Solder Mask Density . Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Thinner than 20 microns may not provide enough protection, while thicker than 50.

from eureka.patsnap.com

Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Thinner than 20 microns may not provide enough protection, while thicker than 50.

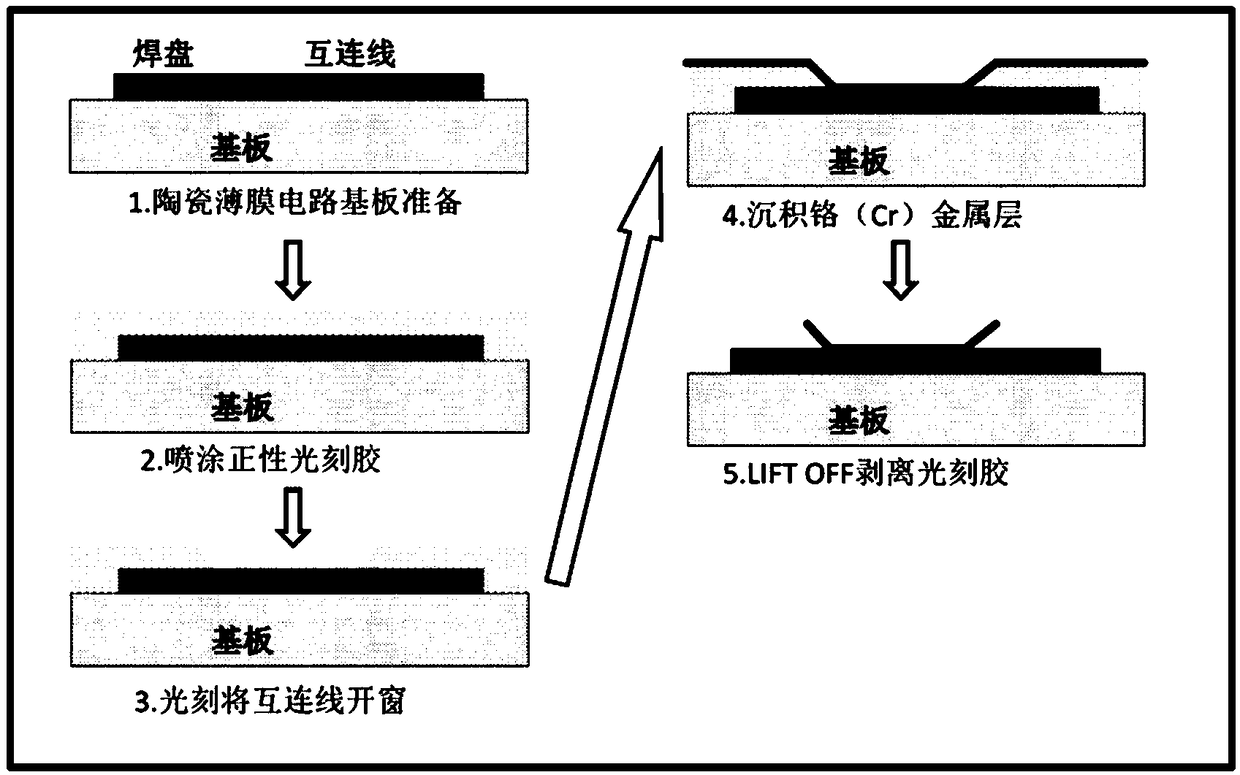

Manufacturing method and product of metal solder mask for highdensity microwave circuit

Solder Mask Density Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Thinner than 20 microns may not provide enough protection, while thicker than 50.

From lctech-pcb.en.made-in-china.com

HighDensity 12Layer PCB with Black Solder Mask China PCB and RigidFlex Board Solder Mask Density Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Thinner than 20 microns may not provide enough protection, while thicker than 50. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. The thickness of your solder stop mask primarily depends on how. Solder Mask Density.

From www.protoexpress.com

What is Solder Mask Layer? Sierra Circuits Solder Mask Density Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Thinner than 20 microns may not provide enough protection, while thicker than 50. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. The thickness of your solder stop. Solder Mask Density.

