Fuel Distillation Process . A refinery's capacity refers to the maximum amount of crude oil. This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. Crude stills are the oldest. Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Learn more about petroleum refining, including its history. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. Distillation involves the separation of materials based on differences in their volatility. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons.

from www.alamy.com

This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. Learn more about petroleum refining, including its history. Distillation involves the separation of materials based on differences in their volatility. Crude stills are the oldest. Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. A refinery's capacity refers to the maximum amount of crude oil. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products.

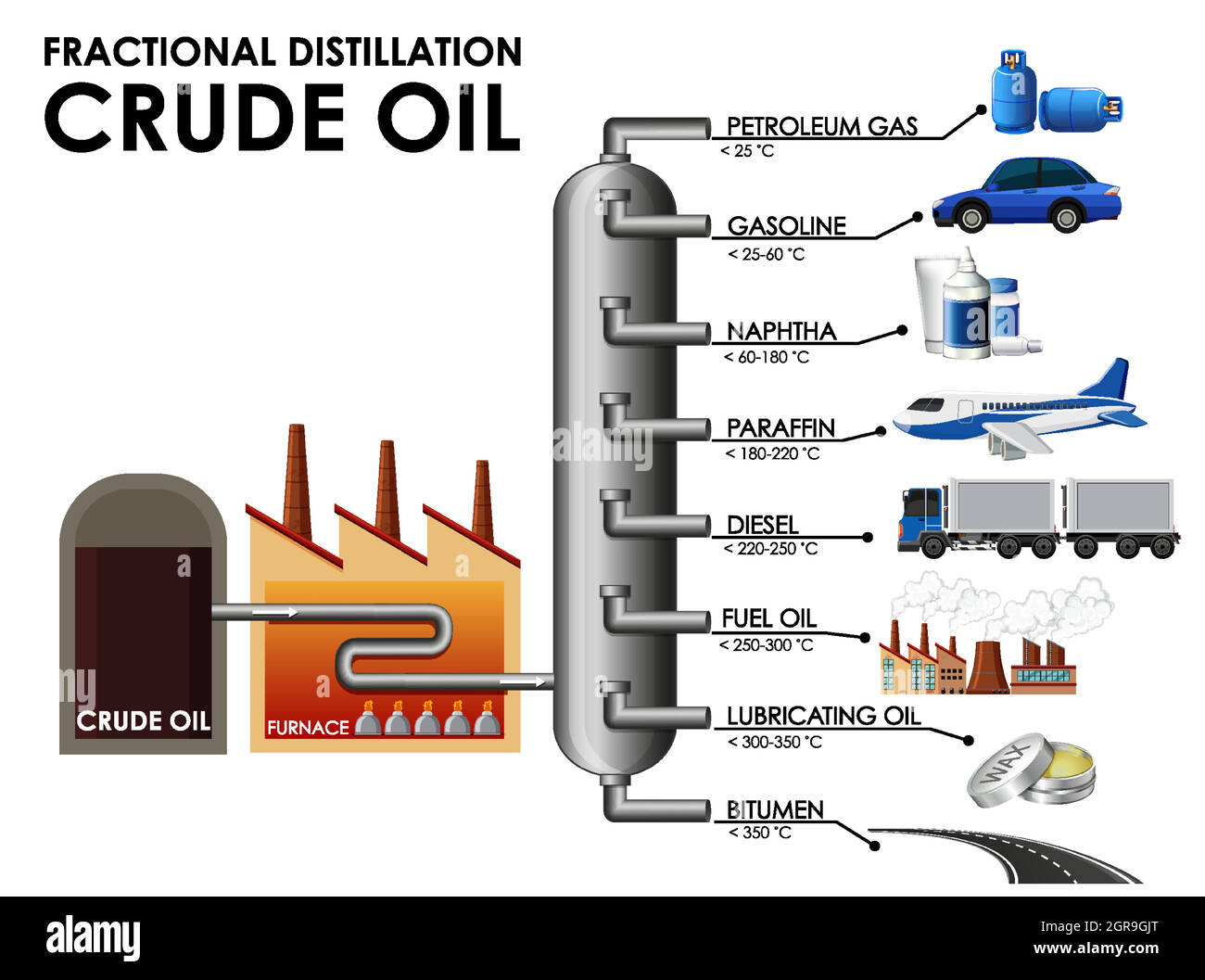

Diagram showing fractional distillation crude oil Stock Vector Image & Art Alamy

Fuel Distillation Process A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. Learn more about petroleum refining, including its history. Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. A refinery's capacity refers to the maximum amount of crude oil. Crude stills are the oldest. Distillation involves the separation of materials based on differences in their volatility. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene.

