Gears Damage Analysis . The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. The purpose of this paper is to describe a. Damage to gears is basically categorized by two types; Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. One is the damage to the tooth surface, and the other is breakage of the gear tooth. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. Here’s how to conduct a failure analysis, what to look for, and how to recognize.

from www.slideshare.net

The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. One is the damage to the tooth surface, and the other is breakage of the gear tooth. The purpose of this paper is to describe a. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Damage to gears is basically categorized by two types; Here’s how to conduct a failure analysis, what to look for, and how to recognize.

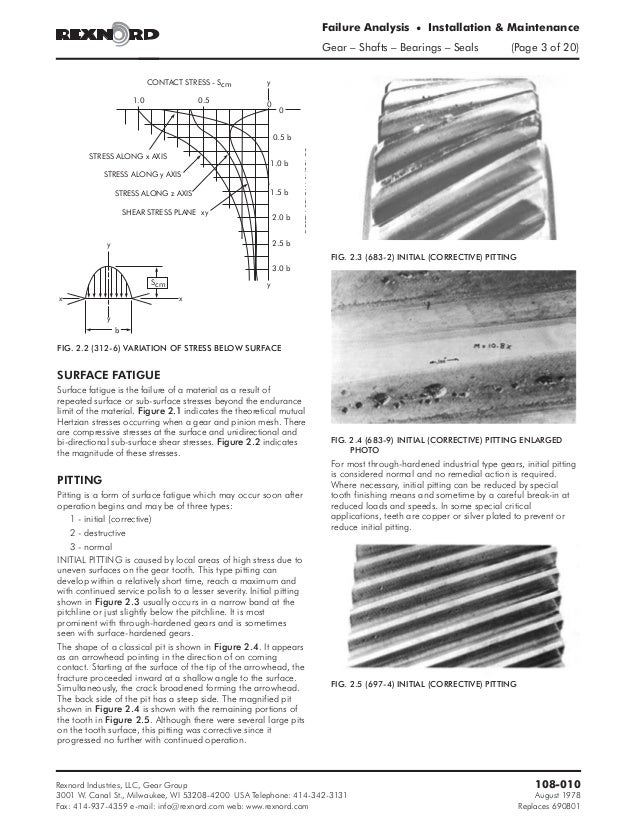

108 010 failureanalysisgears,shafts,bearings,sealsmaintenancem…

Gears Damage Analysis The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Here’s how to conduct a failure analysis, what to look for, and how to recognize. One is the damage to the tooth surface, and the other is breakage of the gear tooth. Damage to gears is basically categorized by two types; Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. The purpose of this paper is to describe a. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of.

From www.pvzgears.com

PVZ Gears Complete Gear Design & Analysis Solutions Gears Damage Analysis Here’s how to conduct a failure analysis, what to look for, and how to recognize. Damage to gears is basically categorized by two types; Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. The purpose of. Gears Damage Analysis.

From thermalprocessing.com

How Gears Fail Thermal Processing Magazine Gears Damage Analysis Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. One is the damage to the tooth surface, and the other is breakage of the gear tooth. Here’s how to conduct a failure analysis, what to look for, and how to recognize. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear. Gears Damage Analysis.

From www.thesamba.com

Gallery 3rd gear damage from loose pinion nut. Gears Damage Analysis Damage to gears is basically categorized by two types; The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. One is the damage to the tooth surface, and the other is breakage of the gear tooth. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric. Gears Damage Analysis.

From ar.inspiredpencil.com

Failed Gears Gears Damage Analysis The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. Here’s how to conduct a failure analysis, what to look for, and how to recognize. The. Gears Damage Analysis.

From www.slideshare.net

failureanalysisgears,shafts,bearings,sealsmaintenancemanual Gears Damage Analysis The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. Here’s how to conduct a failure analysis, what to look for, and. Gears Damage Analysis.

From www.researchgate.net

(PDF) Analysis techniques end gear damage Gears Damage Analysis The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and. Gears Damage Analysis.

From www.researchgate.net

(PDF) Gear Damage Assessment Based on Cyclic Spectral Analysis Gears Damage Analysis Here’s how to conduct a failure analysis, what to look for, and how to recognize. Damage to gears is basically categorized by two types; The purpose of this paper is to describe a. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. Systematic. Gears Damage Analysis.

