How To Check Pump Coupling Alignment . A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. In the absence of a laser alignment system, users can check the alignment with some simple tools. Straight edge and feeler gauge method: View the machine from the pump end, zero the indicators on the left, and then rotate and. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. You can use this method to manually check alignment. Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: Place a straight edge across the coupling and using feeler gauges to measure the gap between them. The necessary tools used for. The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side.

from mungfali.com

The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: View the machine from the pump end, zero the indicators on the left, and then rotate and. Straight edge and feeler gauge method: In the absence of a laser alignment system, users can check the alignment with some simple tools. The necessary tools used for. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. You can use this method to manually check alignment. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several.

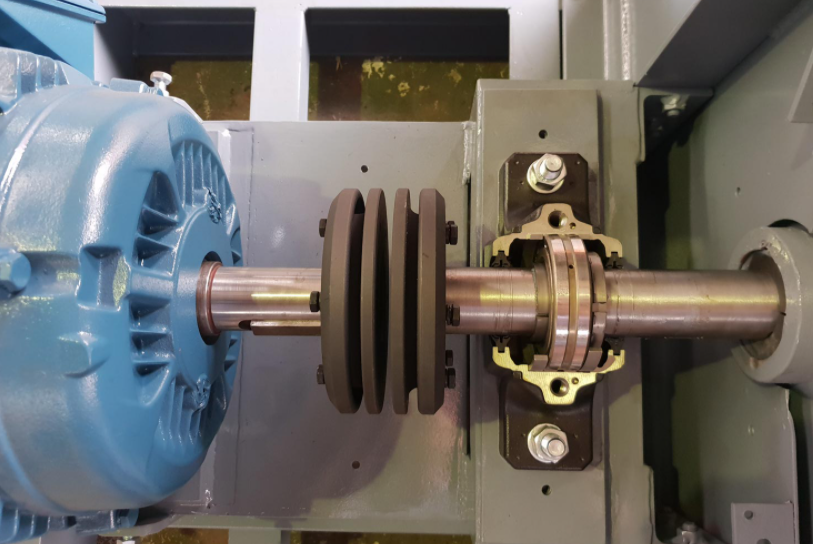

Pump Coupling Alignment

How To Check Pump Coupling Alignment You can use this method to manually check alignment. The necessary tools used for. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. Straight edge and feeler gauge method: Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. You can use this method to manually check alignment. A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. View the machine from the pump end, zero the indicators on the left, and then rotate and. In the absence of a laser alignment system, users can check the alignment with some simple tools. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several.

From constructandcommission.com

CENTRIFUGAL PUMP Commissioning And Alignment How To Check Pump Coupling Alignment Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. View the machine from the pump end,. How To Check Pump Coupling Alignment.

From www.youtube.com

Rough Pump Alignment With Flexible Coupling YouTube How To Check Pump Coupling Alignment Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. You can use this method to manually check alignment. Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: The necessary tools used for. Straight edge and feeler gauge method: Place a straight edge across the. How To Check Pump Coupling Alignment.

From www.nationalpumpcompany.com

A Guide to Properly Align and Install Vertical Turbine Pumps National How To Check Pump Coupling Alignment You can use this method to manually check alignment. In the absence of a laser alignment system, users can check the alignment with some simple tools. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. The horizontal move is the part of the alignment process that aligns the shaft's. How To Check Pump Coupling Alignment.

From www.youtube.com

Alignment of motor pump. 2 axial =1 axial YouTube How To Check Pump Coupling Alignment The necessary tools used for. Straight edge and feeler gauge method: Place a straight edge across the coupling and using feeler gauges to measure the gap between them. Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine). How To Check Pump Coupling Alignment.

From www.midwestindustrialservices.net

Coupling Alignment How To Perfectly Align Your Car How To Check Pump Coupling Alignment Place a straight edge across the coupling and using feeler gauges to measure the gap between them. You can use this method to manually check alignment. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. A straight edge is used to check the parallel misalignment and a caliper is. How To Check Pump Coupling Alignment.

From mavink.com

Pump Alignment Procedure How To Check Pump Coupling Alignment You can use this method to manually check alignment. Straight edge and feeler gauge method: A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. View the machine from the pump end, zero the indicators on the left, and then rotate and. Effective pump alignment incorporates various techniques, each suited. How To Check Pump Coupling Alignment.

From www.slideshare.net

Coupling Alignment How To Check Pump Coupling Alignment Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. The necessary tools used for. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. A straight edge is used to check the parallel misalignment and a caliper is used to check the. How To Check Pump Coupling Alignment.

