Die Cutting Of Plastic . There are two main types of plastic die processes: Die forming and die cutting. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. In the realm of packaging, precision and efficiency are key. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: One vital technique contributing to these. It’s most commonly used for, but not limited to , the. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes.

from www.midlandplastics.com

One vital technique contributing to these. Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. There are two main types of plastic die processes: It’s most commonly used for, but not limited to , the. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. Die forming and die cutting. In the realm of packaging, precision and efficiency are key.

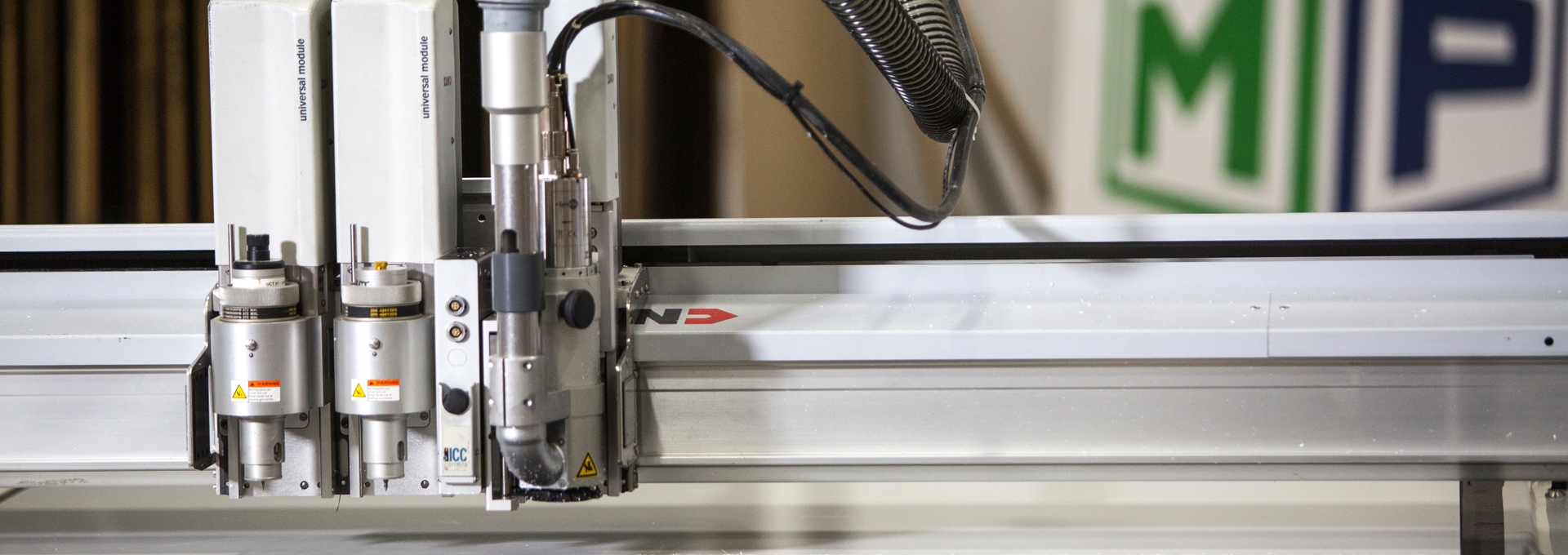

Die Cutting Plastic & CNC Knife Cutting

Die Cutting Of Plastic When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. There are two main types of plastic die processes: In the realm of packaging, precision and efficiency are key. One vital technique contributing to these. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. Die forming and die cutting. Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: It’s most commonly used for, but not limited to , the.

From www.designswan.com

Tips For Beginners Everything You Need to Know About Diecutting Die Cutting Of Plastic The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. One vital technique contributing to these. When it comes to die cutting considerations. Die Cutting Of Plastic.

From freckleface.com

PLASTIC SHEET CUT TO SIZE, PLASTIC SHEETS CUSTOM CUT, CUT TO SIZE Die Cutting Of Plastic When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. One vital technique contributing to these. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a.. Die Cutting Of Plastic.

From www.printart-adc.com

Advent of Die Cutting Services in Manufacturing Industries PrintArt Die Cutting Of Plastic When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: One vital technique contributing to these. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. It’s most commonly used for, but not limited to , the. The process of die cutting plastic involves. Die Cutting Of Plastic.

From www.diecuttingcompanies.com

Plastic Die Cutting, Plastic Die Cutting Services Die Cutting Of Plastic Die forming and die cutting. One vital technique contributing to these. It’s most commonly used for, but not limited to , the. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. The process. Die Cutting Of Plastic.

