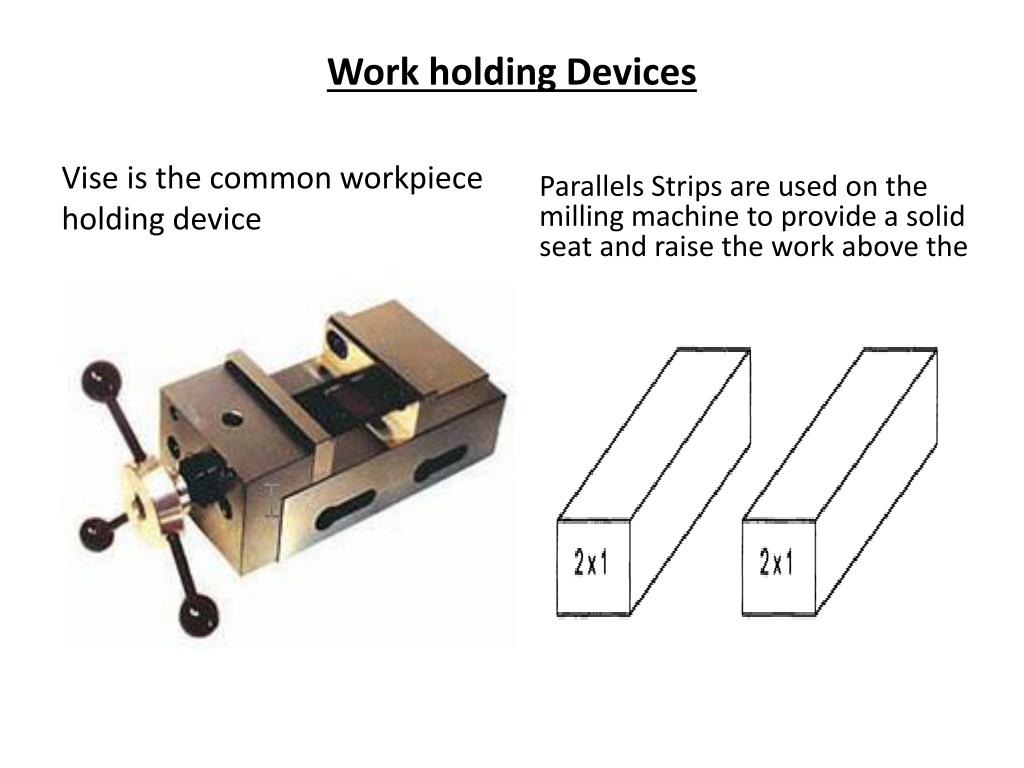

Work Holding Methods Milling . The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. For precision work, the vise must be set so that the clamping. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. In the milling machines, fixtures are still. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The most common method of holding a work piece for machining is a mill vise. Cutter holding devices for milling machines. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. The following are the usual methods of holding work on the milling machine. This document discusses various methods for work holding on milling machines.

from www.slideserve.com

Cutter holding devices for milling machines. The following are the usual methods of holding work on the milling machine. This document discusses various methods for work holding on milling machines. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. For precision work, the vise must be set so that the clamping. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. The most common method of holding a work piece for machining is a mill vise.

PPT Milling Machines PowerPoint Presentation, free download ID2263507

Work Holding Methods Milling The most common method of holding a work piece for machining is a mill vise. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The most common method of holding a work piece for machining is a mill vise. In the milling machines, fixtures are still. This document discusses various methods for work holding on milling machines. The following are the usual methods of holding work on the milling machine. Cutter holding devices for milling machines. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. For precision work, the vise must be set so that the clamping.

From www.coroflot.com

Work Holding Methods by Garett Stimac at Work Holding Methods Milling Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process.. Work Holding Methods Milling.

From www.slideserve.com

PPT Milling Machines PowerPoint Presentation, free download ID2263507 Work Holding Methods Milling It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. In the milling machines, fixtures are still. The following are the usual methods of holding work on the milling machine. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. For precision work, the vise must be. Work Holding Methods Milling.

