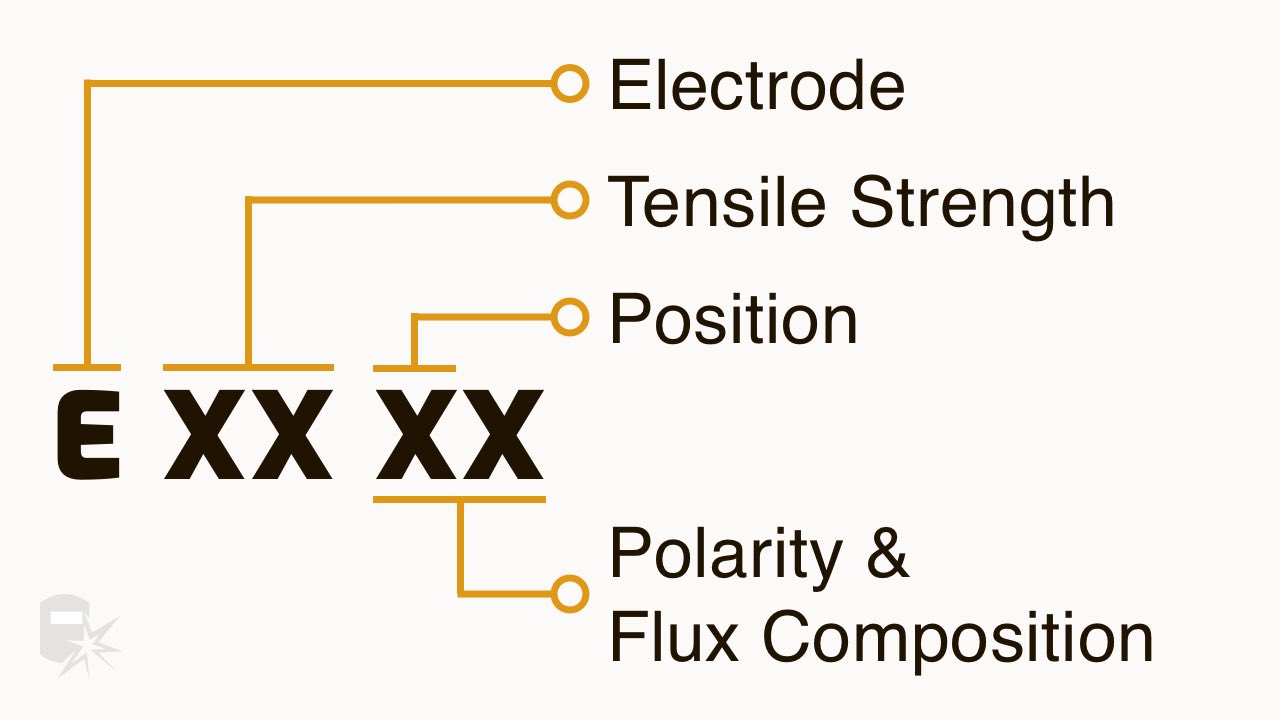

E7018 Electrode Vs E6013 . Including pros and cons of each electrode, including positions, penetration etc. 7018 electrodes both electrodes have different tensile strength; E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. e 6010 vs. e6013 has a rutile flux, while e7018 is a low hydrogen rod. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi.

from weldguru.com

E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi. E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. e6013 has a rutile flux, while e7018 is a low hydrogen rod. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. e 6010 vs. Including pros and cons of each electrode, including positions, penetration etc. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. 7018 electrodes both electrodes have different tensile strength;

Welding Rods Compared 6010, 6011, 6013, 7018 & 7024

E7018 Electrode Vs E6013 e 6010 vs. e 6010 vs. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. e6013 has a rutile flux, while e7018 is a low hydrogen rod. Including pros and cons of each electrode, including positions, penetration etc. 7018 electrodes both electrodes have different tensile strength; the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi.

From www.youtube.com

Not everyone knows the difference between electrodes E7018, E6013 and E7018 Electrode Vs E6013 e6013 has a rutile flux, while e7018 is a low hydrogen rod. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. comparison of 6010,. E7018 Electrode Vs E6013.

From www.studocu.com

Comparison and uses of electrodes Welding Rods Compared 6010, 6011 E7018 Electrode Vs E6013 e 6010 vs. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. 7018 electrodes both electrodes have different tensile strength; while both the wires. E7018 Electrode Vs E6013.

From www.hobartbrothers.com

Basics of AWS Filler Metal and Electrode Classification Hobart Brothers E7018 Electrode Vs E6013 e6013 has a rutile flux, while e7018 is a low hydrogen rod. the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. 7018 electrodes both electrodes have different tensile strength; E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new. E7018 Electrode Vs E6013.

From www.youtube.com

3 Stick Welding Electrodes Compared 6013 vs 7018 vs 6010 YouTube E7018 Electrode Vs E6013 E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. e6013 has a rutile flux, while e7018 is a low hydrogen rod. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating. E7018 Electrode Vs E6013.