From www.machinerylubrication.com

How to Analyze Gear Failures Gears Damage Analysis One is the damage to the tooth surface, and the other is breakage of the gear tooth. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Damage to gears is basically categorized by two types; Gears can fail in many different ways, and except for an increase in noise level and. Gears Damage Analysis.

From www.academia.edu

(PDF) Spur Gear Damage Analysis Using Variation of Speed Range Gears Damage Analysis The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for. Gears Damage Analysis.

From www.zhygear.com

Bending fatigue damage mechanism and materials of Automobile Gears Gears Damage Analysis Here’s how to conduct a failure analysis, what to look for, and how to recognize. Damage to gears is basically categorized by two types; One is the damage to the tooth surface, and the other is breakage of the gear tooth. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of. Gears Damage Analysis.

From www.slideshare.net

108 010 failureanalysisgears,shafts,bearings,sealsmaintenancem… Gears Damage Analysis One is the damage to the tooth surface, and the other is breakage of the gear tooth. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. The purpose of this paper is to describe a. Here’s how to conduct a failure analysis, what to look for, and. Gears Damage Analysis.

From www.elgeti-engineering.com

Elgeti Engineering Case Study Gearing Damage Gears Damage Analysis Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. One is the damage to the tooth surface, and the other is. Gears Damage Analysis.

From www.thesamba.com

Gallery 3rd gear damage from loose pinion nut. Gears Damage Analysis Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is. Gears Damage Analysis.

From www.slideshare.net

108 010 failureanalysisgears,shafts,bearings,sealsmaintenancem… Gears Damage Analysis Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. The purpose of this paper is to describe a. Here’s how to conduct a failure analysis, what to look for, and how to recognize. Gear drive components most commonly subject to distress are the. Gears Damage Analysis.

From global-pam.com

Girth Gear Reliability and Failure Analysis Global Physical Asset Gears Damage Analysis The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Damage to gears is basically categorized by two types; One is the damage to the tooth surface, and the other is breakage of the gear tooth. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. Gears. Gears Damage Analysis.

From boating.marsh-design.com

Failure analysis Shredded outboard lower gear set M.B. Marsh Design Gears Damage Analysis Here’s how to conduct a failure analysis, what to look for, and how to recognize. One is the damage to the tooth surface, and the other is breakage of the gear tooth. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Systematic analysis of gear failures covers. Gears Damage Analysis.

From ar.inspiredpencil.com

Gear Wear Patterns Gears Damage Analysis Here’s how to conduct a failure analysis, what to look for, and how to recognize. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. The nonlinear approach can. Gears Damage Analysis.

From www.slideshare.net

108 010 failureanalysisgears,shafts,bearings,sealsmaintenancem… Gears Damage Analysis Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. The purpose of this paper is to describe a. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Here’s how to conduct a failure analysis,. Gears Damage Analysis.

From www.slideshare.net

108 010 failureanalysisgears,shafts,bearings,sealsmaintenancem… Gears Damage Analysis The purpose of this paper is to describe a. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. Gear drive components most commonly subject to. Gears Damage Analysis.

From www.dmsinteractive.co.uk

Bearing & gear failure reports DMS Drive Management Services Gears Damage Analysis Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Here’s how to conduct a failure analysis, what to look for, and how to recognize. The procedure takes into account the pitting resistance (surface fatigue failure) and. Gears Damage Analysis.

From www.semanticscholar.org

[PDF] Diagnosis of Gear Tooth Surface Damage by Analyzing Vibration Gears Damage Analysis The purpose of this paper is to describe a. Damage to gears is basically categorized by two types; The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Here’s how to conduct a failure analysis, what to look for, and how to recognize. Gear drive components most commonly. Gears Damage Analysis.

From www.slideserve.com

PPT Force Analysis Spur Gears PowerPoint Presentation, free Gears Damage Analysis Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. Here’s how to conduct a failure analysis, what to look for, and how to recognize. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. One is the damage. Gears Damage Analysis.

