish 32 Vs 16 surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. The measure of the total space irregularities on the surface metal is known as surface roughness. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finish specification and comparison. Ra = roughness, average in.. Surface Finish 32 Vs 16.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish 32 Vs 16 Ra = roughness, average in. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finish specification and comparison. additionally, manufacturers can use the surface. Surface Finish 32 Vs 16.

From www.walmart.com

Wall Mounted LED Illuminated 10X Magnifying USB Rechargeable for Hotel Surface Finish 32 Vs 16 surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. Aside from appearance, it also influences part strength,. The measure of the total space irregularities on the surface metal is known as surface roughness. surface finishes define the final appearance of parts after machining. surface finish chart by machining technology in. Surface Finish 32 Vs 16.

From www.walmart.com

Clorox Disinfectant Mist, MultiSurface Spray, Lemongrass Mandarin, 16 Surface Finish 32 Vs 16 surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finishes define the final appearance of parts after machining. Ra = roughness, average in. the following charts and tables convert surface finish or roughness between selected industry standard units. surface finish. Surface Finish 32 Vs 16.

From www.iron-foundry.com

Machining surface finish chart, conversion, comparator, method, degree Surface Finish 32 Vs 16 The measure of the total space irregularities on the surface metal is known as surface roughness. surface finish specification and comparison. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. surface finishes define the. Surface Finish 32 Vs 16.

From www.walmart.com

8mm Blue/black Surface Brushed Tungsten Ring Mens Wedding Band Surface Finish 32 Vs 16 surface finish specification and comparison. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. Ra = roughness, average in. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. surface finish symbols are graphical callouts to. Surface Finish 32 Vs 16.

From tholat.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish 32 Vs 16 Aside from appearance, it also influences part strength,. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. The measure of the total space irregularities on the surface metal is known as surface roughness. additionally, manufacturers can use the surface finish conversion chart to. Surface Finish 32 Vs 16.

From www.walmart.com

010024 Surface Mount Drip Tray, No Drain, Stainless Steel, 4 Brushed Surface Finish 32 Vs 16 surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. The measure of the total space irregularities on the surface metal is known as surface roughness. surface finish specification and comparison. Ra = roughness, average in. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for.. Surface Finish 32 Vs 16.

From dxoumrioi.blob.core.windows.net

Ra To Rz Surface Finish Conversion at Arnold Hayhurst blog Surface Finish 32 Vs 16 surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. Ra = roughness, average in. surface finish specification and comparison. The measure of the total space irregularities. Surface Finish 32 Vs 16.

From nkprom.ru

Набор образцов шероховатости поверхности по ГОСТ 937893, ISO 26321 Surface Finish 32 Vs 16 Ra = roughness, average in. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining. the following charts and tables convert surface finish or roughness between selected industry standard units. surface finish symbols are graphical callouts to indicate surface texture and surface roughness. Surface Finish 32 Vs 16.

From www.surfacegroup.com

SHORELINE Palm Surface Finish 32 Vs 16 Ra = roughness, average in. Aside from appearance, it also influences part strength,. additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for. surface finishes define the final appearance of parts after machining. surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface. Surface Finish 32 Vs 16.

From kianhuatmetal.com

Exploring the Diverse Surface Finishes of Stainless Steel Kian Huat Surface Finish 32 Vs 16 the following charts and tables convert surface finish or roughness between selected industry standard units. surface finishes define the final appearance of parts after machining. Ra = roughness, average in. The measure of the total space irregularities on the surface metal is known as surface roughness. surface finish symbols are graphical callouts to indicate surface texture and. Surface Finish 32 Vs 16.