From www.indiamart.com

Plastic Die Cutting Parts at Rs 30/piece in Faridabad ID 11382138673 Die Cutting Of Plastic It’s most commonly used for, but not limited to , the. Die forming and die cutting. In the realm of packaging, precision and efficiency are key. There are two main types of plastic die processes: When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: Die cutting is a careful process. Die Cutting Of Plastic.

From howtobuypackaging.com

Tooling for Packaging Part One The Cutting Die Die Cutting Of Plastic One vital technique contributing to these. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. It’s most commonly used for, but not limited to , the. In the realm of packaging, precision and efficiency are key. There are two main types of plastic die processes: Die forming and die cutting. When. Die Cutting Of Plastic.

From www.midlandplastics.com

Die Cutting Plastic & CNC Knife Cutting Die Cutting Of Plastic Die forming and die cutting. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. It’s most commonly used for, but not limited to , the. Die forming involves extruding molten. Die Cutting Of Plastic.

From www.aliexpress.com

Buy DIY Die Cutting Machine Plastic Craft Scrapbook Die Cutting Of Plastic In the realm of packaging, precision and efficiency are key. It’s most commonly used for, but not limited to , the. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. When it comes to die cutting considerations for plastics, there. Die Cutting Of Plastic.

From www.youtube.com

PP board cutting Coroplast Corrugated Plastic Sheets 4mm cutting YouTube Die Cutting Of Plastic Die forming and die cutting. In the realm of packaging, precision and efficiency are key. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat. Die Cutting Of Plastic.

From www.youtube.com

Cutting plastic sheets on the Roller Press with a .937" die YouTube Die Cutting Of Plastic Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: Die forming and die cutting. It’s most commonly used for, but not limited to , the. One vital technique contributing. Die Cutting Of Plastic.

From www.jbc-tech.com

Plastics & Films for Custom Die Cutting Die Cutting Of Plastic It’s most commonly used for, but not limited to , the. Die forming and die cutting. In the realm of packaging, precision and efficiency are key. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. When it comes to die cutting considerations for plastics, there are a few important factors to. Die Cutting Of Plastic.

From packhelp.com

Understanding the Die Cutting Process in Custom Packaging Packhelp Die Cutting Of Plastic There are two main types of plastic die processes: In the realm of packaging, precision and efficiency are key. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components. Die Cutting Of Plastic.

From www.tapecase.com

DieCutting TapeCase Die Cutting Of Plastic It’s most commonly used for, but not limited to , the. One vital technique contributing to these. Die forming and die cutting. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. There are. Die Cutting Of Plastic.

From www.customfabricate.com

Custom Die Cutting Custom Fabricating & Supplies Die Cutting Of Plastic One vital technique contributing to these. In the realm of packaging, precision and efficiency are key. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: It’s most commonly used for, but not limited to , the. There are two main types of plastic die processes: Die cutting is a careful. Die Cutting Of Plastic.

From www.upe.vn

Plastic Rubber Die Cutting ISO 90012015 UPE Die Cutting Of Plastic The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. One vital technique contributing to these. Die forming and die cutting. In the realm of packaging, precision and efficiency are key. It’s most commonly used for, but not limited to ,. Die Cutting Of Plastic.

From www.alibaba.com

New Design Portable Cr80 Pvc Plastic Card Die Cutting Machine Buy Die Cutting Of Plastic There are two main types of plastic die processes: In the realm of packaging, precision and efficiency are key. Die forming and die cutting. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. When it comes to die cutting considerations. Die Cutting Of Plastic.

From www.alibaba.com

Plastic Pp Polypropylene Die Cutting Corrugated Sheet For Floor Die Cutting Of Plastic Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. In the realm of packaging, precision and efficiency are key. One vital technique contributing to these. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. The process of die cutting. Die Cutting Of Plastic.

From www.americanmicroinc.com

Plastic Laser Cutting Service Laser Cutting Plastic AMI Die Cutting Of Plastic Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. In the realm of packaging, precision and efficiency are key. One vital technique contributing to these. It’s most commonly used for, but not limited to , the. Die forming and die cutting. Die cutting is a careful process that uses sharp steel blades. Die Cutting Of Plastic.

From jrtindustries.com.au

Laser Cutting of Plastics & Acrylics JRT Bundaberg Die Cutting Of Plastic It’s most commonly used for, but not limited to , the. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. The process of die cutting plastic involves creating a custom die in the required. Die Cutting Of Plastic.

