What Is Moulding Process . The glass moulding process consists of four stages: The molten plastic then cools. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Heating, pressing, annealing, and cooling. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired.

from www.plasticmoulds.net

This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. The molten plastic then cools. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. The glass moulding process consists of four stages: Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Heating, pressing, annealing, and cooling. The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix.

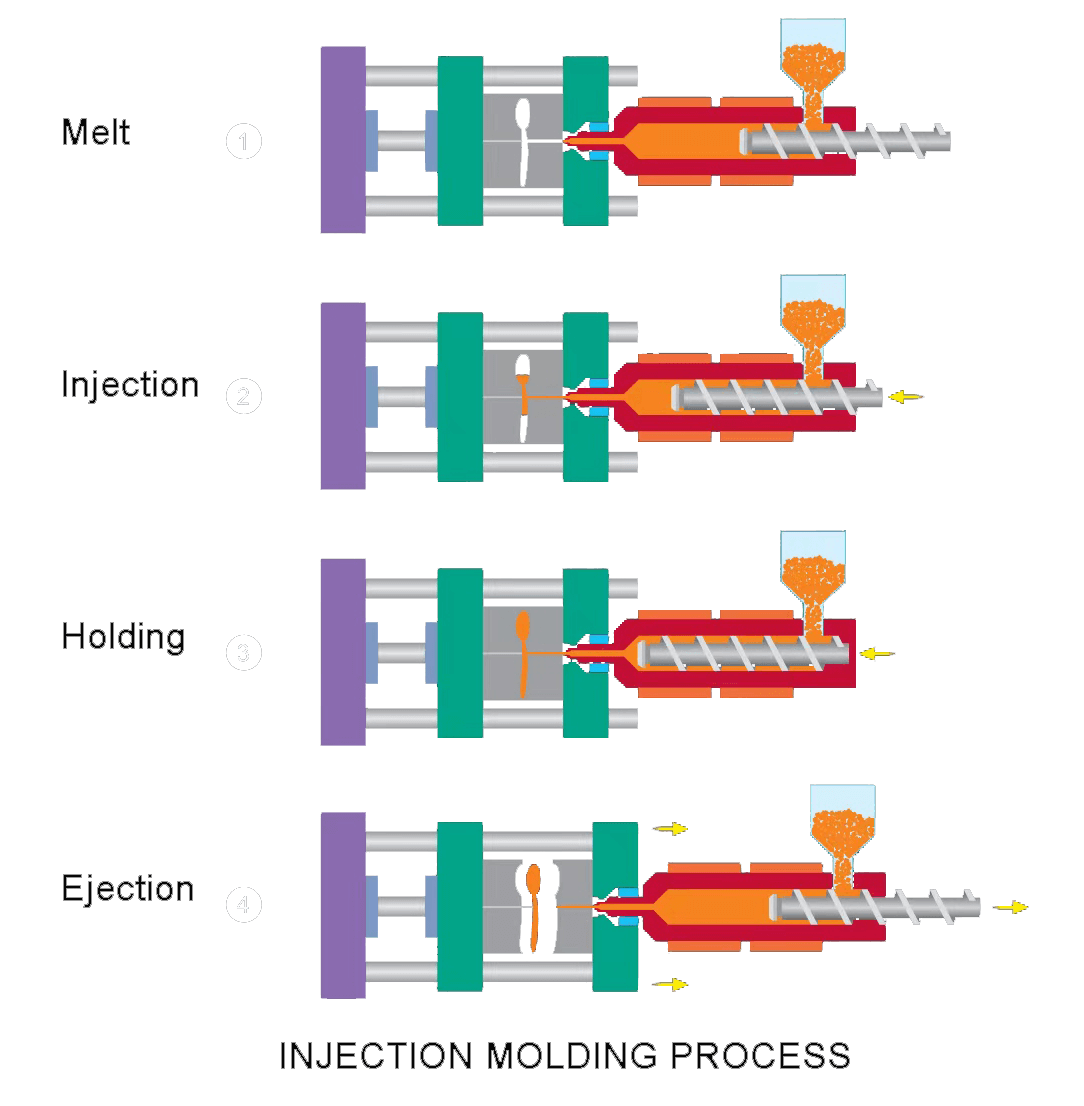

Injection Molding Process Topworks Plastic Molding

What Is Moulding Process A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. The glass moulding process consists of four stages: A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. The molten plastic then cools. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Heating, pressing, annealing, and cooling. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould.

