Optical Vision Inspection . It can be done with: Our inspection and sorting systems are for 100% inspection of small parts. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Visual inspection is the process of conducting an inspection by sight. Simple visual aids like magnifying glasses, rope, and mirrors. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. This technology combines advanced optics, cameras, and image processing capabilities for inspections.

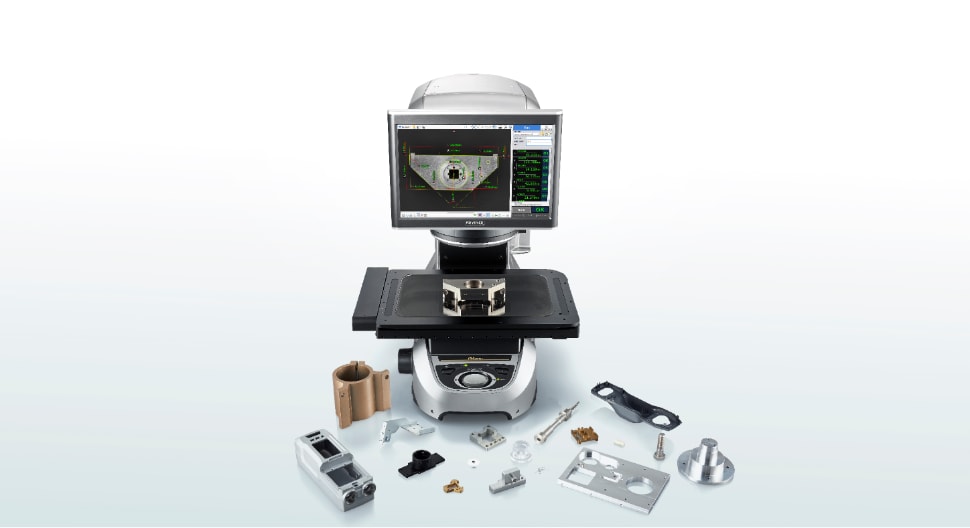

from www.keyence.co.id

Visual inspection is the process of conducting an inspection by sight. This technology combines advanced optics, cameras, and image processing capabilities for inspections. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. It can be done with: Simple visual aids like magnifying glasses, rope, and mirrors. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Our inspection and sorting systems are for 100% inspection of small parts.

Optical Inspection KEYENCE Indonesia

Optical Vision Inspection Our inspection and sorting systems are for 100% inspection of small parts. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. This technology combines advanced optics, cameras, and image processing capabilities for inspections. It can be done with: Visual inspection is the process of conducting an inspection by sight. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Our inspection and sorting systems are for 100% inspection of small parts. Simple visual aids like magnifying glasses, rope, and mirrors.

From shavingsupplier.com

Automated Vision Inspection Systems shavingsupplier Optical Vision Inspection Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. This technology combines advanced optics, cameras, and image processing capabilities for inspections. It can be done with: Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification.. Optical Vision Inspection.

From www.youtube.com

Inspection of optical lenses and flats with machine vision from STEMMER Optical Vision Inspection Our inspection and sorting systems are for 100% inspection of small parts. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. Visual inspection is the process of conducting an inspection by sight. Typical inspection features are the external visible geometry. Optical Vision Inspection.

From www.sipotek.net

Machine Vision Technology in Constructing an Optical Vision Inspection Optical Vision Inspection Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. It can be done with: Visual inspection is the process of conducting an inspection by sight. This technology combines advanced optics, cameras, and image processing capabilities for inspections. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance. Optical Vision Inspection.

From www.sipotek.net

Wide Range Of Automated Visual Inspection Systems Working By High Optical Vision Inspection Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Simple visual aids like magnifying glasses, rope, and mirrors. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Vision inspection systems see beyond the naked eye and. Optical Vision Inspection.

From www.rsipvision.com

Automated Optical Inspection and computer vision in Semiconductors Optical Vision Inspection Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Visual inspection is the process of conducting an inspection by sight. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. Our. Optical Vision Inspection.

From www.inspect-is.com

4K Advanced Optical Inspection System Inspectis Optical Vision Inspection Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. It can be done with: Visual inspection is the process of conducting an inspection by sight. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Visual inspection. Optical Vision Inspection.