From www.monarchplastics.com

3 Axis CNC Cutting & Routing Precision DieCutting Monarch Plastics Die Cutting Of Plastic When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: There are two main types of plastic die processes: Die forming and die cutting. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. One vital technique contributing to these. It’s most commonly used. Die Cutting Of Plastic.

From www.youtube.com

Tippmann Roller die cutting machine die cutting plastic material YouTube Die Cutting Of Plastic The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. Die cutting is a careful process that uses sharp steel blades to precisely cut. Die Cutting Of Plastic.

From www.customshapepros.com

AccuCut GrandeMARK 2 DieCutting Machine Custom Shape Pros Custom Die Cutting Of Plastic Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. There are two main types of plastic die processes: Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. This method allows for intricate designs and structural elements that are essential for. Die Cutting Of Plastic.

From www.iqsdirectory.com

Die Cutting What Is It? How Does It Work? Parts, Design Die Cutting Of Plastic Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. When it comes to die cutting considerations for plastics, there. Die Cutting Of Plastic.

From www.polyalto.com

DIECUTTING OF PLASTIC MATERIALS Die Cutting Of Plastic When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut. Die Cutting Of Plastic.

From www.thrustin.com

Die Cut Plastic Thrust Industries Die Cutting Of Plastic It’s most commonly used for, but not limited to , the. In the realm of packaging, precision and efficiency are key. Die forming and die cutting. One vital technique contributing to these. There are two main types of plastic die processes: Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into. Die Cutting Of Plastic.

From www.iqsdirectory.com

Die Cutting What Is It? How Does It Work? Parts, Design Die Cutting Of Plastic Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. There are two main types of plastic die processes: In the realm of packaging, precision and efficiency are key. This method allows. Die Cutting Of Plastic.

From www.basicrubber.com

Die Cutting Basic Rubber & Plastics Company Inc. Die Cutting Of Plastic It’s most commonly used for, but not limited to , the. One vital technique contributing to these. Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. There are two main types of plastic die processes: This method allows for intricate designs and structural elements that are essential for. Die Cutting Of Plastic.

From www.youtube.com

Tippmann Clicker Steel rule die cutting press cutting plastic using a Die Cutting Of Plastic In the realm of packaging, precision and efficiency are key. There are two main types of plastic die processes: This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped. Die Cutting Of Plastic.

From www.youtube.com

Working with Plastics / Cutting, Drilling and Gluing Plastic YouTube Die Cutting Of Plastic This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. It’s most commonly used for, but not limited to , the. Die forming. Die Cutting Of Plastic.

From www.polyalto.com

DIECUTTING OF PLASTIC MATERIALS Die Cutting Of Plastic This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: It’s most commonly used for, but not limited to , the. Die cutting is a careful process that uses sharp steel blades to. Die Cutting Of Plastic.

From plastics-unlimited.com

Plastics Unlimited Print Laminating & Finishing Die Cutting Of Plastic Die cutting is a careful process that uses sharp steel blades to precisely cut and mold packaging materials into bespoke shapes. One vital technique contributing to these. The process of die cutting plastic involves creating a custom die in the required shape, then using it to cut the finished shaped components out of flat plastic sheets. There are two main. Die Cutting Of Plastic.

From paulmurphyplastics.com

Ultimate Guide to The Plastic Extrusion Process • Paul Murphy Plastics Die Cutting Of Plastic This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. Die forming and die cutting. It’s most commonly used for, but not limited to , the. The process of die cutting plastic involves creating a. Die Cutting Of Plastic.

From roylco.ca

Die Cutting for Paper, Plastics, Woods Die Cutting Of Plastic This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. There are two main types of plastic die processes: In the realm of packaging, precision and efficiency are key. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. One vital technique contributing to these.. Die Cutting Of Plastic.

From www.jbc-tech.com

Precision Die Cutting Custom Die Cutting Services JBC Technologies Die Cutting Of Plastic Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. One vital technique contributing to these. Die forming and die cutting. It’s most commonly used for, but not limited to , the. When it comes to die cutting considerations for plastics, there are a few important factors to keep in mind: This method. Die Cutting Of Plastic.

From www.scrapbook.com

The Ultimate Guide to Die Cutting Die Cutting Of Plastic One vital technique contributing to these. Die forming involves extruding molten plastic through a die to create a continuous shape, such as a. This method allows for intricate designs and structural elements that are essential for both functionality and aesthetic appeal. In the realm of packaging, precision and efficiency are key. The process of die cutting plastic involves creating a. Die Cutting Of Plastic.