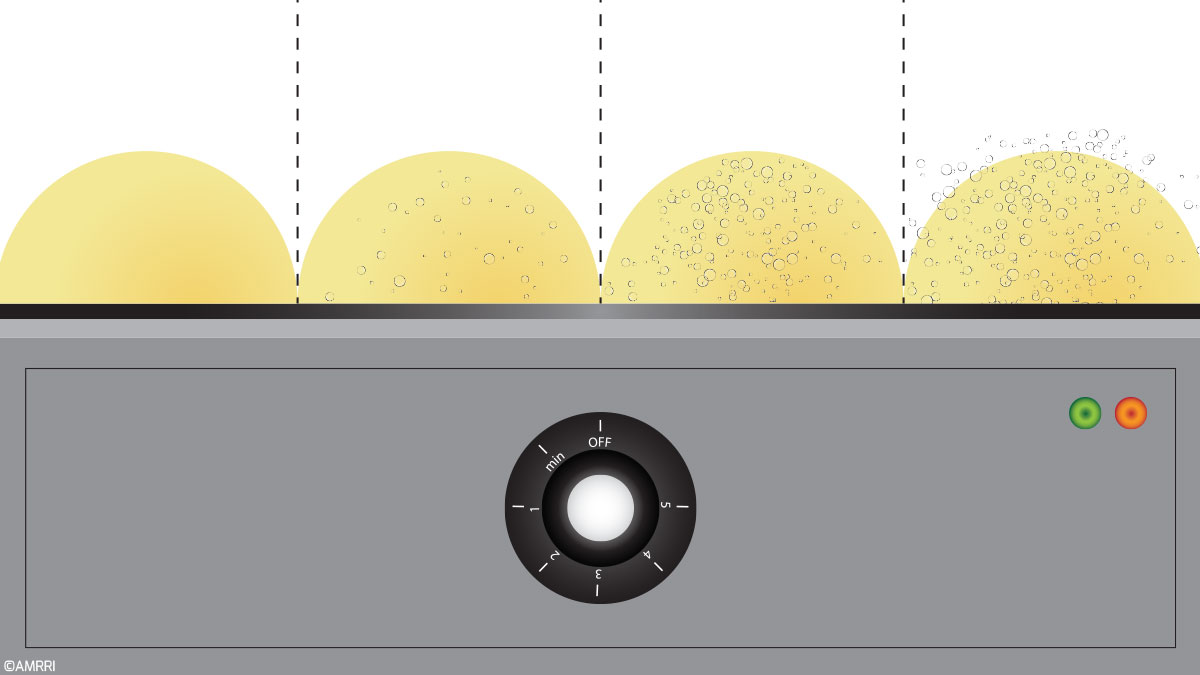

Lube Oil Crackle Test . Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. the crackle test is a simple test to determine whether or not there is water in lubrication oil. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. A drop of oil is. The crackle test can be. While this is an effective test for. the simplest way to determine the presence of water in oil is to use the visual crackle test. The crackle test can be performed in the field using a hot plate. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. the crackle test is a simple test to determine whether or not there is water in lubrication oil.

from precisionlubrication.com

A drop of oil is. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. The crackle test can be performed in the field using a hot plate. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. The crackle test can be. the crackle test is a simple test to determine whether or not there is water in lubrication oil. the simplest way to determine the presence of water in oil is to use the visual crackle test. the crackle test is a simple test to determine whether or not there is water in lubrication oil. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator.

How Reliable and Accurate is the Crackle Test for Oil Analysis?

Lube Oil Crackle Test The crackle test can be performed in the field using a hot plate. While this is an effective test for. the crackle test is a simple test to determine whether or not there is water in lubrication oil. A drop of oil is. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. the crackle test is a simple test to determine whether or not there is water in lubrication oil. The crackle test can be performed in the field using a hot plate. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. the simplest way to determine the presence of water in oil is to use the visual crackle test. The crackle test can be. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil.

From www.coilcleaners.com

Total Lube Oil Test Kit NuCalgon Lube Oil Crackle Test A drop of oil is. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. The crackle test can be. While this is an effective test for. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. This positive result is undoubtedly from the. Lube Oil Crackle Test.

From www.youtube.com

Onboard Lube oil Analysis using TRIBOMAR TEST KIT YouTube Lube Oil Crackle Test the crackle test is a simple test to determine whether or not there is water in lubrication oil. A drop of oil is. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. the crackle test is. Lube Oil Crackle Test.

From testoil.com

Crackel Test (1) TestOil Lube Oil Crackle Test the crackle test is a simple test to determine whether or not there is water in lubrication oil. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. the simplest way to determine the presence of water. Lube Oil Crackle Test.

