Steel Surface Defects . Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Have you ever wondered why some steel products have surface imperfections? Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. • welds • edges •. The four classes of surface condition are: Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate.

from www.frontiersin.org

Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Have you ever wondered why some steel products have surface imperfections? Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. • welds • edges •. Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The four classes of surface condition are: Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;.

Frontiers Multilevel semantic information guided image generation

Steel Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. The four classes of surface condition are: • welds • edges •. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;.

From cherryamrit.blogspot.com

Steel Pipe Surface Defects CherryAmrit Steel Surface Defects The four classes of surface condition are: Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? Detecting surface defects on steel poses a significant challenge attributed to. Steel Surface Defects.

From www.researchgate.net

Steel surface defect image. (a) Crazing, (b) inclusions, (c) patches Steel Surface Defects • welds • edges •. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Have you ever wondered why some steel products have surface imperfections? Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Common surface defects in steel include. Steel Surface Defects.

From www.steeldata.info

Macro Defects in Steel Steel Surface Defects Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. Have you ever wondered why some steel products have surface imperfections? First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Common surface defects in steel include cracks, scratches, folds,. Steel Surface Defects.

From mungfali.com

Metal Surface Defects Steel Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. • welds • edges •. Have you ever wondered why some steel products have surface imperfections? Surface defects of steel bands. Steel Surface Defects.

From www.steeldata.info

Macro Defects in Steel Steel Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes. Steel Surface Defects.

From www.steelwarehouse.com

Steelmaking Defects Steel Warehouse Steel Surface Defects Have you ever wondered why some steel products have surface imperfections? Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. • welds • edges •. Surface defects on steel, arising from factors like steel composition and. Steel Surface Defects.

From www.researchgate.net

Some samples of Metallic surface defects. (a) Crazing. (b) Inclusion Steel Surface Defects Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. Have you ever wondered why some steel products have surface imperfections? Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are. Steel Surface Defects.

From www.researchgate.net

Examples of steel surface defects. a inclusion. b scratches. c crazing Steel Surface Defects The four classes of surface condition are: Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. • welds • edges. Steel Surface Defects.

From www.researchgate.net

Four typical steel plate defects. (A) Pit defect, (B) Edge crack, (C Steel Surface Defects Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Detecting surface defects on steel poses a significant challenge attributed to. Steel Surface Defects.

From www.researchgate.net

Schematic diagram of steel plate defect recognition. Download Steel Surface Defects • welds • edges •. Have you ever wondered why some steel products have surface imperfections? Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Common surface defects in steel include cracks, scratches, folds, ears, scabs. Steel Surface Defects.

From www.semanticscholar.org

Figure 4 from The Strip Steel Surface Defects Classification Method Steel Surface Defects Have you ever wondered why some steel products have surface imperfections? First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate.. Steel Surface Defects.

From www.researchgate.net

Steelsurface defects in the NEUDET dataset (a) crazing, (b Steel Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Have you ever wondered why some steel products have surface imperfections? Detecting surface defects on steel poses a significant challenge attributed to factors such as. Steel Surface Defects.

From www.researchgate.net

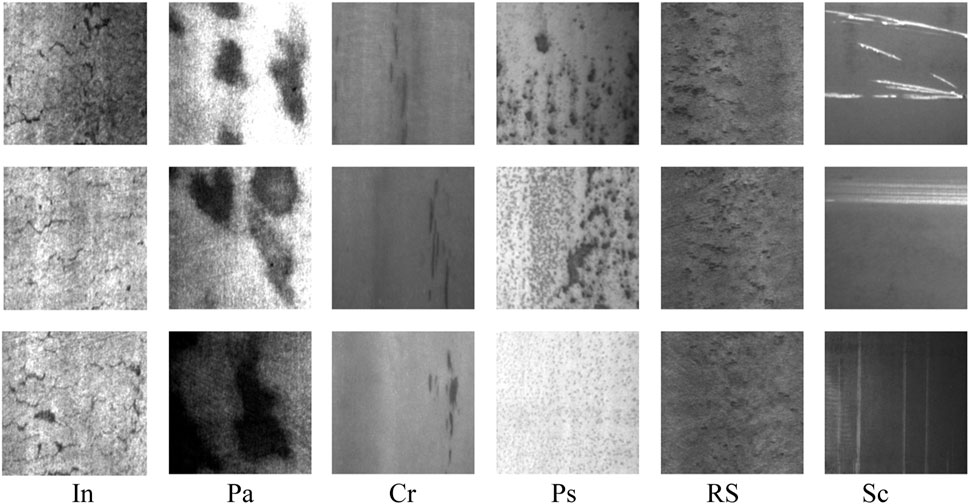

Samples of six kinds of typical surface defects on NEU surface defect Steel Surface Defects Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. Have you ever wondered why some steel products have surface imperfections? First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Class a (plates) shallow depth imperfections, other than cracks,. Steel Surface Defects.

