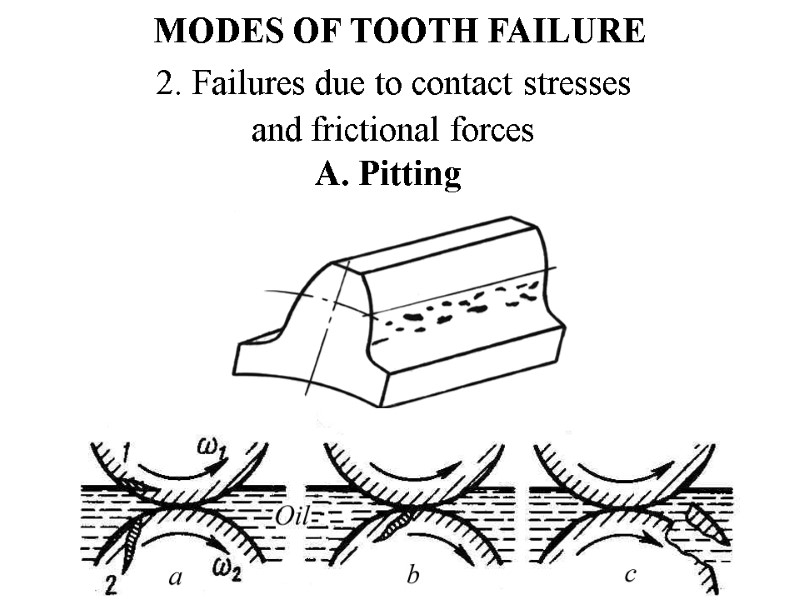

Spur Gear Tooth Damage . In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. This figure is an exaggerated representation of the slight curvature machined. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. The following introduces causes of breakage and. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. Tooth damage and chipping problem: The procedure takes into account the pitting. All eaton® fuller® transmission mainshaft gearing is “crowned”. This creates inaccurate gear and.

from present5.com

This creates inaccurate gear and. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. The procedure takes into account the pitting. This figure is an exaggerated representation of the slight curvature machined. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. The following introduces causes of breakage and. All eaton® fuller® transmission mainshaft gearing is “crowned”.

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH FORCES

Spur Gear Tooth Damage Tooth damage and chipping problem: In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. Tooth damage and chipping problem: The following introduces causes of breakage and. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. The procedure takes into account the pitting. All eaton® fuller® transmission mainshaft gearing is “crowned”. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. This figure is an exaggerated representation of the slight curvature machined. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. This creates inaccurate gear and.

From www.researchgate.net

(PDF) Detection Method of Spur Gear Tooth Root Crack Damage Degree Spur Gear Tooth Damage This figure is an exaggerated representation of the slight curvature machined. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. Tooth damage and chipping problem: In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. The procedure takes into account the pitting.. Spur Gear Tooth Damage.

From www.youtube.com

Spur Gear Tooth Profile Drawing Problem Spur gear design YouTube Spur Gear Tooth Damage The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. Tooth damage and chipping problem: All eaton® fuller® transmission mainshaft gearing is “crowned”. The following introduces causes of breakage and. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. As gear tooth profiles wear down. Spur Gear Tooth Damage.

From www.eco-torque.co.uk

F17 GEARBOX A Guide To Faults & Fixes Spur Gear Tooth Damage Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. Tooth damage and chipping problem: The procedure takes into account the pitting. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. As gear tooth profiles wear down the clearance between meshing teeth. Spur Gear Tooth Damage.

From www.researchgate.net

The four fault types of gear a chipped tooth, b tooth root crack, c Spur Gear Tooth Damage In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. The following introduces causes of breakage and. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue.. Spur Gear Tooth Damage.

From www.researchgate.net

Photographs of spur gear a before modification i.e. unmodified, b after Spur Gear Tooth Damage Tooth damage and chipping problem: In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. All eaton®. Spur Gear Tooth Damage.

From www.dreamstime.com

Macro Shot of a Damaged Bevel Gear with Bevel Teeth, Isolated on a Spur Gear Tooth Damage All eaton® fuller® transmission mainshaft gearing is “crowned”. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. This creates inaccurate gear and. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. In this presentation, the procedure and formulas to estimate a value of gear life. Spur Gear Tooth Damage.