From prototechasia.com

What is Plastic Injection Molding? Our Comprehensive Overview What Is Moulding Process Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into.. What Is Moulding Process.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog What Is Moulding Process The molten plastic then cools. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The glass moulding process consists of four stages: A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. Injection moulding (im) is a manufacturing process in which. What Is Moulding Process.

From www.researchgate.net

Major steps of the ceramic injectionmolding process combined with the What Is Moulding Process Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. This guide explores the types of plastic molding processes, compares their characteristics, and provides. What Is Moulding Process.

From qualiformrubbermolding.com

Rubber Transfer Molding Custom Rubber Transfer Molding Experts What Is Moulding Process A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. The molten plastic then cools. Heating, pressing, annealing, and cooling. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The glass moulding process consists of four stages: Moulding is a manufacturing. What Is Moulding Process.

From www.kaysun.com

Injection Molding Step by Step How Are Plastic Parts Made? What Is Moulding Process The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. The molten plastic then cools. This guide explores the types of plastic molding processes, compares their characteristics, and. What Is Moulding Process.

From www.3erp.com

What is Injection Molding and How Does it Work Definition & Working What Is Moulding Process The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or The glass moulding process consists of four stages: Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. The molten plastic then cools. A molding process. What Is Moulding Process.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained What Is Moulding Process A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Heating, pressing, annealing, and cooling. The glass moulding process consists of four stages: The molten plastic then cools. The raw material, typically. What Is Moulding Process.

From www.slideserve.com

PPT KEY BENEFITS OF THE STRUCTURAL FOAM INJECTION MOLDING PROCESS What Is Moulding Process Heating, pressing, annealing, and cooling. The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and. What Is Moulding Process.

From www.elastomer.kuraray.com

What is injection molding? Kuraray Elastomer What Is Moulding Process Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. The molten plastic then cools. Injection moulding (im) is a manufacturing process in which a polymer is heated to a. What Is Moulding Process.

From www.youtube.com

Shell Moulding Process Working Animation Manufacturing Processes What Is Moulding Process The molten plastic then cools. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. The glass moulding process consists. What Is Moulding Process.

From www.protolabs.com

Overmolding & Insert Molding Parts with Metal Inserts What Is Moulding Process A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. The glass moulding process consists of four stages: This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Injection moulding (im) is a manufacturing process in which a polymer is heated to. What Is Moulding Process.

From www.iqsdirectory.com

Overmolding What Is It? Types, Uses, Processes & Benefits What Is Moulding Process The glass moulding process consists of four stages: This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Heating, pressing, annealing, and cooling. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. Molding, often interchangeably used with ‘moulding’, is a manufacturing. What Is Moulding Process.

From plasticmoldingmanufacturers.com

Integrated Molding Solutions Inc. Plastic Molding Manufacturers What Is Moulding Process This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Heating, pressing, annealing, and cooling. The molten plastic then cools. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. Injection moulding (im) is a manufacturing process in which a. What Is Moulding Process.

From www.iqsdirectory.com

Rubber Overmolding Process, Uses, Considerations & Benefits What Is Moulding Process The molten plastic then cools. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. The glass moulding process consists of four stages: Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under. What Is Moulding Process.

From www.xcentricmold.com

Adding Injection Molding Features to Your Part Xcentric Mold What Is Moulding Process Heating, pressing, annealing, and cooling. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. A molding process uses pressure and heat to fill the cavity. What Is Moulding Process.

