Pin Mill Uses . The pin mill’s wide chamber housing prevents A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. A pin mill is a type of impact mill that operates on the principle of impact grinding. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high.

from studylib.net

And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. The pin mill’s wide chamber housing prevents The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. A pin mill is a type of impact mill that operates on the principle of impact grinding. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in.

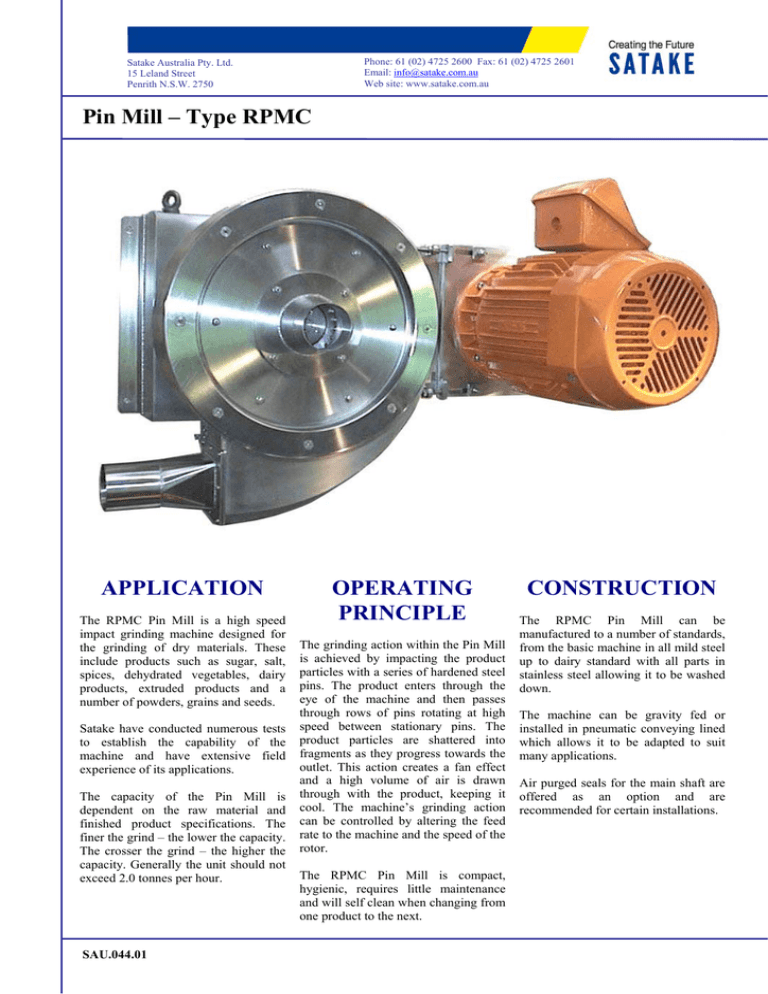

Pin Mill Type RPMC APPLICATION OPERATING PRINCIPLE

Pin Mill Uses The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. A pin mill is a type of impact mill that operates on the principle of impact grinding. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. The pin mill’s wide chamber housing prevents The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials.

From www.lessine.com

Pin mill Lessine Pin Mill Uses And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in.. Pin Mill Uses.

From www.yindamachinery.com

Pin Mill Stainless Steel Pin Mill Uses It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. The pin mill’s wide chamber housing prevents A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to. Pin Mill Uses.

From www.brightsail-asia.com

pin mill pin mill grinder pin mill price Pin Mill Uses A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials.. Pin Mill Uses.

From classifiermillingsystems.com

Pin Mill Classifier Milling Systems Inc. Pin Mill Uses And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. The mill can accept feed materials with a particle size ranging from 20 microns to. Pin Mill Uses.

From www.brightsail-asia.com

pin mill pin mill grinder pin mill price Pin Mill Uses A pin mill is a type of impact mill that operates on the principle of impact grinding. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. The pin mill’s wide chamber housing prevents The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in. Pin Mill Uses.

From www.famaker.com.au

Stainless Steel Pin Mill FA Maker Pin Mill Uses A pin mill is a type of impact mill that operates on the principle of impact grinding. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the. Pin Mill Uses.

From www.technodesignsindia.com

Pin Mill manufacturer, Sugar Pin Mill manufacturer India Pin Mill Uses Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. A pin mill. Pin Mill Uses.

From www.youtube.com

Pin Mill YouTube Pin Mill Uses It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. A pin. Pin Mill Uses.

From www.brightsail-asia.com

pin mill pin mill grinder pin mill price Pin Mill Uses A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. A. Pin Mill Uses.

From studylib.net

Pin Mill Type RPMC APPLICATION OPERATING PRINCIPLE Pin Mill Uses Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. Compared to. Pin Mill Uses.

From www.doingmachine.com

Impact Pin Mill Buy pin mill, Impact Mill, Impact pin mill Product on Pin Mill Uses It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. The mill can accept feed materials with a particle size ranging from 20 microns to. Pin Mill Uses.

