Linear Rail Vs Lead Screw . When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). How to choose the right one. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. Both options have a unique role to. When to apply lead screw linear actuators. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw.

from cnc1.lv

Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When to apply lead screw linear actuators. Both options have a unique role to. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. How to choose the right one. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair.

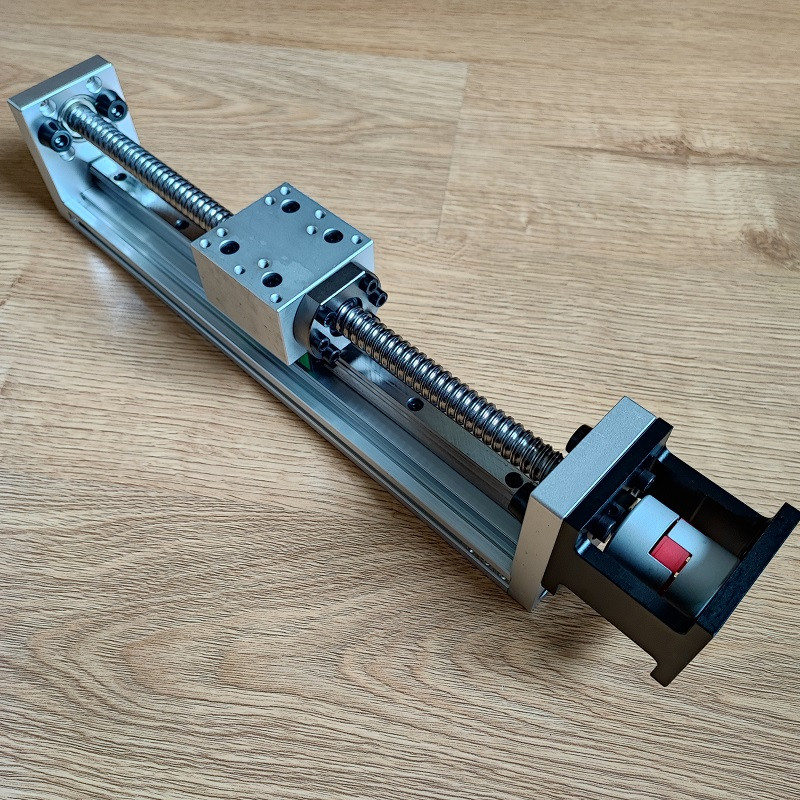

Z axis Linear Actuator Stage, Stroke 200mm 250 mm lead screw 5mm

Linear Rail Vs Lead Screw Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). Both options have a unique role to. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. When to apply lead screw linear actuators. How to choose the right one.

From www.dingsmotionusa.com

NEMA 23 Ball Screw Linear Actuator — DINGS' Motion USA Linear Rail Vs Lead Screw When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion,. Linear Rail Vs Lead Screw.

From www.cnclathing.com

Ball Screw vs Lead Screw, What's the Difference Between Them Linear Rail Vs Lead Screw How to choose the right one. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. When to apply lead screw linear actuators. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Both. Linear Rail Vs Lead Screw.

From www.victoriana.com

Faschismus Heu Ultimativ screw mechanism for linear motion Linear Rail Vs Lead Screw How to choose the right one. When to apply lead screw linear actuators. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust).. Linear Rail Vs Lead Screw.

From www.thomsonlinear.com

Reduce Your Linear Motion Assemblies to a Single Component with Linear Rail Vs Lead Screw When to apply lead screw linear actuators. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. Both options have a unique role to. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). When deciding between lead screws. Linear Rail Vs Lead Screw.

From mellowpine.com

Ball screw vs Lead Screw Which is Better? MellowPine Linear Rail Vs Lead Screw Both options have a unique role to. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Ramp illustration.the function of a lead screw. Linear Rail Vs Lead Screw.

From www.ubuy.co.in

Motorized Linear Guide Rail with Ball Screw, 50mm India Ubuy Linear Rail Vs Lead Screw When to apply lead screw linear actuators. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). When deciding between lead screws and ball screws. Linear Rail Vs Lead Screw.