From www.vrogue.co

Classification Of Defects In Steel Structures Downloa vrogue.co Steel Surface Defects Have you ever wondered why some steel products have surface imperfections? Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. • welds • edges •. The four classes of surface condition are: Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Surface defects on steel, arising. Steel Surface Defects.

From www.researchgate.net

(a) Several examples of steel surface images with their defects labeled Steel Surface Defects Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible. Steel Surface Defects.

From www.mermecgroup.com

SurfaceCheck inspection system Steel Surface Defects Have you ever wondered why some steel products have surface imperfections? • welds • edges •. Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Common surface. Steel Surface Defects.

From www.vrogue.co

Using Surface Defect Detection Systems For Steel Proc vrogue.co Steel Surface Defects The four classes of surface condition are: Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. • welds • edges •. First, this paper summarized the difficulties of steel surface defect recognition,. Steel Surface Defects.

From www.silcotek.com

Identify and Fix Common Stainless Steel Surface Defects Steel Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. The four classes of surface condition are: •. Steel Surface Defects.

From debuggercafe.com

Steel Surface Defect Detection using Object Detection Steel Surface Defects Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. The four classes of surface condition. Steel Surface Defects.

From www.semanticscholar.org

Figure 1 from Application of bandelet transform to surface defect Steel Surface Defects Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. • welds • edges •. Surface defects of steel bands lead to an impairment of their quality, while the classification of these. Steel Surface Defects.

From www.researchgate.net

Surface defects of the parts produced from stainless steel 12X18Н10Т Steel Surface Defects Have you ever wondered why some steel products have surface imperfections? The four classes of surface condition are: Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. Class a (plates) shallow depth imperfections,. Steel Surface Defects.

From debuggercafe.com

Steel Surface Defect Detection using Object Detection Steel Surface Defects Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. Have you ever wondered why some steel products have surface imperfections? Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. • welds. Steel Surface Defects.

From www.mdpi.com

Symmetry Free FullText XSDD A New Benchmark for Hot Rolled Steel Steel Surface Defects The four classes of surface condition are: Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. • welds • edges. Steel Surface Defects.

From www.researchgate.net

Four typical steel plate defects. (A) Pit defect, (B) Edge crack, (C Steel Surface Defects Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. • welds • edges •. Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. Common surface defects in steel include cracks, scratches,. Steel Surface Defects.

From www.frontiersin.org

Frontiers Multilevel semantic information guided image generation Steel Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition,. Steel Surface Defects.

From www.researchgate.net

Image examples of steel surface defects. Red boxes are the groundtruth Steel Surface Defects The four classes of surface condition are: Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. Have you ever wondered why some steel products have surface imperfections? • welds. Steel Surface Defects.

From www.steelwarehouse.com

Hot Rolling Defects Steel Warehouse Steel Surface Defects First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the. The four classes of surface condition are: Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. • welds • edges •. Have you ever wondered why some steel products have. Steel Surface Defects.

From encyclopedia.pub

Defect Synthesis for Automated Visual Inspection Encyclopedia MDPI Steel Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The four classes of surface condition are: Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of. Steel Surface Defects.

From debuggercafe.com

Steel Surface Defect Detection using Object Detection Steel Surface Defects Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. Have you ever wondered why some steel products have surface imperfections? Detecting surface defects on steel poses a significant challenge attributed to factors such as poor contrast, diverse defect types,. The four. Steel Surface Defects.

From steeldata.info

Macro Defects in Steel Steel Surface Defects Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. The four classes of surface condition are: • welds • edges •. Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Class a (plates). Steel Surface Defects.

From www.sciltp.com

Metal Surface Defect Detection Based on MetalYOLOXScilight Steel Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Have you ever wondered why some steel products have surface imperfections? • welds • edges •. Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. The four classes of surface condition are: Detecting surface. Steel Surface Defects.

From www.vrogue.co

Metal Surface Defects vrogue.co Steel Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Have you ever wondered why some steel products have surface imperfections?. Steel Surface Defects.

From www.researchgate.net

Some common steel defects images. (a) scratches, (b) crazing, (c Steel Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The four classes of surface condition are: Surface defects on steel, arising from factors like steel composition and manufacturing techniques, pose significant challenges to. Surface defects of steel bands lead to an impairment of their quality, while the classification of these types. Steel Surface Defects.

From www.researchgate.net

Surface defects of steel plate. Download Scientific Diagram Steel Surface Defects • welds • edges •. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. Detecting surface defects on steel poses a significant challenge. Steel Surface Defects.

From www.researchgate.net

Steelsurface defects in the NEUDET dataset (a) crazing, (b Steel Surface Defects Surface defects of steel bands lead to an impairment of their quality, while the classification of these types of damage makes it possible to quickly identify and eliminate. • welds • edges •. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? Detecting surface. Steel Surface Defects.