Mig Welding Gas Pressure Uk . It serves a dual purpose: I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. Your gauges should be reading between 0 and 2500 psi in. Most mig welding gas pressures are between 3 and 8 psi. Just got the machine converted yesterday but nowhere in the instructions do. I am totally new to mig gas welding. It may be better to invest in. However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. The higher the pressure, the hotter your weld will be. Open the main valve of the cylinder and make sure that there is some gas in it. Shielding the molten weld pool from.

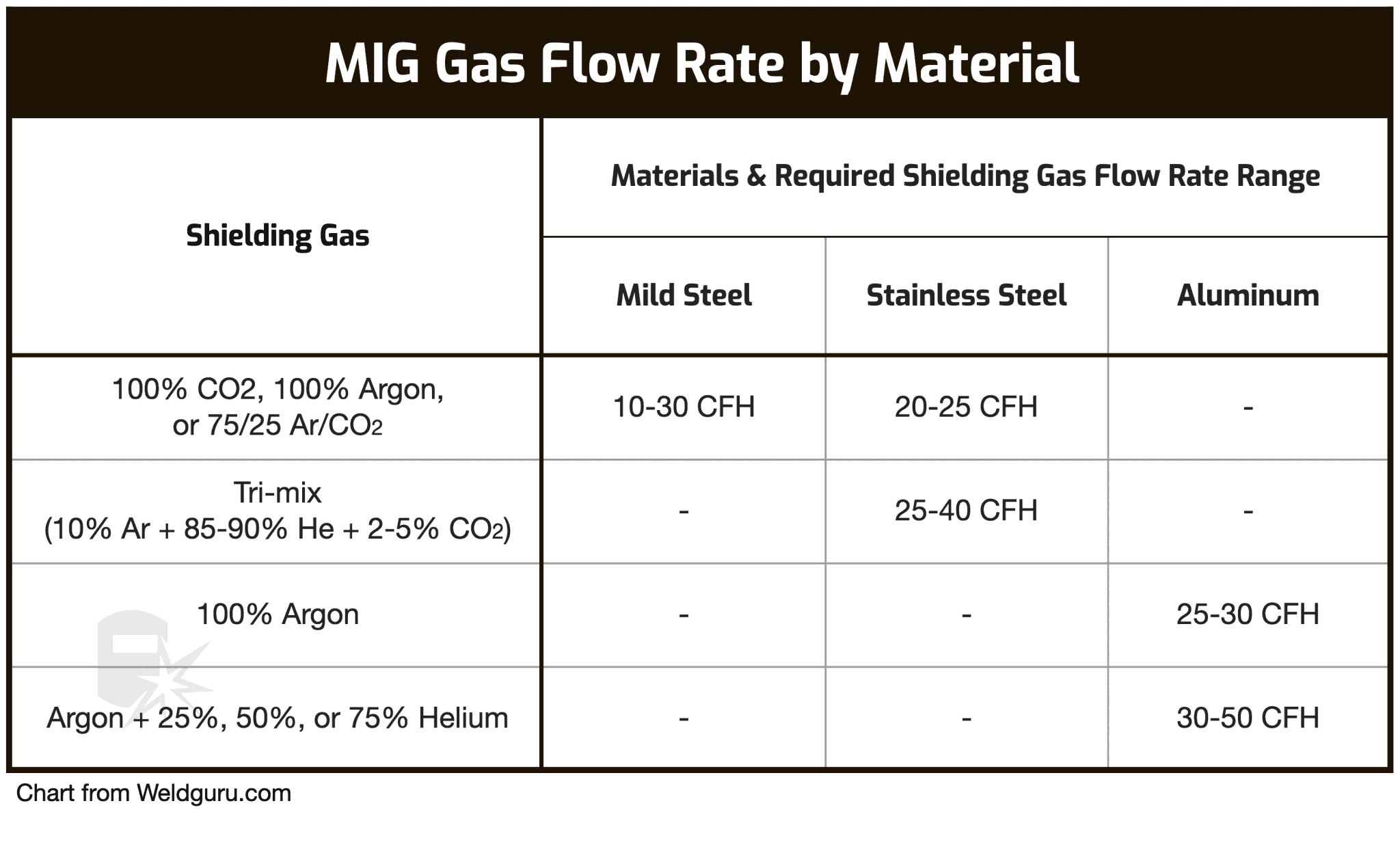

from weldguru.com

Open the main valve of the cylinder and make sure that there is some gas in it. Your gauges should be reading between 0 and 2500 psi in. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. It serves a dual purpose: I am totally new to mig gas welding. It may be better to invest in. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Most mig welding gas pressures are between 3 and 8 psi. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity.