From cnc1.lv

Z axis Linear Actuator Stage, Stroke 200mm 250 mm lead screw 5mm Linear Rail Vs Lead Screw Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. How to choose the right one. Both options have a unique role to. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When. Linear Rail Vs Lead Screw.

From www.aliexpress.com

8x500mm Lead Screw Rod T Shape Linear Rail Bar Shaft Nut 8mm Lead Linear Rail Vs Lead Screw When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors. Linear Rail Vs Lead Screw.

From www.fuyumotion.com

Heavy Duty Actuator Ball Screw Linear Module Double Track Rail Guide Linear Rail Vs Lead Screw Both options have a unique role to. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). How to choose the right one. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When deciding. Linear Rail Vs Lead Screw.

From qtecstore.com

CNC Qmodule linear leadscrew assembly by qtecstore Linear Rail Vs Lead Screw Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. A common way to generate precise linear motion is to use an electric motor (rotary motion) and. Linear Rail Vs Lead Screw.

From www.automotioncomponents.co.uk

Lead Screws and Ball Screws from Automotion Automotion Linear Rail Vs Lead Screw Both options have a unique role to. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When deciding between lead screws and ball. Linear Rail Vs Lead Screw.

From www.alibaba.com

Linear Guide Rails With Lead Screw Slide Guide Rail Ball Screw Manual Linear Rail Vs Lead Screw How to choose the right one. When to apply lead screw linear actuators. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Both. Linear Rail Vs Lead Screw.

From www.aliexpress.com

High Quality Horizontal Shaft 350mm T8 Dual Rail Lead Screw Rod Linear Linear Rail Vs Lead Screw A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. How to choose the right one. When to apply lead screw linear actuators. Two of those types of drive systems that. Linear Rail Vs Lead Screw.

From www.physicsforums.com

Considerations for design of lead screw + guide rail set up Linear Rail Vs Lead Screw Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When to apply lead screw linear actuators. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. When deciding between lead screws and ball screws for linear motion applications, the. Linear Rail Vs Lead Screw.

From rockfordballscrew.com

Profile Linear Guide Rails Motion Simplified by Rockford Ball Screw Linear Rail Vs Lead Screw How to choose the right one. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Both options have a unique role to. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. A. Linear Rail Vs Lead Screw.

From advancedathletesperformance.com.au

YUXIwang Linear Guide Rail Stroke 400mm Actuator CNC Linear Motion Lead Linear Rail Vs Lead Screw Both options have a unique role to. How to choose the right one. When to apply lead screw linear actuators. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). Two of those types of drive systems that are essential to converting rotary motion into linear motion. Linear Rail Vs Lead Screw.

From www.iqsdirectory.com

Lead Screw What Is It? How Is It Used? Types, Threads Linear Rail Vs Lead Screw When to apply lead screw linear actuators. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Ramp illustration.the function of a lead screw. Linear Rail Vs Lead Screw.

From rsvautomotive.co.uk

Industrial Automation & Motion Controls Rotary & Linear Motion Business Linear Rail Vs Lead Screw Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When deciding between lead screws and ball screws for linear motion applications, the choice. Linear Rail Vs Lead Screw.

From www.desertcart.ae

Buy 50mm Effective Travel Length Mini Linear Rail Guide Lead Screw T6x1 Linear Rail Vs Lead Screw When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. When to apply lead screw linear actuators. How to choose the right one. Both options. Linear Rail Vs Lead Screw.

From www.alibaba.com

20mm Ball Screw Linear Guide Rail Set For Diy Cnc Router Kits Buy Linear Rail Vs Lead Screw Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. How to choose the right one. Ramp illustration.the function of a lead screw is to. Linear Rail Vs Lead Screw.

From www.desertcart.in

Buy Filfeel Linear Guide Slide Table Ball Screw Motion Rail, 500mm Linear Rail Vs Lead Screw Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion,. Linear Rail Vs Lead Screw.

