Turbine Housing Temperature . The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature.

from www.cambridge.org

This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. A simulation method and experimental verification are required to predict the life of a turbine housing in the early design.

Performance analysis of an aero engine with interstage turbine burner

Turbine Housing Temperature A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron.

From www.garrettmotion.com

Turbo Tech Turbine Housings 101 Garrett Motion Turbine Housing Temperature The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. The size and shape of the turbocharger housing can have a significant. Turbine Housing Temperature.

From www.niitsu-turbo.com

Niitsu Hit© Turbine Housing Niitsu Turbo Industries Turbine Housing Temperature Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. A simulation method and experimental verification are required to predict the. Turbine Housing Temperature.

From www.cambridge.org

Performance analysis of an aero engine with interstage turbine burner Turbine Housing Temperature The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising. Turbine Housing Temperature.

From www.researchgate.net

Effect of ambient temperature on gas turbine performance. Source Turbine Housing Temperature A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. Turbine housings are also referred. Turbine Housing Temperature.

From www.researchgate.net

Gas turbine showing the different zones with temperature and pressure Turbine Housing Temperature This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. A simulation method and experimental verification are required to predict the life of a. Turbine Housing Temperature.

From www.processinnovations.io

Combustion Gas Turbine Exhaust Temperature Profile Process Innovations Turbine Housing Temperature Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. A simulation method and experimental verification are required to predict the. Turbine Housing Temperature.

From www.researchgate.net

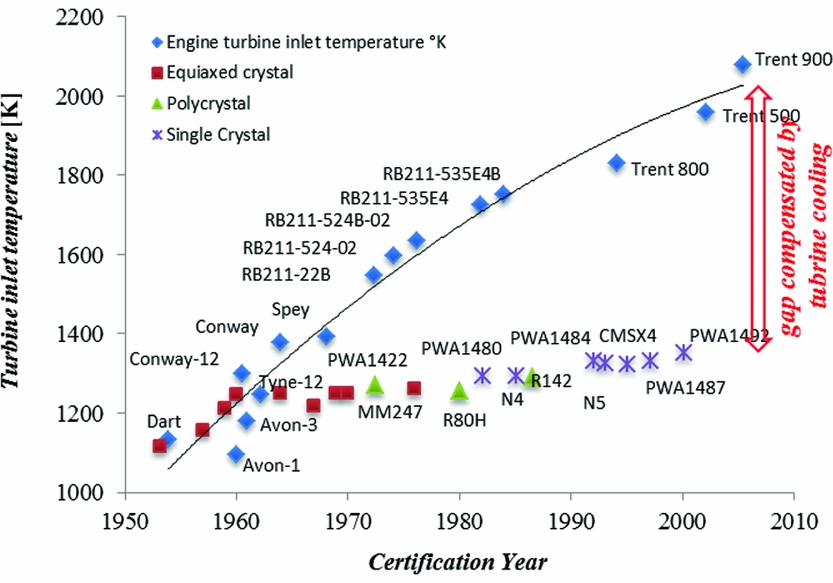

Evolution of turbine inlet temperature and metal operating temperature Turbine Housing Temperature Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. A simulation method and experimental verification are required to predict the life of a turbine housing in. Turbine Housing Temperature.

From www.researchgate.net

Effect of the turbine inlet temperature on the thermal efficiency of Turbine Housing Temperature The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. The heat transfer within the turbocharger changes the temperatures at the. Turbine Housing Temperature.

From turbolabofamerica.com

Choosing turbine housings Turbo Lab Turbine Housing Temperature This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. A simulation method and experimental verification are required to predict the life of a turbine. Turbine Housing Temperature.

From www.grc.nasa.gov

Engine Temperature Variation ETR Turbine Housing Temperature The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. A simulation method and experimental verification are required to predict the life. Turbine Housing Temperature.

From cfd2012.com

ANSYSCFX Gas Turbine Combustor Computational Fluid Dynamics is the Turbine Housing Temperature This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. Because. Turbine Housing Temperature.

From turbotechnics.com

What Is A Turbine Housing? Turbo Technics Turbine Housing Temperature The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. This means that the heat in the head, exhaust manifold, and turbine housing inds it. Turbine Housing Temperature.

From www.researchgate.net

Energy transfer in the turbine housing Download Scientific Diagram Turbine Housing Temperature Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. This means that. Turbine Housing Temperature.

