Tap Machine Problem . Use our list of causes and solutions for different thread tapping problems as a reference for successful. By far, the most obvious sign of an issue is tap breakage. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. This document explains some of the most common causes for tap breakage. If your tool is breaking, cracking, or chipping, you need to administer. Here are three factors to consider that will help. — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. The best way to tackle draft problems is to be prepared. Insufficient tool life is one of the main issues encountered in tapping applications. It is prudent to create a troubleshooting guide to your draft system.

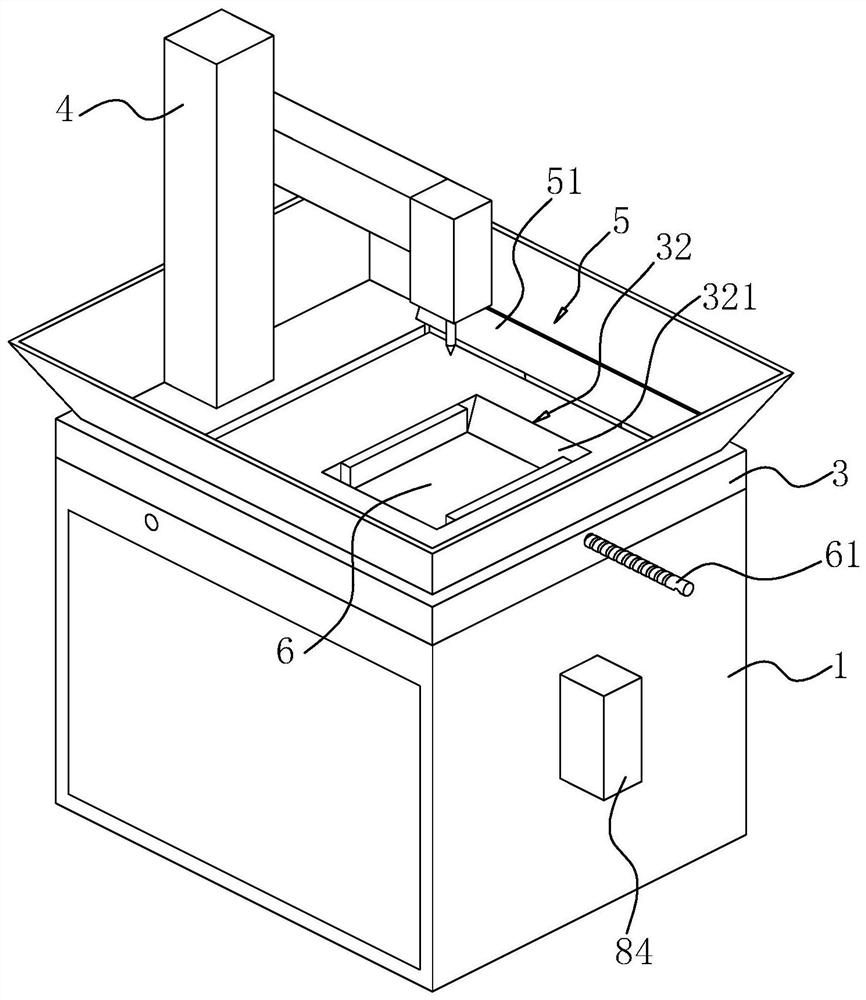

from eureka.patsnap.com

Here are three factors to consider that will help. By far, the most obvious sign of an issue is tap breakage. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. Insufficient tool life is one of the main issues encountered in tapping applications. This document explains some of the most common causes for tap breakage. — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. Use our list of causes and solutions for different thread tapping problems as a reference for successful. If your tool is breaking, cracking, or chipping, you need to administer. It is prudent to create a troubleshooting guide to your draft system. The best way to tackle draft problems is to be prepared.

Tapping machine Eureka Patsnap develop intelligence library

Tap Machine Problem It is prudent to create a troubleshooting guide to your draft system. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. Insufficient tool life is one of the main issues encountered in tapping applications. If your tool is breaking, cracking, or chipping, you need to administer. Use our list of causes and solutions for different thread tapping problems as a reference for successful. This document explains some of the most common causes for tap breakage. — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. It is prudent to create a troubleshooting guide to your draft system. The best way to tackle draft problems is to be prepared. Here are three factors to consider that will help. By far, the most obvious sign of an issue is tap breakage.