From www.ywsbearing.com

600mm SBR16 linear guide SFU1605 1610 ball screw linear actuator Buy Linear Rail Vs Lead Screw When to apply lead screw linear actuators. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. Both options have a unique role to. Screws, whether ball screws or lead screws,. Linear Rail Vs Lead Screw.

From www.pinterest.de

Arrangement of linear rails, lead screw bearing end support, and Linear Rail Vs Lead Screw Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When to apply lead screw linear actuators. How to choose the right one. Both. Linear Rail Vs Lead Screw.

From www.indiamart.com

THK Stainless Steel Ball Screw Guide Rail at Rs 3000 in Pune ID Linear Rail Vs Lead Screw Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). How to choose the right one. Both options have a unique role to. When to apply lead screw linear actuators. A common way to generate precise linear motion is to use an electric motor (rotary motion) and. Linear Rail Vs Lead Screw.

From motionconstrained.com

Motion Constrained Ball Screw Linear Actuator ACTPG80BS165N23 Linear Rail Vs Lead Screw How to choose the right one. When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors. Linear Rail Vs Lead Screw.

From www.aliexpress.com

3D Printer guide rail sets T8 Lead screw length 500mm + linear shaft 8 Linear Rail Vs Lead Screw Both options have a unique role to. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. Ramp illustration.the function of a lead screw is to convert rotational motion to linear. Linear Rail Vs Lead Screw.

From www.desertcart.ae

FUYU FSL30 Mini Linear Stage Actuator Small Slide Guide Rail CNC Screw Linear Rail Vs Lead Screw When to apply lead screw linear actuators. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Ramp illustration.the function of a lead screw. Linear Rail Vs Lead Screw.

From www.fuyumotion.com

High Precision Ball Screw Linear Motion Guide Fuyu Technology Co., Ltd. Linear Rail Vs Lead Screw Both options have a unique role to. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. When deciding between lead screws and. Linear Rail Vs Lead Screw.

From www.amazon.com

Linear Stage Actuator Ball Screw Manual Sliding Table Ballscrew SFU1605 Linear Rail Vs Lead Screw Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. A common way to generate precise linear motion is to use an electric. Linear Rail Vs Lead Screw.

From www.iqsdirectory.com

Linear Rails Types, Applications, Benefits, and Design Linear Rail Vs Lead Screw Both options have a unique role to. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. When to apply lead screw linear actuators. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). A. Linear Rail Vs Lead Screw.

From www.aliexpress.com

400mm linear guide rail ball screw motor nema17 stepper motor Linear Rail Vs Lead Screw When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear. Linear Rail Vs Lead Screw.

From www.progressiveautomations.com

Ball Screw vs Lead Screw in Linear Actuators Progressive Automations Linear Rail Vs Lead Screw When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. When to apply lead screw linear actuators. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Screws, whether ball screws or lead screws, are. Linear Rail Vs Lead Screw.

From alexnld.com

Machifit 150mm MGN12 Linear Rail Guide with T8 Lead Screw Set 8mm Lead Linear Rail Vs Lead Screw Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the. Linear Rail Vs Lead Screw.

From www.desertcart.in

Buy Zeberoxyz 1PCS Mini Linear Rail Guide Slide Actuator T6x1 Lead Linear Rail Vs Lead Screw When to apply lead screw linear actuators. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. A common way to generate precise linear motion is to use an electric motor (rotary motion) and pair. Both options have a unique role to. How to choose the. Linear Rail Vs Lead Screw.

From www.ebay.com

3D Printer 8mm Lead Screw Rod + Nut Z Axis Linear Rail Bar Shaft HP eBay Linear Rail Vs Lead Screw Ramp illustration.the function of a lead screw is to convert rotational motion to linear motion, or rotational force (torque) to linear force (thrust). When deciding between lead screws and ball screws for linear motion applications, the choice largely depends on the specific requirements of. How to choose the right one. Screws, whether ball screws or lead screws, are generally preferred. Linear Rail Vs Lead Screw.