From eureka.patsnap.com

Manufacturing method and product of metal solder mask for highdensity microwave circuit Solder Mask Density Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Thinner than 20 microns may not provide enough protection, while thicker than 50. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to. Solder Mask Density.

From www.linkedin.com

What is Peelable Solder Mask? Solder Mask Density Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Thinner than 20 microns may not provide enough protection, while thicker than 50. Proper solder mask expansion prevents assembly defects by ensuring. Solder Mask Density.

From www.pinterest.com

Purple Solder Mask 4 Layers Gold Plated PCB Board Fabrication Services Printed Circuit Board Solder Mask Density Thinner than 20 microns may not provide enough protection, while thicker than 50. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. The. Solder Mask Density.

From www.researchgate.net

Quality of PDMSFR4 coated with the solder mask adhesive bonds in five... Download Scientific Solder Mask Density Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Thinner than 20 microns may not provide enough protection, while thicker than 50. The thickness of your solder stop mask primarily depends on how thick the copper traces on. Solder Mask Density.

From asia.chemtronics.com

Ultimate Guide to Temporary Solder Mask Chemtronics Asia Solder Mask Density Thinner than 20 microns may not provide enough protection, while thicker than 50. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Today’s solder masks are already exposed to a considerable. Solder Mask Density.

From www.nextpcb.com

Solder Mask Expansion An Essential Consideration in PCB Design and Manufacturing Solder Mask Density A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Today’s solder masks are already exposed to a considerable level of thermal stress, high. Solder Mask Density.

From www.pcba-manufacturers.com

How does PCB solder mask work PCBA Manufacturers Solder Mask Density The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Thinner than. Solder Mask Density.

From www.protoexpress.com

ThroughHole Assembly Design Rules Seirra Circuits Solder Mask Density The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation.. Solder Mask Density.

From pcbprime.com

PCB PRIME Solder Mask Density A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Proper solder mask. Solder Mask Density.

From www.nextpcb.com

Solder Mask Material Everything You Need to Know NextPCB Solder Mask Density Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration.. Solder Mask Density.

From www.raypcb.com

LPI PCB (Liquid Photoimageable (LPI) Solder Mask Application RAYPCB Solder Mask Density Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Today’s solder masks are already exposed to a considerable level of thermal stress, high. Solder Mask Density.

From www.pcbaaa.com

PCB solder mask an ultimate guide for beginners IBE Electronics Solder Mask Density A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Thinner than 20 microns may not provide enough protection, while thicker than 50. Ceasolder is a temporary latex mask. Solder Mask Density.

From www.pcbkingtech.com

4 Layers High Density Interconnect Pcb Customizable Green Solder Mask Solder Mask Density A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Thinner than 20 microns may not provide enough protection, while thicker than 50. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Today’s solder masks are already exposed to a considerable. Solder Mask Density.

From www.pcbaaa.com

PCB solder mask an ultimate guide for beginners IBE Electronics Solder Mask Density The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Thinner than 20 microns may not provide enough protection, while thicker than 50. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Today’s solder masks are already exposed to a considerable level of thermal stress, high. Solder Mask Density.

From www.pcbaaa.com

PCB solder mask an ultimate guide for beginners IBE Electronics Solder Mask Density Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. A typical recommendation is a minimum solder mask expansion of. Solder Mask Density.

From jlypcb.en.made-in-china.com

TopGrade Green Solder Mask Printed Circuit Board China HighDensity PCB Design and 6Layer Solder Mask Density The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Thinner than 20 microns may not provide enough protection, while thicker than 50. Today’s solder masks are already exposed. Solder Mask Density.

From www.nextpcb.com

Solder Mask Expansion An Essential Consideration in PCB Design and Manufacturing Solder Mask Density Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width. Solder Mask Density.

From www.nextpcb.com

Solder Mask Material Everything You Need to Know NextPCB Solder Mask Density A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board.. Solder Mask Density.