From www.yakinmaju.com

Precision Gear type Automatic Tapping Machine Tapping, Machinery Tap Machine Problem Here are three factors to consider that will help. Insufficient tool life is one of the main issues encountered in tapping applications. It is prudent to create a troubleshooting guide to your draft system. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. — problems encountered in tapping are often the fault of the. Tap Machine Problem.

From eureka.patsnap.com

Drilling and tapping machine Eureka Patsnap develop intelligence Tap Machine Problem Here are three factors to consider that will help. Insufficient tool life is one of the main issues encountered in tapping applications. If your tool is breaking, cracking, or chipping, you need to administer. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. The best way to tackle draft problems is to be prepared.. Tap Machine Problem.

From www.nextgentooling.com

Thinking about synchronous tapping to reduce CNC cycle time? NEXT Tap Machine Problem The best way to tackle draft problems is to be prepared. This document explains some of the most common causes for tap breakage. It is prudent to create a troubleshooting guide to your draft system. If your tool is breaking, cracking, or chipping, you need to administer. By far, the most obvious sign of an issue is tap breakage. Use. Tap Machine Problem.

From issuu.com

What Is the Maintenance Requirement for a Tapping Machine? by Dynamic Tap Machine Problem It is prudent to create a troubleshooting guide to your draft system. This document explains some of the most common causes for tap breakage. Here are three factors to consider that will help. By far, the most obvious sign of an issue is tap breakage. Insufficient tool life is one of the main issues encountered in tapping applications. If your. Tap Machine Problem.

From eureka.patsnap.com

Vertical adjusting device for tapping machine Eureka Patsnap Tap Machine Problem Insufficient tool life is one of the main issues encountered in tapping applications. The best way to tackle draft problems is to be prepared. Here are three factors to consider that will help. By far, the most obvious sign of an issue is tap breakage. It is prudent to create a troubleshooting guide to your draft system. Use our list. Tap Machine Problem.

From derbyphotoscouk.blogspot.com

www.derbyphotos.co.uk The blog by Andy Savage Washing Machine Valve Tap Machine Problem If your tool is breaking, cracking, or chipping, you need to administer. By far, the most obvious sign of an issue is tap breakage. The best way to tackle draft problems is to be prepared. Insufficient tool life is one of the main issues encountered in tapping applications. It is prudent to create a troubleshooting guide to your draft system.. Tap Machine Problem.

From blog.thepipingmart.com

Self Tapping vs Machine Screw What's the Difference Tap Machine Problem By far, the most obvious sign of an issue is tap breakage. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. The best way to tackle draft problems is to be prepared. Use our list of causes and solutions for different thread tapping problems as a reference for successful. If your tool is breaking,. Tap Machine Problem.

From eureka-patsnap-com.libproxy.mit.edu

Bench tapping machine Eureka Patsnap develop intelligence library Tap Machine Problem Use our list of causes and solutions for different thread tapping problems as a reference for successful. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. It is prudent to create a troubleshooting guide to your draft system. — problems encountered in tapping are often the fault of the tapping machine, tap holding device. Tap Machine Problem.

From www.youtube.com

Tapping problem YouTube Tap Machine Problem Here are three factors to consider that will help. This document explains some of the most common causes for tap breakage. If your tool is breaking, cracking, or chipping, you need to administer. Use our list of causes and solutions for different thread tapping problems as a reference for successful. Insufficient tool life is one of the main issues encountered. Tap Machine Problem.

From armpremfg.com

How to Tap Effectively and Optimize Tool Life ARMPRO Tap Machine Problem By far, the most obvious sign of an issue is tap breakage. Insufficient tool life is one of the main issues encountered in tapping applications. — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. Use our list of causes and solutions for different thread tapping. Tap Machine Problem.

From hgrinc.com

Used Speedycut Tapping Machine HGR Industrial Surplus Tap Machine Problem The best way to tackle draft problems is to be prepared. Here are three factors to consider that will help. This document explains some of the most common causes for tap breakage. It is prudent to create a troubleshooting guide to your draft system. If your tool is breaking, cracking, or chipping, you need to administer. Use our list of. Tap Machine Problem.

From www.aliexpress.com

Cut Off The Tap Machine Broken Taps Remover Wire Edm Machine AliExpress Tap Machine Problem The best way to tackle draft problems is to be prepared. If your tool is breaking, cracking, or chipping, you need to administer. — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and. Tap Machine Problem.

