Equipment Repair Procedure . Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. It's a meticulously crafted guide, offering detailed. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Learn about the role, strategies, and best practices for maintaining equipment in various industries.

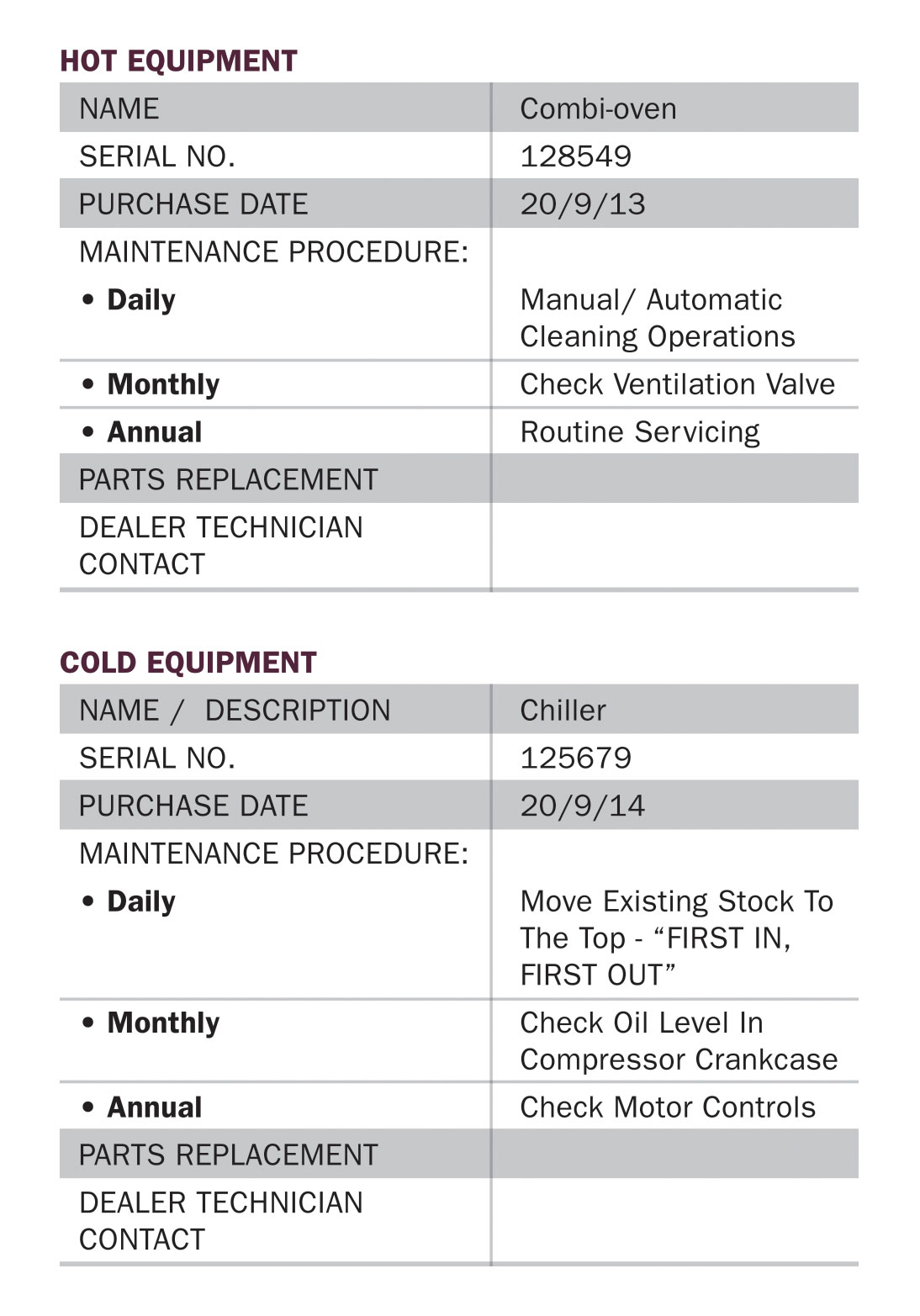

from miseenplaceasia.com

Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. It's a meticulously crafted guide, offering detailed. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Learn about the role, strategies, and best practices for maintaining equipment in various industries. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of.

setting up an EQUIPMENT MAINTENANCE program mise en place

Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. It's a meticulously crafted guide, offering detailed. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Learn about the role, strategies, and best practices for maintaining equipment in various industries. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Equipment Repair Procedure Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of.. Equipment Repair Procedure.

