Sand Blasting Parts Cleaning . Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Explore techniques and best practices. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece.

from proleantech.com

Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Explore techniques and best practices. (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify.

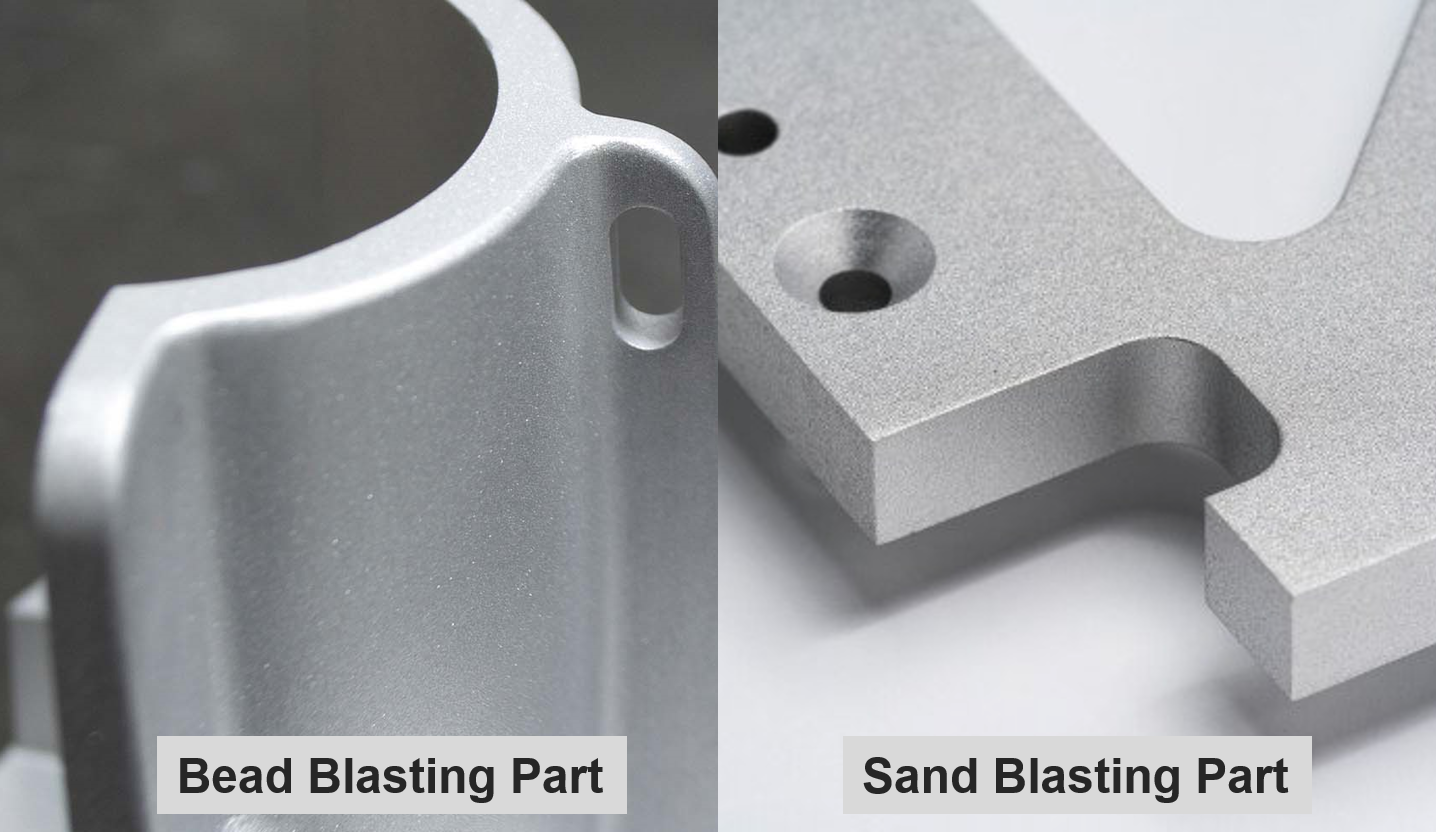

Beadblasting Vs Sandblasting A Detailed Comparision Guide

Sand Blasting Parts Cleaning Explore techniques and best practices. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Explore techniques and best practices. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece.