From www.protoexpress.com

Automated Optical Inspection Sierra Circuits Optical Vision Inspection Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. It can be. Optical Vision Inspection.

From www.sipotek.net

Automated Optical Vision Inspection Machine Malaysia Sipotek Visual Optical Vision Inspection This technology combines advanced optics, cameras, and image processing capabilities for inspections. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. It can be done with: Vision. Optical Vision Inspection.

From www.youtube.com

What is Optical Character Recognition? OCR Vision Inspection Systems Optical Vision Inspection Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Simple visual aids like magnifying glasses, rope, and mirrors. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance. Optical Vision Inspection.

From qualitastech.com

5 Advantages of Automated Vision Inspection Systems Optical Vision Inspection This technology combines advanced optics, cameras, and image processing capabilities for inspections. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Visual inspection is the process of conducting an inspection by sight. Our inspection and sorting systems are for 100% inspection of small parts. Visual inspection is a technique for. Optical Vision Inspection.

From mmsis.com

3D Automated Optical & Vision Inspection Machine Supplier In Malaysia Optical Vision Inspection Simple visual aids like magnifying glasses, rope, and mirrors. It can be done with: Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing. Optical Vision Inspection.

From eitpl.com

Automated optical inspection Services AOI Automated Optical Inspection Optical Vision Inspection Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. This technology combines advanced optics, cameras, and image processing capabilities for inspections. Visual inspection is the process of conducting an inspection by sight. Our inspection and sorting systems are for 100% inspection of small parts. It can be done with: Visual. Optical Vision Inspection.

From interconics.co.uk

PCB Automated Optical Inspection AOI • Interconics AOI System Optical Vision Inspection Simple visual aids like magnifying glasses, rope, and mirrors. It can be done with: Visual inspection is the process of conducting an inspection by sight. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. Automated optical inspection (aoi) is a. Optical Vision Inspection.

From www.sipotek.net

The application of automated optical visual inspection machine in label Optical Vision Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. Visual inspection is the process of conducting an inspection by sight. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality. Optical Vision Inspection.

From www.aajjo.com

Infinity 50hz Optical Vision Inspection System, 230vac in Pune Optical Vision Inspection Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. This technology combines advanced optics, cameras, and image processing capabilities for inspections.. Optical Vision Inspection.

From www.kasdonpcb.com

Quality Assurance Test & Automated Optical Inspection (AOI) Optical Vision Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. This technology combines advanced optics, cameras, and image processing capabilities for inspections. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Simple visual aids like magnifying. Optical Vision Inspection.

From aoi-spi.com

Automatic Optical Inspection(AOI) VCTATB810 Two vision systems Optical Vision Inspection Our inspection and sorting systems are for 100% inspection of small parts. It can be done with: Simple visual aids like magnifying glasses, rope, and mirrors. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Visual. Optical Vision Inspection.

From dailygram.com

Top 10 Improvements for Automated Optical Vision Inspection Technology Optical Vision Inspection Our inspection and sorting systems are for 100% inspection of small parts. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Visual inspection is the process of conducting an inspection by sight. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. This technology combines advanced. Optical Vision Inspection.

From htgdmachine.en.made-in-china.com

High Accuracy Automatic Optical Vision Inspection Machine SMT Testing Optical Vision Inspection It can be done with: This technology combines advanced optics, cameras, and image processing capabilities for inspections. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Our inspection and sorting systems are for 100% inspection of small parts. Visual inspection is a technique for detecting defects by using the naked. Optical Vision Inspection.

From www.viscom.com

Optical Inspection 3D AOI Optical Vision Inspection Simple visual aids like magnifying glasses, rope, and mirrors. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. This technology combines advanced optics, cameras, and image processing capabilities for inspections. Visual inspection is the process of conducting an inspection by sight. Visual inspection is a technique for detecting defects by. Optical Vision Inspection.

From www.youtube.com

Manual Load Automated Vision Inspection Machines for Quality Control Optical Vision Inspection Simple visual aids like magnifying glasses, rope, and mirrors. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. It can be done with: This technology combines advanced optics, cameras, and image processing capabilities for inspections. Visual. Optical Vision Inspection.