From limblecmms.com

How To Effectively Manage Breakdown Maintenance Equipment Repair Procedure Learn about the role, strategies, and best practices for maintaining equipment in various industries. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. Equipment maintenance and repair encompass a range of procedures. Equipment Repair Procedure.

From worksafetyqld.com

Plant & Equipment Maintenance Policy & Procedure Template Work Safety QLD Equipment Repair Procedure Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. It's a meticulously. Equipment Repair Procedure.

From www.fleetio.com

Equipment Maintenance Procedures Guide Equipment Repair Procedure Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of.. Equipment Repair Procedure.

From www.gofmx.com

Maintenance SOP FMX Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. It's a meticulously crafted guide, offering detailed. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. Learn how to create and implement standard operating procedures (sops) for equipment. Equipment Repair Procedure.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs. Equipment Repair Procedure.

From www.sampletemplates.com

FREE 61+ SOP Templates in PDF MS Word Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques.. Equipment Repair Procedure.

From www.researchgate.net

Sample of Maintenance Procedures Collected Download Table Equipment Repair Procedure Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk. Equipment Repair Procedure.

From www.examples.com

Maintenance Checklist 25+ Examples, Format, Pdf Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Learn about the role, strategies, and best practices for maintaining equipment in various industries. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. Equipment maintenance and repair. Equipment Repair Procedure.

From www.template.net

Equipment Maintenance Procedure Template Edit Online & Download Equipment Repair Procedure Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of.. Equipment Repair Procedure.

From gloriafersshannon.blogspot.com

Which of the Following Simplifies Pms Maintenance Procedures Equipment Repair Procedure Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Learn about the role, strategies, and best practices for maintaining equipment in various industries. Sops provide maintenance teams with clear instructions on. Equipment Repair Procedure.

From manje1.fra1.cdn.digitaloceanspaces.com

Discover The 4 Types Of Maintenance And Unlock Equipment Efficiency Equipment Repair Procedure Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. It's a meticulously crafted guide, offering detailed. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and. Equipment Repair Procedure.

From morganwells.z19.web.core.windows.net

Inoperative Equipment Flow Chart Equipment Repair Procedure Learn about the role, strategies, and best practices for maintaining equipment in various industries. Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. It's a meticulously crafted guide, offering detailed.. Equipment Repair Procedure.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Equipment Repair Procedure Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Learn about the role, strategies, and best practices for maintaining equipment in various industries. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. Sops provide maintenance teams with clear instructions on. Equipment Repair Procedure.

From sitemate.com

Lifting equipment inspection procedure Here's the right procedure for you Equipment Repair Procedure Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. Learn about the role, strategies, and best practices for maintaining equipment in various industries. By following the iso 9001 equipment maintenance plan template, organizations. Equipment Repair Procedure.

From www.researchgate.net

Main steps of the maintenance procedure Download Scientific Diagram Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. By. Equipment Repair Procedure.

From www.manula.com

Preventive Maintenance Highway West Standard Operating Procedures 1 Equipment Repair Procedure It's a meticulously crafted guide, offering detailed. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. By following the iso 9001 equipment maintenance plan template, organizations can. Equipment Repair Procedure.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Equipment Repair Procedure Learn about the role, strategies, and best practices for maintaining equipment in various industries. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. It's a meticulously crafted guide, offering detailed. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Learn how to. Equipment Repair Procedure.

From www.hkdivedi.com

MAINTENANCE PRACTICE AND PROCEDURE ENGINEERING APPLICATIONS Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. Learn. Equipment Repair Procedure.