From www.extrica.com

Modal analysis of spur gears for varied teeth root cracks Spur Gear Tooth Damage The following introduces causes of breakage and. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. All eaton® fuller® transmission mainshaft gearing is “crowned”. This figure is an exaggerated representation of the slight curvature machined. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue.. Spur Gear Tooth Damage.

From www.youtube.com

Spur Gear Tooth by Tooth Induction Hardening Spur Gear Induction Heat Spur Gear Tooth Damage As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. This figure is an exaggerated representation of the slight curvature machined. Tooth damage and chipping problem: The following introduces causes of breakage and. The procedure takes into. Spur Gear Tooth Damage.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH FORCES Spur Gear Tooth Damage In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. The procedure takes into account the pitting. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. All eaton® fuller® transmission mainshaft gearing is “crowned”. This figure is an exaggerated representation of the. Spur Gear Tooth Damage.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Spur Gear Tooth Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears.. Spur Gear Tooth Damage.

From www.dreamstime.com

Broken Teeth on the Gear. Mechanical and Repair Concept Spur Gear Tooth Damage In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. This figure is an exaggerated representation of the slight curvature machined. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Spur gear teeth can become damaged. Spur Gear Tooth Damage.

From www.youtube.com

CONSTRUCTION OF SPUR GEAR TEETH PROFILE for gears of less than 30 Spur Gear Tooth Damage This figure is an exaggerated representation of the slight curvature machined. All eaton® fuller® transmission mainshaft gearing is “crowned”. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. The tooth breakage caused by. Spur Gear Tooth Damage.

From www.qsl.net

T2X rotator repair Spur Gear Tooth Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. This figure is an exaggerated representation of the slight curvature machined. The procedure takes into account the pitting. This creates inaccurate gear and. As gear tooth profiles wear down the clearance between meshing teeth or the backlash. Spur Gear Tooth Damage.

From www.arrmaforum.com

Damaged spur gear ARRMA RC Forum Spur Gear Tooth Damage All eaton® fuller® transmission mainshaft gearing is “crowned”. The following introduces causes of breakage and. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. As gear. Spur Gear Tooth Damage.

From www.youtube.com

Construction of teeth profile Problem Spur gear Drawing Involute Spur Gear Tooth Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Tooth damage and chipping problem: This figure is an exaggerated representation of the slight curvature machined. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. The tooth breakage caused by. Spur Gear Tooth Damage.

From www.semanticscholar.org

[PDF] Spur Gear Tooth Strain Semantic Scholar Spur Gear Tooth Damage This creates inaccurate gear and. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. The following introduces causes of breakage and. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. All eaton® fuller® transmission mainshaft gearing is “crowned”. In this paper, gear tooth pitting propagation. Spur Gear Tooth Damage.

From www.dreamstime.com

Macro Shot of a Damaged Bevel Gear with Bevel Teeth, Isolated on a Spur Gear Tooth Damage All eaton® fuller® transmission mainshaft gearing is “crowned”. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. Spur gear teeth can become damaged or chipped due. Spur Gear Tooth Damage.

From www.alamy.com

Macro shot of a two damaged bevel gears with beveled teeth, isolated on Spur Gear Tooth Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. The procedure takes into account the pitting. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. The following introduces causes of breakage and. In this paper, gear tooth pitting. Spur Gear Tooth Damage.

From www.youtube.com

BIG SPUR GEAR TEETH CUTTING YouTube Spur Gear Tooth Damage The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. This creates inaccurate gear and. The procedure takes into account the pitting. The following introduces causes of breakage and. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. As. Spur Gear Tooth Damage.

From www.researchgate.net

Spur gear teeth reconstruction via direct laser deposition Spur Gear Tooth Damage As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. Tooth damage and chipping problem: All eaton® fuller® transmission mainshaft gearing is “crowned”. The following introduces causes of breakage and. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. This creates inaccurate gear. Spur Gear Tooth Damage.

From www.youtube.com

Gear Tooth Failures (Modes of Gear Failure) YouTube Spur Gear Tooth Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. The procedure takes into account the pitting. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. This creates inaccurate gear and. This figure is an exaggerated. Spur Gear Tooth Damage.

From www.surescreenscientifics.com

Library of Failure Testing SureScreen Scientifics Spur Gear Tooth Damage This figure is an exaggerated representation of the slight curvature machined. The following introduces causes of breakage and. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. In this presentation, the procedure and formulas to estimate. Spur Gear Tooth Damage.