From domfesasl.com

The sandblasting technique Industrial Machinery and Boilermaking Sand Blasting Parts Cleaning Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Sandblasting. Sand Blasting Parts Cleaning.

From yugongmachine.en.made-in-china.com

Crawler Type Casting Parts Surface Cleaning Sand Blasting Machine China Cleaning Equipment and Sand Blasting Parts Cleaning (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it. Sand Blasting Parts Cleaning.

From www.iqsdirectory.com

Abrasive Blast Equipment What Is It? How Does It Work? Uses Sand Blasting Parts Cleaning Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Sandblasting impacts the surface of the material by spraying abrasive. Sand Blasting Parts Cleaning.

From www.iqsdirectory.com

Abrasive Blast Equipment What Is It? How Does It Work? Uses Sand Blasting Parts Cleaning Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Dry ice cleaning is. Sand Blasting Parts Cleaning.

From premiumplantservices.com

Sand Blasting Premium Plant Services Sand Blasting Parts Cleaning Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Sandblasting impacts. Sand Blasting Parts Cleaning.

From www.sandblasters.co.uk

A Guide to Sand Blast Sand Blasting Parts Cleaning Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Explore techniques and best practices. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Sand, glass beads, steel shot, etc.) at high. Sand Blasting Parts Cleaning.

From www.specialistblastcleaning.co.uk

Blasting types Specialist Blast Cleaning Sand Blasting Parts Cleaning Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Learn how to effectively remove sand residue and ensure a. Sand Blasting Parts Cleaning.

From yugong797.en.made-in-china.com

Sand Blast Chamber, Sand Blasting Room, Cleaning Sandblasting Room for Large Parts China Sand Blasting Parts Cleaning Explore techniques and best practices. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Learn how to effectively remove sand residue and ensure a thorough clean after. Sand Blasting Parts Cleaning.

From galvanizeit.org

Abrasive Blasting American Galvanizers Association Sand Blasting Parts Cleaning Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also. Sand Blasting Parts Cleaning.

From home.alquilercastilloshinchables.info

Clarke Sandblasting Parts Home Alqu Sand Blasting Parts Cleaning Explore techniques and best practices. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Sandblasting can also create small rounded. Sand Blasting Parts Cleaning.

From www.youtube.com

Dry Ice Cleaning versus Sand Blasting Car Parts What's the Difference? YouTube Sand Blasting Parts Cleaning (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles,. Sand Blasting Parts Cleaning.

From www.growmechanical.com

6 Common Method of Pipeline Cleaning Grow Mechanical Sand Blasting Parts Cleaning Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. (3) sandblasting can clean. Sand Blasting Parts Cleaning.

From www.istockphoto.com

View Of The Manuel Sandblasting To The Large Pipe Abrasive Blasting More Commonly Known As Sand Blasting Parts Cleaning Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Learn how to effectively remove sand residue and ensure a. Sand Blasting Parts Cleaning.

From www.iqsdirectory.com

Sandblasting Machinery What Is It? How Does It Work? Types Sand Blasting Parts Cleaning Explore techniques and best practices. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting, often also called. Sand Blasting Parts Cleaning.

From www.freepik.com

Premium Photo Male worker sand blasting process cleaning pipeline surface Sand Blasting Parts Cleaning Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Explore techniques and best practices. Dry ice cleaning is a great way to clean automotive parts and accessories,. Sand Blasting Parts Cleaning.

From www.graco.com

Abrasive Blasting Equipment EcoQuip Sand Blasting Parts Cleaning Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Explore techniques and best practices. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing. Sand Blasting Parts Cleaning.

From qdbesttech.en.made-in-china.com

Sand Blast Chamber, Sand Blasting Room, Cleaning Sandblasting Room for Large Parts China Sand Blasting Parts Cleaning Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Explore techniques and best. Sand Blasting Parts Cleaning.

From www.youtube.com

Sandblasting Process Introduction, Materials& their Uses YouTube Sand Blasting Parts Cleaning Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Sand, glass beads,. Sand Blasting Parts Cleaning.

From stock.adobe.com

Sand blasting process, Industial worker using sand blasting process preparation cleaning surface Sand Blasting Parts Cleaning Explore techniques and best practices. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Sandblasting can also create small. Sand Blasting Parts Cleaning.