From www.fleetio.com

Equipment Maintenance Procedures Guide Fleetio Equipment Repair Procedure Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Learn about the. Equipment Repair Procedure.

From www.template.net

Maintenance Standard Operating Procedure Template in Word, Google Docs Equipment Repair Procedure Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Learn about the role, strategies, and best practices for maintaining equipment in various industries. By following the iso. Equipment Repair Procedure.

From studylib.net

Plant and Equipment Management Procedure Equipment Repair Procedure Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. It's a meticulously crafted guide, offering detailed. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Equipment maintenance and repair encompass a range of procedures aimed at ensuring. Equipment Repair Procedure.

From ezo.io

Equipment Maintenance Best Practices Basics, Objectives and Functions Equipment Repair Procedure Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. It's a meticulously crafted guide, offering detailed. Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive. Equipment Repair Procedure.

From www.primedeq.com

Refurbished Medical Equipment 8 critical process steps Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to.. Equipment Repair Procedure.

From safety-online.co.za

Equipment Maintenance Procedure Equipment Repair Procedure Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. It's a meticulously crafted guide, offering detailed. Find out how to create your own checklist, choose the right certification, and use advanced tools. Equipment Repair Procedure.

From miseenplaceasia.com

setting up an EQUIPMENT MAINTENANCE program mise en place Equipment Repair Procedure Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Learn about the role, strategies, and best practices for maintaining equipment in various industries. Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. It's a meticulously crafted guide, offering detailed.. Equipment Repair Procedure.

From www.allsafety.com.au

Procedure Maintenance of Equipment Workplace Health and Safety Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Learn about the role, strategies, and best practices for maintaining equipment in various industries. It's a meticulously crafted. Equipment Repair Procedure.

From www.allbusinesstemplates.com

Equipment Repair Process Templates at Equipment Repair Procedure Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Find out how. Equipment Repair Procedure.

From limblecmms.com

What is Maintenance Procedure? Limble CMMS Equipment Repair Procedure Establishing equipment maintenance procedures for your fleet is the most effective way to keep all of your tools and small. It's a meticulously crafted guide, offering detailed. Learn about the role, strategies, and best practices for maintaining equipment in various industries. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety.. Equipment Repair Procedure.

From aps-online.net

Preventive Maintenance (PM) Procedure Writing Services APS Equipment Repair Procedure Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs. Equipment Repair Procedure.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Equipment Repair Procedure Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. It's a meticulously crafted guide, offering detailed. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Learn how to create and implement standard operating procedures (sops) for equipment. Equipment Repair Procedure.

From www.aplyon.com

Preventive Maintenance Procedure Equipment Repair Procedure By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk. Equipment Repair Procedure.

From www.gofmx.com

How to Establish an Effective Equipment Maintenance Program FMX Equipment Repair Procedure Find out how to create your own checklist, choose the right certification, and use advanced tools and techniques. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. Learn about the role, strategies, and best practices for maintaining equipment in various industries. Learn how to create and implement standard operating procedures. Equipment Repair Procedure.

From docslib.org

Amtrak Equipment Maintenance Department Standard Maintenance Procedure Equipment Repair Procedure Learn about the role, strategies, and best practices for maintaining equipment in various industries. By following the iso 9001 equipment maintenance plan template, organizations can proactively schedule regular inspections, maintenance, and repairs to. It's a meticulously crafted guide, offering detailed. Learn how to create and implement standard operating procedures (sops) for equipment maintenance, including preventive and corrective tasks, safety. Equipment. Equipment Repair Procedure.

From www.academia.edu

(DOC) .4 SOP equipment maintenance v wellington akuinor Academia.edu Equipment Repair Procedure Learn about the role, strategies, and best practices for maintaining equipment in various industries. Sops provide maintenance teams with clear instructions on how to carry out these tasks, ensuring consistency in approach and minimizing the risk of. Equipment maintenance and repair encompass a range of procedures aimed at ensuring machinery and tools operate as expected. Find out how to create. Equipment Repair Procedure.