From www.abmtools.com

Work Holding Devices ABM Tools Work Holding Methods Milling For precision work, the vise must be set so that the clamping. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. The following are the usual methods of holding work on the milling machine.. Work Holding Methods Milling.

From fractory.com

CNC Milling a Complete Guide to Understand the Process Work Holding Methods Milling There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. For precision work, the vise must be set so that the clamping. The most common method of holding a work piece for machining is a mill vise. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding.. Work Holding Methods Milling.

From seisanzai-japan.com

Machining 08 What are work holding devices? Industry and Work Holding Methods Milling It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The following are the usual methods of holding work on the milling machine. This document discusses various methods for work holding on milling machines. For precision work,. Work Holding Methods Milling.

From www.fictiv.com

Introduction to Workholding Options for CNC Machining Fictiv Work Holding Methods Milling This document discusses various methods for work holding on milling machines. For precision work, the vise must be set so that the clamping. Cutter holding devices for milling machines. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. There are various types of workholding devices available, each designed for specific workpieces,. Work Holding Methods Milling.

From www.youtube.com

Work and Tool Holding Devices for Lathes YouTube Work Holding Methods Milling Cutter holding devices for milling machines. In the milling machines, fixtures are still. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The most common method of holding a work piece for machining is a mill vise. The following are the usual methods of holding work on the milling machine. The choice. Work Holding Methods Milling.

From www.youtube.com

Milling Machine Tool holding devices, Types of cutter, and Operations Work Holding Methods Milling For precision work, the vise must be set so that the clamping. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. In the milling machines, fixtures are still. You can have a great design. Work Holding Methods Milling.

From www.iqsdirectory.com

CNC Machining What Is It? How Does It Work? Types, Codes Work Holding Methods Milling Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. For precision work, the vise must be set so that the clamping. The most common method of holding a work piece for machining is a mill vise. It describes milling vises, soft jaws, parallels,. Work Holding Methods Milling.

From www.youtube.com

Tool and Work Holding on the Milling Machine YouTube Work Holding Methods Milling For precision work, the vise must be set so that the clamping. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. The following are the usual methods of holding work on the milling machine. In. Work Holding Methods Milling.

From www.fictiv.com

Introduction to Workholding Options for CNC Machining Fictiv Work Holding Methods Milling For precision work, the vise must be set so that the clamping. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. This document discusses various methods. Work Holding Methods Milling.

From www.trunniontable.com

Custom CNC Workholding Martin Trunnion Tables Work Holding Methods Milling For precision work, the vise must be set so that the clamping. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. This document discusses various methods for work holding on milling machines. Cutter holding. Work Holding Methods Milling.

From www.youtube.com

Work Holding Device for Milling Machine YouTube Work Holding Methods Milling It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. For precision work, the vise must be set so that the clamping. The following are the usual methods of holding work on the milling machine. You can have a great design and program for your part and the best machine and material to work. Work Holding Methods Milling.

From the-shed.nz

Milling showing restraint The Shed Work Holding Methods Milling This document discusses various methods for work holding on milling machines. For precision work, the vise must be set so that the clamping. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. In the. Work Holding Methods Milling.

From www.pinterest.co.uk

Workholding That’s on Point Modern Machine Shop Machine shop Work Holding Methods Milling You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. Cutter holding devices for milling machines. The choice of. Work Holding Methods Milling.

From www.methods-equipment.com

Workholding Methods & Equipment Associates Work Holding Methods Milling There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Cutter holding devices for milling machines. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a. Work Holding Methods Milling.

From www.coroflot.com

Work Holding Methods by Garett Stimac at Work Holding Methods Milling Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. In the milling machines, fixtures are still. The choice of workholding solution can significantly impact the efficiency, precision,. Work Holding Methods Milling.

From shuntool.com

A Guide To The Various Work Holding Methods On Lathe Machines ShunTool Work Holding Methods Milling The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. It describes milling vises, soft jaws, parallels,. Work Holding Methods Milling.

From www.youtube.com

Work and Tool Holding in the Metal Lathe YouTube Work Holding Methods Milling Cutter holding devices for milling machines. This document discusses various methods for work holding on milling machines. In the milling machines, fixtures are still. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. For precision work,. Work Holding Methods Milling.