From www.marineengineersknowledge.com

Lubricating oil properties and lube oil test carried out on board ship Lube Oil Crackle Test the crackle test is a simple test to determine whether or not there is water in lubrication oil. While this is an effective test for. The crackle test can be. The crackle test can be performed in the field using a hot plate. the crackle test is a simple test to determine whether or not there is water. Lube Oil Crackle Test.

From www.marineinsight.com

How to Test Lube Oil (Lubricating Oil) Onboard Ship? Lube Oil Crackle Test The crackle test can be. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. the crackle test is a. Lube Oil Crackle Test.

From www.marineengineersknowledge.com

LUBE OIL TESTS Marine engineers knowledge Lube Oil Crackle Test However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. While this is an effective test for. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result. Lube Oil Crackle Test.

From precisionlubrication.com

How Reliable and Accurate is the Crackle Test for Oil Analysis? Lube Oil Crackle Test the crackle test is a simple test to determine whether or not there is water in lubrication oil. the simplest way to determine the presence of water in oil is to use the visual crackle test. While this is an effective test for. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. the. Lube Oil Crackle Test.

From www.mjlbl.com

MJL Bangladesh PLC. Mobil Lube Oil Crackle Test However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. the simplest way to determine the presence of water in oil is to use the visual crackle test. Of these, the only sample that would have an obvious. Lube Oil Crackle Test.

From www.youtube.com

How does the oil lubricity tester work? Let's find out! YouTube Lube Oil Crackle Test the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. The crackle test can be performed in the field using a. Lube Oil Crackle Test.

From www.marineengineersknowledge.com

Lubricating oil properties and lube oil test carried out on board ship Lube Oil Crackle Test This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. the crackle test is a simple test to determine whether or not there is water in lubrication oil. While this is an effective test for. The crackle test. Lube Oil Crackle Test.

From www.youtube.com

Crackle Test 2412 ppm Water Polyglycol Compressor Oil YouTube Lube Oil Crackle Test This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. While this is an effective test for. The crackle test can be performed in the field using a hot plate. the crackle test is a simple test to determine whether or not there is water in lubrication oil. the crackle test is a simple test. Lube Oil Crackle Test.

From www.martechnic.com

Martechnic® Products > Testkit Lube Oil Crackle Test While this is an effective test for. The crackle test can be performed in the field using a hot plate. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. A drop of oil is. the crackle test. Lube Oil Crackle Test.

From www.atlaslab.in

lube oil testing report, lube oil analysis report Lube Oil Crackle Test The crackle test can be. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. The crackle test can be performed in the field using a. Lube Oil Crackle Test.

From commodities.bureauveritas.com

Lubricating Oil Analysis Lubricants Testing Bureau Veritas Lube Oil Crackle Test The crackle test can be performed in the field using a hot plate. the simplest way to determine the presence of water in oil is to use the visual crackle test. A drop of oil is. The crackle test can be. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. While this is an effective. Lube Oil Crackle Test.

From www.youtube.com

Crackle Test 48 ppm Water Paraffinic Mineral Oil YouTube Lube Oil Crackle Test Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. A drop of oil is. While this is an effective test for. the crackle test. Lube Oil Crackle Test.

From www.marineengineersknowledge.com

LUBE OIL TESTS Marine engineers knowledge Lube Oil Crackle Test However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. the crackle test is a simple test to determine whether or not there is water in lubrication oil. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with. Lube Oil Crackle Test.

From www.tuv-nord.com

Lube Oil / Lubricating Oil Analysis Blog TUV India Lube Oil Crackle Test Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. the simplest way to determine the presence of water in oil is to use the visual crackle test. the crackle test is a simple test to determine. Lube Oil Crackle Test.

From oilanalysislab.com

UK oil analysis lab testing machinery lube oil samples Lube Oil Crackle Test The crackle test can be performed in the field using a hot plate. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. the crackle test is a simple test to determine whether or not there is water in lubrication oil. Of these, the only sample that would have an obvious. Lube Oil Crackle Test.

From lubeoiltestinglabs.blogspot.com

Lube Oil Testing Labs Lube Oil Crackle Test the crackle test is a simple test to determine whether or not there is water in lubrication oil. The crackle test can be performed in the field using a hot plate. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. While this is an effective test for. the crackle. Lube Oil Crackle Test.

From www.youtube.com

How to test Lube Oil Viscosity? Lube Oil Analysis Onboard Ship YouTube Lube Oil Crackle Test A drop of oil is. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. the simplest way to determine the presence of water in oil is to use the visual crackle test. the crackle test is a simple test to determine whether or not there is water in lubrication. Lube Oil Crackle Test.

From www.marineinsight.com

How to Test Lube Oil (Lubricating Oil) Onboard Ship? Lube Oil Crackle Test the simplest way to determine the presence of water in oil is to use the visual crackle test. the crackle test is a simple test to determine whether or not there is water in lubrication oil. The crackle test can be performed in the field using a hot plate. the crackle test is a simple test to. Lube Oil Crackle Test.