From www.mdaturbines.com

Gas Turbine Exhaust Temperature Spreads MD&A Turbines Turbine Housing Temperature A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be. Turbine Housing Temperature.

From www.grc.nasa.gov

Power Turbine Thermodynamics Turbine Housing Temperature Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust. Turbine Housing Temperature.

From journals.sagepub.com

Design of a gate system and riser optimization for turbine housing and Turbine Housing Temperature Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. A simulation method and experimental verification are required to predict the life of a turbine. Turbine Housing Temperature.

From www.crazycarlsturbos.com

Turbine Housing 1.15 Turbine Housing Temperature The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. Turbine housings are also referred to as the “hot side” of the turbo because of its. Turbine Housing Temperature.

From chemengineerkey.com

1 Overview of Gas Turbines for Propulsion and Power Generation Turbine Housing Temperature The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. Because they have. Turbine Housing Temperature.

From www.researchgate.net

TURBINE INLET TEMPERATURE. Download Scientific Diagram Turbine Housing Temperature Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. The size and shape of the turbocharger housing can have a. Turbine Housing Temperature.

From momentumworx.com

Turbine Housing Explained Which A/R works best? Momentum Worx Turbine Housing Temperature This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. A simulation method and experimental verification are required to predict the life of a. Turbine Housing Temperature.

From www.benteler.com

Thermal & Tubular BENTELER International AG Turbine Housing Temperature Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have. Turbine Housing Temperature.

From catalysts.basf.com

Temperature Sensors for Gas Turbines BASF Catalysts Turbine Housing Temperature The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels. Turbine Housing Temperature.

From www.mdpi.com

Clean Technol. Free FullText Thermal Investigation of a Turbine Housing Temperature Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. The compressor. Turbine Housing Temperature.

From www.mdpi.com

Clean Technol. Free FullText Thermal Investigation of a Turbine Housing Temperature The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. The size and shape of the turbocharger housing can have a significant impact on the. Turbine Housing Temperature.

From store.kinugawaturbosystems.com

Which Turbine Housing A/R Works Best? Kinugawa Turbo Systems Turbine Housing Temperature The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. The compressor housing can be. Turbine Housing Temperature.

From arashidynamics.com

How to choose the right sized turbine housing? Arashi Dynamics Turbine Housing Temperature The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be. Turbine Housing Temperature.

From savree.com

Steam Turbine Siemens SST5000 Explained saVRee Turbine Housing Temperature A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. Because they have to withstand. Turbine Housing Temperature.

From www.ikts.fraunhofer.de

Hightemperature pressure sensors for use in turbines and engines Turbine Housing Temperature The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. A simulation method and experimental verification are required to predict the life of a turbine housing in the early. Turbine Housing Temperature.

From www.garrettmotion.com

Turbo Tech Turbine Housings 101 Garrett Motion Turbine Housing Temperature The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. The size and shape of the turbocharger housing can have a significant impact on the. Turbine Housing Temperature.

From www.researchgate.net

Effect of the turbine inlet temperature on the exhaust temperature of Turbine Housing Temperature A simulation method and experimental verification are required to predict the life of a turbine housing in the early design. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. The heat. Turbine Housing Temperature.

From www.researchgate.net

Thermal images of turbine housing for three radiation coefficients for Turbine Housing Temperature The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. The size and shape of the turbocharger housing can have a significant impact on the turbocharger’s performance. Turbine housings are also referred to as the “hot side” of the turbo because of its. Turbine Housing Temperature.

From www.garrettmotion.com

Turbo Tech Turbine Housings 101 Garrett Motion Turbine Housing Temperature Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. The compressor housing can be made from aluminium since has to withstand lower temperature,. Turbine Housing Temperature.

From www.coursehero.com

[Solved] Thermodynamics 1. Air enters a gas turbine with two stages of Turbine Housing Temperature This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of. The size and shape of the turbocharger housing can have a significant impact on the. Turbine Housing Temperature.

From www.researchgate.net

2 Specific core power with turbine rotor inlet temperature Turbine Housing Temperature This means that the heat in the head, exhaust manifold, and turbine housing inds it way to the turbo’s center housing, raising its temperature. The heat transfer within the turbocharger changes the temperatures at the inlet and outlet of compressor and turbine. A simulation method and experimental verification are required to predict the life of a turbine housing in the. Turbine Housing Temperature.

From www.afrinhewitt.com

Gas turbine fundamentals Turbine Housing Temperature The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. A simulation method and experimental verification are required to predict the. Turbine Housing Temperature.