MIG Welding Gas Pressure Settings (with Charts)

Mig Welding Gas Pressure Uk Open the main valve of the cylinder and make sure that there is some gas in it. It may be better to invest in. However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. The higher the pressure, the hotter your weld will be. Most mig welding gas pressures are between 3 and 8 psi. Just got the machine converted yesterday but nowhere in the instructions do. Open the main valve of the cylinder and make sure that there is some gas in it. It serves a dual purpose: Shielding the molten weld pool from. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. I am totally new to mig gas welding. Your gauges should be reading between 0 and 2500 psi in. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld.

From weldingwatch.com

MIG Welding Gas Pressure What You Need To Know WeldingWatch Mig Welding Gas Pressure Uk Your gauges should be reading between 0 and 2500 psi in. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Shielding the molten weld pool from. It serves a dual purpose: I am totally new to mig gas welding. Just got the machine converted yesterday but nowhere. Mig Welding Gas Pressure Uk.

From exolxbpbb.blob.core.windows.net

What Gas Pressure Should I Use For Mig Welding at John Cammarata blog Mig Welding Gas Pressure Uk I am totally new to mig gas welding. However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Open the main valve of the cylinder and make. Mig Welding Gas Pressure Uk.

From nationalweldsupplies.co.uk

SIP WELDMATE® AUTOPLUS 250A MIG/ARC/TIG Welder 05751 National welding Mig Welding Gas Pressure Uk I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Just got the machine converted yesterday but nowhere in the instructions do. It may be better to invest in. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. Most mig. Mig Welding Gas Pressure Uk.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER Mig Welding Gas Pressure Uk Shielding the molten weld pool from. Your gauges should be reading between 0 and 2500 psi in. It may be better to invest in. Just got the machine converted yesterday but nowhere in the instructions do. I am totally new to mig gas welding. Most mig welding gas pressures are between 3 and 8 psi. Between 5 to 10 lpm. Mig Welding Gas Pressure Uk.

From workshopinsider.com

How to Optimize MIG Welding Shielding Gas Pressure Mig Welding Gas Pressure Uk Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. The higher the pressure, the hotter your weld will be. Your gauges should be reading between 0 and 2500 psi in. Just got the machine converted yesterday but nowhere in the instructions do. However, if there’s too much. Mig Welding Gas Pressure Uk.

From nishikawa-ltd.com

aluminum mig welding settings chart Mig Welding Gas Pressure Uk However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. It serves a dual purpose: Shielding the molten weld pool from. I am totally new to mig gas welding. Open the main valve of the cylinder and make sure that there is some gas in it.. Mig Welding Gas Pressure Uk.

From www.ebay.co.uk

New Argon CO2 Mig Tig Pressure Reducer Gas Regulator Flow Meter Welding Mig Welding Gas Pressure Uk It serves a dual purpose: Just got the machine converted yesterday but nowhere in the instructions do. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. The higher. Mig Welding Gas Pressure Uk.

From exolxbpbb.blob.core.windows.net

What Gas Pressure Should I Use For Mig Welding at John Cammarata blog Mig Welding Gas Pressure Uk Just got the machine converted yesterday but nowhere in the instructions do. Shielding the molten weld pool from. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Open the main valve of the cylinder and make sure that there is some gas in it. However, if there’s. Mig Welding Gas Pressure Uk.

From hxelrxwol.blob.core.windows.net

Mig Welding Gas Cost at Virgilio Smith blog Mig Welding Gas Pressure Uk Open the main valve of the cylinder and make sure that there is some gas in it. Just got the machine converted yesterday but nowhere in the instructions do. It may be better to invest in. Most mig welding gas pressures are between 3 and 8 psi. However, if there’s too much gas pressure at the weld, you can draw. Mig Welding Gas Pressure Uk.