From www.weetect.com

Polycarbonate Injection Molding The Complete Guide Wee Tect What Is Moulding Process The glass moulding process consists of four stages: Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The molten plastic then cools. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Moulding is a manufacturing process that uses a mold, typically made of metal or sand,. What Is Moulding Process.

From www.researchgate.net

Schematic of the rotational molding process Download Scientific Diagram What Is Moulding Process A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. Heating, pressing, annealing, and cooling. The glass moulding process consists of four stages: Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure. What Is Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits What Is Moulding Process The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Moulding is a manufacturing process that uses a mold, typically made of. What Is Moulding Process.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn What Is Moulding Process Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Heating, pressing, annealing, and cooling. Moulding is a manufacturing process that uses a mold, typically made. What Is Moulding Process.

From mungfali.com

Injection Molding Process What Is Moulding Process Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. Heating, pressing, annealing, and cooling. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. This guide explores. What Is Moulding Process.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube What Is Moulding Process Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure. What Is Moulding Process.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process What Is Moulding Process The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or Heating, pressing, annealing, and cooling. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Moulding is a manufacturing process that uses. What Is Moulding Process.

From www.youtube.com

Injection Moulding Process Explained Polymer Matrix Composites What Is Moulding Process The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or Heating, pressing, annealing, and cooling. The glass moulding process consists of four stages: The molten plastic then cools. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin. What Is Moulding Process.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation What Is Moulding Process The glass moulding process consists of four stages: Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Heating, pressing, annealing, and cooling. The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies. What Is Moulding Process.

From www.cavitymold.com

OVERMOLDING INJECTION MOLDING Plastic Injection Molding and Mold What Is Moulding Process This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. The molten plastic then cools. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The. What Is Moulding Process.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials What Is Moulding Process This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. The glass moulding process consists of four stages: Heating, pressing, annealing, and cooling. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. Moulding is a manufacturing process that uses a mold,. What Is Moulding Process.

From www.plasticmoulds.net

Injection Molding Process Topworks Plastic Molding What Is Moulding Process Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The glass moulding process consists of four stages: The molten plastic then cools. The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it solidifies or This guide explores the types of plastic molding processes, compares their. What Is Moulding Process.

From www.wundermold.com

3 Components of Injection Molding 🥇 Injection Molding Applications What Is Moulding Process Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. The glass moulding process consists of four stages: Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. Heating, pressing, annealing, and cooling. The molten plastic then cools. The raw. What Is Moulding Process.

From www.iqsdirectory.com

Rotational Molding What Is It? How Does It Work? Types Of What Is Moulding Process Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Molding, often interchangeably used with ‘moulding’, is a. What Is Moulding Process.

From www.ennomotive.com

Revolutionizing the Injection Molding Process What Is Moulding Process A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. The glass moulding process consists of four stages: Molding, often interchangeably used with ‘moulding’,. What Is Moulding Process.

From dpseals.com

Rubber Moulding Process Comparisons DP Seals What Is Moulding Process Heating, pressing, annealing, and cooling. The molten plastic then cools. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. The glass moulding process consists of four stages: The raw material, typically a pliable one like plastic, glass, or ceramic, is kept under pressure until it. What Is Moulding Process.

From www.mimsupplier.com

Metal Injection Molding MIM Supplier What Is Moulding Process Heating, pressing, annealing, and cooling. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. The raw material, typically a pliable one like plastic, glass, or. What Is Moulding Process.

From www.youtube.com

Blow Moulding YouTube What Is Moulding Process The molten plastic then cools. Moulding is a manufacturing process that uses a mold, typically made of metal or sand, to shape materials like metal or resin into desired. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix. Molding, often interchangeably used with ‘moulding’, is a manufacturing. What Is Moulding Process.

From www.plasticmoulds.net

Various Plastic Molding Process What Is Moulding Process Heating, pressing, annealing, and cooling. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of. What Is Moulding Process.

From www.mecholic.com

Shell moulding process What Is Moulding Process Heating, pressing, annealing, and cooling. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. The molten plastic then cools. Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also. What Is Moulding Process.