From iosyyds.net

Welding electrodes Understanding the SMAW electrode symbols Welding NDT E7018 Electrode Vs E6013 E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. 7018 electrodes both electrodes have different tensile strength; the 6013 electrode is best used. E7018 Electrode Vs E6013.

From www.youtube.com

7018 vs 6013 / Which rod should I use for my projects? YouTube E7018 Electrode Vs E6013 E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. e6013 has a rutile flux, while e7018 is a low hydrogen rod. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. e. E7018 Electrode Vs E6013.

From www.youtube.com

Diferença entre eletrodos E6013 e E7018 YouTube E7018 Electrode Vs E6013 E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi. e 6010 vs. the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. Including pros and cons of each electrode, including positions, penetration etc. 7018 electrodes both electrodes have different tensile strength; comparison of. E7018 Electrode Vs E6013.

From www.vrogue.co

Will Identify Standards And Numbers On Welding Electr vrogue.co E7018 Electrode Vs E6013 E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. e6013 has a rutile flux, while e7018 is a low hydrogen rod. while both the wires are mild steel based, the coating on both. E7018 Electrode Vs E6013.

From www.youtube.com

Beginner welder's Must know The difference between E7018 and E6013 E7018 Electrode Vs E6013 comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. e 6010 vs. 7018 electrodes both electrodes have different tensile strength; The e6013 is used almost exclusively for thin sheets,. E7018 Electrode Vs E6013.

From weldguru.com

Welding Rods Compared 6010, 6011, 6013, 7018 & 7024 E7018 Electrode Vs E6013 e6013 has a rutile flux, while e7018 is a low hydrogen rod. 7018 electrodes both electrodes have different tensile strength; comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. while both. E7018 Electrode Vs E6013.

From www.pinterest.com.mx

mild steel electrodes chart Maurice Welding projects, Welding table E7018 Electrode Vs E6013 the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. E 6010 has a tensile strength value of 60,000 psi, while e 7018 of. E7018 Electrode Vs E6013.

From giojypsqd.blob.core.windows.net

Best Stick Electrode For Thin Metal at Derrick Espitia blog E7018 Electrode Vs E6013 while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. Including pros and cons of each electrode, including positions, penetration etc. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. 7018 electrodes both electrodes have different tensile strength; e. E7018 Electrode Vs E6013.

From exowkrlgh.blob.core.windows.net

Electrode E7018 Used at Aretha Mair blog E7018 Electrode Vs E6013 The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. e6013 has a rutile flux, while. E7018 Electrode Vs E6013.

From www.youtube.com

Electrode welding E6013 vs E7016 vs E7018 that you should know YouTube E7018 Electrode Vs E6013 Including pros and cons of each electrode, including positions, penetration etc. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. 7018 electrodes both electrodes have different. E7018 Electrode Vs E6013.

From shopee.ph

FUJIWELD Welding Rod E6011 / E6012 / E6013 / E7018 (PER KILO) Shopee E7018 Electrode Vs E6013 e 6010 vs. E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. Including pros and cons of each electrode, including positions, penetration etc. 7018 electrodes both electrodes have different tensile strength; e6013 has a rutile flux, while e7018 is a low hydrogen rod. . E7018 Electrode Vs E6013.

From sea.itwwelding.com

ITW Welding Singapore Carbon Steel Stick Electrode Basics E7018 Electrode Vs E6013 Including pros and cons of each electrode, including positions, penetration etc. E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. 7018 electrodes both electrodes have different tensile strength; E 6010 has a tensile strength value. E7018 Electrode Vs E6013.

From www.hobartbrothers.com

Basics of AWS Filler Metal and Electrode Classification Hobart Brothers E7018 Electrode Vs E6013 The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. e 6010 vs. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. Including pros and. E7018 Electrode Vs E6013.

From weldguru.com

Welding Rods Compared 6010, 6011, 6013, 7018 & 7024 E7018 Electrode Vs E6013 The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. e6013 has a rutile flux, while. E7018 Electrode Vs E6013.

From www.weldingandndt.com

Welding electrodes Understanding the SMAW electrode symbols welding E7018 Electrode Vs E6013 E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. the 6013 electrode is best used for light. E7018 Electrode Vs E6013.

From dxonuyvqw.blob.core.windows.net

Stick Welding Amperage Chart Pdf at Jacquelyn Johson blog E7018 Electrode Vs E6013 e 6010 vs. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. 7018 electrodes both electrodes have different tensile strength; Including pros and cons of each electrode, including positions, penetration etc. the 7018 rod is a medium penetration electrode and has better. E7018 Electrode Vs E6013.

From beginnerweldingguide.com

6013 vs 7018 Welding Rod Comparison Beginner Welding Guide E7018 Electrode Vs E6013 the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. e 6010 vs. 7018 electrodes both electrodes have different tensile strength; the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. The. E7018 Electrode Vs E6013.