From yesyen.com

Shaft Alignment Methods Training Class How To Check Pump Coupling Alignment Straight edge and feeler gauge method: Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. In the absence of a laser alignment system, users can check the alignment with some. How To Check Pump Coupling Alignment.

From mungfali.com

Pump And Motor Alignment Procedure How To Check Pump Coupling Alignment In the absence of a laser alignment system, users can check the alignment with some simple tools. A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. Straight edge and feeler gauge method: The necessary tools used for. View the machine from the pump end, zero the indicators on the. How To Check Pump Coupling Alignment.

From www.linkedin.com

Reverse dial indicator shaft alignment procedure How To Check Pump Coupling Alignment Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. View the machine from the pump end, zero the indicators on the left, and then rotate and. The horizontal move is the part of the alignment. How To Check Pump Coupling Alignment.

From mavink.com

Pump Alignment With Dial Indicator How To Check Pump Coupling Alignment The necessary tools used for. In the absence of a laser alignment system, users can check the alignment with some simple tools. You can use this method to manually check alignment. View the machine from the pump end, zero the indicators on the left, and then rotate and. Effective pump alignment incorporates various techniques, each suited to different situations and. How To Check Pump Coupling Alignment.

From www.youtube.com

Shaft coupling Alignment Procedure Rim and Face Method part 2 YouTube How To Check Pump Coupling Alignment The necessary tools used for. View the machine from the pump end, zero the indicators on the left, and then rotate and. A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. You can use this method to manually check alignment. Effective pump alignment incorporates various techniques, each suited to. How To Check Pump Coupling Alignment.

From www.youtube.com

How To Align Shafts Using A TwoPiece Rigid Coupling YouTube How To Check Pump Coupling Alignment A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. The necessary tools used for. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. View the machine from the pump end, zero the indicators on the left, and then. How To Check Pump Coupling Alignment.

From empoweringpumps.com

ANSI Centrifugal Pump Alignment [Video] Empowering Pumps and Equipment How To Check Pump Coupling Alignment Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: View the machine from the pump end, zero the indicators on the left, and then rotate and. The necessary tools used for. You can use this. How To Check Pump Coupling Alignment.

From www.pumpsandsystems.com

Pump Commissioning Alignment, Field Balancing and Startup Pumps How To Check Pump Coupling Alignment The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: Place a straight edge across the coupling. How To Check Pump Coupling Alignment.

From www.youtube.com

How to install and align a pump and motor coupling on an API 610 VS4 How To Check Pump Coupling Alignment You can use this method to manually check alignment. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. View the machine from the pump end, zero the indicators on the left, and. How To Check Pump Coupling Alignment.

From mungfali.com

Pump Coupling Alignment How To Check Pump Coupling Alignment Straight edge and feeler gauge method: In the absence of a laser alignment system, users can check the alignment with some simple tools. View the machine from the pump end, zero the indicators on the left, and then rotate and. The necessary tools used for. A straight edge is used to check the parallel misalignment and a caliper is used. How To Check Pump Coupling Alignment.

From www.midwestindustrialservices.net

Coupling Alignment How To Perfectly Align Your Car How To Check Pump Coupling Alignment A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. You can use this method to manually check alignment. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. Place a straight edge across the coupling and using feeler gauges. How To Check Pump Coupling Alignment.

From mavink.com

Pump And Motor Alignment Procedure How To Check Pump Coupling Alignment You can use this method to manually check alignment. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. Straight edge and feeler gauge method: View the machine from the. How To Check Pump Coupling Alignment.

From mungfali.com

Coupling Alignment Chart How To Check Pump Coupling Alignment A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. In the absence of a laser alignment system, users can check the alignment with some simple tools. Place a straight. How To Check Pump Coupling Alignment.

From www.mechanical-knowledge.com

Machine Alignment A Practical Guide to Shaft Alignment How To Check Pump Coupling Alignment In the absence of a laser alignment system, users can check the alignment with some simple tools. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. View the machine from the pump end, zero the indicators on the left, and then rotate and. Fixing pump misalignment (i.e., alignment issues between the pump. How To Check Pump Coupling Alignment.

From repairfixsolorzanori.z21.web.core.windows.net

Couplings On A Pump How To Check Pump Coupling Alignment View the machine from the pump end, zero the indicators on the left, and then rotate and. You can use this method to manually check alignment. In the absence of a laser alignment system, users can check the alignment with some simple tools. The necessary tools used for. Place a straight edge across the coupling and using feeler gauges to. How To Check Pump Coupling Alignment.