From www.jetmillmfg.com

Pin Mill Pin Mill Uses A pin mill is a type of impact mill that operates on the principle of impact grinding. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. Pin mills use. Pin Mill Uses.

From www.yindamachinery.com

Pin Mill Stainless Steel Pin Mill Uses Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness.. Pin Mill Uses.

From electricalworkbook.com

What is Pin Mill? Working Principle, Construction, Diagram, Advantages Pin Mill Uses The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it. Pin Mill Uses.

From www.exportersindia.com

Pin Mill at Best Price in Ahmedabad Ultra Febtech Pvt Ltd Pin Mill Uses It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind. Pin Mill Uses.

From www.myande.in.th

ผู้ผลิต Pin Mill คุณภาพดี Myande Group Co., Ltd. Pin Mill Uses And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs. Pin Mill Uses.

From www.brightsail-asia.com

pin mill pin mill grinder pin mill price Pin Mill Uses It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. A pin mill is a type of impact mill that operates on the principle of impact grinding. Compared to roller. Pin Mill Uses.

From www.hywellco.com

Pin mill, Universal Pulverizer Manufacturer Hywell Machinery Pin Mill Uses The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. The pin mill’s wide chamber housing prevents A pin mill is a. Pin Mill Uses.

From www.aaronequipment.com

Used Finex Pin Mill, Model PM200, Stainless Stee Pin Mill Uses A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. The pin mill’s wide chamber housing prevents A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. It consists of a cylindrical chamber with a set of pins. Pin Mill Uses.

From www.chemengonline.com

Advances in Pin Mill Technology Chemical Engineering Page 1 Pin Mill Uses And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. Compared to. Pin Mill Uses.

From www.lessine.com

Pin mill Lessine Pin Mill Uses A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. A pin mill is one of the most commonly used impact mills for. Pin Mill Uses.

From pharmacyscope.com

Pin Mill Pharmacy Scope Pin Mill Uses Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the. Pin Mill Uses.

From www.nupharmamachine.com

Pin Mill NU Pharma Pin Mill Uses The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. A pin mill is a type of impact mill that operates on the principle of impact grinding. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. The. Pin Mill Uses.

From www.brightsail-asia.com

pin mill pin mill grinder pin mill price Pin Mill Uses Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. And a mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed size. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. The mill can accept. Pin Mill Uses.

From www.youtube.com

Impact Pin Mill YouTube Pin Mill Uses The pin mill’s wide chamber housing prevents It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing. Pin Mill Uses.

From www.epic-powder.com

Pin Mill Qingdao EPIC Powder Machinery Pin Mill Uses A pin mill is a type of impact mill that operates on the principle of impact grinding. The pin mill’s wide chamber housing prevents The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. And a mohs hardness of 4, reducing particles down to as. Pin Mill Uses.

From www.directindustry.com

Pin mill PM series Mill Powder Tech Co., Ltd. horizontal / food Pin Mill Uses Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. A pin mill is one of the most commonly used. Pin Mill Uses.

From www.brightsail-asia.com

pin mill pin mill grinder pin mill price Pin Mill Uses A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. The pin mill’s wide chamber housing prevents Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. A pin mill is one of the most commonly used impact mills for grinding bulk solid. Pin Mill Uses.

From bauermeisterusa.com

Double Acting Pin Mill Bauermeister Size Reduction Equipment Pin Mill Uses It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. A pin mill is a type of impact mill that operates on the principle of impact grinding. The pin mill, unlike the. Pin Mill Uses.

From www.brightsail-asia.com

pin mill pin mill grinder pin mill price Pin Mill Uses Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. It consists of a cylindrical chamber with. Pin Mill Uses.

From airjetmill.com

Milling Pin Mill Pin Mill Uses It consists of a cylindrical chamber with a set of pins or rods arranged in a concentric pattern on a. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. The pin mill’s wide chamber housing prevents The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged. Pin Mill Uses.

From www.nupharmamachine.com

Pin Mill NU Pharma Pin Mill Uses A pin mill is a type of impact mill that operates on the principle of impact grinding. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. The pin mill,. Pin Mill Uses.

From www.millplant.com

Working principle of pin mill machine Knowledge Pin Mill Uses The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. A pin mill is a type of impact mill that operates on the principle of impact grinding. A. Pin Mill Uses.

From www.paxaa.com

Paxaa Size Reduction & Classifying Universal Mill Pin Mill Pin Mill Uses Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. A pin mill is an industrial grinding mill that utilizes closely spaced, intermeshing pins to finely grind or pulverize a variety of. The pin mill, unlike the. Pin Mill Uses.

From www.scribd.com

Pin Milling Mill (Grinding) Turbine Pin Mill Uses The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal. The pin mill, unlike the hammer mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high.. Pin Mill Uses.