From sipotek.blogspot.com

Sipotek Visual Inspection Machine,Automated optical inspection machine Optical Vision Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. Simple visual aids like magnifying glasses, rope, and mirrors. It can be done with: Visual inspection is the process of conducting an inspection by sight. Automated optical inspection (aoi) is a. Optical Vision Inspection.

From www.jenoptik.com

Vision systems for optical inspection Jenoptik Optical Vision Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. This technology combines advanced optics, cameras, and image processing capabilities for inspections. Our inspection and sorting systems are for 100% inspection of small parts. Vision inspection systems see beyond the naked. Optical Vision Inspection.

From sipotek.blogspot.com

Sipotek Visual Inspection Machine,Automated optical inspection machine Optical Vision Inspection This technology combines advanced optics, cameras, and image processing capabilities for inspections. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Visual inspection is the process of conducting an inspection by sight. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is. Optical Vision Inspection.

From www.keyence.co.id

Optical Inspection KEYENCE Indonesia Optical Vision Inspection Visual inspection is the process of conducting an inspection by sight. Our inspection and sorting systems are for 100% inspection of small parts. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Simple visual aids like magnifying glasses, rope, and mirrors.. Optical Vision Inspection.

From www.sipotek.net

Automatic Optical XY Linear Motion Guide Vision Inspection Machine Optical Vision Inspection Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Visual inspection is the process of conducting an inspection by sight. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Typical inspection. Optical Vision Inspection.

From metrology.news

Automated Optical Inspection Versus Traditional Manual Inspection Optical Vision Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to specification. Simple visual aids like magnifying glasses, rope, and mirrors. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently. Optical Vision Inspection.

From www.sinowon.com

automated optical inspection system Sinowon Optical Vision Inspection Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Our inspection and sorting systems are for 100% inspection of small parts. This technology combines advanced optics, cameras, and image processing capabilities for inspections. Vision inspection systems see beyond the naked eye. Optical Vision Inspection.

From www.elunic.com

AI.SEE™ Automated Visual Inspection using AI Optical Vision Inspection It can be done with: Simple visual aids like magnifying glasses, rope, and mirrors. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Visual inspection is a. Optical Vision Inspection.

From dailygram.com

Top 10 Improvements for Automated Optical Vision Inspection Technology Optical Vision Inspection It can be done with: Our inspection and sorting systems are for 100% inspection of small parts. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Simple visual aids like magnifying glasses, rope, and mirrors. Typical inspection features are the external. Optical Vision Inspection.

From mungfali.com

Machine Vision Inspection System Optical Vision Inspection It can be done with: This technology combines advanced optics, cameras, and image processing capabilities for inspections. Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Simple visual aids like magnifying glasses, rope, and mirrors. Visual. Optical Vision Inspection.

From www.youtube.com

Automated Optical Inspection (AOI) Manual Load PCB Vision Inspection Optical Vision Inspection Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Our inspection and sorting systems are for 100% inspection of small parts. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Vision inspection systems see beyond the. Optical Vision Inspection.

From mjsdesigns.com

Explaining MJS Designs’ Dedication to Automatic Optical Inspection and Optical Vision Inspection Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Our inspection and sorting systems are for 100% inspection of small parts. Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing. Optical Vision Inspection.

From www.wilco.com

Automated Visual Inspection WILCO AG Optical Vision Inspection Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. It can be done with: Automated optical inspection (aoi) is a visual inspection technology widely used in the electronic manufacturing industry to enhance product quality by efficiently identifying defects during the manufacturing process. Visual inspection is a technique for detecting defects. Optical Vision Inspection.

From www.sipotek.net

Machine Vision Technology in Constructing an Optical Vision Inspection Optical Vision Inspection Vision inspection systems see beyond the naked eye and capture minute contaminants, flaws, defects, and measuring errors that are. It can be done with: Simple visual aids like magnifying glasses, rope, and mirrors. This technology combines advanced optics, cameras, and image processing capabilities for inspections. Typical inspection features are the external visible geometry (diameters, radi, lengths, angles, detection of. Automated. Optical Vision Inspection.