From www.slideshare.net

Coupling Alignment How To Check Pump Coupling Alignment A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. In the absence of a laser alignment system, users can check the alignment with some simple tools. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. Fixing pump misalignment (i.e., alignment issues. How To Check Pump Coupling Alignment.

From athome-solutions.com

What Is Alignment Coupling? Alignment coupling How To Check Pump Coupling Alignment Place a straight edge across the coupling and using feeler gauges to measure the gap between them. View the machine from the pump end, zero the indicators on the left, and then rotate and. The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. Straight edge and feeler gauge method: In. How To Check Pump Coupling Alignment.

From benchmarkpdm.com

Align Your Machines Using Coupling Tolerances Benchmark PDM How To Check Pump Coupling Alignment View the machine from the pump end, zero the indicators on the left, and then rotate and. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: In the absence of a laser alignment system, users can check the. How To Check Pump Coupling Alignment.

From www.pumpsandsystems.com

How to Check Alignment of Flexible Couplings Pumps & Systems How To Check Pump Coupling Alignment View the machine from the pump end, zero the indicators on the left, and then rotate and. Straight edge and feeler gauge method: The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. You can use this method to manually check alignment. Effective pump alignment incorporates various techniques, each suited to. How To Check Pump Coupling Alignment.

From www.meoexamz.co.in

Alignment of Pumps & Shafts How To Check Pump Coupling Alignment Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. Straight edge and feeler gauge method: The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side. How To Check Pump Coupling Alignment.

From mungfali.com

Pump Coupling Alignment How To Check Pump Coupling Alignment The necessary tools used for. The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. You can use this method to manually check alignment. Place a straight edge across the coupling and using feeler gauges to measure the gap between them. Fixing pump misalignment (i.e., alignment issues between the pump and. How To Check Pump Coupling Alignment.

From www.youtube.com

Cara Ngelement Cara Alignment Pump And Motor Aligment Coupling How To Check Pump Coupling Alignment A straight edge is used to check the parallel misalignment and a caliper is used to check the angular misalignment. You can use this method to manually check alignment. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. View the machine from the pump end, zero the indicators on. How To Check Pump Coupling Alignment.

From mungfali.com

Pump Coupling Alignment How To Check Pump Coupling Alignment Place a straight edge across the coupling and using feeler gauges to measure the gap between them. Straight edge and feeler gauge method: Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: You can use this method to manually check alignment. The necessary tools used for. The horizontal move is the part of the alignment. How To Check Pump Coupling Alignment.

From www.slideshare.net

Coupling Alignment How To Check Pump Coupling Alignment The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. Fixing pump misalignment (i.e., alignment issues between the pump and its driver, such as a motor or engine) involves several. View the machine from the pump end, zero the indicators on the left, and then rotate and. Place a straight edge. How To Check Pump Coupling Alignment.

From mungfali.com

Pump Coupling Alignment How To Check Pump Coupling Alignment Straight edge and feeler gauge method: Place a straight edge across the coupling and using feeler gauges to measure the gap between them. In the absence of a laser alignment system, users can check the alignment with some simple tools. The horizontal move is the part of the alignment process that aligns the shaft's centerlines from side to side. Fixing. How To Check Pump Coupling Alignment.

From allindustrial-equipments.com

Pump Coupling Alignment What You Should Recognize How To Check Pump Coupling Alignment View the machine from the pump end, zero the indicators on the left, and then rotate and. You can use this method to manually check alignment. The necessary tools used for. In the absence of a laser alignment system, users can check the alignment with some simple tools. Fixing pump misalignment (i.e., alignment issues between the pump and its driver,. How To Check Pump Coupling Alignment.

From www.youtube.com

Shaft coupling Alignment Procedure Rim and Face Method part 1 YouTube How To Check Pump Coupling Alignment In the absence of a laser alignment system, users can check the alignment with some simple tools. Straight edge and feeler gauge method: Place a straight edge across the coupling and using feeler gauges to measure the gap between them. You can use this method to manually check alignment. Fixing pump misalignment (i.e., alignment issues between the pump and its. How To Check Pump Coupling Alignment.

From www.youtube.com

Dial gauge PumpMotor Alignment Process YouTube How To Check Pump Coupling Alignment You can use this method to manually check alignment. Effective pump alignment incorporates various techniques, each suited to different situations and precision levels: View the machine from the pump end, zero the indicators on the left, and then rotate and. The necessary tools used for. The horizontal move is the part of the alignment process that aligns the shaft's centerlines. How To Check Pump Coupling Alignment.