From giomhnfsr.blob.core.windows.net

Argon Regulator Setting For Mig Welding at Cristina Wilt blog Mig Welding Gas Pressure Uk It serves a dual purpose: I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Your gauges should be reading between 0 and 2500 psi in. Most mig welding gas pressures are between 3 and 8 psi. Just got the machine converted yesterday but nowhere in the instructions do. However, if. Mig Welding Gas Pressure Uk.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Mig Welding Gas Pressure Uk It serves a dual purpose: I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Most mig welding gas pressures are between 3 and 8 psi. Shielding the molten. Mig Welding Gas Pressure Uk.

From www.ebay.co.uk

New Argon CO2 Mig Tig Pressure Reducer Gas Regulator Flow Meter Welding Mig Welding Gas Pressure Uk It serves a dual purpose: I am totally new to mig gas welding. Open the main valve of the cylinder and make sure that there is some gas in it. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. It may be better to invest in. Your gauges should. Mig Welding Gas Pressure Uk.

From migweldingexpert.com

How to Set Gas the Flow on a MIG Welder? Mig Welding Expert Mig Welding Gas Pressure Uk The higher the pressure, the hotter your weld will be. It serves a dual purpose: I am totally new to mig gas welding. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. It may be better to invest in. Between 5 to 10 lpm gas flow, but be aware. Mig Welding Gas Pressure Uk.

From bceweb.org

Welding Gases Chart A Visual Reference of Charts Chart Master Mig Welding Gas Pressure Uk I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. I am totally new to mig gas welding. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Gas pressure plays a pivotal role in mig welding as it. Mig Welding Gas Pressure Uk.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire Mig Welding Gas Pressure Uk I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. The higher the pressure, the hotter your weld will be. Just got the machine converted yesterday but nowhere in the instructions do. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your. Mig Welding Gas Pressure Uk.

From beststudwelders.com

MIG Welding Gas Pressure Settings Complete Guide best stud welders Mig Welding Gas Pressure Uk Shielding the molten weld pool from. Open the main valve of the cylinder and make sure that there is some gas in it. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Most mig welding gas pressures are between 3 and 8 psi. However, if there’s too. Mig Welding Gas Pressure Uk.

From gioaefebi.blob.core.windows.net

Mig Welding Gas Regulator Settings at Margaret Santiago blog Mig Welding Gas Pressure Uk Just got the machine converted yesterday but nowhere in the instructions do. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Open the main valve of the cylinder and make sure that there is some gas in it. The higher the pressure, the hotter your weld will. Mig Welding Gas Pressure Uk.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Mig Welding Gas Pressure Uk However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. I am totally new to mig gas welding. Open the main valve of the cylinder and make sure that there is some gas in it. Just got the machine converted yesterday but nowhere in the instructions. Mig Welding Gas Pressure Uk.

From nationalweldsupplies.co.uk

SIP WELDMATE® AUTOPLUS 250A MIG/ARC/TIG Welder 05751 National welding Mig Welding Gas Pressure Uk Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. The higher the pressure, the hotter your weld will be. It may be better to invest in. Just got the machine converted yesterday but nowhere in the instructions do. However, if there’s too much gas pressure at the weld, you. Mig Welding Gas Pressure Uk.

From nationalweldsupplies.co.uk

SIP WELDMATE® AUTOPLUS 250A MIG/ARC/TIG Welder 05751 National welding Mig Welding Gas Pressure Uk Open the main valve of the cylinder and make sure that there is some gas in it. Shielding the molten weld pool from. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type,. Mig Welding Gas Pressure Uk.

From nationalweldsupplies.co.uk

SIP WELDMATE® AUTOPLUS 250A MIG/ARC/TIG Welder 05751 National welding Mig Welding Gas Pressure Uk Just got the machine converted yesterday but nowhere in the instructions do. Shielding the molten weld pool from. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. However, if there’s. Mig Welding Gas Pressure Uk.

From mavink.com

Mig Welding Gas Flow Chart Mig Welding Gas Pressure Uk The higher the pressure, the hotter your weld will be. Just got the machine converted yesterday but nowhere in the instructions do. It may be better to invest in. Shielding the molten weld pool from. Your gauges should be reading between 0 and 2500 psi in. Between 5 to 10 lpm gas flow, but be aware that the dial type. Mig Welding Gas Pressure Uk.