From www.mechanicdrive.com

Spur gear, module 2, number of teeth 13 Spur Gear Tooth Damage In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. This creates inaccurate gear and. The following introduces causes of breakage and. All eaton® fuller® transmission mainshaft gearing is “crowned”. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. As gear tooth. Spur Gear Tooth Damage.

From www.academia.edu

(PDF) Spur Gear Damage Analysis Using Variation of Speed Range Spur Gear Tooth Damage Tooth damage and chipping problem: As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. This figure. Spur Gear Tooth Damage.

From www.researchgate.net

Load distribution of spur gear tooth surface before and after parabolic Spur Gear Tooth Damage The following introduces causes of breakage and. Tooth damage and chipping problem: Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. This creates inaccurate gear and. All eaton® fuller® transmission mainshaft gearing is “crowned”. In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of. Spur Gear Tooth Damage.

From eureka.patsnap.com

Method for simulation analysis on meshing stiffness of cylindrical spur Spur Gear Tooth Damage This creates inaccurate gear and. This figure is an exaggerated representation of the slight curvature machined. All eaton® fuller® transmission mainshaft gearing is “crowned”. As gear tooth profiles wear down the clearance between meshing teeth or the backlash will increase. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. Tooth damage and. Spur Gear Tooth Damage.

From www.geartechnology.com

Tooth Flank Fracture Basic Principles and Calculation Model for a Sub Spur Gear Tooth Damage This figure is an exaggerated representation of the slight curvature machined. The following introduces causes of breakage and. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. The procedure. Spur Gear Tooth Damage.

From dokumen.tips

(PDF) Spur Gear Tooth Pitting Propagation Assessment Using Model Spur Gear Tooth Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. This figure is an exaggerated representation of the slight curvature machined. The procedure takes into account the pitting. The following. Spur Gear Tooth Damage.

From www.semanticscholar.org

[PDF] Diagnosis of Gear Tooth Surface Damage by Analyzing Vibration Spur Gear Tooth Damage All eaton® fuller® transmission mainshaft gearing is “crowned”. The procedure takes into account the pitting. Spur gear teeth can become damaged or chipped due to impact loads, foreign debris, or material fatigue. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. As gear tooth profiles wear. Spur Gear Tooth Damage.

From www.dreamstime.com

Macro Shot of a Damaged Bevel Gear with Bevel Teeth, Isolated on a Spur Gear Tooth Damage The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. This figure is an exaggerated representation of the slight curvature machined. Tooth damage and chipping problem: In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for a pair of spur gears. The procedure takes into account the pitting.. Spur Gear Tooth Damage.

From vtol.org

A VibroAcoustic Methodology for the Detection and Characterization of Spur Gear Tooth Damage The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Tooth damage and chipping problem: In this paper, gear tooth pitting propagation to neighboring teeth is modeled and investigated for. Spur Gear Tooth Damage.

From www.qsl.net

T2X rotator repair Spur Gear Tooth Damage Tooth damage and chipping problem: This figure is an exaggerated representation of the slight curvature machined. The following introduces causes of breakage and. This creates inaccurate gear and. All eaton® fuller® transmission mainshaft gearing is “crowned”. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears. The procedure takes into account the pitting.. Spur Gear Tooth Damage.

From www.machinerylubrication.com

How to Analyze Gear Failures Spur Gear Tooth Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. All eaton® fuller® transmission mainshaft gearing is “crowned”. The procedure takes into account the pitting. This figure is an exaggerated representation of the slight curvature machined. The tooth breakage caused by partial contact at the tooth end,. Spur Gear Tooth Damage.

From journals.sagepub.com

Experimental investigations of surface wear assessment of spur gear Spur Gear Tooth Damage Tooth damage and chipping problem: This figure is an exaggerated representation of the slight curvature machined. The procedure takes into account the pitting. The following introduces causes of breakage and. All eaton® fuller® transmission mainshaft gearing is “crowned”. This creates inaccurate gear and. The tooth breakage caused by partial contact at the tooth end, occurs on spur or bevel gears.. Spur Gear Tooth Damage.

From www.researchgate.net

(PDF) Experimental Study on Fatigue Fracture Damage of Symmetric Spur Spur Gear Tooth Damage This figure is an exaggerated representation of the slight curvature machined. All eaton® fuller® transmission mainshaft gearing is “crowned”. Tooth damage and chipping problem: In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. The following introduces causes of breakage and. Spur gear teeth can become damaged. Spur Gear Tooth Damage.