From www.youtube.com

CWI Course Module 8 Difference between E7018 and E6010 YouTube E7018 Electrode Vs E6013 E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi. e 6010 vs. the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. E 6010 electrode can. E7018 Electrode Vs E6013.

From www.youtube.com

Welding Tips_ Electrode Classifications E7018,6010,7024 ..etc YouTube E7018 Electrode Vs E6013 comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. 7018 electrodes both electrodes have different tensile strength; the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium. E7018 Electrode Vs E6013.

From mundakawg.com

E7018 General Purpose/Mild Steel Electrode Mundaka Technologies E7018 Electrode Vs E6013 The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. Including pros and cons of each electrode, including positions, penetration etc. comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. the 6013 electrode is best used for light to medium penetration on. E7018 Electrode Vs E6013.

From giojypsqd.blob.core.windows.net

Best Stick Electrode For Thin Metal at Derrick Espitia blog E7018 Electrode Vs E6013 Including pros and cons of each electrode, including positions, penetration etc. e 6010 vs. the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. 7018 electrodes both electrodes have different tensile strength; The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range. E7018 Electrode Vs E6013.

From weldguru.com

Welding Rods Compared 6010, 6011, 6013, 7018 & 7024 E7018 Electrode Vs E6013 the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. E 6010 has a tensile strength value of 60,000 psi, while e 7018 of 70,000 psi. E 6010 electrode can be used on painted,. E7018 Electrode Vs E6013.

From dxoshvpvw.blob.core.windows.net

Best Arc Welding Rod 2.5 Mm at Gerard Tandy blog E7018 Electrode Vs E6013 Including pros and cons of each electrode, including positions, penetration etc. the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. The e6013 is used almost exclusively for thin sheets, while the e7018 can. E7018 Electrode Vs E6013.

From tianyu.en.made-in-china.com

E6013/6011/7018 Welding Rods 2.0mm/2.5mm/3.2mm/4.0mm Carbon Steel E7018 Electrode Vs E6013 Including pros and cons of each electrode, including positions, penetration etc. the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. comparison of 6010, 6011, 6013,. E7018 Electrode Vs E6013.

From workshopinsider.com

A Guide to 6010, 6011, 6013, and 7018 Welding Rods Insider E7018 Electrode Vs E6013 Including pros and cons of each electrode, including positions, penetration etc. The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. 7018 electrodes both electrodes have different tensile strength; E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is. E7018 Electrode Vs E6013.

From www.abatix.com

Premium E7018 Welding Electrodes, 1/8" x 14", 10 lb E7018 Electrode Vs E6013 7018 electrodes both electrodes have different tensile strength; the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. the 7018 rod is a. E7018 Electrode Vs E6013.

From canadaweldingsupply.ca

Électrodes couvertes en acier doux Canada Welding Supply Inc. E7018 Electrode Vs E6013 7018 electrodes both electrodes have different tensile strength; E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. Including pros and cons of each electrode, including positions, penetration etc.. E7018 Electrode Vs E6013.

From bakersgas.com

Electrode Amperage Chart Baker's Gas & Welding Supplies, Inc. E7018 Electrode Vs E6013 the 6013 electrode is best used for light to medium penetration on thin or sheet metal pieces. E 6010 electrode can be used on painted, galvanized, and unclean surfaces, while e 7018 is used on clean or new sheet metal. Including pros and cons of each electrode, including positions, penetration etc. e 6010 vs. the 7018 rod. E7018 Electrode Vs E6013.

From www.alibaba.com

Esab 2.5mm 3.2mm 4mm Welding Electrode E6013 E7016 E7018 Buy Esab 4mm E7018 Electrode Vs E6013 comparison of 6010, 6011, 6013, 7018 and 7024 welding rods. the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. Including pros and cons of each electrode, including positions, penetration etc. while both the wires are mild steel based, the coating on both are very different, the 7018 has a. E7018 Electrode Vs E6013.

From www.weldingandndt.com

Welding electrodes Understanding the SMAW electrode symbols Welding E7018 Electrode Vs E6013 The e6013 is used almost exclusively for thin sheets, while the e7018 can handle thicker workpieces, a wider range of materials, and has better strength. e6013 has a rutile flux, while e7018 is a low hydrogen rod. while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen. E7018 Electrode Vs E6013.

From www.youtube.com

RANGO DE AMPERAJE PARA ELECTRODOS 6011 6013 7018 308L E7018 Electrode Vs E6013 while both the wires are mild steel based, the coating on both are very different, the 7018 has a low hydrogen potassium coating whereas the coating on. 7018 electrodes both electrodes have different tensile strength; the 7018 rod is a medium penetration electrode and has better impact properties at temperatures below zero. the 6013 electrode is best. E7018 Electrode Vs E6013.