From www.marineengineersknowledge.com

LUBE OIL TESTS Marine engineers knowledge Lube Oil Crackle Test A drop of oil is. The crackle test can be. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. The. Lube Oil Crackle Test.

From www.marineengineersknowledge.com

LUBE OIL TESTS Marine engineers knowledge Lube Oil Crackle Test the crackle test is a simple test to determine whether or not there is water in lubrication oil. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. The crackle test can be performed in the field using a hot plate. the crackle test is a standard laboratory test to. Lube Oil Crackle Test.

From gpmhydraulic.com

What is a Crackle Test? GPM HYDRAULIC CONSULTING, INC. Lube Oil Crackle Test A drop of oil is. The crackle test can be. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. the crackle test is a simple test to determine whether or not there is water in lubrication oil. the crackle test is a standard laboratory test to detect the presence. Lube Oil Crackle Test.

From www.youtube.com

Lube oil Viscosity Test Lube oil Spot Test Onboard Lube oil test Lube Oil Crackle Test While this is an effective test for. The crackle test can be performed in the field using a hot plate. the crackle test is a simple test to determine whether or not there is water in lubrication oil. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. the simplest way to determine the presence. Lube Oil Crackle Test.

From studyfinder.org

The Ultimate Guide on How to Perform a Crackle Test on Different Types Lube Oil Crackle Test the simplest way to determine the presence of water in oil is to use the visual crackle test. A drop of oil is. While this is an effective test for. The crackle test can be performed in the field using a hot plate. the crackle test is a standard laboratory test to detect the presence of water in. Lube Oil Crackle Test.

From www.bcl.co.za

Crackle test for water in oil Blue Chip Lubricants Lube Oil Crackle Test A drop of oil is. the simplest way to determine the presence of water in oil is to use the visual crackle test. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil.. Lube Oil Crackle Test.

From www.youtube.com

Lubricant Testing 101 Dropping Point by Nye Lubricants YouTube Lube Oil Crackle Test the crackle test is a simple test to determine whether or not there is water in lubrication oil. the simplest way to determine the presence of water in oil is to use the visual crackle test. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. The crackle test can. Lube Oil Crackle Test.

From www.zematra-marine.com

Lube Oil Test Kit Zematra Marine Lube Oil Crackle Test the simplest way to determine the presence of water in oil is to use the visual crackle test. The crackle test can be. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. the crackle test is a simple test to determine whether or not there is water in lubrication. Lube Oil Crackle Test.

From www.youtube.com

Crackle Test 2063 ppm Water Polyether Polyol Synthetic Hightemp Lube Oil Crackle Test the crackle test is a simple test to determine whether or not there is water in lubrication oil. the crackle test is a standard laboratory test to detect the presence of water in lubricating oil. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. The crackle test can be.. Lube Oil Crackle Test.

From www.pinterest.com

How to Test Lube Oil (Lubricating Oil) Onboard Ship? in 2020 Lube Lube Oil Crackle Test the simplest way to determine the presence of water in oil is to use the visual crackle test. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. the crackle test is a simple test to determine whether or not there is water in lubrication oil. The crackle test can. Lube Oil Crackle Test.

From www.tribonet.org

Lubricant Testing About Tribology Lube Oil Crackle Test The crackle test can be performed in the field using a hot plate. Of these, the only sample that would have an obvious and clearly observed “positive” crackle test result was the chiller compressor sample, with only 464 ppm h2o as the measured result. A drop of oil is. The crackle test can be. While this is an effective test. Lube Oil Crackle Test.

From www.youtube.com

"CRACKLE TEST LUBE OIL" determinazione contaminazione di acqua negli Lube Oil Crackle Test The crackle test can be performed in the field using a hot plate. While this is an effective test for. A drop of oil is. the crackle test is a simple test to determine whether or not there is water in lubrication oil. the crackle test is a standard laboratory test to detect the presence of water in. Lube Oil Crackle Test.

From studyfinder.org

The Ultimate Guide on How to Perform a Crackle Test on Different Types Lube Oil Crackle Test the simplest way to determine the presence of water in oil is to use the visual crackle test. While this is an effective test for. the crackle test is a simple test to determine whether or not there is water in lubrication oil. the crackle test is a simple test to determine whether or not there is. Lube Oil Crackle Test.

From theviswagroup.com

Lube Oil Testing The Viswa Group Lube Oil Crackle Test A drop of oil is. the crackle test is a simple test to determine whether or not there is water in lubrication oil. This positive result is undoubtedly from the refrigerant absorbed into the lubricating oil. However, it is not a quantitative method, presents safety concerns, and provides inconsistent results from operator to operator. The crackle test can be. Lube Oil Crackle Test.