From allaboutweldingjobs.com

MIG Welding Gas Pressure Best Helpful Guide & Review Mig Welding Gas Pressure Uk The higher the pressure, the hotter your weld will be. I am totally new to mig gas welding. It serves a dual purpose: However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. I think gas pressure changes depending on the situation your welding in i.e. Mig Welding Gas Pressure Uk.

From www.artofit.org

Mig welding gas pressure settings with charts Artofit Mig Welding Gas Pressure Uk Shielding the molten weld pool from. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. I am totally new to mig gas welding. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. However, if there’s too. Mig Welding Gas Pressure Uk.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Mig Welding Gas Pressure Uk I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. It serves a dual purpose: However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. It may be better to invest in. Open the main valve of. Mig Welding Gas Pressure Uk.

From nationalweldsupplies.co.uk

SIP WELDMATE® AUTOPLUS 250A MIG/ARC/TIG Welder 05751 National welding Mig Welding Gas Pressure Uk The higher the pressure, the hotter your weld will be. Open the main valve of the cylinder and make sure that there is some gas in it. However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. Most mig welding gas pressures are between 3 and. Mig Welding Gas Pressure Uk.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Mig Welding Gas Pressure Uk The higher the pressure, the hotter your weld will be. I am totally new to mig gas welding. Your gauges should be reading between 0 and 2500 psi in. Shielding the molten weld pool from. Open the main valve of the cylinder and make sure that there is some gas in it. However, if there’s too much gas pressure at. Mig Welding Gas Pressure Uk.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Mig Welding Gas Pressure Uk Shielding the molten weld pool from. Open the main valve of the cylinder and make sure that there is some gas in it. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. It may be better to invest in. However, if there’s too much gas pressure at the weld, you. Mig Welding Gas Pressure Uk.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Mig Welding Gas Pressure Uk Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Open the main valve of the cylinder and make sure that there is some gas in it. It. Mig Welding Gas Pressure Uk.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use Mig Welding Gas Pressure Uk I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Just got the machine converted yesterday but nowhere in the instructions do. It serves a dual purpose: Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength of the weld. It may be better. Mig Welding Gas Pressure Uk.

From xpressmobilewelding.com

Argon Pressure for Mig Welding MIG (Metal Inert Gas) Mig Welding Gas Pressure Uk Open the main valve of the cylinder and make sure that there is some gas in it. It may be better to invest in. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. Gas pressure plays a pivotal role in mig welding as it directly affects the quality and strength. Mig Welding Gas Pressure Uk.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Mig Welding Gas Pressure Uk Between 5 to 10 lpm gas flow, but be aware that the dial type gauge as fitted to your regulator are poor. Most mig welding gas pressures are between 3 and 8 psi. I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. I am totally new to mig gas welding.. Mig Welding Gas Pressure Uk.

From giomhnfsr.blob.core.windows.net

Argon Regulator Setting For Mig Welding at Cristina Wilt blog Mig Welding Gas Pressure Uk I think gas pressure changes depending on the situation your welding in i.e material thickness, material type, stick out. The higher the pressure, the hotter your weld will be. It may be better to invest in. Most mig welding gas pressures are between 3 and 8 psi. Between 5 to 10 lpm gas flow, but be aware that the dial. Mig Welding Gas Pressure Uk.

From www.pinterest.com.au

Ensuring the proper gas flow rate is essential to the quality of the Mig Welding Gas Pressure Uk Open the main valve of the cylinder and make sure that there is some gas in it. However, if there’s too much gas pressure at the weld, you can draw oxygen into the arc plasma and contaminate the bead, causing porosity. The higher the pressure, the hotter your weld will be. I think gas pressure changes depending on the situation. Mig Welding Gas Pressure Uk.

From allaboutweldingjobs.com

MIG Welding Gas Pressure Best Helpful Guide & Review Mig Welding Gas Pressure Uk I am totally new to mig gas welding. Your gauges should be reading between 0 and 2500 psi in. Most mig welding gas pressures are between 3 and 8 psi. It may be better to invest in. Just got the machine converted yesterday but nowhere in the instructions do. However, if there’s too much gas pressure at the weld, you. Mig Welding Gas Pressure Uk.