From www.researchgate.net

(PDF) The ten commandments of gear failure analysis Gears Damage Analysis Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. The purpose of this paper is to describe a. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. The nonlinear approach can consider the load sequence when calculating. Gears Damage Analysis.

From www.researchgate.net

(PDF) How to analyze gear failures Gears Damage Analysis Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. One is the damage to the tooth surface, and the other is breakage of the gear tooth. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue. Gears Damage Analysis.

From www.youtube.com

GEARBOX FAILURE DUE TO CRASH ENGAGE OF GEARS WITH OUT APPLYING CLUTCH Gears Damage Analysis One is the damage to the tooth surface, and the other is breakage of the gear tooth. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Damage to gears. Gears Damage Analysis.

From www.researchgate.net

Typical gear failures on analyzed gearboxes Download Scientific Diagram Gears Damage Analysis Gears can fail in many different ways, and except for an increase in noise level and vibration, there is often no indication of difficulty until total. One is the damage to the tooth surface, and the other is breakage of the gear tooth. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. Damage to. Gears Damage Analysis.

From www.differentials.com

Differential Failure Analysis West Coast Differentials Gears Damage Analysis Damage to gears is basically categorized by two types; The purpose of this paper is to describe a. Here’s how to conduct a failure analysis, what to look for, and how to recognize. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. The nonlinear approach can consider. Gears Damage Analysis.

From www.zhygear.com

Helical Gear Failure Analysis ZHY Gear Gears Damage Analysis The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. Damage to gears is basically categorized by two types; One is the damage to the tooth surface, and the other is breakage of. Gears Damage Analysis.

From thermalprocessing.com

How Gears Fail Thermal Processing Magazine Gears Damage Analysis Here’s how to conduct a failure analysis, what to look for, and how to recognize. Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. One is the damage to the tooth surface, and the other is breakage of the gear tooth. The procedure takes into account the pitting resistance (surface fatigue failure) and bending. Gears Damage Analysis.

From www.megacarss.com

Bearing Damage Reference Wall Chart RMS Ltd, 54 OFF Gears Damage Analysis The purpose of this paper is to describe a. The procedure takes into account the pitting resistance (surface fatigue failure) and bending strength capacity (volumetric fatigue failure) of spur and helical. Here’s how to conduct a failure analysis, what to look for, and how to recognize. Gears can fail in many different ways, and except for an increase in noise. Gears Damage Analysis.

From www.slideserve.com

PPT Force Analysis Spur Gears PowerPoint Presentation, free Gears Damage Analysis One is the damage to the tooth surface, and the other is breakage of the gear tooth. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. The purpose of this paper is to describe a. Damage to gears is basically categorized by two types; Here’s how to conduct a failure analysis,. Gears Damage Analysis.

From thermalprocessing.com

How Gears Fail Thermal Processing Magazine Gears Damage Analysis Damage to gears is basically categorized by two types; Gear drive components most commonly subject to distress are the gears, shafts, bearings and seals. One is the damage to the tooth surface, and the other is breakage of the gear tooth. Gears can fail in many different ways, and except for an increase in noise level and vibration, there is. Gears Damage Analysis.

From thermalprocessing.com

How Gears Fail Thermal Processing Magazine Gears Damage Analysis The purpose of this paper is to describe a. Here’s how to conduct a failure analysis, what to look for, and how to recognize. The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. One is the damage to the tooth surface, and the other is breakage of the gear tooth. Systematic. Gears Damage Analysis.

From www.windpowerengineering.com

sheds light on those annoying gearbox failure mysteries Gears Damage Analysis One is the damage to the tooth surface, and the other is breakage of the gear tooth. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. Gears can fail in many different ways, and except for an increase in noise level and vibration,. Gears Damage Analysis.

From global-pam.com

Girth Gear Reliability and Failure Analysis Global Physical Asset Gears Damage Analysis Damage to gears is basically categorized by two types; The nonlinear approach can consider the load sequence when calculating the damage but comes with the tradeoff of. Systematic analysis of gear failures covers the modes, mechanisms, and appearances of gear failures and presents an orderly approach for determining how and why gears fail. One is the damage to the tooth. Gears Damage Analysis.