From marketrealist.com

What is the process of crude oil refining Fuel Distillation Process Learn more about petroleum refining, including its history. A refinery's capacity refers to the maximum amount of crude oil. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. Distillation involves the. Fuel Distillation Process.

From www.chemicals.co.uk

Distillation Of A Product From A Reaction The Chemistry Blog Fuel Distillation Process Crude stills are the oldest. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Distillation involves the separation of materials based on differences in their volatility. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. A crude oil refinery is a group of industrial facilities that turns crude. Fuel Distillation Process.

From www.vectorstock.com

Diagram showing fractional distillation crude oil Vector Image Fuel Distillation Process Distillation involves the separation of materials based on differences in their volatility. Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Learn more about petroleum refining, including its history. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated. Fuel Distillation Process.

From thepetrosolutions.com

Crude distillation unit Archives The Petro Solutions Fuel Distillation Process Crude stills are the oldest. Distillation involves the separation of materials based on differences in their volatility. Learn more about petroleum refining, including its history. A refinery's capacity refers to the maximum amount of crude oil. Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights. Fuel Distillation Process.

From chem.libretexts.org

8.9 Distillation Chemistry LibreTexts Fuel Distillation Process Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Distillation involves the separation of materials based on differences in their volatility. A refinery's capacity refers to the maximum amount of crude oil. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline. Fuel Distillation Process.

From owlcation.com

Making Crude Oil Useful Fractional Distillation and Cracking Owlcation Fuel Distillation Process Distillation involves the separation of materials based on differences in their volatility. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Crude. Fuel Distillation Process.

From www.pinterest.com.au

Crude Oil Refining and Australia's Fuel Security Animated Infographic Crude oil, Fractional Fuel Distillation Process Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. Crude stills are the oldest. Cracking involves breaking up heavy molecules into lighter (and more valuable). Fuel Distillation Process.

From www.pinterest.ca

How fractional distillation of crude oil works. Fractional distillation, Crude oil, Petroleum Fuel Distillation Process Distillation involves the separation of materials based on differences in their volatility. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. This is the first and most basic step in the refining process, and. Fuel Distillation Process.

From crudeoildatsuhata.blogspot.com

Crude Oil The Fractional Distillation Of Crude Oil Fuel Distillation Process Crude stills are the oldest. Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Distillation involves the separation of materials based on differences in their volatility. This is the first and most basic. Fuel Distillation Process.

From www.vectorstock.com

Crude oil distillation process isolated on white Vector Image Fuel Distillation Process A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline. Fuel Distillation Process.

From www.theengineersperspectives.com

Types of Distillation Definition, Process, Uses & Examples Fuel Distillation Process Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Learn more about petroleum refining, including its history. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and. Fuel Distillation Process.

From www.researchgate.net

Scheme of the atmospheric distillation process in an oil refinery,... Download Scientific Diagram Fuel Distillation Process Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. This is the first and most basic step in the refining process, and is the precursor to. Fuel Distillation Process.

From www.dreamstime.com

Fractional Distillation of Crude Oil Labeled Educational Explanation Scheme Stock Vector Fuel Distillation Process This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. Crude stills are the oldest. A refinery's capacity refers to the maximum amount of crude oil. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Fractional distillation is. Fuel Distillation Process.

From www.americangeosciences.org

Oil Refining and Gas Processing American Geosciences Institute Fuel Distillation Process This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Crude stills are the oldest. Learn more about petroleum refining, including its history. Distillation involves the separation of materials based on differences in. Fuel Distillation Process.

From sites.google.com

Fractional Distillation IGCSE SCIENCE eLab Fuel Distillation Process Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. A refinery's capacity refers to the maximum amount of crude oil. Different hydrocarbon chain lengths all. Fuel Distillation Process.

From www.flextrades.com

How It's Made Gasoline FlexTrades Fuel Distillation Process Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel,. Fuel Distillation Process.

From www.youtube.com

Petroleum refining processes explained simply YouTube Fuel Distillation Process A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Crude stills are the oldest. Distillation involves the separation of materials based on differences in their volatility. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Crude distillation is the. Fuel Distillation Process.

From www.vectorstock.com

Diagram showing fractional distillation crude oil Vector Image Fuel Distillation Process Distillation involves the separation of materials based on differences in their volatility. This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Petroleum refining, conversion of crude oil into. Fuel Distillation Process.