From www.practicalmachinist.com

A Guide to Tapping and Threading Practical Machinist Practical Tap Machine Problem The best way to tackle draft problems is to be prepared. Use our list of causes and solutions for different thread tapping problems as a reference for successful. It is prudent to create a troubleshooting guide to your draft system. If your tool is breaking, cracking, or chipping, you need to administer. Here are three factors to consider that will. Tap Machine Problem.

From inmoldtapping.com

The most widely used tapping machine Tap Machine Problem — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. This document explains some of the most common causes for tap breakage. Use our list of causes and solutions for different thread tapping problems as a reference for successful. Use oversize taps for cutting materials such. Tap Machine Problem.

From www.youtube.com

How To Solve Tap Sign Problem While Washing In Automatic Front Load Tap Machine Problem The best way to tackle draft problems is to be prepared. Here are three factors to consider that will help. This document explains some of the most common causes for tap breakage. By far, the most obvious sign of an issue is tap breakage. If your tool is breaking, cracking, or chipping, you need to administer. It is prudent to. Tap Machine Problem.

From eureka.patsnap.com

Tapping machine Eureka Patsnap develop intelligence library Tap Machine Problem By far, the most obvious sign of an issue is tap breakage. The best way to tackle draft problems is to be prepared. This document explains some of the most common causes for tap breakage. Insufficient tool life is one of the main issues encountered in tapping applications. Use oversize taps for cutting materials such as copper alloy, aluminum alloy,. Tap Machine Problem.

From www.pinterest.com

GroovPin TapLok Hand Installation Tool for 1032 Threaded Inserts Tap Machine Problem Use our list of causes and solutions for different thread tapping problems as a reference for successful. It is prudent to create a troubleshooting guide to your draft system. If your tool is breaking, cracking, or chipping, you need to administer. This document explains some of the most common causes for tap breakage. By far, the most obvious sign of. Tap Machine Problem.

From eureka.patsnap.com

Tapping machine Eureka Patsnap develop intelligence library Tap Machine Problem The best way to tackle draft problems is to be prepared. Here are three factors to consider that will help. It is prudent to create a troubleshooting guide to your draft system. Use our list of causes and solutions for different thread tapping problems as a reference for successful. This document explains some of the most common causes for tap. Tap Machine Problem.

From benchmarkinstitute.org

tapping process Cheaper Than Retail Price> Buy Clothing, Accessories Tap Machine Problem The best way to tackle draft problems is to be prepared. Use our list of causes and solutions for different thread tapping problems as a reference for successful. This document explains some of the most common causes for tap breakage. By far, the most obvious sign of an issue is tap breakage. Insufficient tool life is one of the main. Tap Machine Problem.

From www.yi-chang.net

Tapping Machine Automatic HT2223 for Yi Chang Machinery Co., Ltd. Tap Machine Problem This document explains some of the most common causes for tap breakage. It is prudent to create a troubleshooting guide to your draft system. The best way to tackle draft problems is to be prepared. By far, the most obvious sign of an issue is tap breakage. — problems encountered in tapping are often the fault of the tapping machine,. Tap Machine Problem.

From eureka.patsnap.com

Tapping machine Eureka Patsnap develop intelligence library Tap Machine Problem — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. It is prudent to create a troubleshooting guide to your draft system. Here are three factors to consider that will help. The best way to tackle draft problems is to be prepared. Use our list of. Tap Machine Problem.

From www.youtube.com

Factors Controlling Machine Performance Pronic Tap Machine Jarvis Tap Machine Problem Insufficient tool life is one of the main issues encountered in tapping applications. By far, the most obvious sign of an issue is tap breakage. If your tool is breaking, cracking, or chipping, you need to administer. Here are three factors to consider that will help. The best way to tackle draft problems is to be prepared. It is prudent. Tap Machine Problem.

From eureka.patsnap.com

Fixing sealing device for tapping machine Eureka Patsnap develop Tap Machine Problem Use our list of causes and solutions for different thread tapping problems as a reference for successful. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. Insufficient tool life is one of the main issues encountered in tapping applications. This document explains some of the most common causes for tap breakage. If your tool. Tap Machine Problem.