From reversepcb.com

About Solder Mask All You Need to Know Solder Mask Density Thinner than 20 microns may not provide enough protection, while thicker than 50. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. A typical recommendation is a minimum solder mask. Solder Mask Density.

From www.nextpcb.com

What Is Solder Mask Dam? — NextPCB Solder Mask Density Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Thinner than 20 microns may not provide enough protection, while thicker than 50. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering. Solder Mask Density.

From www.raypcb.com

What is the Significance of Solder Mask Defined Pads in Solder Pad PCBs? RAYPCB Solder Mask Density Thinner than 20 microns may not provide enough protection, while thicker than 50. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Proper solder mask expansion prevents assembly defects by ensuring. Solder Mask Density.

From mx.techspray.com

Cómo usar la máscara de puntos para la soldadura por onda y el recubrimiento conformado Solder Mask Density Thinner than 20 microns may not provide enough protection, while thicker than 50. Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary. Solder Mask Density.

From www.csm-circuiti.it

Solder Mask for PCB Solder Mask Density Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Thinner than 20 microns may not provide enough protection, while thicker than 50. A typical recommendation is a minimum solder mask expansion of 3. Solder Mask Density.

From www.researchgate.net

FTIR spectra of solder mask test specimens in the wavenumber. (a) From... Download Scientific Solder Mask Density Thinner than 20 microns may not provide enough protection, while thicker than 50. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Ceasolder. Solder Mask Density.

From www.researchgate.net

Representative photographs of the solder masks appearance before and... Download Scientific Solder Mask Density Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Thinner than 20 microns may not provide enough protection, while thicker than 50. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary. Solder Mask Density.

From pcb-hl.en.made-in-china.com

Quick Turn Prototype BGA Green Solder Mask High Precision High Density PCB Board China PCB and Solder Mask Density Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Thinner than 20 microns may not provide enough protection, while thicker than 50. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Ceasolder. Solder Mask Density.

From resources.altium.com

What Is Solder Mask Expansion and Which Value Should You Use? Zach Peterson PCB Layout Solder Mask Density Thinner than 20 microns may not provide enough protection, while thicker than 50. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Today’s solder masks are already exposed. Solder Mask Density.

From www.fs-pcba.com

2023 PCB Solder Mask Introduction and Guidelines FS PCBA Solder Mask Density Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable.. Solder Mask Density.

From www.pcbpower.us

PCB assembly services are available at PCB Power. PCB manufacturing process is also conducted Solder Mask Density Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Thinner than 20 microns may not provide enough protection, while thicker than 50. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Today’s solder masks are already exposed. Solder Mask Density.

From xmdcircuit.en.made-in-china.com

Premium Green Solder Mask Circuit Board China HighDensity PCB Design and 6Layer Tin PCB Solder Mask Density The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Today’s solder masks are already. Solder Mask Density.

From www.circuits-diy.com

PCB Solder Mask What is it & Why do you need it? Solder Mask Density Today’s solder masks are already exposed to a considerable level of thermal stress, high humidity and/or condensation. The thickness of your solder stop mask primarily depends on how thick the copper traces on your circuit board. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration.. Solder Mask Density.

From www.nextpcb.com

Solder Mask Expansion An Essential Consideration in PCB Design and Manufacturing Solder Mask Density Ceasolder is a temporary latex mask designed for electronic assembly applications that is peelable. Thinner than 20 microns may not provide enough protection, while thicker than 50. A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Today’s solder masks are already exposed to a considerable. Solder Mask Density.

From www.protoexpress.com

Solder Mask Layer in PCBs Top 4 DFM Guidelines Sierra Circuits Solder Mask Density A typical recommendation is a minimum solder mask expansion of 3 mils on all sides to account for up to 2 mils of misregistration. Proper solder mask expansion prevents assembly defects by ensuring sufficient soldering surface and maintaining the necessary solder dam width between adjacent pads. The thickness of your solder stop mask primarily depends on how thick the copper. Solder Mask Density.