From www.youtube.com

Tool and Work holding devices for CNC machines and their types with Work Holding Methods Milling In the milling machines, fixtures are still. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. This document discusses various methods for work holding on milling machines. Workholding devices are essential tools used in. Work Holding Methods Milling.

From www.cnccookbook.com

Total Guide to CNC Milling Machine Workholding Work Holding Methods Milling The following are the usual methods of holding work on the milling machine. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. For precision work, the vise must be set so that the clamping. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or. Work Holding Methods Milling.

From informacionpublica.svet.gob.gt

Lathe Machine Work Holding Device informacionpublica.svet.gob.gt Work Holding Methods Milling There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. For precision work, the vise must be set so that the clamping. This document discusses various methods for work holding on milling machines. Cutter holding devices for milling machines. It describes milling vises, soft jaws, parallels, and work stops as basic styles of. Work Holding Methods Milling.

From www.cnccookbook.com

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills Work Holding Methods Milling For precision work, the vise must be set so that the clamping. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. Cutter holding devices for milling machines. The choice of workholding solution can significantly. Work Holding Methods Milling.

From www.pinterest.com

Low Profile Clamps Milling machine projects, Milling machine, Machine Work Holding Methods Milling The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. In the milling machines, fixtures are still. This document discusses various methods for work holding on milling machines. The most common method of holding a work piece for machining is a mill vise. There are various types of workholding devices available, each. Work Holding Methods Milling.

From www.harveyperformance.com

Workholding Styles & Considerations In The Loupe Work Holding Methods Milling Cutter holding devices for milling machines. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. For precision work, the vise must be set so that the clamping. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations.. Work Holding Methods Milling.

From www.youtube.com

Milling Tool and Work Holding Devices YouTube Work Holding Methods Milling Cutter holding devices for milling machines. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. This document discusses various methods for work holding on milling machines. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining. Work Holding Methods Milling.

From www.miteebite.com

12/11/15 New Workholding Devices Enable 4th Axis Machining MiteeBite Work Holding Methods Milling You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. In the milling machines, fixtures are still. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process.. Work Holding Methods Milling.

From www.cutwel.co.uk

Tool Holding Explained An Expert Guide Cutwel Ltd Work Holding Methods Milling The following are the usual methods of holding work on the milling machine. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. You can have a great design and program for your part and the. Work Holding Methods Milling.

From www.pinterest.com

Pin on Cnc Work Holding Methods Milling This document discusses various methods for work holding on milling machines. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. It describes milling vises, soft. Work Holding Methods Milling.

From www.mechical.com

Work Holding Devices in Lathe Machine and Their Types Work Holding Methods Milling The most common method of holding a work piece for machining is a mill vise. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. In the milling. Work Holding Methods Milling.

From www.slideshare.net

Methods of holding work piece Work Holding Methods Milling In the milling machines, fixtures are still. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. The following are the usual methods of holding work on. Work Holding Methods Milling.

From pawsworkholding.com

MultiVise PAWS Workholding Work Holding Methods Milling The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. The most common method of holding a work piece for machining is a mill vise. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper. Work Holding Methods Milling.

From www.youtube.com

Crash Course in Milling Chapter 4 Work Holding, by Glacern Machine Work Holding Methods Milling The following are the usual methods of holding work on the milling machine. The most common method of holding a work piece for machining is a mill vise. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. This document discusses various methods for work holding on milling machines. There are various types of. Work Holding Methods Milling.

From www.hvrmagnet.com

Workholding for Lathe/Grinding/Milling/CNC Machining Centers Work Holding Methods Milling The most common method of holding a work piece for machining is a mill vise. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. The. Work Holding Methods Milling.

From pepmfg.us

What is the Difference Between CNC Milling and Turning? PEP Mfg., Inc. Work Holding Methods Milling This document discusses various methods for work holding on milling machines. For precision work, the vise must be set so that the clamping. You can have a great design and program for your part and the best machine and material to work with, but if you don’t have the proper means to hold the material (keeping it as. In the. Work Holding Methods Milling.