From www.researchgate.net

Generic Fractional Distillation in the Crude Oil Refining Process. Download Scientific Diagram Fuel Distillation Process This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and. Fuel Distillation Process.

From carbiketech.com

Diesel Fuel How Is it Made? Its Benefits & Disadvantages CarBikeTech Fuel Distillation Process Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Crude stills are the oldest. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. This is the first and most basic step. Fuel Distillation Process.

From www.e-education.psu.edu

Atmospheric and Vacuum Distillation Units FSC 432 Petroleum Refining Fuel Distillation Process A refinery's capacity refers to the maximum amount of crude oil. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. Crude distillation is the first step in processing crude oil into. Fuel Distillation Process.

From chem.libretexts.org

4.7 Fossil Fuels Chemistry LibreTexts Fuel Distillation Process Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Distillation involves the separation of materials based on differences. Fuel Distillation Process.

From eng.libretexts.org

2.2 The process of crude oil refining Engineering LibreTexts Fuel Distillation Process Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Distillation involves the separation of materials based on differences in their volatility. A. Fuel Distillation Process.

From oilandgasproductionhandbook.blogspot.com

Oil and Gas Production Handbook Refining Fuel Distillation Process Crude stills are the oldest. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Learn more about petroleum refining, including its history. This is the first and most basic step in the refining process,. Fuel Distillation Process.

From www.e-education.psu.edu

Desalting and Distillation FSC 432 Petroleum Refining Fuel Distillation Process Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Learn. Fuel Distillation Process.

From www.crownoil.co.uk

Fractional Distillation of Crude Oil Refining Petroleum Products Crown Oil Fuel Distillation Process Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Learn more about petroleum refining, including its history. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Fractional distillation is the process. Fuel Distillation Process.

From ndstudies.gov

Transporting and Processing ND Studies Energy Curriculum Fuel Distillation Process Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. Distillation involves the separation of materials based on differences in. Fuel Distillation Process.

From www.oceansplasticleanup.com

NAPHTHA Fuel Distillation Process Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. Crude distillation is the first step in processing crude oil into its different end products, including gasoline, kerosene, diesel, jet fuel, asphalt, and more. Cracking involves breaking up heavy molecules into lighter (and more. Fuel Distillation Process.

From www.ex-pect.com

The crude oil distillation unit Expect Asia Fuel Distillation Process Crude stills are the oldest. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Distillation involves the separation of materials based on differences in their volatility. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Cracking involves breaking up heavy molecules into lighter. Fuel Distillation Process.

From www.vectorstock.com

Crude oil fractional distillation labeled diagram Vector Image Fuel Distillation Process Cracking involves breaking up heavy molecules into lighter (and more valuable) hydrocarbons. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. A refinery's capacity refers to the maximum amount of crude. Fuel Distillation Process.

From byjus.com

What is Petroleum? Petroleum Refining, Definition, Formation & Uses Fuel Distillation Process A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Crude stills are the oldest. Distillation involves the separation of materials based on differences in their volatility. Learn more about petroleum refining, including its history. A refinery's capacity refers to the maximum amount of crude oil. Fractional distillation is. Fuel Distillation Process.

From www.alamy.com

Diagram showing fractional distillation crude oil Stock Vector Image & Art Alamy Fuel Distillation Process Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Learn more about petroleum refining, including its history. A refinery's capacity refers to the maximum amount of. Fuel Distillation Process.

From jacquelenek-distillation-science.weebly.com

Practical Uses DISTILLATION Fuel Distillation Process This is the first and most basic step in the refining process, and is the precursor to cracking and reforming. A refinery's capacity refers to the maximum amount of crude oil. Petroleum refining, conversion of crude oil into useful products, including fuel oils, gasoline (petrol), asphalt, and kerosene. Distillation involves the separation of materials based on differences in their volatility.. Fuel Distillation Process.

From www.alamy.com

Crude oil distillation process isolated on white background illustration Stock Vector Image Fuel Distillation Process A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Crude stills are the oldest. Learn more about petroleum refining, including its history. Different hydrocarbon chain lengths all have progressively higher boiling points, so they can all be separated by distillation. Fractional distillation is the process by which oil. Fuel Distillation Process.

From www.chemicals.co.uk

What is Fractional Distillation? The Chemistry Blog Fuel Distillation Process Fractional distillation is the process by which oil refineries separate crude oil into different, more useful hydrocarbon products based on their relative molecular weights in a. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. Learn more about petroleum refining, including its history. Distillation involves the separation of. Fuel Distillation Process.