From engtechnik.com

Tapping machine for cutting, reaming and tapping of metal materials Tap Machine Problem Here are three factors to consider that will help. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. This document explains some of the most common causes for tap breakage. If your tool is breaking, cracking, or chipping, you need to administer. Use our list of causes and solutions for different thread tapping problems. Tap Machine Problem.

From www.brokentapremover.com

Removing Broken Tap Tap Machine Problem The best way to tackle draft problems is to be prepared. Here are three factors to consider that will help. This document explains some of the most common causes for tap breakage. If your tool is breaking, cracking, or chipping, you need to administer. Insufficient tool life is one of the main issues encountered in tapping applications. — problems encountered. Tap Machine Problem.

From eureka.patsnap.com

Automatic floating tapping machine Eureka Patsnap develop Tap Machine Problem — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. This document explains some of the most common causes for tap breakage. The best way to tackle draft problems is to be prepared. Insufficient tool life is one of the main issues encountered in tapping applications.. Tap Machine Problem.

From www.tapmachine.com

Dual Bottle Tap Machine Tap Machine, Inc. Tap Machine Problem Use our list of causes and solutions for different thread tapping problems as a reference for successful. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. The best way to tackle draft problems is to be prepared. This document explains some of the most common causes for tap breakage. Insufficient tool life is one. Tap Machine Problem.

From eureka.patsnap.com

Tapping machine Eureka Patsnap develop intelligence library Tap Machine Problem Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. The best way to tackle draft problems is to be prepared. This document explains some of the most common causes for tap breakage. Insufficient tool life is one of the main issues encountered in tapping applications. By far, the most obvious sign of an issue. Tap Machine Problem.

From www.youtube.com

All Lathe Machine Operations Turning, Facing, Taper Turning, Boring Tap Machine Problem This document explains some of the most common causes for tap breakage. The best way to tackle draft problems is to be prepared. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. If your tool is breaking, cracking, or chipping, you need to administer. By far, the most obvious sign of an issue is. Tap Machine Problem.

From www.researchgate.net

(PDF) Intelligent Tapping Machine Tap Geometry Inspection Tap Machine Problem Use our list of causes and solutions for different thread tapping problems as a reference for successful. Insufficient tool life is one of the main issues encountered in tapping applications. It is prudent to create a troubleshooting guide to your draft system. Here are three factors to consider that will help. The best way to tackle draft problems is to. Tap Machine Problem.

From www.researchgate.net

(PDF) Intelligent Tapping Machine Tap Geometry Inspection Tap Machine Problem The best way to tackle draft problems is to be prepared. By far, the most obvious sign of an issue is tap breakage. If your tool is breaking, cracking, or chipping, you need to administer. Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. — problems encountered in tapping are often the fault of. Tap Machine Problem.

From www.instructables.com

Manual Thread Tapping Machine 8 Steps (with Pictures) Instructables Tap Machine Problem By far, the most obvious sign of an issue is tap breakage. The best way to tackle draft problems is to be prepared. This document explains some of the most common causes for tap breakage. Insufficient tool life is one of the main issues encountered in tapping applications. It is prudent to create a troubleshooting guide to your draft system.. Tap Machine Problem.

From www.youtube.com

Automatic Tapping Machine High Speed Tapping Machine That Can Change Tap Machine Problem Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. By far, the most obvious sign of an issue is tap breakage. If your tool is breaking, cracking, or chipping, you need to administer. This document explains some of the most common causes for tap breakage. Insufficient tool life is one of the main issues. Tap Machine Problem.

From www.protoolreviews.com

How to Use a Tap and Die to Create or Repair Threads Pro Tool Reviews Tap Machine Problem Use oversize taps for cutting materials such as copper alloy, aluminum alloy, and cast iron. By far, the most obvious sign of an issue is tap breakage. This document explains some of the most common causes for tap breakage. Here are three factors to consider that will help. The best way to tackle draft problems is to be prepared. If. Tap Machine Problem.

From krais.com

HETT Tube Tapping Machine for Retubing KRAIS Tube Expanders Tap Machine Problem Insufficient tool life is one of the main issues encountered in tapping applications. — problems encountered in tapping are often the fault of the tapping machine, tap holding device and conditions of the hole to be tapped. The best way to tackle draft problems is to be prepared. By far, the most obvious sign of an issue is tap breakage.. Tap Machine Problem.