From www.groupebellemare.com

Blast Cleaning and Surface Preparation Groupe Bellemare Sand Blasting Parts Cleaning Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Explore techniques and best. Sand Blasting Parts Cleaning.

From proleantech.com

Beadblasting Vs Sandblasting A Detailed Comparision Guide Sand Blasting Parts Cleaning Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Dry ice cleaning is. Sand Blasting Parts Cleaning.

From www.dreamstime.com

Sandblasting in Chamber. Worker Makes Sand Blast Cleaning of Metal Detail Stock Photo Image of Sand Blasting Parts Cleaning Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Explore techniques and best practices. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Dry. Sand Blasting Parts Cleaning.

From cleanblast.com

Sand blasting Machine with Accessories Clean Blast International Sand Blasting Parts Cleaning Explore techniques and best practices. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. (3) sandblasting can clean the small burrs. Sand Blasting Parts Cleaning.

From www.bigstockphoto.com

Sand Blasting Process Image & Photo (Free Trial) Bigstock Sand Blasting Parts Cleaning Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Sandblasting can also create small rounded corners at the. Sand Blasting Parts Cleaning.

From phoenixmetalfinishing.net

Knowing the sandblasting process Phoenix Metal Finishing Sand Blasting Parts Cleaning (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and. Sand Blasting Parts Cleaning.

From www.bigstockphoto.com

Sand Blasting Process Image & Photo (Free Trial) Bigstock Sand Blasting Parts Cleaning Explore techniques and best practices. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. (3) sandblasting can clean the small burrs on the surface of machined. Sand Blasting Parts Cleaning.

From orlandosandblastingpros.com

Sandblasting Orlando Media, Dustless, Mobile Blasting Sand Blasting Parts Cleaning Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen. Sand Blasting Parts Cleaning.

From jkirestoration.com

What exactly is sandblasting? JK Industries, Inc. Sand Blasting Parts Cleaning Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen. Sand Blasting Parts Cleaning.

From www.iqsdirectory.com

Sandblasting Machinery What Is It? How Does It Work? Types Sand Blasting Parts Cleaning Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Dry ice cleaning is a great way to. Sand Blasting Parts Cleaning.

From www.empcasting.com

4 differences between sandblasting and shot blasting EMP Tech Co.,Ltd Sand Blasting Parts Cleaning Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting, often also called abrasive blasting, is a method used to remove surface. Sand Blasting Parts Cleaning.

From istsurface.com

ECO 420 Sandblast for LightDuty Applications ISTblast Sand Blasting Parts Cleaning Explore techniques and best practices. Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Learn how to effectively remove sand residue and ensure a thorough clean after. Sand Blasting Parts Cleaning.

From www.iqsdirectory.com

Sandblasting Machinery What Is It? How Does It Work? Types Sand Blasting Parts Cleaning Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting is the process of cleaning, smoothing, or etching a surface by forcing fine particles, such as sand, at high. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Dry ice cleaning is a. Sand Blasting Parts Cleaning.

From www.rm-contractors.co.uk

Sandblasting RM Contractors Sand Blasting Parts Cleaning Sandblasting impacts the surface of the material by spraying abrasive particles (e.g. Sandblasting, often also called abrasive blasting, is a method used to remove surface contamination, smoothen rough surfaces, and also roughen smooth surfaces. Dry ice cleaning is a great way to clean automotive parts and accessories, but how does. Explore techniques and best practices. Sand, glass beads, steel shot,. Sand Blasting Parts Cleaning.

From www.promain.co.uk

Sandblasting Methods For The Preparation of Steel Promain Resource Centre Sand Blasting Parts Cleaning (3) sandblasting can clean the small burrs on the surface of machined parts and make the surface smoother, eliminating the harm of burrs and improving the quality of the workpiece. Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Sandblasting. Sand Blasting Parts Cleaning.

From cleanblast.com

Sand blasting Equipment for Superior Surface Preparation Clean Blast International Sand Blasting Parts Cleaning Learn how to effectively remove sand residue and ensure a thorough clean after abrasive blasting. Sandblasting can also create small rounded corners at the junction of the workpiece’s surface, making it more beautiful and precise. Sand, glass beads, steel shot, etc.) at high speed to clean, strengthen and modify. Sandblasting is the process of cleaning, smoothing, or etching a surface. Sand Blasting Parts Cleaning.